Maintaining precision instruments is essential for ensuring their optimal functionality and longevity. This section focuses on the process of restoring a specific type of mechanical device, which plays a crucial role in regulating light exposure in photography. Understanding the intricacies involved can enhance not only the performance but also the overall user experience.

The intricacies of these mechanisms can often lead to challenges for users. Various issues may arise over time, affecting the operation and efficiency of the device. By exploring common problems and their solutions, individuals can gain valuable insights into troubleshooting techniques and effective restoration strategies.

Through this comprehensive overview, enthusiasts and professionals alike will learn essential techniques for addressing common malfunctions. With careful attention to detail and a methodical approach, restoring these complex devices can be a rewarding endeavor that revitalizes their original functionality.

Common Issues with Compur Shutters

Mechanical devices can often experience various challenges that affect their performance. Understanding these issues is crucial for maintaining optimal functionality. In this section, we will explore some frequent problems encountered with these particular devices, offering insights into their causes and potential solutions.

1. Inconsistent Timing

One of the most common challenges is inconsistent timing during operation. This can lead to unexpected results in the captured images, making it difficult for users to achieve the desired exposure. Often, this issue arises from worn components or a lack of proper lubrication, which can hinder the smooth movement of internal parts.

2. Sticking Mechanism

An additional concern is the sticking mechanism, where the device fails to open or close properly. This malfunction can be attributed to dust accumulation or dried lubricants that prevent the mechanisms from functioning smoothly. Regular maintenance and cleaning can help mitigate this issue and ensure reliable operation.

Tools Needed for Repairs

When it comes to maintaining and fixing precision devices, having the right instruments is crucial for achieving optimal results. The selection of tools can greatly influence the efficiency and effectiveness of the task at hand, ensuring that every component is handled with care and precision.

Essential tools include a variety of implements designed for fine work. A set of precision screwdrivers is necessary to handle small screws without causing damage. Additionally, tweezers can assist in manipulating tiny parts, while a magnifying glass can provide better visibility during intricate procedures.

Other useful items are cleaning brushes and microfiber cloths to remove dust and debris from sensitive areas. A reliable workbench equipped with a proper light source will facilitate the entire process, making it easier to see and access components as needed.

Step-by-Step Repair Process

This section outlines a detailed approach to addressing issues commonly encountered in precision devices. By following a systematic procedure, you can ensure thorough examination and effective resolution of problems, ultimately restoring functionality.

Initial Assessment

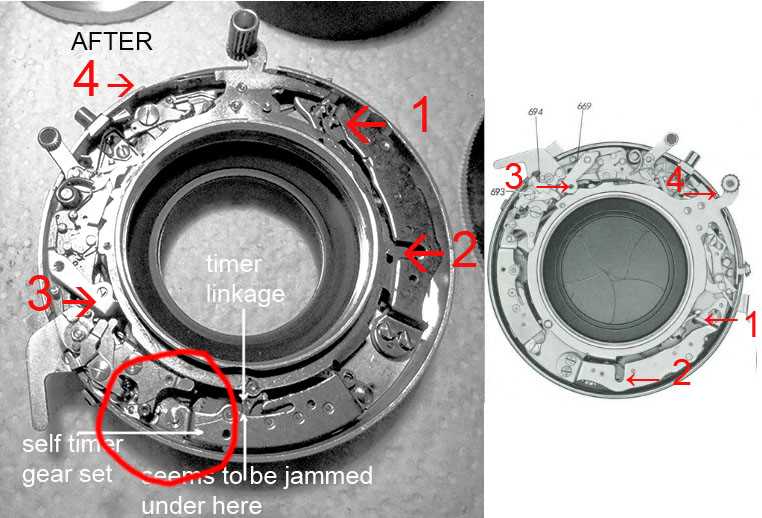

Begin by conducting a careful evaluation of the equipment to identify visible signs of malfunction. This may include examining the components for wear, ensuring all mechanisms are aligned correctly, and checking for any obstructions that could hinder operation.

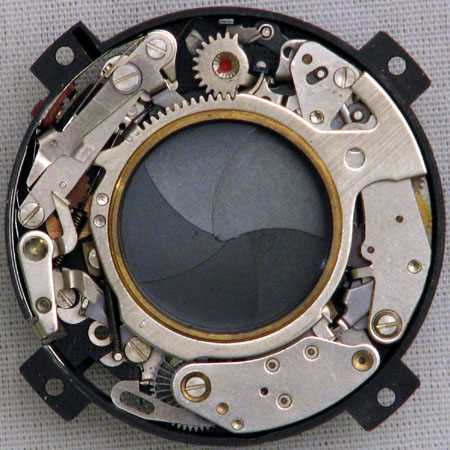

Disassembly and Cleaning

Once the initial assessment is complete, proceed to disassemble the unit with care. Document each step to facilitate reassembly later. Clean all components meticulously to remove dust and debris, which can impede performance. Use appropriate tools to avoid damaging delicate parts during the process.

Identifying Shutter Malfunctions

Understanding the common issues that can arise in photographic mechanisms is essential for ensuring optimal performance. Various signs may indicate a problem, and recognizing these early can prevent further complications. Below are some typical symptoms to watch for, along with their potential causes.

Common Symptoms of Mechanical Issues

- Inconsistent exposure times

- Failure to open or close completely

- Unexpected light leaks

- Unusual noises during operation

Potential Causes

- Worn or damaged components

- Dirt or debris affecting the movement

- Improper lubrication

- Age-related wear and tear

By monitoring these indicators, users can better maintain their devices and address issues promptly to ensure smooth operation.

Cleaning Techniques for Shutter Components

Maintaining the functionality of intricate optical devices requires careful attention to the cleanliness of their internal parts. Regular cleaning ensures that moving elements operate smoothly and efficiently, ultimately enhancing performance and prolonging the lifespan of the equipment. This section outlines effective methods for cleaning delicate components without causing damage.

Essential Tools and Materials

Before starting the cleaning process, it is crucial to gather the necessary tools and materials:

- Soft, lint-free cloths

- Small brushes with soft bristles

- Compressed air canister

- Cleaning solution specifically designed for optical devices

- Cotton swabs

Step-by-Step Cleaning Process

Follow these steps to ensure thorough and safe cleaning:

- Begin by carefully disassembling the components, ensuring all parts are laid out in an organized manner.

- Use a soft cloth to gently wipe down surfaces, removing any dust or debris.

- Utilize compressed air to blow away particles from hard-to-reach areas.

- For stubborn residues, apply a small amount of cleaning solution to a cotton swab and gently clean the affected areas.

- Allow all components to dry completely before reassembling.

Reassembly Tips for Success

Successfully putting together intricate devices requires careful attention to detail and methodical approaches. Following best practices can ensure that every component is correctly positioned and functioning optimally.

Here are some essential strategies to consider during the reassembly process:

- Organize Parts: Keep all components organized in separate containers to avoid confusion.

- Refer to Diagrams: Use detailed diagrams or photos from the disassembly phase as a guide.

- Follow a Sequence: Reassemble parts in the reverse order of disassembly to maintain clarity.

- Check for Alignment: Ensure all elements are aligned correctly before securing them.

- Test as You Go: Perform functional checks at each stage to identify issues early.

By implementing these techniques, the chances of achieving a successful reassembly are significantly enhanced.

Maintaining Your Compur Shutter

Proper upkeep of your photographic device is essential for ensuring optimal functionality and longevity. Regular attention to the components involved in the image-capturing process can prevent issues and enhance performance over time.

Here are some key practices to consider:

- Regular Cleaning: Dust and debris can accumulate and affect the internal mechanisms. Use a soft brush or air blower to gently clean the exterior and any accessible areas.

- Lubrication: Apply suitable lubricants to moving parts as specified by the manufacturer. This helps to reduce friction and maintain smooth operation.

- Temperature Control: Store your device in a climate-controlled environment. Extreme temperatures can adversely affect the materials and functionality.

- Inspection: Periodically check all parts for signs of wear or damage. Early detection of issues can save time and costs associated with more significant repairs.

By adhering to these maintenance tips, you can significantly extend the life of your photographic instrument and ensure that it continues to deliver high-quality results for years to come.

Common Mistakes to Avoid

When dealing with intricate mechanisms, it is essential to recognize and steer clear of prevalent errors that can hinder functionality or lead to further complications. Awareness of these pitfalls can significantly enhance the effectiveness of the maintenance process.

- Neglecting to read the documentation thoroughly before beginning work.

- Over-tightening components, which can cause damage or misalignment.

- Forgetting to clean parts adequately, as residue can impair performance.

- Ignoring signs of wear or damage during inspection.

- Using incorrect tools for disassembly and reassembly, leading to unintended consequences.

By avoiding these mistakes, individuals can ensure a smoother experience when handling delicate equipment and achieve better results.

Replacement Parts and Their Sources

When undertaking the restoration of precision devices, sourcing high-quality components is crucial. Various elements may require substitution, and understanding where to find these essential parts can significantly enhance the success of the process. This section provides insights into potential sources for obtaining these necessary components.

Types of Components

Several critical elements may need to be replaced during the refurbishment. The following list outlines the common types:

- Spring mechanisms

- Gear assemblies

- Control levers

- Mounting plates

- Seals and gaskets

Where to Find Replacement Parts

Identifying reliable sources for these components is vital. Consider the following options:

- Online Retailers: Numerous specialized online shops offer a wide range of replacement parts for various devices.

- Local Camera Stores: Established retailers often have an inventory of components or can order them on request.

- Manufacturer Direct: Contacting the original manufacturer can yield authentic parts tailored for specific models.

- Second-hand Markets: Platforms such as eBay or dedicated forums can be treasure troves for hard-to-find components.

When to Seek Professional Help

Knowing when to consult an expert can make a significant difference in the outcome of your equipment’s functionality. While some issues can be addressed through basic troubleshooting, others may require specialized knowledge and tools. Understanding the signs that indicate professional intervention is essential for maintaining the integrity of your device.

Signs Indicating Professional Assistance is Needed

- Frequent malfunctions or erratic behavior.

- Unusual noises or vibrations during operation.

- Visible signs of damage or wear that affect performance.

- Inability to resolve issues after multiple attempts at troubleshooting.

- Limited knowledge or experience with similar devices.

Benefits of Professional Support

- Expert diagnosis leading to more effective solutions.

- Access to specialized tools and replacement parts.

- Time-saving; allows you to focus on other important tasks.

- Increased longevity of the equipment through proper maintenance.