Maintaining a high-performance off-road machine is essential for ensuring its longevity and optimal performance. This guide provides valuable insights into various aspects of upkeep, addressing common challenges and offering solutions to enhance your riding experience. Whether you’re a seasoned enthusiast or a newcomer, understanding the intricacies of your vehicle can make all the difference.

Knowledge of your vehicle not only improves its functionality but also instills confidence in your riding capabilities. Familiarity with the technical aspects enables you to identify potential issues before they escalate, ensuring a smoother journey on rugged terrains. By delving into essential components and maintenance practices, you will be equipped to handle most scenarios that may arise.

From routine inspections to more intricate repairs, this guide emphasizes the importance of hands-on experience and informed decision-making. With detailed instructions and practical tips, you will learn how to keep your machine in peak condition, allowing you to enjoy every ride to the fullest. Let’s embark on this journey towards better understanding and care of your vehicle.

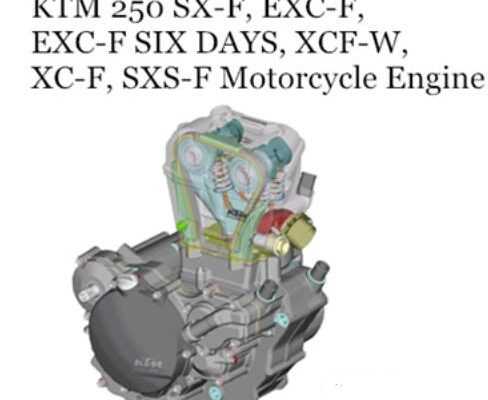

Understanding KTM 250 SX Specifications

Grasping the specifications of a motocross model is crucial for enthusiasts and riders alike. These details provide insight into the bike’s performance, handling characteristics, and overall design. Familiarity with these attributes not only aids in making informed decisions but also enhances the riding experience by ensuring that the motorcycle meets the rider’s expectations.

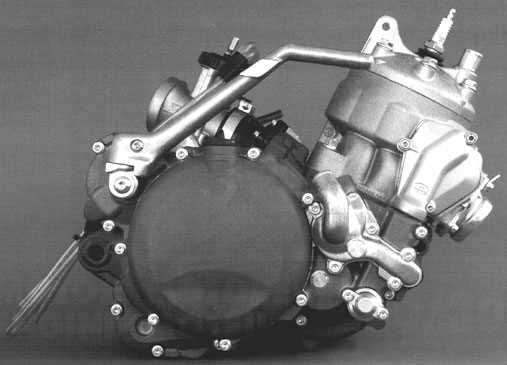

Engine and Performance

The heart of any off-road machine lies in its engine, which is typically characterized by its displacement, type, and output. Key metrics such as horsepower and torque directly influence acceleration and speed. Additionally, features like fuel delivery systems and exhaust designs play a significant role in performance efficiency and responsiveness.

The chassis design and suspension setup are equally vital components. A lightweight frame contributes to agility, while an advanced suspension system ensures stability and comfort over various terrains. Understanding the geometry and materials used in the frame can enhance the rider’s ability to maneuver effectively, ultimately leading to improved handling and safety.

Common Issues with KTM 250 SX

Every rider encounters challenges with their off-road machine. Understanding typical problems can enhance performance and extend the lifespan of the bike. Identifying these issues early is crucial for ensuring a smooth riding experience.

Frequent Mechanical Concerns

Owners often report various mechanical difficulties that can affect overall performance. Regular maintenance and timely interventions can help mitigate these problems.

| Issue | Description | Potential Solutions |

|---|---|---|

| Overheating | Excessive heat can lead to engine failure. | Check coolant levels and inspect the radiator for clogs. |

| Electrical Failures | Malfunctioning electrical systems can cause starting issues. | Inspect the battery and wiring for damage. |

| Suspension Problems | Poor handling may indicate worn suspension components. | Regularly check and service forks and shock absorbers. |

Common Performance Issues

Performance-related challenges can detract from the riding experience. Addressing these concerns promptly will improve functionality and rider satisfaction.

| Issue | Description | Potential Solutions |

|---|---|---|

| Power Loss | Reduced power output can affect acceleration. | Inspect air filters and fuel lines for blockages. |

| Excessive Vibration | Unusual vibrations may indicate imbalance. | Check wheel alignment and tire pressure. |

| Brake Wear | Increased stopping distance can signal brake issues. | Regularly inspect brake pads and fluid levels. |

Tools Needed for Repairs

Proper maintenance and troubleshooting require specific instruments to ensure effective work. Having the right equipment on hand not only streamlines the process but also enhances safety and efficiency. Each task demands a unique set of tools tailored to its requirements, so familiarity with these essentials is crucial for any enthusiast.

Basic Hand Tools: A reliable collection of hand tools is fundamental. This includes wrenches, screwdrivers, and pliers, which are essential for loosening or tightening components. A good socket set can also be invaluable for accessing hard-to-reach areas.

Specialized Equipment: Some tasks necessitate specialized instruments. For example, a torque wrench is critical for ensuring that bolts are fastened to the correct specifications. Additionally, a feeler gauge can help in measuring gaps with precision, ensuring optimal performance.

Cleaning Supplies: Keeping parts clean is vital for proper functioning. Tools like brushes, rags, and degreasers help maintain cleanliness, preventing wear and extending the lifespan of components.

Safety Gear: Always prioritize safety. Protective eyewear, gloves, and durable clothing are essential to prevent injuries during maintenance activities. Ensuring personal safety is just as important as the task at hand.

In summary, having the right array of instruments is key to successful upkeep and troubleshooting. Investing in quality tools not only makes tasks easier but also enhances overall performance and longevity.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring your two-wheeler remains in optimal condition. Regular upkeep not only extends the lifespan of the machine but also enhances performance, safety, and overall riding experience.

Essential Tools and Equipment

Before beginning any maintenance tasks, gather the necessary tools to facilitate a smooth process. Here’s a list of essential items:

| Tool | Purpose |

|---|---|

| Wrench Set | Adjusting bolts and nuts |

| Screwdriver Set | Tightening or loosening screws |

| Oil Filter Wrench | Changing oil filter |

| Air Compressor | Cleaning air filters |

Maintenance Steps

Follow these systematic steps to maintain your machine effectively:

- Check and change the engine oil regularly.

- Inspect and replace the air filter as needed.

- Examine the brake system for wear and tear.

- Ensure the chain is clean and lubricated.

- Inspect tire pressure and tread depth.

Engine Troubleshooting Techniques

When dealing with engine issues, understanding the common problems and applying effective diagnostic methods is crucial. Proper identification of symptoms can lead to timely solutions, minimizing downtime and ensuring optimal performance.

Common Symptoms and Their Causes

- Engine Misfiring:

- Faulty spark plug

- Fuel delivery issues

- Electrical connection problems

- Overheating:

- Insufficient coolant

- Thermostat failure

- Clogged radiator

- Strange Noises:

- Worn bearings

- Loose components

- Exhaust leaks

Diagnostic Steps

- Perform a visual inspection for leaks or damaged components.

- Check fluid levels and quality.

- Use diagnostic tools to read error codes.

- Test electrical connections and wiring.

- Conduct compression tests to assess engine health.

By following these techniques, you can systematically identify and address issues, ensuring a well-functioning engine.

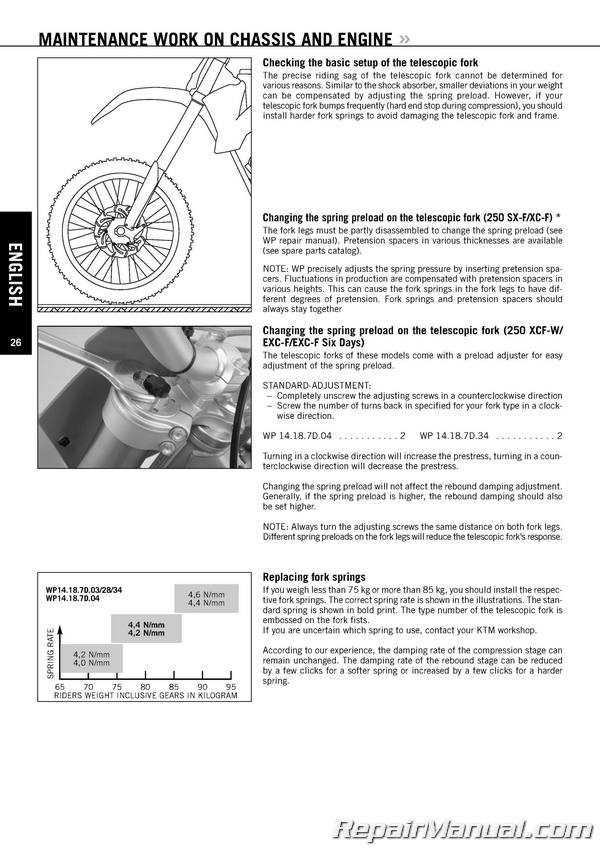

Suspension Adjustment and Maintenance

Proper management of the suspension system is crucial for optimizing performance and ensuring a smooth ride. Regular tuning and upkeep can significantly enhance handling characteristics, making it essential for riders to familiarize themselves with the various components and their adjustments. A well-maintained suspension system not only improves comfort but also contributes to the overall safety and stability of the vehicle.

Key Components and Adjustments

Understanding the primary elements of the suspension, including the forks and rear shock, is fundamental. Adjusting the compression and rebound settings can dramatically influence ride quality and responsiveness. Riders should start by consulting the specifications for their specific setup, making incremental changes to find the ideal balance for their riding style and terrain. Regular inspections for leaks or wear are also critical to ensure optimal performance.

Maintenance Practices

Routine maintenance tasks, such as cleaning and lubricating suspension components, play a vital role in extending their lifespan. Checking the oil levels and replacing fluids according to manufacturer guidelines can prevent damage and maintain functionality. Additionally, keeping an eye on the seals and bushings for signs of wear will help identify issues before they escalate, allowing for timely interventions and ensuring consistent performance.

Brake System Inspection Procedures

Ensuring optimal performance of the braking mechanism is crucial for safety and efficiency. Regular evaluations help identify potential issues that could lead to reduced functionality. This section outlines the essential steps to conduct a thorough assessment of the brake system.

Start by visually inspecting the brake components for any signs of wear or damage. Check the brake pads for thickness, looking for uneven wear patterns that may indicate misalignment or other issues. Inspect the rotors for signs of scoring or warping, which can affect braking efficiency.

Next, examine the hydraulic system. Ensure there are no leaks in the lines and that the fluid levels are within the recommended range. A soft or spongy brake lever can indicate air in the hydraulic lines, necessitating a bleed procedure to restore proper function.

Finally, conduct a functional test of the braking system. Engage the brakes at various speeds to assess responsiveness and feel. Listen for unusual noises that could suggest mechanical problems. Regular inspections not only enhance performance but also extend the lifespan of the braking components.

Cleaning and Replacing Air Filters

Maintaining optimal engine performance relies heavily on ensuring that air intake systems remain clean and efficient. Regularly cleaning and replacing filters is essential to prevent dirt and debris from entering the engine, which can lead to reduced power and potential damage. This section outlines the steps necessary for effectively managing air filters to ensure your vehicle runs smoothly.

Cleaning Air Filters

Cleaning air filters is a straightforward process that can be done at regular intervals. Follow these steps for effective cleaning:

- Remove the filter from its housing carefully to avoid damaging any surrounding components.

- Inspect the filter for any tears or severe wear that may require replacement.

- Use compressed air or a soft brush to remove loose dirt and debris from the filter surface.

- If the filter is reusable, wash it with a mild detergent and warm water, ensuring all residues are eliminated.

- Rinse the filter thoroughly and allow it to dry completely before reinstalling.

Replacing Air Filters

In cases where the filter is too damaged or clogged to clean, replacement is necessary. Here’s how to do it:

- Purchase a suitable replacement filter that matches the specifications required for your vehicle.

- Remove the old filter from the housing, ensuring to note any positioning for the new filter.

- Install the new filter, making sure it fits snugly and is positioned correctly to prevent air leaks.

- Secure the housing and double-check all connections to ensure everything is in place.

Regular attention to air filters will help maintain the efficiency and longevity of your engine, ensuring that it performs at its best.

Chain and Sprocket Maintenance Tips

Maintaining the transmission components of your machine is crucial for optimal performance and longevity. Regular attention to these parts not only ensures smooth operation but also enhances safety during rides. Neglecting proper care can lead to accelerated wear and costly replacements.

Regular Inspection

Routine checks are essential for identifying signs of wear. Look for any unusual noise during operation, as this may indicate that the chain or sprockets are not functioning correctly. Inspect the chain for signs of rust or stiff links, and examine the sprockets for uneven wear patterns. Early detection can prevent further damage.

Cleaning and Lubrication

Keeping the chain clean is vital for its lifespan. Use a suitable cleaner to remove dirt and debris, followed by a thorough rinse. After cleaning, apply a quality lubricant to ensure smooth movement. Remember to avoid over-lubrication, as excess oil can attract more dirt, creating a cycle of grime buildup.

By following these maintenance tips, you can prolong the life of your transmission components and maintain peak performance for your vehicle.

Fuel System Cleaning Techniques

Maintaining optimal performance of any engine requires regular attention to the fuel system. Over time, fuel lines and injectors can accumulate deposits that hinder functionality. Employing effective cleaning techniques not only enhances performance but also prolongs the lifespan of the components involved.

One common approach involves using specialized cleaning solutions designed to dissolve carbon buildup and varnish from injectors and carburetors. These products are typically introduced through the fuel system, allowing them to circulate and remove impurities. It’s crucial to follow the manufacturer’s instructions for the proper dilution and application methods.

Another effective method is the use of ultrasonic cleaning devices. These tools create high-frequency sound waves that generate microscopic bubbles in a cleaning solution, effectively loosening dirt and grime from surfaces. Components such as injectors and fuel filters can be submerged in the solution for thorough cleaning.

Regularly inspecting and replacing fuel filters is also essential. Clogged filters can restrict fuel flow and lead to performance issues. Replacing them at recommended intervals helps maintain a clean fuel system.

Additionally, some enthusiasts opt for a manual cleaning approach, where disassembled parts are scrubbed using brushes and appropriate solvents. This method requires care and attention to detail to avoid damage to sensitive components.

Incorporating these cleaning techniques into routine maintenance can significantly enhance engine performance and reliability, ensuring a smoother and more efficient operation.

Electrical System Diagnostics

The electrical system of a motorcycle is crucial for its overall performance and reliability. Diagnosing issues within this system requires a systematic approach to identify faults and ensure all components are functioning as intended. By employing specific diagnostic techniques, riders and technicians can effectively troubleshoot and resolve electrical problems.

Key Components: Understanding the primary elements of the electrical system is essential. This includes the battery, wiring harness, ignition system, and various sensors. Each component plays a vital role in the bike’s operation, and any malfunction can lead to performance issues.

Diagnostic Tools: Utilizing appropriate tools such as multimeters and diagnostic scanners is fundamental for accurate assessments. These instruments help measure voltage, current, and resistance, allowing for the identification of anomalies within the system.

Common Issues: Riders often encounter several electrical challenges, including battery failure, faulty connections, and malfunctioning switches. Recognizing symptoms such as dim lights, starting difficulties, or erratic behavior can guide effective troubleshooting efforts.

Step-by-Step Process: Begin by inspecting the battery for charge and connection integrity. Follow with a visual examination of the wiring for wear or corrosion. Next, test individual components using a multimeter to pinpoint the source of the issue. Documenting findings throughout this process aids in tracking recurring problems.

Ultimately, thorough diagnostics can enhance the longevity and reliability of the motorcycle’s electrical system, ensuring a smooth and enjoyable riding experience.

Best Practices for Storage

Proper storage is essential for maintaining the longevity and performance of your two-wheeled vehicle. By following effective techniques, you can prevent damage caused by environmental factors and ensure that your machine remains in top condition for your next adventure.

Preparation Steps

Before placing your vehicle into storage, it’s important to take several preparatory steps. Cleaning the machine thoroughly will help prevent rust and corrosion. Additionally, draining the fuel system or using a fuel stabilizer can mitigate issues caused by old fuel. Don’t forget to check and change the oil if necessary, as old oil can cause engine damage over time.

Ideal Storage Conditions

Finding the right environment for storage is crucial. A climate-controlled space is preferable, as it protects the vehicle from extreme temperatures and humidity. Ensure that the area is dry, clean, and free from pests. Using a cover can also help shield the machine from dust and debris.

| Storage Aspect | Best Practice |

|---|---|

| Location | Indoor, climate-controlled environment |

| Fuel System | Drain or stabilize fuel |

| Cleaning | Thorough wash and dry |

| Fluid Levels | Change oil and check other fluids |

| Pests | Keep the area clean and sealed |