Owning an all-terrain vehicle (ATV) comes with the responsibility of ensuring its optimal performance and longevity. Proper upkeep not only enhances the riding experience but also safeguards your investment. This section delves into the essential procedures and insights necessary for effective maintenance and troubleshooting of your vehicle.

Understanding the intricacies of your machine can significantly reduce downtime and prevent costly repairs. From routine checks to advanced fixes, having a thorough grasp of your ATV’s components is crucial. This guide aims to equip you with the knowledge needed to tackle various challenges, ensuring your off-road adventures remain uninterrupted.

Whether you are a seasoned enthusiast or a newcomer to the world of ATVs, the ability to perform essential tasks will empower you. Familiarity with the vehicle’s structure and functions can help you diagnose issues before they escalate. Explore the insights provided here to become more adept at maintaining and optimizing your vehicle’s performance.

Understanding the Polaris Trail Boss 330

This segment delves into the intricacies of a versatile all-terrain vehicle designed for both utility and recreational use. With its robust construction and reliable performance, this machine is favored by enthusiasts and casual riders alike. Knowledge of its features and specifications is essential for maintaining optimal functionality and ensuring a smooth riding experience.

Engine Performance: At the heart of this vehicle lies a powerful engine that offers a perfect blend of torque and horsepower. This allows for efficient handling of diverse terrains, making it suitable for various applications, from farming tasks to off-road adventures.

Design and Build: The rugged exterior is complemented by a well-thought-out design that prioritizes user comfort and safety. Features such as adjustable seating and a robust chassis contribute to its appeal, ensuring that operators can tackle any journey with confidence.

Maintenance Considerations: Regular upkeep is vital to prolonging the lifespan of this vehicle. Understanding the key components, such as the transmission and braking systems, can aid in troubleshooting and routine checks, helping owners avoid potential issues before they escalate.

Community and Support: Owners of this all-terrain vehicle often benefit from a robust community of enthusiasts. Engaging with fellow riders can provide valuable insights and tips, enhancing the overall ownership experience.

Key Features of the 2005 Model

This model stands out in its class due to a combination of robust performance and user-friendly design. Equipped with a powerful engine, it offers impressive acceleration and handling, making it ideal for various terrains. Durability is a hallmark, ensuring that it withstands the rigors of outdoor adventures.

Performance and Handling

With a well-engineered suspension system, this vehicle delivers a smooth ride over rough surfaces. The responsive steering enhances control, allowing riders to navigate tight turns with ease. Powerful braking ensures safety, even in challenging conditions.

Comfort and Utility

Designed with ergonomics in mind, the seating provides optimal support for long rides. Ample storage options cater to practical needs, making it versatile for both leisure and work tasks. Enhanced visibility through well-placed lighting systems adds to the overall convenience during night rides.

Common Issues with Trail Boss 330

When it comes to maintaining all-terrain vehicles, enthusiasts often encounter specific challenges that can affect performance and reliability. Understanding these prevalent issues is essential for proper care and longevity of the machine.

Starting Problems: One of the most frequently reported concerns is difficulty in starting the engine. This can stem from various factors, including a weak battery, faulty ignition components, or issues with the fuel delivery system.

Overheating: Another common issue involves overheating, which can be attributed to inadequate cooling system maintenance, such as low coolant levels or a clogged radiator. Regular checks can help prevent this problem.

Transmission Issues: Users may experience difficulties with shifting gears smoothly. This could indicate worn or damaged transmission components, requiring inspection and possible replacement to ensure optimal functionality.

Electrical Failures: Electrical system malfunctions are also prevalent, often caused by corroded connectors, blown fuses, or malfunctioning switches. A thorough electrical system check can help diagnose and rectify these issues.

Suspension Wear: Over time, the suspension components may show signs of wear, leading to a decrease in ride quality and handling. Regular inspections and timely replacements of worn parts are crucial for maintaining performance.

By being aware of these common challenges, owners can take proactive steps to address them, ensuring a smoother and more enjoyable experience on their off-road adventures.

Essential Maintenance Tips

Regular upkeep is crucial for ensuring the longevity and optimal performance of your all-terrain vehicle. Adhering to a routine maintenance schedule not only enhances safety but also prevents costly repairs down the line. Understanding the key areas that require attention will keep your machine running smoothly and efficiently.

1. Fluid Checks and Changes

It is essential to monitor and replace various fluids, including engine oil, coolant, and brake fluid. Regular inspections help identify leaks and prevent damage. Make it a habit to check fluid levels before each ride and schedule complete changes based on the manufacturer’s recommendations.

2. Tire Care and Inspection

The condition of your tires directly affects handling and safety. Inspecting tire pressure and tread regularly ensures optimal grip and reduces the risk of blowouts. Rotating tires periodically can also promote even wear, extending their lifespan significantly.

Tools Needed for Repairs

When it comes to maintenance and fixing mechanical equipment, having the right instruments is essential for ensuring efficiency and effectiveness. A well-equipped toolkit allows for smooth operations and minimizes the risk of damage during the process.

| Tool | Purpose |

|---|---|

| Wrench Set | To tighten or loosen bolts and nuts of various sizes. |

| Screwdriver Set | For driving screws in and out of components. |

| Pliers | To grip, twist, or cut wires and other materials. |

| Socket Set | For reaching fasteners in tight spaces with ease. |

| Torque Wrench | To ensure bolts are tightened to the correct specifications. |

| Multi-tool | A versatile option for various tasks, combining several tools in one. |

| Jack and Stands | To lift and securely support the equipment while working underneath. |

| Safety Gear | Includes gloves, goggles, and masks to protect the user during maintenance. |

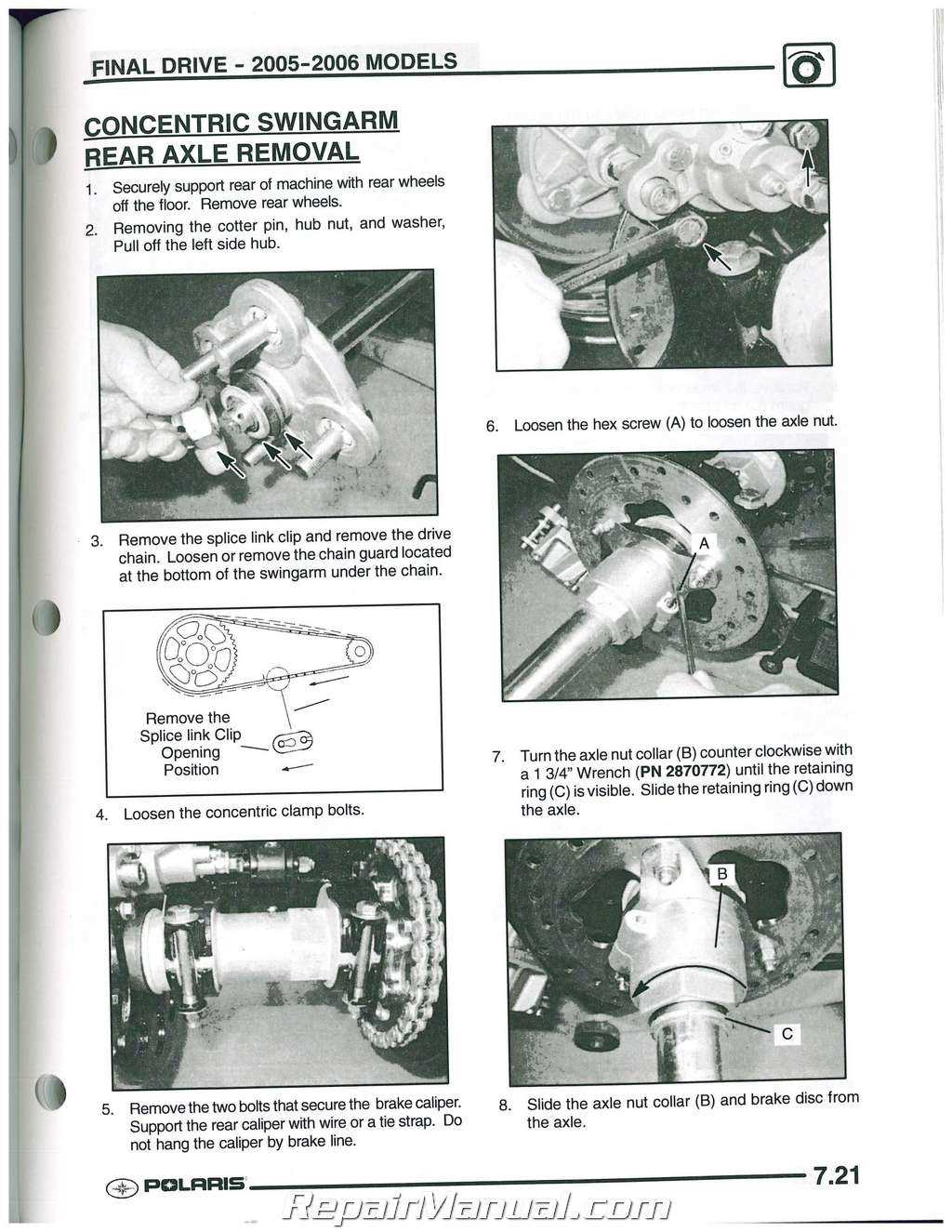

Step-by-Step Repair Procedures

This section provides a detailed guide for performing maintenance and troubleshooting tasks effectively. Following a structured approach ensures that each aspect of the process is addressed systematically, promoting efficiency and safety.

- Preparation

- Gather all necessary tools and equipment.

- Review any relevant documentation and guidelines.

- Ensure a clean and well-lit workspace.

- Inspection

- Examine the vehicle for visible damage or wear.

- Check fluid levels and look for leaks.

- Assess tire condition and pressure.

- Dismantling Components

- Carefully remove necessary panels and covers.

- Label and store screws and parts in an organized manner.

- Document any disassembly for reference during reassembly.

- Repair or Replacement

- Identify parts that require servicing or replacement.

- Use manufacturer-approved components to ensure compatibility.

- Follow safety protocols while handling tools and parts.

- Reassembly

- Reattach all components in the reverse order of disassembly.

- Ensure all fasteners are tightened to the specified torque.

- Double-check connections and alignment of parts.

- Testing

- Start the vehicle and listen for unusual sounds.

- Test all systems to verify proper functionality.

- Conduct a test drive in a safe area to ensure stability and performance.

- Final Inspection

- Perform a thorough check of all systems and components.

- Document the work completed and any observations.

- Clean the workspace and dispose of any waste properly.

By adhering to these steps, individuals can ensure comprehensive and effective service, prolonging the lifespan of the vehicle while enhancing safety and performance.

Electrical System Troubleshooting

The electrical system of an off-road vehicle plays a crucial role in its overall performance. Identifying and resolving issues within this system can significantly enhance reliability and functionality. Understanding the components and their interactions is essential for effective troubleshooting.

Start by examining the battery and its connections. A weak or dead battery can lead to a range of problems. Ensure that terminals are clean and tightly secured. Use a multimeter to check voltage levels; a reading below the standard threshold may indicate the need for replacement.

Circuit integrity is another vital aspect to consider. Inspect wiring for any signs of wear, fraying, or corrosion. Damaged wires can cause intermittent faults and erratic behavior. If any issues are found, replace or repair the affected sections as necessary.

Next, focus on the fuses and relays. These components serve as protective devices for various electrical circuits. A blown fuse can interrupt power flow, while a malfunctioning relay can prevent components from receiving the necessary voltage. Check each fuse for continuity and replace any that are faulty.

Additionally, test the ground connections. Poor grounding can lead to a variety of electrical issues, including flickering lights or failure to start. Ensure all ground points are clean, secure, and free from rust or debris.

Finally, consider using a diagnostic tool if available. These devices can provide valuable insights into error codes and system performance, making it easier to pinpoint issues. By systematically addressing these areas, one can effectively troubleshoot and resolve electrical problems, ensuring a smoother ride.

Engine and Transmission Insights

The engine and transmission are crucial components that determine the performance and reliability of any all-terrain vehicle. Understanding their intricacies can enhance maintenance practices and prolong the lifespan of the machine. A well-functioning powertrain ensures efficient power delivery, optimal fuel consumption, and seamless operation across various terrains.

Focusing on the engine, it is vital to regularly check for signs of wear and tear, including oil quality and coolant levels. Proper adjustments and timely replacements of filters can significantly impact overall performance. Regular inspection of ignition components is equally important to maintain starting reliability and throttle response.

On the transmission side, recognizing the importance of fluid quality and level cannot be overstated. Routine checks can prevent overheating and ensure smooth gear shifts. Understanding the operation of the drivetrain can help in diagnosing issues such as slippage or unusual noises, which often indicate deeper mechanical problems.

Overall, maintaining the health of both the engine and transmission not only enhances the vehicle’s performance but also contributes to a safer and more enjoyable riding experience. Investing time in learning about these systems can yield significant dividends in performance and longevity.

Importance of Regular Servicing

Routine maintenance is crucial for ensuring the longevity and optimal performance of any mechanical equipment. Consistent attention to the various components can prevent minor issues from escalating into major problems, ultimately saving time and money.

Benefits of Regular Maintenance

- Increased Reliability: Regular check-ups enhance the dependability of your machinery, allowing for smoother operations.

- Enhanced Performance: Routine servicing ensures that all parts function efficiently, contributing to better overall performance.

- Cost Savings: Preventative care helps avoid expensive repairs by identifying issues early.

- Safety Assurance: Regular inspections reduce the risk of malfunctions, ensuring a safer user experience.

- Higher Resale Value: Well-maintained equipment typically retains its value better in the marketplace.

Key Aspects of Maintenance

- Fluid Checks: Regularly inspect and replace fluids to ensure optimal functioning.

- Component Inspections: Examine key parts for wear and tear, addressing any concerns promptly.

- Cleaning: Keep equipment clean to prevent dirt accumulation that can lead to malfunctions.

- Lubrication: Ensure all moving parts are properly lubricated to minimize friction and wear.

- Documentation: Maintain records of all service activities to track maintenance history.

Upgrades and Modifications Options

Enhancing the performance and capabilities of your vehicle can significantly improve your riding experience. Whether you seek better power, improved handling, or added comfort, there are various modifications to consider. Below are some popular options that can help you tailor your machine to your specific needs.

- Suspension Upgrades:

- Upgrading shocks for improved comfort and handling.

- Installing lift kits to increase ground clearance.

- Engine Performance:

- Installing a high-performance air filter to enhance airflow.

- Upgrading the exhaust system for better power output.

- Wheels and Tires:

- Choosing all-terrain tires for improved traction.

- Upgrading to lightweight wheels to reduce unsprung weight.

- Electrical Accessories:

- Adding LED lights for better visibility at night.

- Installing a winch for added utility during off-road adventures.

- Comfort Enhancements:

- Adding a better seat for increased comfort on long rides.

- Installing a windshield to protect against wind and debris.

These modifications can help you customize your ride to match your style and usage preferences. Consider your specific needs and riding conditions when selecting upgrades to maximize your enjoyment and safety on the trails.

Where to Find Replacement Parts

Locating suitable components for your all-terrain vehicle can greatly enhance its performance and longevity. Whether you’re in need of specific items for routine maintenance or unexpected repairs, having access to reliable sources is essential.

Authorized Dealers

One of the most dependable places to obtain parts is through authorized dealerships. These outlets provide original equipment manufacturer (OEM) components, ensuring compatibility and quality. They often have knowledgeable staff who can assist you in identifying the right parts for your model.

Online Retailers and Marketplaces

Another effective option is to explore online retailers and marketplaces. Websites specializing in vehicle parts often feature extensive catalogs and user reviews, allowing you to compare prices and quality. Be sure to verify the seller’s reputation and return policies before making a purchase. Additionally, consider joining online forums or groups where enthusiasts share their experiences and recommendations.

Resources for DIY Mechanics

For those who enjoy tackling mechanical challenges on their own, having access to the right materials and tools is essential. Whether you’re a novice or an experienced enthusiast, a variety of resources can enhance your ability to maintain and repair your machinery effectively.

Online Forums and Communities

- Discussion Boards: Engaging in forums allows you to share experiences, seek advice, and learn from others facing similar challenges.

- Social Media Groups: Platforms like Facebook and Reddit host groups where mechanics can exchange tips and troubleshooting techniques.

- Video Tutorials: Websites like YouTube offer a plethora of instructional videos covering everything from basic repairs to advanced modifications.

Printed and Digital Resources

- Guides and Handbooks: Comprehensive books provide step-by-step instructions and technical details for various models.

- Technical Specifications: Access to specifications and schematics can be invaluable for precise repairs.

- Manufacturer Websites: Many manufacturers offer downloadable resources, including parts lists and maintenance schedules.