Understanding the intricacies of engine upkeep is essential for any vehicle enthusiast. A well-maintained power unit not only enhances performance but also prolongs the lifespan of your automobile. This section delves into the critical aspects of servicing and troubleshooting for one of the most reliable engine types available.

As you navigate through this guide, you will uncover various techniques and practices that can be applied to ensure optimal functionality. Each topic is designed to equip you with the knowledge needed to address common issues and perform essential tasks with confidence. Whether you’re a novice or an experienced mechanic, this resource aims to be an invaluable tool in your automotive journey.

From understanding the underlying mechanics to executing detailed procedures, mastering these elements will empower you to tackle any challenge. Join us as we explore the essential strategies that will keep your engine running smoothly and efficiently.

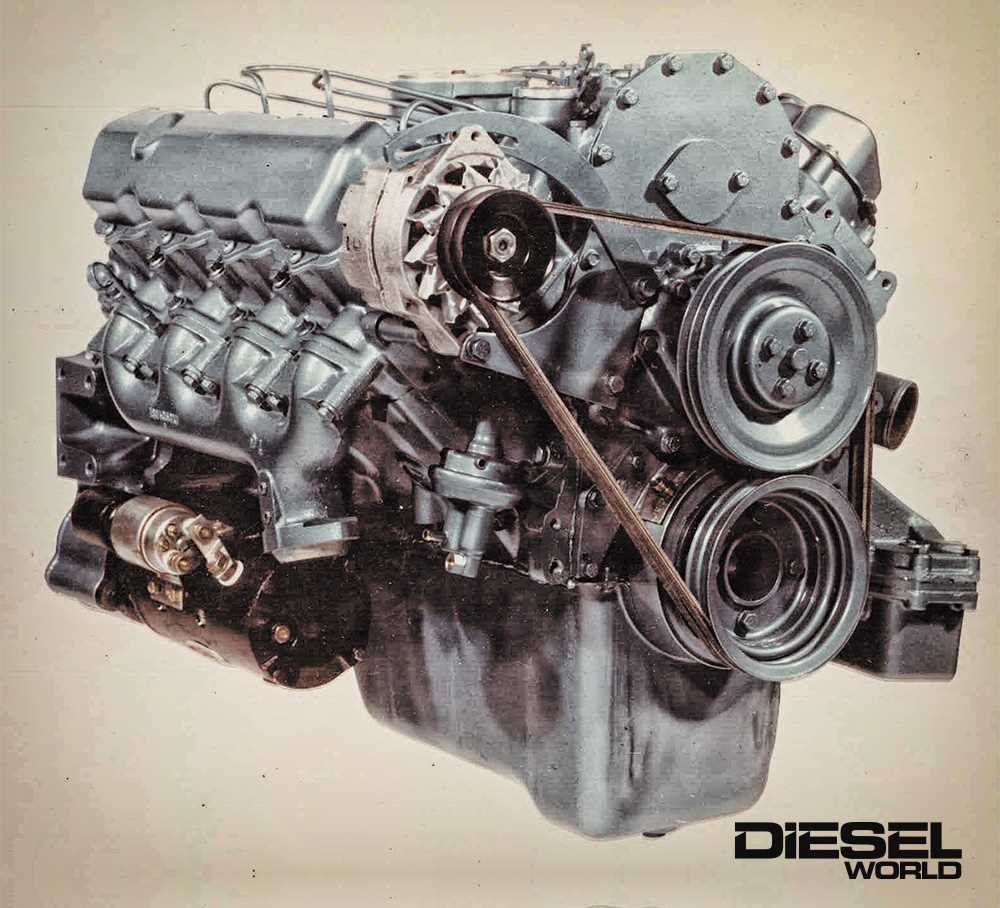

Overview of 7.3 Idi Diesel Engine

This section provides a comprehensive understanding of a prominent power unit known for its robust performance and reliability. Often utilized in various heavy-duty applications, this engine has garnered a loyal following among enthusiasts and professionals alike. Its design emphasizes durability and ease of maintenance, making it a preferred choice for many users.

Key Features

- High torque output for enhanced towing capacity

- Simple mechanical components for straightforward servicing

- Solid construction suitable for demanding environments

- Fuel efficiency that balances power with economy

Applications

- Trucks and vans for commercial transportation

- Heavy machinery in construction and agriculture

- Utility vehicles for off-road conditions

- Custom builds for enthusiasts seeking performance upgrades

Overall, this engine has proven to be a versatile and dependable choice, fulfilling various requirements across multiple sectors.

Common Issues with 7.3 Idi Diesel

The engine in question is renowned for its durability and performance, yet like any mechanical system, it is not immune to certain challenges. Understanding these common problems can help owners maintain their vehicle effectively and prolong its lifespan. Recognizing symptoms early on can prevent more significant issues down the road.

Fuel System Concerns

One frequent issue involves the fuel delivery system, where clogged filters or failing injectors can lead to poor performance and reduced efficiency. Additionally, air leaks in the fuel lines can cause starting difficulties and erratic engine behavior. Regular inspection and timely replacement of filters are essential to keep the system functioning optimally.

Electrical System Failures

Electrical problems often arise, particularly with the glow plug system. Malfunctioning glow plugs can result in hard starts, especially in colder climates. Furthermore, wiring issues or corroded connections may lead to inconsistent power delivery, affecting overall performance. Addressing these electrical concerns promptly is crucial for reliable operation.

Essential Tools for Diesel Repair

When it comes to maintaining and fixing powerful engines, having the right instruments is crucial for efficiency and accuracy. A well-equipped workshop can make a significant difference in the outcome of your projects. Below are some indispensable tools that every technician should consider adding to their collection.

- Wrenches: A variety of wrenches, including adjustable and socket types, are necessary for loosening and tightening various components.

- Screwdrivers: Both flathead and Phillips screwdrivers in multiple sizes are essential for working with different fasteners.

- Torque Wrench: This tool ensures that bolts are tightened to the specified torque, preventing damage and ensuring safety.

- Multimeter: A multimeter is vital for diagnosing electrical issues and checking voltages and resistances.

In addition to basic hand tools, some specialized instruments can greatly enhance your capabilities:

- Fuel Pressure Gauge: This tool helps monitor the fuel system’s pressure, which is crucial for performance.

- Compression Tester: Used to assess the health of the engine by measuring compression in each cylinder.

- Scan Tool: A diagnostic scanner provides valuable data and error codes from the engine control unit.

- Engine Hoist: Essential for lifting heavy engine components safely and efficiently during assembly or disassembly.

Investing in high-quality tools not only enhances your efficiency but also improves the overall quality of your work. Proper maintenance and attention to detail can lead to longer-lasting performance and reliability in heavy machinery.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to effectively addressing common issues encountered in specific engine systems. Following these systematic instructions ensures a thorough understanding of each phase, allowing for efficient troubleshooting and maintenance.

1. Preparation: Begin by gathering all necessary tools and components. Ensure a clean and organized workspace to facilitate smooth progress throughout the process.

2. Diagnosis: Identify the symptoms accurately. Conduct tests to pinpoint the root cause of the malfunction, taking detailed notes for reference.

3. Disassembly: Carefully dismantle the components as per the outlined sequence. Use appropriate techniques to avoid damage, labeling parts as needed for easy reassembly.

4. Inspection: Examine each component meticulously for wear, cracks, or other signs of failure. This step is crucial for determining what needs to be replaced or repaired.

5. Replacement: Install new or refurbished parts following manufacturer specifications. Ensure that all fittings are secure and that each piece is correctly aligned.

6. Reassembly: Reverse the disassembly process with attention to detail. Double-check all connections and torque specifications to maintain integrity.

7. Testing: Once reassembled, conduct a series of tests to verify functionality. Monitor performance closely to ensure that the initial issue has been resolved.

8. Final Check: After successful testing, perform a final inspection of the entire system. Clean the workspace and document the completed work for future reference.

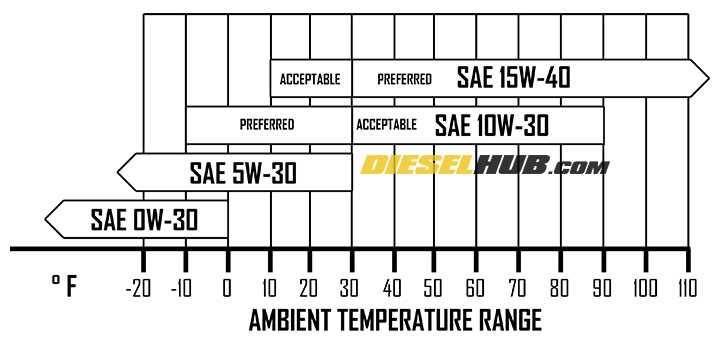

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your engine requires consistent care and attention. By following a structured maintenance routine, you can enhance performance and extend its lifespan. Here are some essential practices to consider:

- Regular Fluid Checks: Monitor oil, coolant, and fuel levels frequently to prevent issues.

- Scheduled Oil Changes: Change the lubricant according to the manufacturer’s recommendations to keep internal components clean.

- Filter Maintenance: Replace air and fuel filters periodically to ensure optimal airflow and fuel delivery.

- Inspect Belts and Hoses: Regularly check for wear and tear, replacing any damaged parts promptly to avoid breakdowns.

- Monitor Engine Temperature: Keep an eye on the temperature gauge to detect overheating issues early.

- Fuel Quality: Use high-quality fuel to maintain combustion efficiency and engine performance.

By adhering to these guidelines, you can significantly improve reliability and reduce the risk of costly repairs down the line.

Identifying Engine Noises and Problems

Recognizing unusual sounds from an engine can be crucial in diagnosing underlying issues. These noises often serve as early indicators of potential malfunctions, helping owners take timely action to prevent further damage. Understanding the nature and source of these sounds can significantly aid in the maintenance and longevity of the vehicle.

Common Types of Noises

Different sounds can signify various problems. A knocking noise may indicate issues with internal components, such as bearings or pistons. Conversely, a hissing or whistling sound could suggest a leak in the air intake or exhaust system. Each noise carries specific implications, so it’s essential to pay close attention to changes in the sound profile of the engine.

Addressing the Issues

Upon identifying a concerning noise, it is advisable to conduct a thorough inspection. Start by examining the engine’s fluid levels and condition, as low or contaminated fluids can lead to performance issues. If the noise persists, consulting a qualified technician for a comprehensive diagnosis may be necessary. Early intervention can save both time and resources in the long run.

Understanding Fuel System Components

The fuel system is a critical element in the performance and efficiency of any engine. It comprises various parts that work together to ensure the proper delivery and atomization of fuel. A thorough comprehension of these components is essential for effective maintenance and troubleshooting, ultimately leading to enhanced engine functionality.

Key Components of the Fuel System

Several essential elements make up the fuel delivery network. The fuel tank serves as the storage unit, while the fuel pump facilitates the movement of fuel from the tank to the engine. Additionally, the fuel filter plays a vital role in removing impurities, ensuring that only clean fuel enters the combustion chamber.

The Role of Injectors

Injectors are fundamental in the process of fuel atomization. They spray a fine mist of fuel directly into the combustion chamber at precise intervals, allowing for optimal mixing with air. This precise delivery contributes significantly to engine performance and emissions control. Understanding how injectors function and their maintenance needs can greatly influence the longevity of the engine.

Electrical System Troubleshooting Guide

This section provides essential insights for diagnosing issues within the electrical framework of your vehicle. Understanding the underlying principles and common pitfalls can significantly enhance your ability to identify and rectify problems effectively.

Before diving into specific troubleshooting techniques, familiarize yourself with the fundamental components of the electrical system. This knowledge will serve as a foundation for systematic evaluation.

Common Symptoms of Electrical Issues

- Dim or flickering lights

- Inconsistent starting behavior

- Electrical components malfunctioning

- Unusual noises from the starter

Step-by-Step Troubleshooting Process

- Visual Inspection: Check for frayed wires, loose connections, and corrosion.

- Battery Assessment: Measure voltage and ensure proper connections. Replace if necessary.

- Fuses and Relays: Inspect for blown fuses and faulty relays that may disrupt power flow.

- Ground Connections: Verify the integrity of ground connections to ensure proper circuit function.

- Testing Components: Use a multimeter to test individual components such as alternators and starters.

By following these steps, you can systematically identify and address electrical system concerns, ensuring reliable performance and longevity of your vehicle’s components.

Upgrades for Enhanced Performance

Improving engine efficiency and power output can significantly enhance overall driving experience. With the right modifications, enthusiasts can unlock greater potential from their vehicles, achieving better throttle response, increased horsepower, and improved fuel economy. Below are several upgrades that can contribute to a more powerful and responsive engine.

- High-Performance Air Intake System: Replacing the stock air intake with a high-flow system can improve airflow, resulting in better combustion and increased power.

- Enhanced Exhaust System: Upgrading to a performance exhaust allows for better exhaust flow, reducing back pressure and enhancing engine performance.

- ECU Remapping: Reprogramming the engine control unit can optimize fuel delivery and ignition timing, leading to improved performance and efficiency.

- Intercooler Upgrade: A larger or more efficient intercooler can reduce intake temperatures, resulting in denser air and increased power output.

- Fuel Injector Upgrade: High-flow injectors can deliver more fuel to the engine, supporting increased power levels, especially when combined with other modifications.

Incorporating these enhancements not only elevates performance but also contributes to a more enjoyable and responsive driving experience. Careful consideration of each upgrade will ensure compatibility and maximize benefits.