The journey of crafting intricate designs often encounters challenges that can impede progress. Understanding the nuances of maintaining your creative apparatus is essential for ensuring its longevity and optimal performance. This section aims to provide valuable insights into troubleshooting common issues and preserving the functionality of your device.

Proper care and timely interventions can significantly enhance your crafting experience. By familiarizing yourself with the inner workings of your equipment, you can tackle minor hiccups before they escalate into major setbacks. This guide will cover essential tips and techniques to keep your apparatus in peak condition.

Whether you are a seasoned creator or just embarking on your artistic journey, knowing how to address potential complications is invaluable. With the right knowledge at your fingertips, you can continue to bring your imaginative visions to life without interruption. Let’s delve into the essential practices that will empower you to maintain your textile creation device effectively.

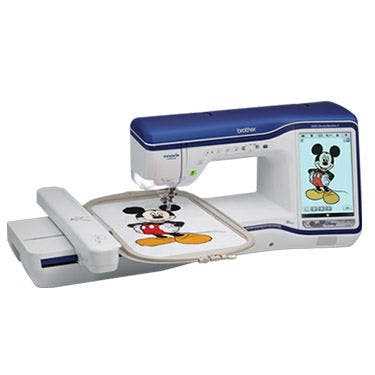

Understanding Brother Embroidery Machines

Exploring the intricacies of sewing technology reveals a world where creativity meets precision. These devices offer a blend of artistry and functionality, allowing users to transform their imaginative designs into tangible fabric works. Understanding how these tools operate is essential for both enthusiasts and professionals alike.

Modern sewing devices are equipped with various features that enhance usability and expand creative possibilities. From customizable patterns to automated stitching options, they cater to a wide range of user preferences and skill levels. Familiarity with these functionalities can greatly improve the overall experience.

| Feature | Description |

|---|---|

| Custom Patterns | Create unique designs tailored to individual tastes. |

| Automatic Threading | Simplifies the process of threading the needle, saving time. |

| Built-in Designs | Includes a variety of preloaded patterns for quick access. |

| User Interface | Intuitive controls and displays that enhance ease of use. |

| Connectivity Options | Allows for linking with computers for pattern downloads and updates. |

Recognizing the components and features of these innovative tools enables users to maximize their potential and explore new horizons in fabric artistry. Whether for personal projects or professional endeavors, understanding these devices is the key to unlocking their full capabilities.

Common Issues with Embroidery Machines

Understanding the frequent challenges that can arise with textile embellishing equipment is essential for users seeking smooth operation. From thread-related problems to mechanical glitches, identifying these issues can greatly enhance the crafting experience.

Typical Challenges

- Thread Breakage: This often occurs due to improper tension settings or low-quality thread.

- Skipped Stitches: A common problem that can result from a dull needle or incorrect needle placement.

- Thread Bunching: Often caused by the thread getting caught or tangled during the stitching process.

- Inconsistent Stitch Quality: This can happen due to varying fabric types or incorrect settings for the specific project.

Troubleshooting Tips

- Check the tension settings regularly to ensure optimal performance.

- Replace needles frequently to maintain stitch quality.

- Use high-quality threads to minimize breakage and tangling.

- Perform regular maintenance to keep the equipment in good condition.

Basic Troubleshooting Techniques

This section focuses on essential methods to identify and resolve common issues that may arise during the operation of your equipment. By following these straightforward steps, users can efficiently address problems and enhance the overall functionality of their device.

Identifying Common Issues

Basic Adjustments and Maintenance

Essential Tools for Repairs

Having the right instruments is crucial for maintaining and restoring your equipment effectively. These tools not only facilitate the process but also ensure precision and longevity in the performance of the device. Below is a list of fundamental items that every technician should have at their disposal.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening and tightening screws in various components. |

| Pliers | Useful for gripping, twisting, and cutting wires or small parts. |

| Replacement Needles | Essential for ensuring optimal performance and preventing issues. |

| Cleaning Brushes | Helps in removing dust and debris from hard-to-reach areas. |

| Lubricant | Reduces friction between moving parts, prolonging lifespan. |

| Multimeter | Measures electrical values to diagnose issues effectively. |

| Thread Snips | For quick and clean cutting of threads during adjustments. |

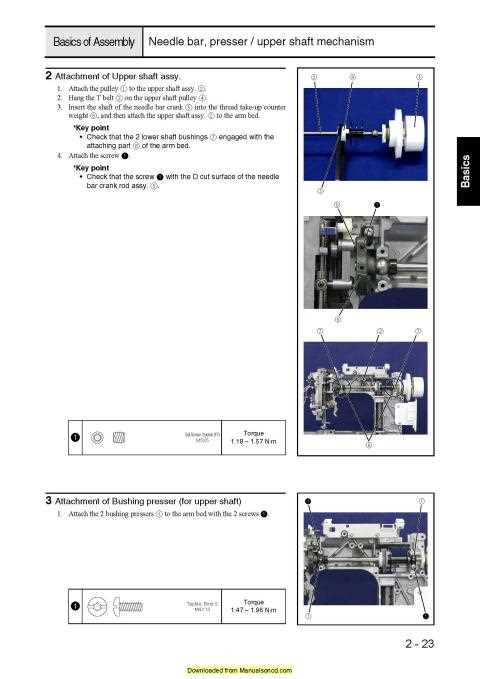

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing common issues encountered during the operation of your device. Following a systematic process can help you identify problems and restore functionality effectively.

| Step | Action | Description |

|---|---|---|

| 1 | Inspection | Carefully examine the unit for any visible signs of damage or wear. |

| 2 | Power Check | Ensure that the power source is functional and connections are secure. |

| 3 | Reset | Perform a reset of the device to clear any temporary errors. |

| 4 | Clean | Remove dust and debris from components to prevent blockages. |

| 5 | Calibration | Recalibrate settings as needed to ensure proper operation. |

| 6 | Test | Run a test cycle to verify that all functions are operating correctly. |

| 7 | Documentation | Keep a record of any issues and the steps taken to resolve them for future reference. |

By following these steps, you can systematically address issues and maintain the optimal performance of your equipment.

How to Clean Your Machine

Regular maintenance is essential for ensuring optimal performance and longevity of your stitching device. A clean apparatus not only enhances the quality of your work but also prevents potential issues caused by dust and debris accumulation. Here’s a straightforward guide to keep your equipment in top shape.

- Gather Your Supplies:

- Soft cloths

- Brushes (soft-bristled)

- Vacuum with a small nozzle

- Lubricating oil (if applicable)

- Cleaning solution (non-abrasive)

- Power Off and Unplug: Ensure that your device is completely powered down and disconnected from any power source before starting the cleaning process.

- Remove Attachments: Detach any additional components, such as the foot or needle, to allow for thorough cleaning.

- Dusting: Use a soft cloth to wipe down the exterior. Employ a soft brush or vacuum to eliminate dust from hard-to-reach areas.

- Interior Cleaning:

- Gently brush away lint and debris from the feed dogs and bobbin area.

- Use a vacuum to remove any remaining particles.

- Wipe down internal parts with a soft cloth.

- Lubrication: If recommended by the manufacturer, apply a small amount of lubricant to moving parts as indicated in the guidelines.

- Reassemble: Once everything is clean and dry, carefully reattach all components.

Following these steps regularly will ensure that your device remains efficient and continues to produce beautiful results.

Replacing Worn Parts Effectively

Maintaining optimal performance in your device is crucial for longevity and efficiency. Over time, certain components may wear down, leading to reduced functionality. Identifying and replacing these parts in a timely manner can significantly enhance overall productivity and reduce the risk of further issues.

Firstly, it is essential to recognize the signs of wear. Components that show visible damage, unusual noises, or inconsistent operation should be assessed. Regular inspections can help pinpoint these issues before they escalate.

When it comes to replacement, selecting high-quality components is paramount. Using parts from reputable sources ensures compatibility and durability. Additionally, consulting the manufacturer’s guidelines or trusted resources can provide valuable insights into the specific requirements for your device.

During the replacement process, take care to follow safety precautions. Disconnecting the power supply and using the appropriate tools will help prevent accidents. Furthermore, documenting the steps taken during the replacement can assist in future maintenance tasks.

Finally, after installation, conducting a thorough test is vital. Ensuring that the new components function correctly will help maintain the efficiency of the entire system. With proper attention to detail and regular upkeep, you can ensure that your device remains in peak condition for years to come.

Updating Machine Software Safely

Maintaining the latest version of your device’s software is crucial for optimal performance and security. However, the process of updating can sometimes pose risks if not approached with care. Ensuring a smooth and secure update experience is essential for safeguarding your investment and enhancing functionality.

Before initiating any updates, it is vital to back up your current settings and data. This precaution helps prevent data loss in case something goes awry during the installation process. Utilize the built-in backup features or save your configurations externally to ensure a seamless recovery if needed.

Next, verify that you are downloading the correct software version. Always source updates from reputable providers or the manufacturer’s official website. Double-check the compatibility of the new software with your current system to avoid any conflicts that may arise from incorrect versions.

Additionally, make sure your device has a stable power source throughout the update procedure. Interruptions due to power loss can lead to incomplete installations and potential malfunctions. If possible, conduct the update while plugged in or during times when power fluctuations are minimal.

Finally, after successfully completing the update, monitor the performance closely. This allows you to quickly identify any issues that may occur as a result of the new software. If problems arise, consult the documentation or support channels for troubleshooting advice.

Preventative Maintenance Tips

Regular upkeep is essential for ensuring the longevity and optimal performance of your equipment. By implementing a routine maintenance schedule, you can minimize issues and enhance productivity.

- Clean Regularly: Dust and debris can accumulate and affect functionality. Make it a habit to clean the working area and the device itself.

- Check for Wear: Inspect all moving parts for signs of wear and tear. Replacing worn components promptly can prevent more significant problems down the line.

- Oil Moving Parts: Lubricate any necessary areas as per the guidelines. This will help reduce friction and prolong the life of mechanical components.

- Update Software: Ensure that any operating software is up to date. This can improve efficiency and fix known issues.

- Calibration: Regularly calibrate the system to ensure precision in operation. This can greatly impact the quality of results.

Following these straightforward suggestions can contribute to a more reliable and efficient performance, ultimately saving time and resources in the long run.

When to Seek Professional Help

Understanding the right moments to call in an expert can save time, frustration, and potential damage to your equipment. While many issues can be resolved with basic troubleshooting, certain situations demand the expertise of a qualified technician to ensure everything functions properly and safely.

Common Signs of Trouble

Pay attention to specific indicators that suggest professional assistance is necessary. Ignoring these signs can lead to more severe problems and costly repairs. Here are some typical situations:

| Indicator | Description |

|---|---|

| Unusual Noises | Any strange sounds during operation may indicate internal issues that require expert assessment. |

| Inconsistent Performance | If the output quality fluctuates or there are repeated failures, it’s a sign of underlying complications. |

| Error Codes | Displaying error messages that cannot be resolved through standard troubleshooting often necessitates professional intervention. |

| Physical Damage | Visible wear or damage can compromise functionality, necessitating expert repairs to prevent further issues. |

Benefits of Professional Assistance

Engaging a specialist brings numerous advantages, including access to advanced diagnostic tools and in-depth knowledge of complex issues. This not only expedites the resolution process but also ensures that your equipment is restored to optimal performance, thereby prolonging its lifespan.

Finding Replacement Parts Online

Locating components for your device can be a straightforward process if you know where to look. The internet offers a wealth of resources for sourcing the items you need, from specialized websites to broader marketplaces. Understanding how to navigate these options will save time and ensure you find the right parts for your needs.

Here are some useful strategies for finding replacement components:

| Resource Type | Description | Examples |

|---|---|---|

| Manufacturer Websites | Direct source for authentic parts; often includes support and guides. | Official brand sites |

| Online Retailers | Large platforms offering a variety of components, sometimes at competitive prices. | Amazon, eBay |

| Specialized Stores | Shops dedicated to specific types of equipment that may offer hard-to-find items. | Craft supply stores, sewing shops |

| Forums and Communities | Online groups where users share advice and can suggest where to find parts. | Reddit, Facebook groups |

Utilizing these resources effectively will help you acquire the necessary components for optimal performance. Always check for compatibility and warranty information before making a purchase to ensure a seamless experience.

Frequently Asked Questions about Repairs

This section aims to address common inquiries regarding maintenance and troubleshooting for your equipment. Understanding these aspects can enhance your experience and prolong the lifespan of your device.

- What should I do if my device won’t turn on?

- Check the power source and ensure it’s plugged in securely.

- Inspect the power cord for any visible damage.

- Try a different outlet to rule out any electrical issues.

- How can I resolve threading issues?

- Ensure the thread is correctly threaded through all guides.

- Check for any knots or tangles in the thread.

- Replace the needle if it appears bent or dull.

- What maintenance tasks should I perform regularly?

- Clean the area around the needle and feed dogs.

- Lubricate moving parts as recommended by the manufacturer.

- Replace the needle periodically to avoid damage to the fabric.

- When should I seek professional assistance?

- If there are persistent error messages that you cannot resolve.

- When unusual noises occur during operation.

- If you notice physical damage that might affect performance.

Resources for Further Learning

Expanding your knowledge in the art of textile creation can greatly enhance your skills and understanding of the craft. Various resources are available to assist enthusiasts and professionals alike in mastering the intricacies of their craft. Whether you seek instructional videos, online courses, or community forums, the options are plentiful.

Online Courses and Tutorials

Many platforms offer comprehensive courses designed to cater to different skill levels. Websites such as Skillshare and Udemy provide a range of tutorials that cover everything from the basics to advanced techniques. Engaging with these resources can help you develop a deeper understanding of your craft.

Community Forums and Support Groups

Joining online communities can be invaluable for sharing experiences and obtaining support. Websites like Reddit and specialized forums allow users to ask questions, share tips, and connect with fellow artisans. These platforms often feature discussions that can illuminate common challenges and innovative solutions.