Understanding the intricacies of maintaining your lifting machinery is essential for ensuring its longevity and efficiency. Proper attention to detail can prevent minor issues from escalating into significant problems, ultimately saving time and resources. This guide aims to provide insights into the necessary steps for keeping your equipment in optimal condition.

In the world of industrial tools, familiarity with the various components and their functions is crucial. This knowledge not only aids in effective maintenance but also enhances safety practices during operation. By delving into specific techniques and troubleshooting methods, you will be better equipped to handle any challenges that may arise.

Whether you are a seasoned professional or new to the field, understanding how to care for your machinery will empower you to perform tasks with confidence. This comprehensive resource will offer valuable tips and instructions, ensuring that your equipment remains reliable and efficient for years to come.

Understanding Cat Pallet Jacks

In the realm of material handling, certain devices play a crucial role in enhancing efficiency and safety. These tools are designed to facilitate the movement of heavy loads, making them essential in various industries, from warehousing to retail. This section aims to explore the fundamental aspects of these invaluable instruments.

Key Features

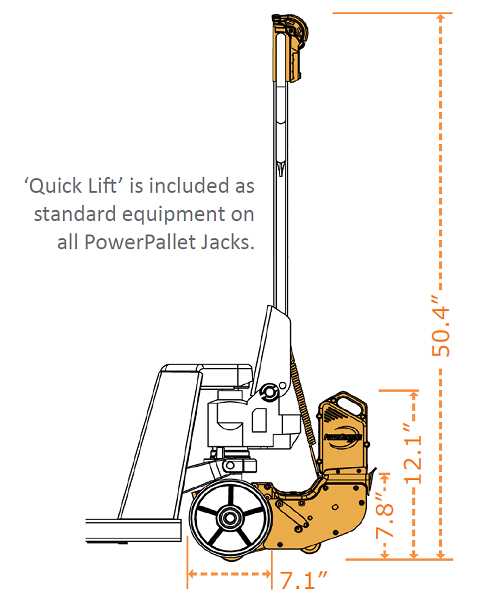

One of the most significant characteristics of these lifting devices is their ergonomic design. This feature not only maximizes user comfort but also minimizes the risk of injury. Additionally, robust construction ensures durability, allowing for frequent use without compromising performance. Understanding these features is vital for choosing the right equipment for specific tasks.

Operational Basics

To operate such machinery effectively, users must be familiar with its fundamental principles. Typically, these devices employ a hydraulic system that facilitates smooth lifting and lowering of loads. Proper training and adherence to safety guidelines are essential for ensuring both the operator’s safety and the integrity of the cargo being transported.

In summary, comprehending the intricacies of these handling tools can significantly impact productivity and workplace safety, underscoring the importance of knowledge and proper usage.

Common Issues with Cat Pallet Jacks

When it comes to material handling equipment, certain challenges frequently arise that can hinder performance and efficiency. Understanding these common issues is essential for maintaining optimal functionality and ensuring safety in the workplace. Below are some prevalent problems encountered with this type of machinery.

Hydraulic Problems

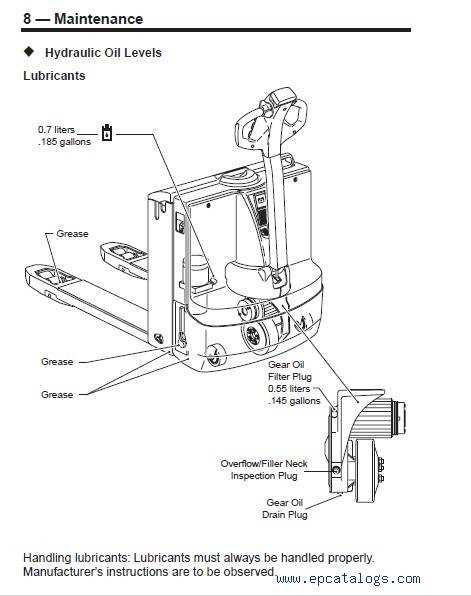

One of the most typical concerns involves the hydraulic system. Leaks can develop in the cylinder or hoses, leading to decreased lifting capacity. If the fluid levels drop too low, it can result in sluggish or unresponsive movement. Regular inspection and maintenance of the hydraulic components are crucial to avoid these setbacks.

Worn Wheels and Rollers

Wheels can wear down over time, affecting maneuverability and stability. Insufficient lubrication or debris accumulation can exacerbate this issue, making it difficult to navigate. Replacing worn wheels promptly not only improves performance but also enhances safety during operation.

Addressing these issues proactively will extend the lifespan of your equipment and improve overall efficiency in your operations. Regular maintenance checks and timely replacements are key to ensuring uninterrupted workflow.

Essential Tools for Repairs

When addressing mechanical issues, having the right instruments on hand can significantly enhance efficiency and effectiveness. A well-equipped toolkit is crucial for diagnosing and fixing problems, ensuring that every task is approached with the appropriate resources. This section highlights the fundamental implements that are indispensable for successful maintenance and troubleshooting.

Basic Hand Tools

The foundation of any repair endeavor lies in basic hand instruments. These include items such as wrenches, screwdrivers, and pliers. Each tool serves a unique purpose, allowing for adjustments, tightening, or loosening of various components. Investing in a quality set of these essentials can save time and effort in the long run.

Specialized Equipment

In addition to standard tools, certain specialized equipment is vital for more complex tasks. Torque wrenches are essential for ensuring components are secured to the manufacturer’s specifications, while multimeters aid in diagnosing electrical issues. Having these advanced tools can make a significant difference in the thoroughness and accuracy of your work.

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring the functionality of your lifting device. Following a structured method ensures that you effectively address any issues while enhancing the longevity of the equipment. By breaking down the process into manageable steps, you can confidently tackle each phase of the task.

1. Initial Assessment: Begin by thoroughly examining the unit for visible signs of wear or damage. Check for leaks, unusual noises, or any mechanical failures that might affect performance.

2. Gather Tools and Parts: Prepare all necessary tools and replacement components before starting. This may include wrenches, screwdrivers, seals, and lubricants.

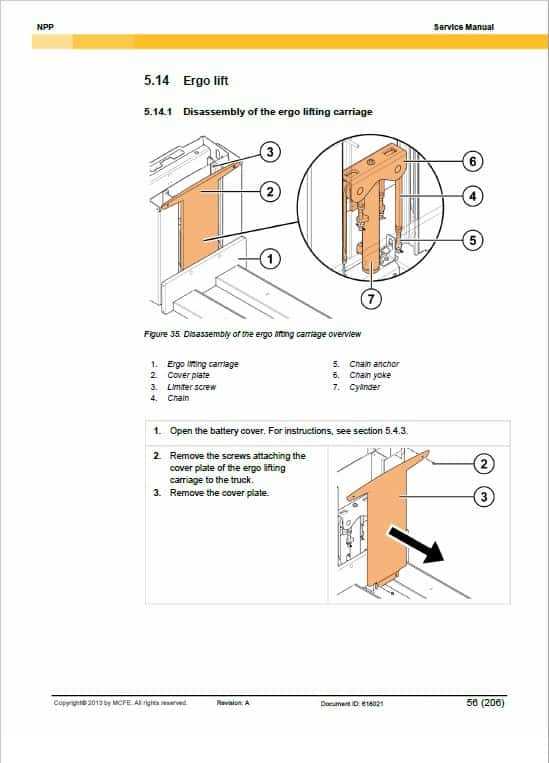

3. Disassembly: Carefully take apart the equipment, noting the arrangement of parts for easier reassembly later. Use a labeled container to organize screws and small pieces.

4. Clean and Inspect: Clean all components to remove dirt and grime. Inspect each part for cracks, wear, or any irregularities that could hinder functionality.

5. Replace Worn Components: Swap out any damaged parts with new ones. Ensure that all replacements are compatible with your specific model.

6. Reassembly: Follow your earlier notes to reassemble the device correctly. Ensure that all screws and fittings are tightened securely.

7. Testing: After reassembly, conduct a thorough test to confirm that the unit operates smoothly and meets safety standards. Monitor for any anomalies during operation.

8. Final Adjustments: Make any necessary adjustments based on your test results. Ensure that all settings are optimized for performance.

By adhering to these steps, you can efficiently restore your equipment and maintain its functionality for future use.

Regular Maintenance Tips

Consistent upkeep is essential for ensuring the longevity and efficient performance of your equipment. Implementing a routine maintenance schedule can help identify potential issues before they escalate, thereby reducing downtime and repair costs. Here are some key practices to keep your machinery in optimal condition.

Daily Checks

Start each day with a brief inspection. Look for visible signs of wear and tear, such as leaks, damaged components, or loose connections. Ensure that all moving parts are adequately lubricated and that the battery or power source is functioning correctly. Addressing minor issues promptly can prevent more significant problems later.

Periodic Servicing

In addition to daily inspections, schedule regular servicing based on usage. This includes thorough cleaning, checking hydraulic systems, and replacing worn-out parts as needed. Keeping detailed records of maintenance activities will help track the performance and service history, aiding in future assessments.

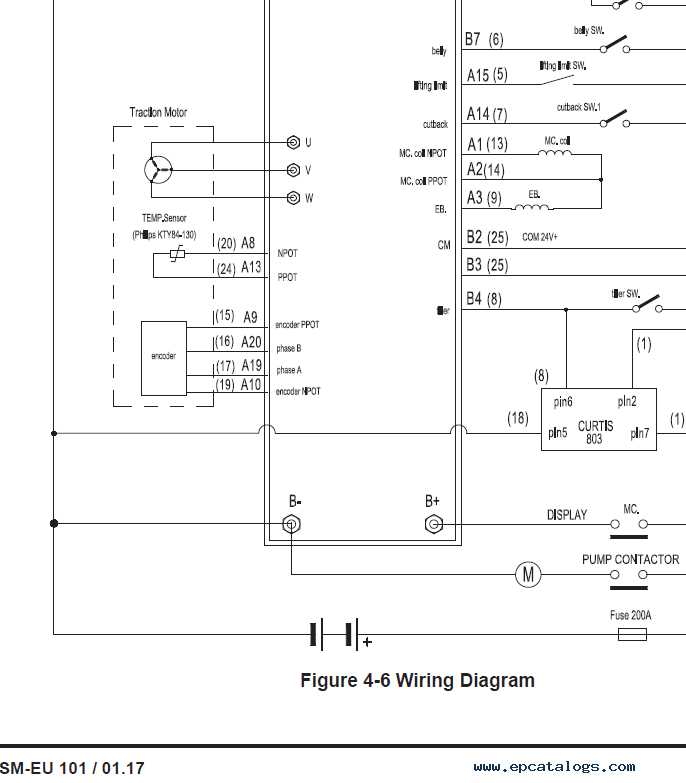

Troubleshooting Electrical Problems

Addressing electrical issues can be a complex task that requires a systematic approach. Identifying the root cause of malfunctioning components is essential to restoring functionality. This section provides guidance on common electrical problems and their solutions.

Common Symptoms of Electrical Issues

- Unresponsive controls

- Intermittent power supply

- Strange noises or sparks

- Overheating components

Steps for Troubleshooting

- Ensure all connections are secure and free from corrosion.

- Inspect fuses and circuit breakers for any signs of damage or tripping.

- Utilize a multimeter to check voltage levels at critical points.

- Examine wiring for frays, breaks, or loose connections.

- Test individual components to isolate the faulty part.

Following these steps can help identify and resolve electrical issues efficiently. Always prioritize safety by disconnecting power sources before beginning any inspection or repairs.

Hydraulic System Overview

The hydraulic system is a crucial component that enables the lifting and maneuvering of heavy loads with precision and ease. This system operates based on the principles of fluid mechanics, utilizing pressurized fluid to transfer force throughout various parts of the machinery. Understanding its function and structure is essential for ensuring optimal performance and longevity.

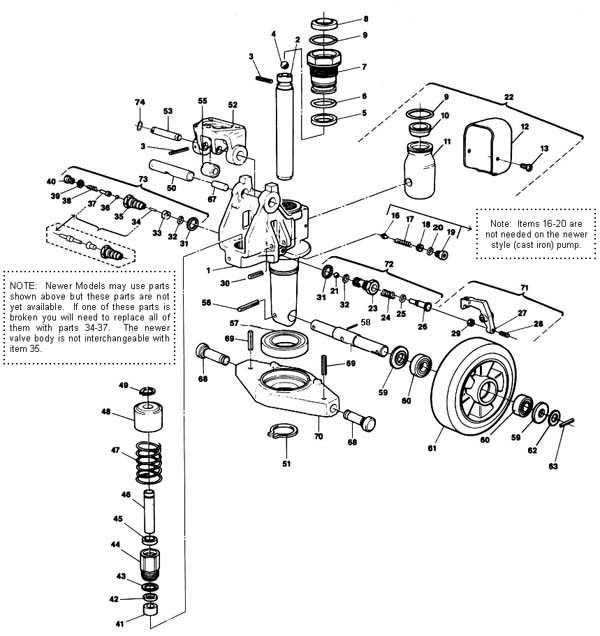

At its core, the hydraulic mechanism comprises several key elements, including a pump, cylinders, and valves. The pump generates pressure by drawing fluid from a reservoir and pushing it into the hydraulic circuit. As fluid flows into the cylinders, it creates the necessary force to lift or lower objects. Valves play a pivotal role in controlling this flow, allowing operators to direct the movement as needed.

Maintaining the integrity of the hydraulic system is vital for operational efficiency. Regular inspections for leaks, wear, and fluid quality are necessary to prevent malfunctions. Additionally, understanding the specifications and capacities of the hydraulic components can aid in troubleshooting and enhance overall functionality.

Replacing Worn-Out Components

Maintaining optimal performance in lifting equipment requires regular attention to various parts that may wear down over time. Identifying and substituting these components is crucial for ensuring safety and efficiency in operations. This section focuses on the necessary steps and considerations for effectively handling deteriorated elements in your machinery.

Inspection Process

Begin by conducting a thorough examination of all parts, paying close attention to areas that experience the most stress and friction. Look for signs of wear such as cracks, deformities, or excessive play. Keeping a maintenance log can help track the lifespan of components and predict when replacements may be needed.

Choosing Replacement Parts

When it comes to sourcing new components, opt for high-quality replacements that match the specifications of the original parts. This ensures compatibility and longevity. It is advisable to consult the manufacturer’s guidelines or seek expert advice to select the most suitable options.

Installation Guidelines

Follow precise installation procedures to ensure that new components are fitted correctly. Use the appropriate tools and take care to align everything as intended. If necessary, refer to technical documentation for specific instructions relevant to the components being replaced.

Testing and Maintenance

After replacement, it is essential to perform a series of tests to verify that the equipment functions smoothly. Monitor the machinery closely during initial operations to detect any irregularities. Establish a regular maintenance schedule to prevent future wear and extend the lifespan of your equipment.

Safety Precautions During Repairs

Ensuring a safe environment while conducting maintenance on equipment is crucial for both the technician and the machinery involved. Adhering to proper safety guidelines minimizes the risk of accidents and promotes effective work practices.

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and steel-toed boots.

- Work in a well-ventilated area to avoid inhalation of harmful fumes.

- Keep the workspace clean and organized to prevent slips, trips, and falls.

Before beginning any task, it is essential to:

- Ensure that the machinery is turned off and properly secured to prevent unintended movements.

- Disconnect any power sources or batteries to eliminate electrical hazards.

- Inspect tools and equipment for any damage or defects before use.

In case of an emergency, be familiar with the location of first aid kits and emergency exits. Always report any incidents or near misses to enhance safety awareness among colleagues.

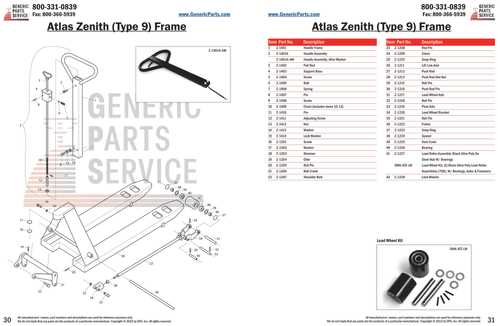

Finding Replacement Parts

Locating suitable components for your equipment is essential for ensuring optimal performance and longevity. Whether you’re dealing with wear and tear or a malfunction, understanding where to find the right parts can save time and money.

Where to Look for Parts

- Authorized Dealers: Start by checking with authorized distributors who specialize in your brand. They often have access to genuine parts and can provide support.

- Online Retailers: Numerous e-commerce platforms offer a wide range of components. Be sure to verify the seller’s reputation and the part’s compatibility.

- Local Hardware Stores: Some hardware outlets may stock common parts or can order them for you, which is convenient for quick fixes.

- Second-Hand Markets: Websites and local classifieds can sometimes yield great deals on used parts, but exercise caution regarding quality and condition.

Tips for Ensuring Compatibility

- Always refer to the specifications and model numbers of your equipment to avoid mismatches.

- Consult forums and user groups for advice on compatible parts and where to find them.

- Consider purchasing from reputable brands known for quality components.

- Ask for warranties or guarantees when buying parts to ensure your investment is protected.

Professional Repair Services

Ensuring the longevity and efficiency of your equipment is crucial for optimal performance. When faced with mechanical issues, seeking the expertise of trained professionals can make all the difference. These specialists possess the knowledge and tools necessary to address a variety of challenges, providing you with peace of mind and reliable solutions.

Expert Technicians are equipped with extensive training and experience, allowing them to quickly diagnose problems and implement effective strategies. Their familiarity with industry standards and practices ensures that all interventions are carried out to the highest quality, minimizing downtime and maximizing productivity.

Comprehensive Services cover everything from routine maintenance to complex overhauls. Whether it’s a minor adjustment or a significant overhaul, professional assistance can save you time and resources. Utilizing advanced techniques and high-quality parts, these services aim to restore equipment to its original performance levels, ensuring your operations run smoothly.

Benefits of DIY Repairs

Engaging in self-led maintenance tasks can yield numerous advantages, enhancing both skill sets and personal satisfaction. Tackling projects independently allows individuals to develop a deeper understanding of their equipment, leading to improved functionality and longevity.

Cost Efficiency

One of the primary benefits of undertaking maintenance on your own is the potential for significant cost savings. By eliminating labor expenses, individuals can allocate resources more effectively. Key points include:

- Avoiding high service fees charged by professionals.

- Using readily available materials and tools instead of purchasing specialized parts.

- Reducing the need for frequent replacements due to better upkeep.

Enhanced Knowledge and Skills

Taking on repair tasks fosters a wealth of knowledge that can be beneficial in various contexts. Consider the following advantages:

- Developing problem-solving skills through hands-on experience.

- Gaining insights into the mechanics and functionalities of the equipment.

- Building confidence that encourages tackling more complex projects in the future.

Resources for Further Learning

Expanding your knowledge in the realm of equipment maintenance can greatly enhance your skills and efficiency. Below are various resources that provide valuable insights, tutorials, and community support to help you deepen your understanding and practical abilities.

-

Online Forums:

- Maintenance World – A community for sharing tips and experiences.

- Industrial Repair Forum – A platform for discussing specific issues and solutions.

-

YouTube Channels:

- Equipment Maintenance – Offers video tutorials on various maintenance techniques.

- Repair Master – Focuses on practical repairs and troubleshooting advice.

-

Books:

- Essential Repair Guide – A comprehensive resource for understanding various systems.

- Hands-On Equipment Maintenance – Provides step-by-step procedures for common tasks.

-

Workshops and Courses:

- Local Community College Workshops – Hands-on learning experiences with industry professionals.

- Online Learning Platforms – Flexible courses covering various aspects of equipment upkeep.