In the world of automotive service, ensuring optimal functionality of specialized apparatus is crucial for efficient operations. Understanding the intricacies of these tools not only enhances productivity but also extends their lifespan, allowing professionals to deliver high-quality results.

Effective maintenance practices can prevent common issues that arise during use, thereby minimizing downtime and costly repairs. This section aims to provide comprehensive insights into the techniques and procedures that should be employed to keep your essential equipment in peak condition.

By familiarizing yourself with the best practices, troubleshooting tips, and safety measures, you can significantly improve the reliability of your tools. Whether you are a seasoned technician or a newcomer to the field, this guide serves as a valuable resource for maintaining your equipment with confidence and expertise.

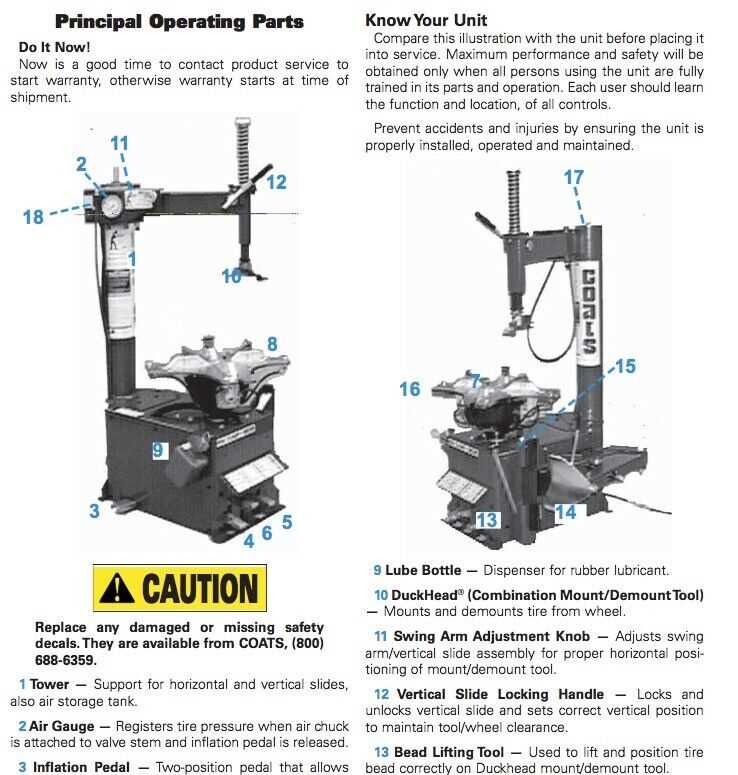

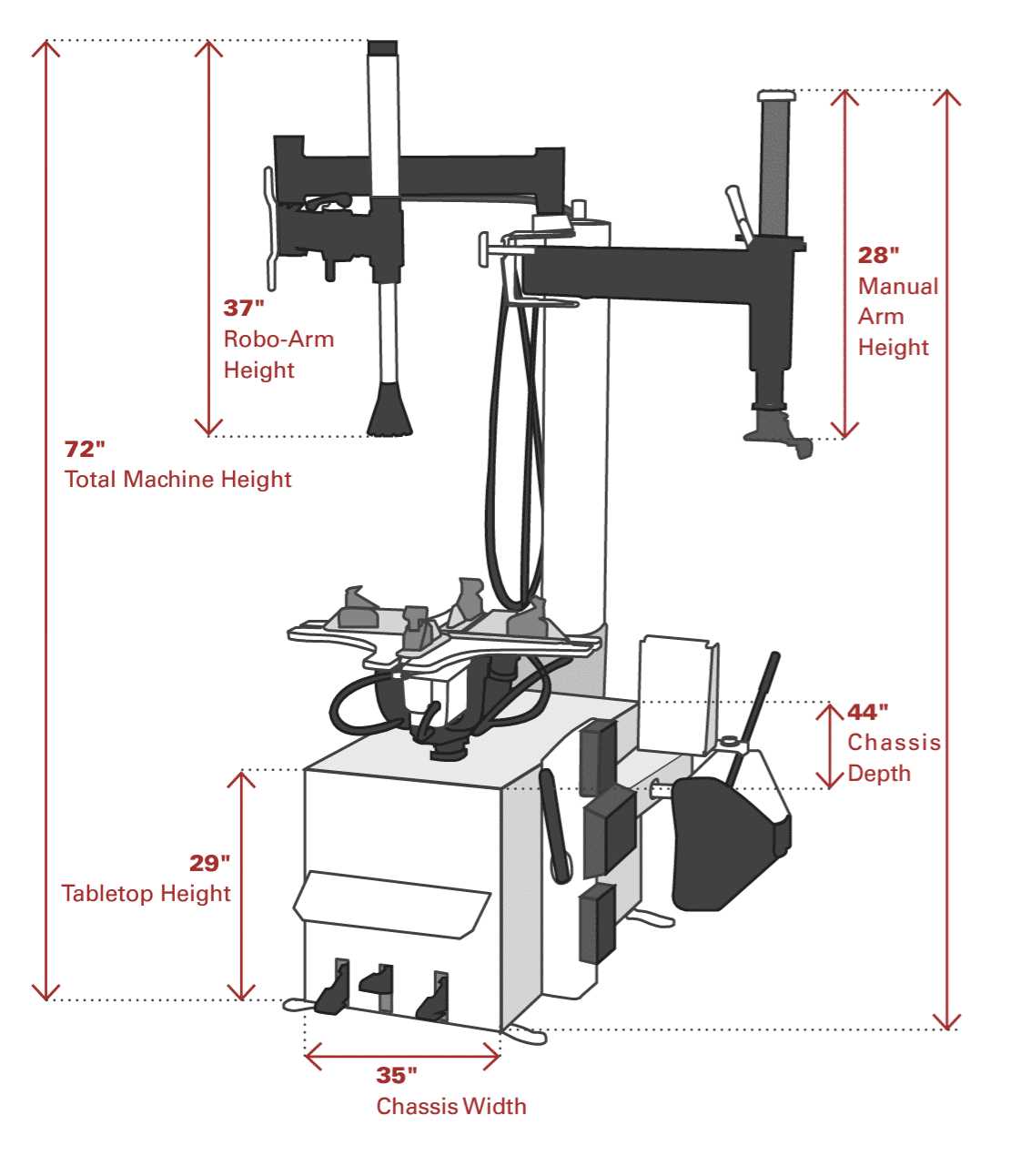

Overview of Coats Tire Machines

This section provides an insightful look into a prominent brand known for its innovative equipment designed for the automotive industry. The focus is on the functionality and performance of these devices, which play a crucial role in enhancing efficiency and precision during service operations.

Designed for durability, these tools incorporate advanced technology to streamline processes, ensuring that professionals can work with confidence. The equipment is engineered to handle a variety of tasks, making it a versatile choice for workshops of all sizes.

Moreover, user-friendly interfaces and robust construction contribute to their popularity among technicians. Regular updates and support services further enhance the value, allowing users to stay current with best practices and maintenance protocols.

In summary, this brand stands out for its commitment to quality and innovation, making it a preferred option in the competitive landscape of automotive service solutions.

Common Tire Machine Issues

In the realm of automotive service, certain challenges frequently arise that can hinder the efficiency and effectiveness of equipment. Identifying these prevalent concerns is crucial for maintaining optimal functionality and ensuring safe operation.

Frequent Problems Encountered

- Inconsistent Performance: Variations in output may occur, leading to ineffective operation.

- Excessive Noise: Unusual sounds can indicate underlying mechanical issues.

- Hydraulic Failures: Loss of pressure can affect the unit’s ability to function properly.

- Electrical Malfunctions: Problems with wiring or components may disrupt performance.

- Wear and Tear: Regular usage can lead to deterioration of parts, impacting overall efficiency.

Potential Causes

- Poor Maintenance: Lack of regular servicing can exacerbate issues over time.

- Operator Error: Incorrect usage can lead to premature breakdowns.

- Quality of Components: Subpar parts can compromise reliability and safety.

- Environmental Factors: Exposure to extreme conditions may affect functionality.

By recognizing these common challenges and their potential causes, users can take proactive measures to enhance performance and extend the lifespan of their equipment.

Tools Needed for Repairs

When it comes to maintaining and fixing equipment, having the right instruments at your disposal is crucial. This section outlines the essential items you will require to effectively address issues that may arise during service. Proper tools not only facilitate the process but also ensure safety and efficiency.

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | For adjusting screws and components. |

| Pliers | For gripping, twisting, and cutting wires or small parts. |

| Torque Wrench | To apply a specific torque to fasteners. |

| Safety Goggles | To protect eyes from debris and hazards. |

| Lubricant | To reduce friction on moving parts. |

| Cleaning Supplies | For maintaining a clean work environment and tools. |

Step-by-Step Repair Process

This section provides a comprehensive guide to effectively troubleshoot and restore your equipment. By following these outlined procedures, you can ensure optimal functionality and longevity. Each stage is crucial for diagnosing issues and implementing the necessary fixes.

Initial Assessment

Begin with a thorough evaluation of the device to identify any visible signs of malfunction. Inspect connections, components, and overall condition. Document any anomalies you observe, as this will aid in the subsequent steps. A systematic approach will enhance your understanding of the underlying issues.

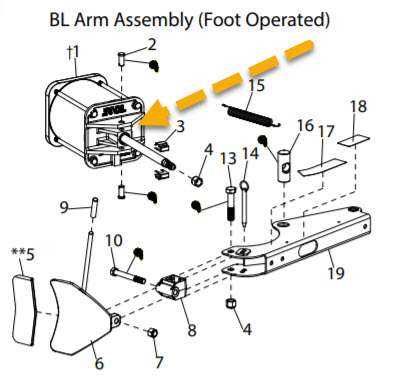

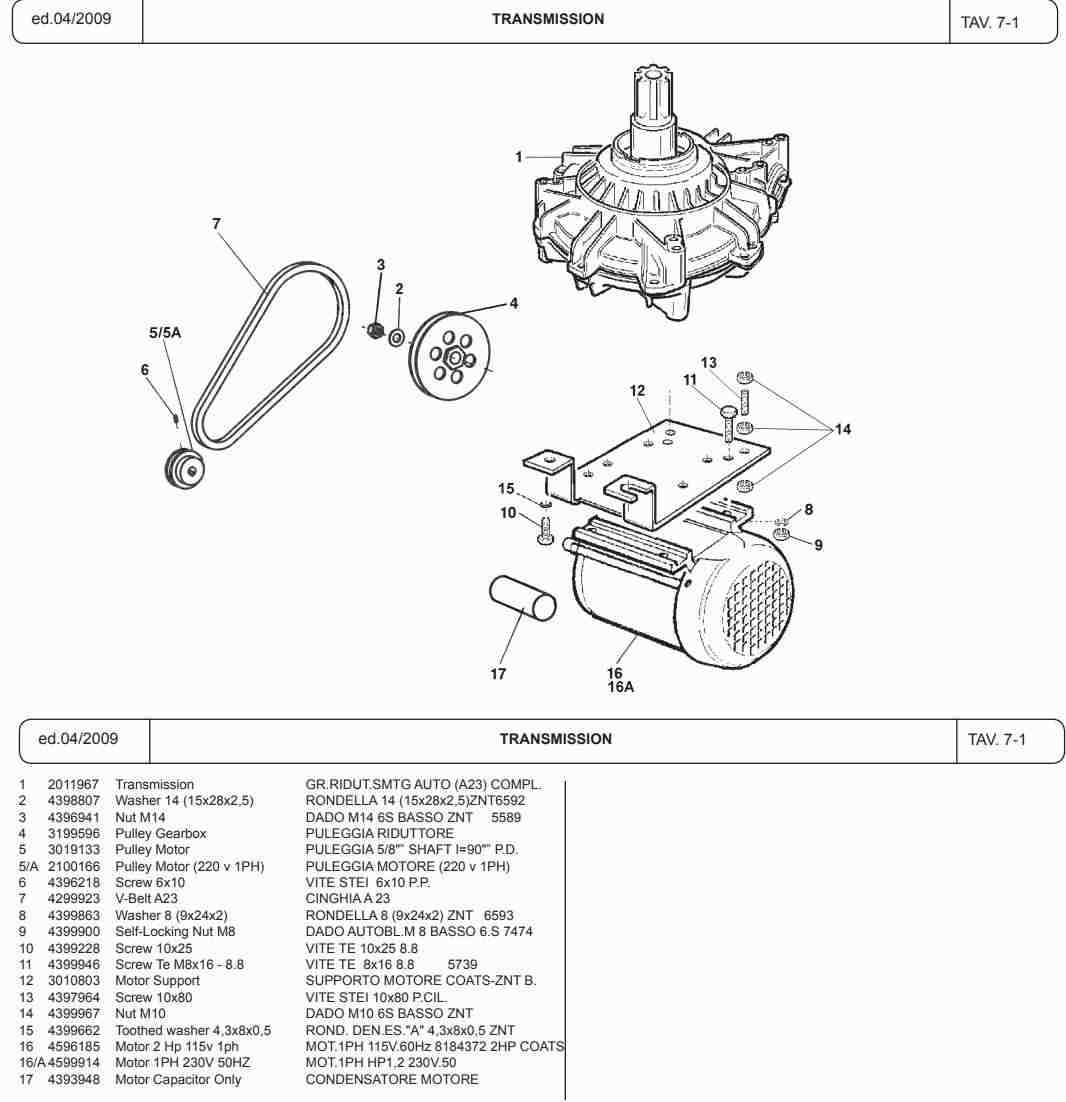

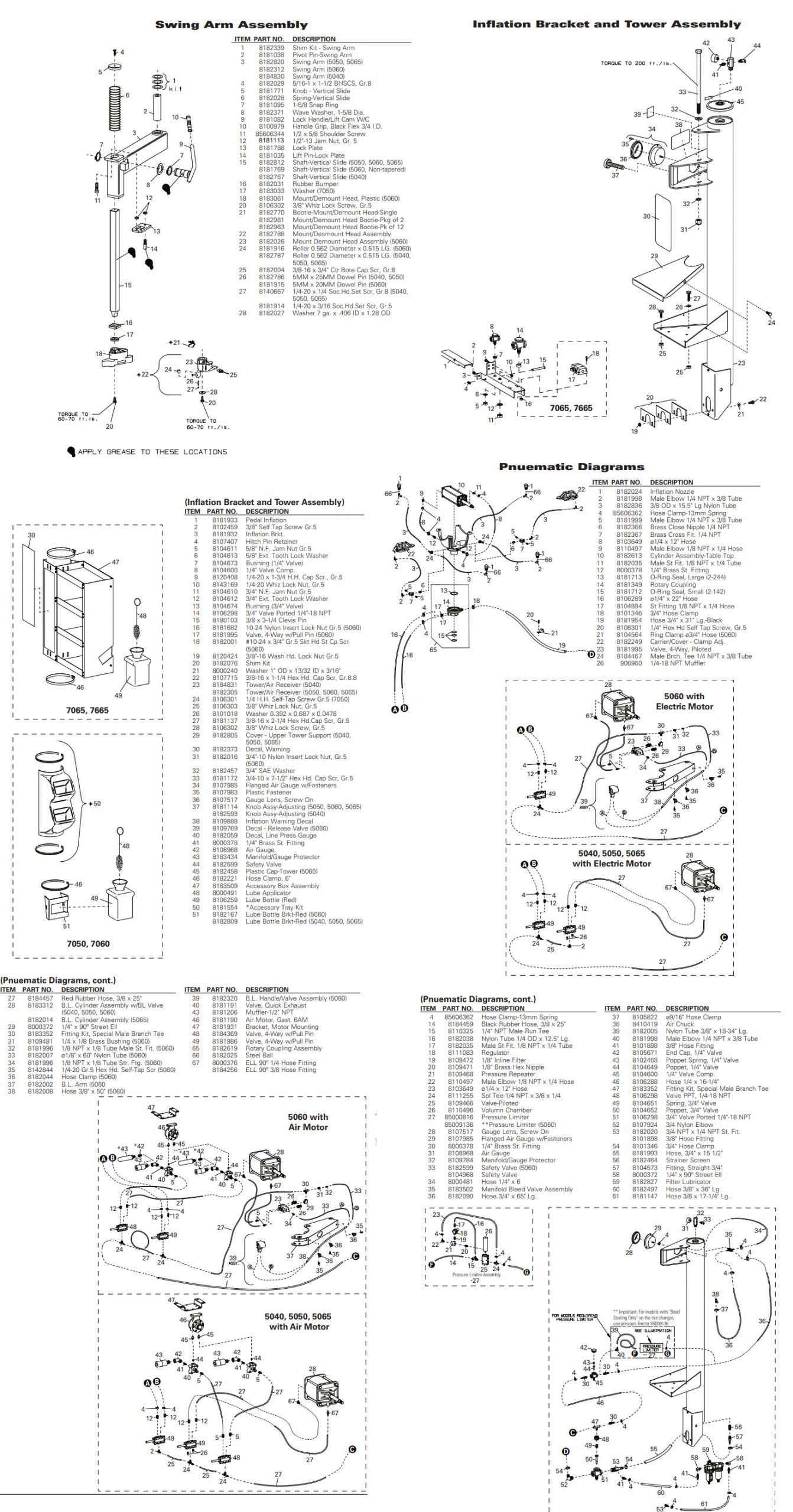

Disassembly and Inspection

Once the initial assessment is complete, proceed to carefully disassemble the unit. Pay attention to how each part fits together, and consider taking notes or photographs for reference. Examine internal components for wear or damage, ensuring that you replace any defective items before reassembling the system.

Preventive Maintenance Tips

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Implementing a systematic approach to maintenance not only minimizes downtime but also enhances safety and efficiency. This section outlines key practices that can help you maintain your tools in peak condition.

Routine Inspections

Conducting frequent evaluations of your equipment is vital. Check for signs of wear and tear, loose components, or any unusual sounds during operation. Addressing minor issues before they escalate can save time and costs in the long run. Establish a checklist for these inspections to ensure consistency.

Proper Lubrication

Keeping moving parts well-lubricated is crucial for smooth operation. Use the recommended lubricants and apply them as per the manufacturer’s guidelines. Regularly scheduled lubrication not only prevents friction but also reduces the risk of overheating and mechanical failure.

Incorporating these preventive measures into your routine will significantly enhance the performance and reliability of your equipment.

Diagnosing Electrical Problems

Identifying issues related to electrical components can be a challenging yet essential task. Proper assessment ensures optimal functionality and prevents further complications. Understanding common signs of malfunction and utilizing systematic approaches can lead to effective troubleshooting.

Common Symptoms of Electrical Failures

- Intermittent power loss

- Unexpected shutdowns

- Inconsistent performance

- Visible damage to wiring or connectors

- Unusual sounds or odors

Troubleshooting Steps

- Check the power source for consistency.

- Inspect wiring for signs of wear or damage.

- Test connectors for secure connections.

- Use a multimeter to assess voltage levels.

- Review relevant diagrams for proper component arrangement.

Following these guidelines can aid in pinpointing electrical issues efficiently, paving the way for appropriate corrective measures.

Hydraulic System Troubleshooting

Understanding the functionality and potential issues within hydraulic systems is essential for ensuring optimal performance. This section focuses on common problems that may arise, their symptoms, and effective strategies for resolution. By identifying these issues early, one can maintain efficiency and prevent further complications.

| Problem | Symptoms | Possible Solutions |

|---|---|---|

| Fluid Leakage | Visible fluid on components, low fluid levels | Inspect seals and hoses; replace damaged parts |

| Inadequate Pressure | Poor performance, slow actuation | Check pump operation; inspect for obstructions |

| Overheating | High temperature readings, system shutdown | Inspect fluid levels; ensure proper ventilation |

| Noisy Operation | Unusual sounds during operation | Check for air in the system; inspect components for wear |

Regular maintenance and timely troubleshooting are crucial for the longevity of hydraulic systems. By addressing these issues proactively, operators can ensure reliable and safe operation.

Replacing Worn-Out Components

Maintaining optimal functionality requires the timely replacement of aged or damaged parts. Regular assessments help ensure that all elements work harmoniously, enhancing performance and extending the lifespan of the equipment.

Identifying components that need replacement involves several key steps:

- Conduct a thorough inspection of the entire system.

- Look for signs of wear, such as cracks, corrosion, or unusual noises.

- Check for decreased efficiency during operation.

Once worn-out elements are identified, follow these guidelines for replacement:

- Ensure you have the correct replacement parts by consulting specifications.

- Power down the system and follow safety protocols before starting work.

- Use appropriate tools to carefully remove the old components.

- Install new parts, ensuring proper alignment and secure fastening.

After replacement, it’s essential to test the system to confirm that everything functions correctly. Regular monitoring and timely replacements will promote reliability and efficiency.

Calibrating the Tire Machine

Ensuring optimal performance of your equipment requires precise adjustments and configurations. Calibration is essential for achieving accurate results and prolonging the lifespan of your tools. Properly setting parameters allows for efficient operation and enhances safety during use.

Steps for Accurate Calibration

Begin by reviewing the manufacturer’s specifications to understand the necessary settings. Use appropriate measurement tools to assess current configurations. Adjust the dials and settings gradually, testing functionality after each modification. It’s crucial to document changes to track improvements and ensure consistency.

Regular Maintenance and Recalibration

Consistent upkeep is vital for sustaining accuracy over time. Schedule routine checks to reassess settings, especially after extensive use or equipment adjustments. Keeping a log of maintenance activities will help identify patterns and predict when recalibration may be necessary.

Safety Precautions During Repairs

When performing maintenance on equipment, ensuring safety is paramount. Proper precautions help prevent accidents, protect personal well-being, and maintain operational integrity. This section outlines essential measures to observe while conducting any work on tools and devices.

Personal Protective Equipment (PPE)

Using appropriate protective gear is vital in any work environment. Essential items include gloves, goggles, and sturdy footwear. Each piece of equipment serves a specific purpose in safeguarding against potential hazards.

| Type of PPE | Purpose |

|---|---|

| Gloves | Protect hands from sharp objects and chemicals. |

| Goggles | Shield eyes from debris and harmful substances. |

| Footwear | Prevent foot injuries from heavy items and provide slip resistance. |

Workspace Organization

A tidy and organized workspace significantly reduces risks. Tools and materials should be stored properly to avoid tripping hazards. Additionally, ensuring adequate lighting can prevent accidents related to poor visibility.

Upgrading Your Tire Machine

Enhancing your equipment can significantly boost efficiency and performance. By integrating the latest technologies and features, you can streamline operations, reduce downtime, and ultimately increase productivity. This section explores various strategies for modernizing your apparatus, ensuring it meets the demands of today’s market.

Incorporating Advanced Features

One effective approach is to install upgraded components that offer enhanced functionalities. Look for options that include digital displays, automated settings, and improved safety features. These advancements not only make operations smoother but also help in minimizing the risk of errors during use.

Regular Maintenance and Training

In addition to physical upgrades, ensuring that personnel are well-trained on the latest techniques and maintenance practices is crucial. Regular training sessions can keep your team informed about new features and best practices, further maximizing the potential of your upgraded apparatus.

Where to Find Replacement Parts

Finding suitable components for your equipment can be a challenging task. Fortunately, there are various avenues to explore for sourcing these essential items, ensuring your apparatus remains functional and efficient.

- Authorized Dealers: One of the most reliable sources for components is through authorized distributors. They often carry original parts and can provide guidance on compatibility.

- Online Retailers: Numerous websites specialize in selling parts for various types of machinery. Look for reputable e-commerce platforms that offer a wide range of components with customer reviews.

- Local Parts Stores: Visit nearby hardware or automotive supply shops. Many of them stock a selection of essential components or can order them for you.

- Manufacturer’s Website: The official website of the equipment’s manufacturer typically features a section for purchasing parts directly. This ensures you receive authentic and compatible items.

- Surplus and Salvage Yards: These locations can be treasure troves for hard-to-find components. Inspecting used parts can lead to significant savings.

- Online Marketplaces: Platforms like eBay and Craigslist often have listings for new and used components. Ensure to verify the seller’s credibility before making a purchase.

By exploring these options, you can effectively locate the parts necessary to maintain and enhance the performance of your equipment.

FAQs About Coats Tire Machines

This section addresses common inquiries regarding the equipment used for handling wheel assemblies. These questions aim to clarify the functionalities, maintenance, and troubleshooting of various models to enhance user understanding and efficiency.

| Question | Answer |

|---|---|

| What types of wheels can this equipment handle? | The equipment is designed to accommodate a wide range of wheel sizes and types, including both standard and specialty variations. |

| How often should I perform maintenance? | Regular maintenance is recommended every few months, or as specified in the guidelines, to ensure optimal performance and longevity. |

| What should I do if the device malfunctions? | If you experience issues, refer to the troubleshooting section of the guidelines or contact customer support for assistance. |

| Are replacement parts readily available? | Yes, replacement components can be sourced from authorized dealers or directly from the manufacturer. |

| Can I use this equipment for heavy-duty applications? | Many models are built to handle heavy-duty tasks; however, it’s essential to check the specifications to ensure compatibility. |