Understanding the intricacies of garage door opener systems is essential for ensuring their longevity and efficiency. This section provides essential insights into troubleshooting and servicing these devices, enabling users to maintain optimal performance.

From identifying common issues to implementing effective solutions, this guide covers a range of topics that empower users to take control of their opener’s functionality. Whether you’re facing minor setbacks or require more in-depth knowledge, this resource aims to assist in the proper upkeep of your equipment.

Empowering yourself with knowledge about these mechanisms not only saves time but also enhances safety and convenience. With a focus on practical advice, this section encourages proactive measures to keep your opener in excellent condition.

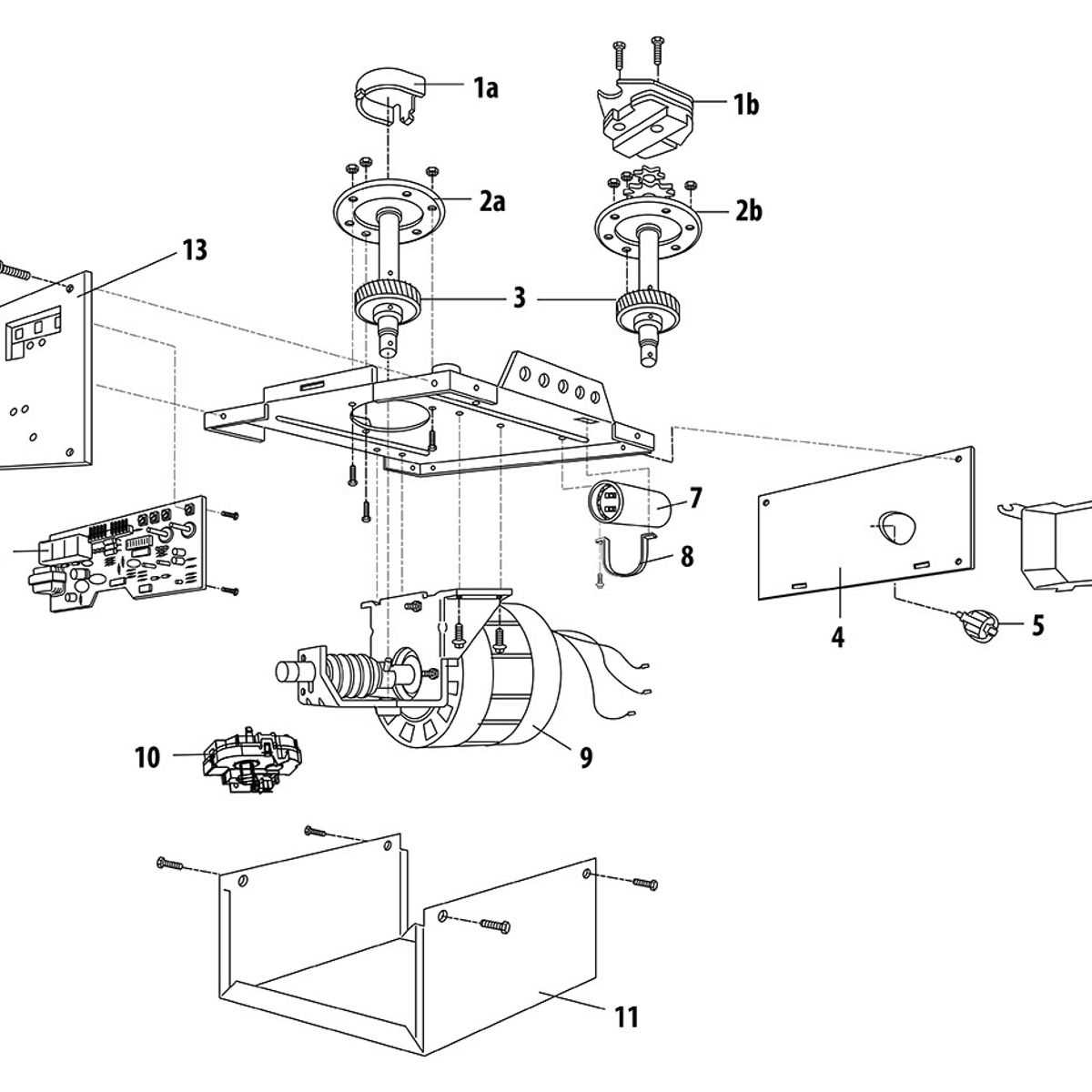

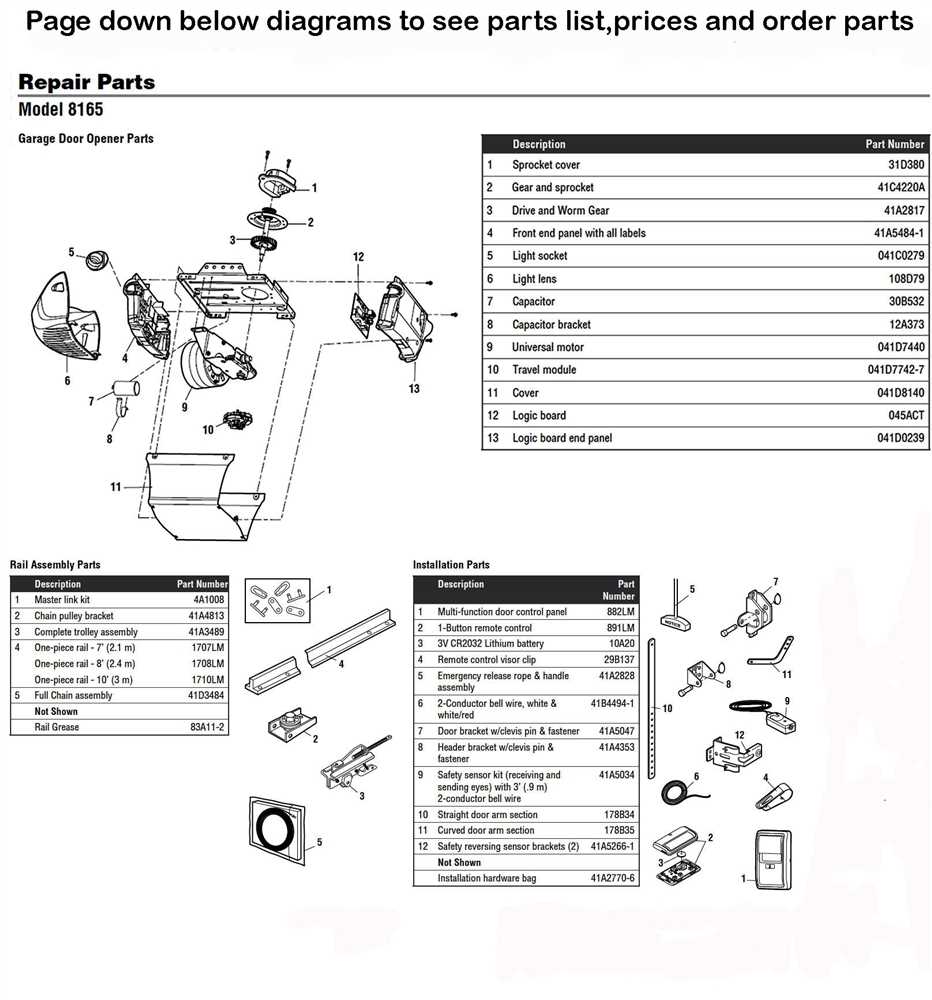

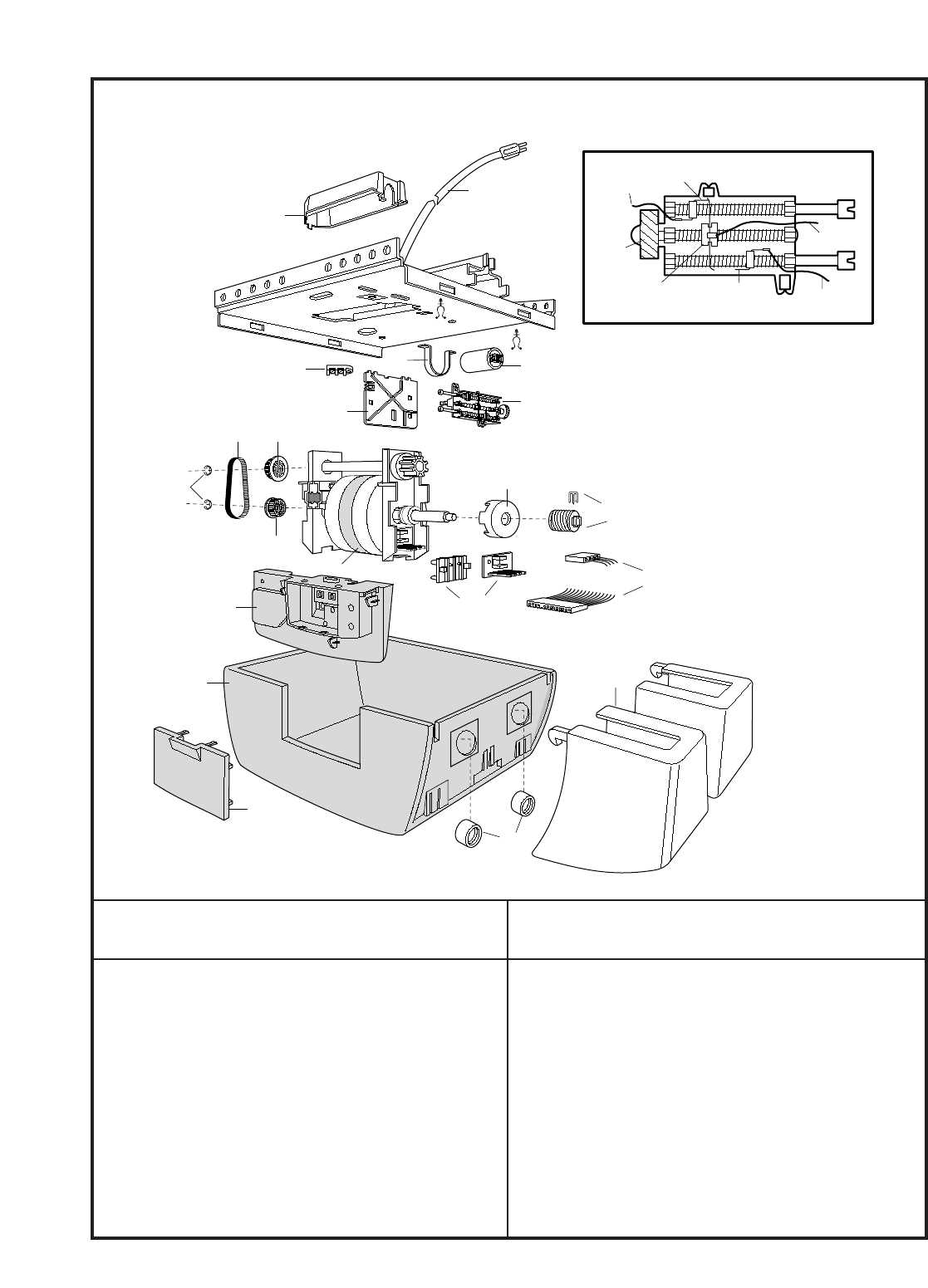

Understanding Liftmaster Components

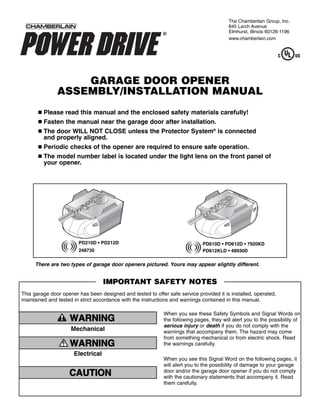

This section aims to provide insight into the essential elements that comprise automatic door operators. Familiarity with these components is crucial for effective maintenance and troubleshooting.

Key Elements of Automatic Operators

The main parts of these systems include the motor unit, which drives the door’s movement, and the track system that guides it. Sensors play a vital role in ensuring safety by detecting obstacles during operation.

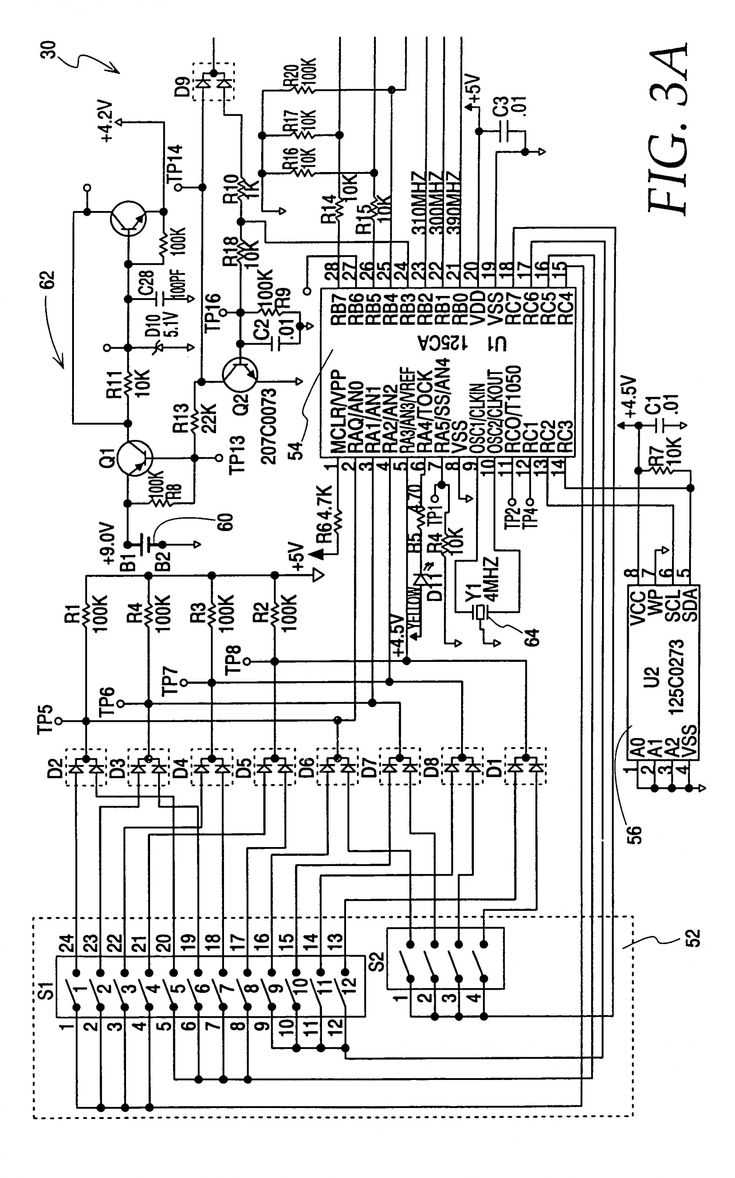

Control Systems and Their Functions

Control boards serve as the brain of the mechanism, coordinating actions based on input from remote devices. Understanding how these systems interact can help users diagnose issues and ensure proper functionality.

Common Issues with Chamberlain Systems

Many homeowners experience various challenges with their automatic door opening mechanisms. Understanding these frequent problems can aid in troubleshooting and restoring functionality effectively.

Below are some typical complications encountered:

| Issue | Possible Causes | Solutions |

|---|---|---|

| Door does not open | Power failure, faulty remote, obstruction | Check power source, replace batteries, clear any obstructions |

| Door closes partially | Misaligned sensors, damaged tracks | Realign sensors, inspect and repair tracks |

| Unusual noises during operation | Lack of lubrication, worn rollers | Lubricate moving parts, replace worn components |

| Remote control not working | Dead batteries, interference | Replace batteries, check for sources of interference |

Step-by-Step Troubleshooting Guide

This guide provides a systematic approach to diagnosing and resolving issues with automatic door operators. Following these steps can help identify common problems and offer potential solutions, ensuring smooth operation.

- Check the Power Supply

- Ensure the unit is plugged in securely.

- Inspect the circuit breaker for any tripped switches.

- Test the outlet with another device to confirm functionality.

- Examine the Remote Control

- Replace the batteries if the remote is unresponsive.

- Check for any obstruction between the remote and the sensor.

- Reprogram the remote according to the manufacturer’s instructions.

- Inspect the Door Mechanism

- Look for any visible obstructions in the door track.

- Ensure the door is aligned properly and not stuck.

- Lubricate the moving parts to reduce friction.

- Test Safety Features

- Check the photo eye sensors for alignment and dirt.

- Ensure the safety features are not disabled or malfunctioning.

- Manually test the reverse function to confirm it operates correctly.

- Consult the Documentation

- Review any troubleshooting sections for specific issues.

- Follow any additional troubleshooting steps provided by the manufacturer.

If the problem persists after following these steps, consider seeking professional assistance to ensure safety and proper resolution.

Safety Precautions for Repairs

Ensuring a safe environment during maintenance tasks is crucial. Adhering to specific guidelines can prevent accidents and enhance overall efficiency when addressing issues with equipment. The following considerations are essential for anyone involved in such activities.

Essential Guidelines

- Always disconnect power before starting any work to avoid electric shocks.

- Use appropriate personal protective equipment, including gloves and safety glasses.

- Ensure a well-lit workspace to improve visibility and reduce the risk of accidents.

- Keep tools organized and within reach to minimize distractions and enhance focus.

Proper Tool Handling

- Inspect all tools before use to ensure they are in good condition.

- Store tools properly after each use to prevent trip hazards.

- Use tools for their intended purpose to avoid malfunctions and injuries.

Tools Required for Maintenance

To ensure the longevity and optimal performance of your equipment, having the right instruments at hand is essential. Proper maintenance involves a variety of tasks that require specific tools to facilitate effective servicing and troubleshooting.

Essential Tools

The following items are crucial for routine upkeep:

- Screwdrivers: Both flathead and Phillips varieties are necessary for securing or loosening screws.

- Wrenches: A set of adjustable wrenches can help with tightening or loosening bolts.

- Pliers: These are useful for gripping and bending various components.

- Lubricants: Regular application of appropriate lubricants can minimize friction and wear on moving parts.

Additional Considerations

In addition to the basic tools, consider having the following items available:

- Safety Gear: Gloves and goggles to protect yourself during maintenance tasks.

- Cleaning Supplies: Cloths and brushes for keeping the system clean.

- Multimeter: This tool is useful for diagnosing electrical issues.

Equipping yourself with the proper tools will greatly enhance your ability to conduct effective maintenance and address any issues that arise.

Replacing Worn Parts Effectively

Maintaining the longevity of your lifting mechanism often involves the timely replacement of components that show signs of wear. Addressing these issues promptly not only enhances performance but also prevents further damage to the system.

Identifying Signs of Wear

Before initiating the replacement process, it’s crucial to recognize the indicators of deterioration. Common symptoms include unusual noises during operation, decreased lifting power, and visible damage to parts. Regular inspections can help you spot these issues early.

Steps for Replacement

Once you identify the worn components, follow these steps for a successful replacement:

- Gather Necessary Tools: Ensure you have all the tools required for the job, including wrenches, screwdrivers, and safety gear.

- Remove the Affected Part: Carefully detach the worn component, taking note of how it connects to the overall system.

- Install the New Part: Align and secure the new component, ensuring it fits properly and functions as intended.

By following these guidelines, you can ensure efficient and effective replacements, contributing to the reliable operation of your system.

Adjusting Sensor Alignment

Proper alignment of the sensors is crucial for the smooth operation of any lifting mechanism. Misalignment can lead to malfunctioning, preventing the system from detecting obstacles effectively and ensuring safe performance.

To begin the adjustment process, first, locate the sensors on either side of the opening. Ensure they are clean and free of obstructions. If the indicators on the sensors are not illuminated or are flashing, this may signal a misalignment issue.

Next, gently reposition the sensors until the lights remain solid. This often requires slight adjustments, so be patient and make small changes to their positioning. Ensure that both sensors are facing each other directly; they should be aligned within the same horizontal plane.

Once aligned, test the system by activating it. If the sensors function properly and the operation is seamless, the alignment is successful. If problems persist, double-check the placement and cleanliness of the sensors to confirm that nothing is obstructing their view.

Programming Remote Controls

Setting up remote access for your lifting device is essential for convenience and functionality. This section outlines the necessary steps to ensure your remote controls are configured correctly, enabling seamless operation.

Steps to Program Remote Devices

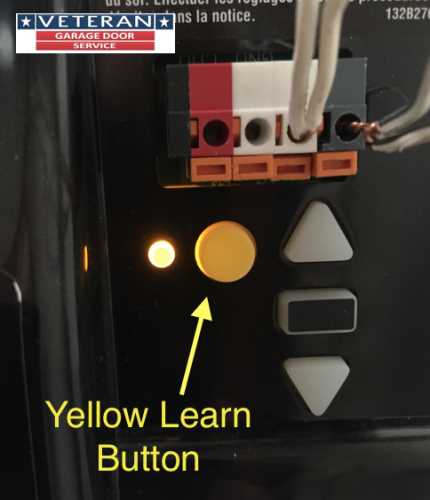

- Locate the “Learn” button on the main unit. This button is typically found on the back or side of the device.

- Press and release the “Learn” button. A light will usually flash to indicate that the system is ready to accept a new remote.

- Within 30 seconds, press the button on the remote control that you wish to program. The light on the main unit should blink to confirm successful programming.

- Test the remote by pressing the programmed button to ensure it activates the device correctly.

Tips for Effective Programming

- Ensure the remote is within range of the main unit during the programming process.

- If programming fails, repeat the steps to reset the unit and try again.

- Consult the specific guidelines for your model if you encounter any issues.

Regular Maintenance Practices

To ensure optimal performance and longevity of your lifting mechanism, it is essential to implement consistent upkeep routines. These practices not only enhance functionality but also help in identifying potential issues before they escalate into major problems.

Inspection of Components

Regularly examine all parts of the system for signs of wear and tear. This includes checking the cables, pulleys, and brackets for any signs of damage or corrosion. Timely identification of compromised components can prevent operational failures.

Lubrication and Cleaning

Maintain a clean environment around the equipment and lubricate moving parts to reduce friction. Use a suitable lubricant for rollers and hinges to promote smooth operation. Additionally, ensure that dust and debris are cleared away to maintain efficiency.

Recognizing Warning Signs of Failure

Identifying early indicators of malfunction is crucial for maintaining the functionality of automated systems. Awareness of potential issues can prevent unexpected breakdowns and costly repairs.

One common sign to watch for is unusual noise during operation. If you notice grinding, squeaking, or popping sounds, it may indicate wear on internal components. Frequent interruptions in performance, such as slow movement or failure to respond to commands, can also signal underlying problems.

Additionally, inconsistent behavior, like the unit stopping unexpectedly or reversing direction without cause, is often a precursor to more serious issues. Regular observation and prompt attention to these signs can enhance longevity and reliability.

Customer Support Resources

Accessing reliable assistance is crucial for ensuring optimal functionality of your garage door operating systems. Various resources are available to address inquiries and provide solutions to common issues, ensuring a smooth experience for users.

- Online Help Center: A comprehensive online resource offering troubleshooting guides, FAQs, and instructional videos to assist users in resolving issues independently.

- Customer Service Hotline: Direct communication with knowledgeable representatives ready to provide assistance, whether it’s answering questions or guiding you through specific problems.

- Local Service Providers: A directory of certified technicians in your area who can offer hands-on support and repairs when needed.

- Community Forums: Engaging with fellow users on discussion boards can provide valuable insights and solutions based on shared experiences.

- Email Support: For more detailed inquiries, users can reach out via email to receive tailored assistance from support teams.

Utilizing these resources can significantly enhance the experience and longevity of your garage door operating systems, ensuring any challenges are met with effective solutions.