Keeping your small engine equipment in top condition is essential for optimal performance and longevity. This section delves into effective strategies for enhancing the functionality of your machinery, ensuring you can tackle any issues that may arise.

Understanding the intricacies of your engine’s components is crucial for achieving seamless operation. This guide provides insights into various troubleshooting techniques, allowing you to identify common problems and implement practical solutions.

By familiarizing yourself with the essential practices of upkeep and troubleshooting, you empower yourself to manage your equipment efficiently. Armed with knowledge, you can confidently address issues, extending the lifespan of your engine and enhancing its reliability.

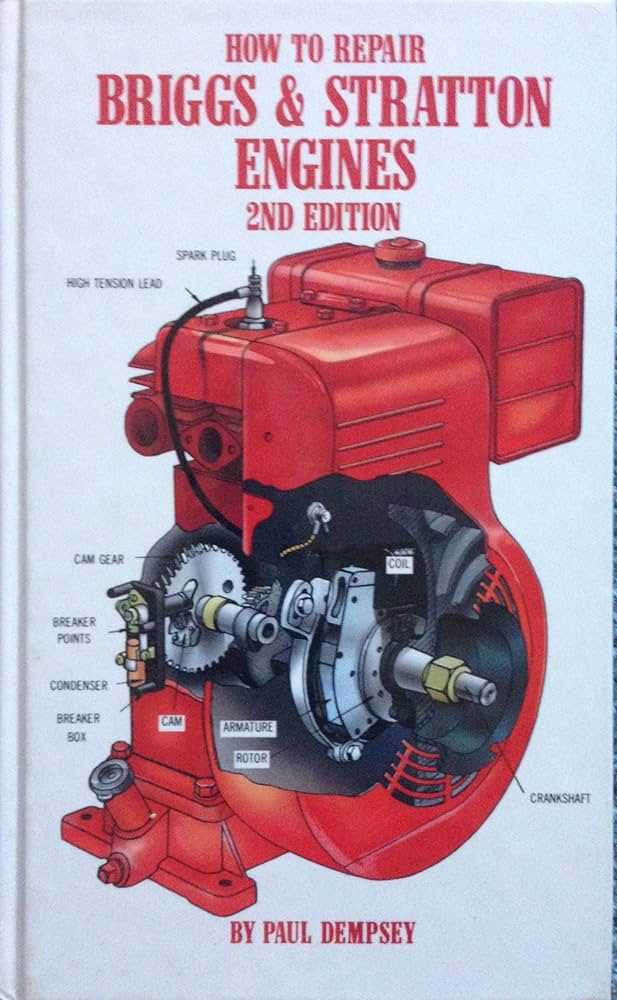

Understanding Briggs & Stratton Engines

The engines produced by this renowned manufacturer are widely recognized for their reliability and performance in various applications. These power units are designed to meet the diverse needs of users, ranging from residential to commercial uses. Understanding the core features and functionalities of these engines can significantly enhance their operation and longevity.

Key Features of These Power Units

- Durability: Built to withstand rigorous conditions, these engines offer long-lasting performance.

- Ease of Use: Engine designs emphasize user-friendliness, facilitating straightforward operation.

- Versatility: Suitable for a range of equipment, these engines power everything from lawn mowers to pressure washers.

Common Applications

- Lawn Care Equipment

- Generators for Backup Power

- Pressure Washers for Cleaning Tasks

- Garden and Landscape Tools

By familiarizing oneself with the characteristics and applications of these engines, users can make informed decisions about maintenance and usage, ultimately ensuring optimal performance in their respective tasks.

Common Issues in Engine Performance

Engine performance can be affected by various factors that lead to reduced efficiency and effectiveness. Understanding these common problems can help in identifying the underlying causes and improving overall functionality.

Fuel-Related Problems

One of the primary issues affecting engine performance is related to fuel. Problems in this category can stem from:

- Contaminated fuel

- Incorrect fuel type

- Clogged fuel filters

These issues can result in poor combustion and reduced power output, making it essential to use clean and appropriate fuel.

Ignition System Malfunctions

The ignition system plays a crucial role in engine operation. Common failures in this area include:

- Worn-out spark plugs

- Defective ignition coils

- Improperly timed ignition

Addressing these problems promptly can significantly enhance the engine’s responsiveness and overall performance.

Essential Tools for Repairs

When it comes to maintaining and fixing small engines, having the right equipment is crucial. This section highlights the fundamental tools that every enthusiast should have in their workshop. Equipped with these items, individuals can effectively address various issues and ensure optimal performance.

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | Essential for removing and securing screws. |

| Wrench Set | Used for gripping and turning fasteners. |

| Pliers | Handy for gripping, twisting, and cutting wires. |

| Torque Wrench | Ensures fasteners are tightened to specific torque specifications. |

| Fuel Line Wrench | Facilitates the removal of fuel lines without damage. |

| Oil Filter Wrench | Used for removing and installing oil filters. |

Step-by-Step Repair Process

This section outlines a systematic approach to resolving issues commonly faced with outdoor power equipment. By following a structured methodology, users can effectively address problems, ensuring the machinery operates smoothly and efficiently.

Preparation for the Task

Before starting the troubleshooting process, gather all necessary tools and materials. It’s crucial to work in a well-lit, organized space to enhance safety and efficiency. Review the equipment specifications to understand the components involved and potential issues.

Execution of the Process

The next step involves a detailed inspection of the unit. Start by checking fuel levels and inspecting filters. Follow these steps:

| Step | Description |

|---|---|

| 1 | Examine the air filter for cleanliness; replace if necessary. |

| 2 | Inspect spark plugs and clean or replace as needed. |

| 3 | Check fuel lines for leaks or blockages. |

| 4 | Review oil levels and change if they are low or dirty. |

| 5 | Test the ignition system to ensure it functions properly. |

Completing these steps will help identify and rectify common issues, promoting the longevity and effectiveness of the equipment.

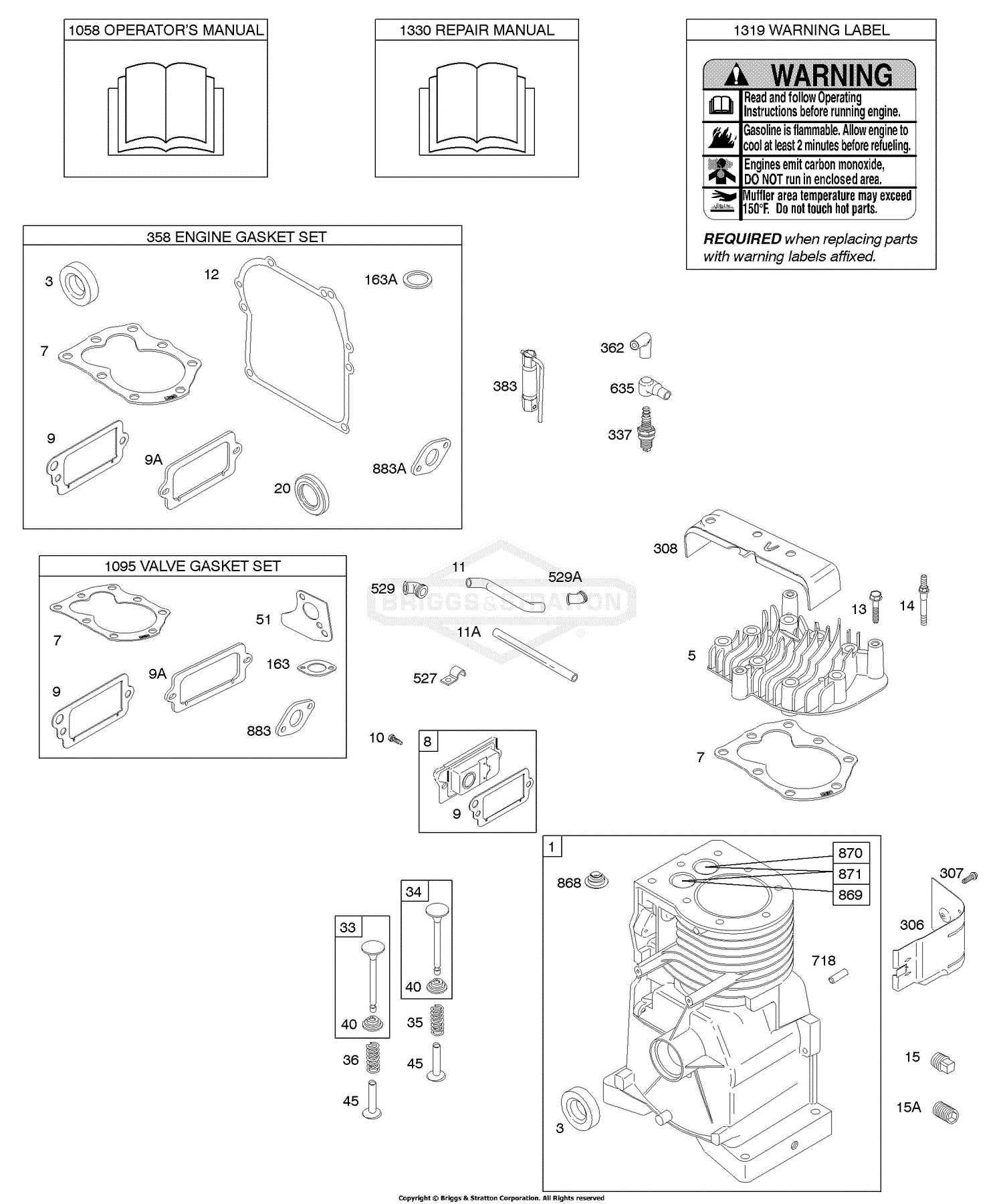

Replacing Key Engine Components

Maintaining optimal performance of a small engine often involves the replacement of critical components. This process can enhance efficiency and prolong the life of the machinery. Understanding which parts to change and how to execute the task is essential for effective upkeep.

Key components that may require attention include:

- Piston

- Rings

- Valves

- Cylinder head

- Carburetor

Each of these parts plays a vital role in the overall functioning of the engine. Here is a brief overview of the replacement process:

- Gather Tools: Ensure you have the necessary tools, such as wrenches, screwdrivers, and a torque wrench.

- Disconnect Power: Always disconnect the spark plug to prevent accidental starts during maintenance.

- Remove Old Component: Carefully take out the old part, following any specific guidelines related to that component.

- Install New Part: Place the new piece in position, ensuring a snug fit and proper alignment.

- Reconnect and Test: Once everything is in place, reconnect the spark plug and run the engine to verify proper operation.

By following these steps and focusing on the replacement of these essential parts, you can ensure your engine runs smoothly and efficiently.

Maintaining Engine Efficiency

Ensuring optimal performance of an engine requires regular upkeep and attention. A well-maintained engine not only operates more effectively but also has a longer lifespan, reducing the need for significant repairs over time. By adhering to some essential practices, users can significantly enhance the efficiency and reliability of their machinery.

- Regular Oil Changes: Fresh oil is crucial for lubricating engine components, reducing friction and wear.

- Clean Air Filters: Keeping air filters free from debris allows for better airflow, which is vital for combustion efficiency.

- Inspecting Spark Plugs: Spark plugs should be checked frequently, as worn plugs can lead to poor ignition and reduced performance.

- Fuel System Maintenance: Regularly cleaning fuel lines and injectors ensures optimal fuel delivery and combustion.

- Checking Belts and Hoses: Inspecting for cracks or wear in belts and hoses can prevent unexpected breakdowns.

By implementing these practices, individuals can maintain their engine’s efficiency, ensuring reliable operation and extending its operational life.

Safety Precautions During Repairs

Ensuring a secure working environment is crucial when performing maintenance tasks on engines. Adhering to safety measures not only protects the individual but also contributes to the longevity of the equipment. Understanding the risks involved and implementing appropriate precautions can prevent accidents and injuries.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear.

- Work in a well-ventilated area to avoid inhaling harmful fumes and gases.

- Keep the workspace clean and free from clutter to minimize the risk of slips and falls.

Equipment Handling and Maintenance

- Disconnect the power source before starting any maintenance tasks.

- Use the correct tools for each task to avoid damaging components or causing injury.

- Handle all parts carefully to prevent cuts and bruises from sharp edges.

Diagnosing Fuel System Problems

Identifying issues within the fuel delivery system is essential for optimal engine performance. Several symptoms may indicate that the fuel system is not functioning correctly, and recognizing these signs early can prevent further complications.

Common symptoms of fuel system issues include:

- Engine stalling or difficulty starting

- Unusual engine noises

- Inconsistent power output during operation

- Increased fuel consumption

To accurately diagnose these problems, follow these steps:

- Check the fuel level in the tank to ensure it is not empty.

- Inspect fuel lines for any signs of leaks or blockages.

- Examine the fuel filter and replace it if it appears clogged or dirty.

- Test the fuel pump for proper operation by listening for a humming sound when the engine is turned on.

- Verify the condition of the fuel injectors, ensuring they are not clogged or malfunctioning.

By systematically assessing each component of the fuel system, you can effectively pinpoint the root cause of the issues and take the necessary corrective actions.

Troubleshooting Electrical Issues

When encountering problems with power-operated equipment, understanding electrical components is crucial. Various issues may arise, often linked to wiring, connections, or the power source. Identifying these challenges can lead to effective solutions, ensuring optimal functionality.

Here are common electrical problems and their potential causes:

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Equipment won’t start | Dead battery, faulty switch | Check battery charge, replace or repair the switch |

| Intermittent power loss | Loose connections, damaged wiring | Inspect and tighten connections, replace damaged wires |

| Flickering lights | Voltage fluctuations, overloaded circuits | Check circuit load, adjust or redistribute power usage |

When to Seek Professional Help

Understanding the right moment to engage an expert can significantly impact the longevity and performance of your equipment. While some issues may appear manageable, there are situations where the complexity or potential risk of DIY interventions necessitates professional assistance.

For instance, if you encounter persistent operational problems that do not resolve with standard troubleshooting methods, it may indicate a deeper issue that requires specialized knowledge. Additionally, if you lack the necessary tools or experience to address a particular malfunction, consulting a technician can save time and prevent further damage.

Furthermore, safety should always be a priority. If you find yourself dealing with fuel leaks, electrical concerns, or any hazards that could lead to injury, it is crucial to seek help from a qualified individual. Remember, expert services not only ensure proper handling of repairs but also provide peace of mind regarding the safety and functionality of your machinery.

Resources for Further Assistance

When tackling mechanical challenges, having access to additional resources can significantly enhance your understanding and problem-solving capabilities. Various platforms provide valuable insights, detailed guides, and community support to help you navigate through complex issues effectively.

Online Communities and Forums

Engaging with online communities allows you to connect with fellow enthusiasts and experts. These platforms are ideal for sharing experiences, asking questions, and discovering innovative solutions to common problems.

Official Websites and Documentation

Manufacturer websites often feature a wealth of information, including product specifications, maintenance tips, and troubleshooting advice. Utilizing these official resources ensures you receive accurate and reliable guidance.

| Resource Type | Description | Link |

|---|---|---|

| Community Forum | A platform for discussions and shared experiences. | Visit Forum |

| Manufacturer Site | Official site with manuals and support. | Visit Site |

| YouTube Tutorials | Video guides on maintenance and troubleshooting. | Watch Videos |