Ensuring optimal performance and longevity of your outdoor power equipment is essential for efficient operation. This section delves into crucial aspects of maintenance, offering valuable insights and guidance for enhancing the functionality of various engines. By understanding the intricacies of care and troubleshooting, you can effectively address common issues and keep your machinery running smoothly.

Knowledge of specific components is vital for anyone looking to undertake maintenance tasks. From identifying essential parts to understanding their roles, this guide provides a thorough examination of the elements involved. By familiarizing yourself with these components, you can gain confidence in your ability to manage basic upkeep and repairs.

Moreover, recognizing signs of wear and tear is crucial in preventing more significant problems down the line. This resource outlines practical steps for identifying potential issues early, allowing for timely interventions. By staying proactive, you can save both time and resources while ensuring your equipment remains in top-notch condition.

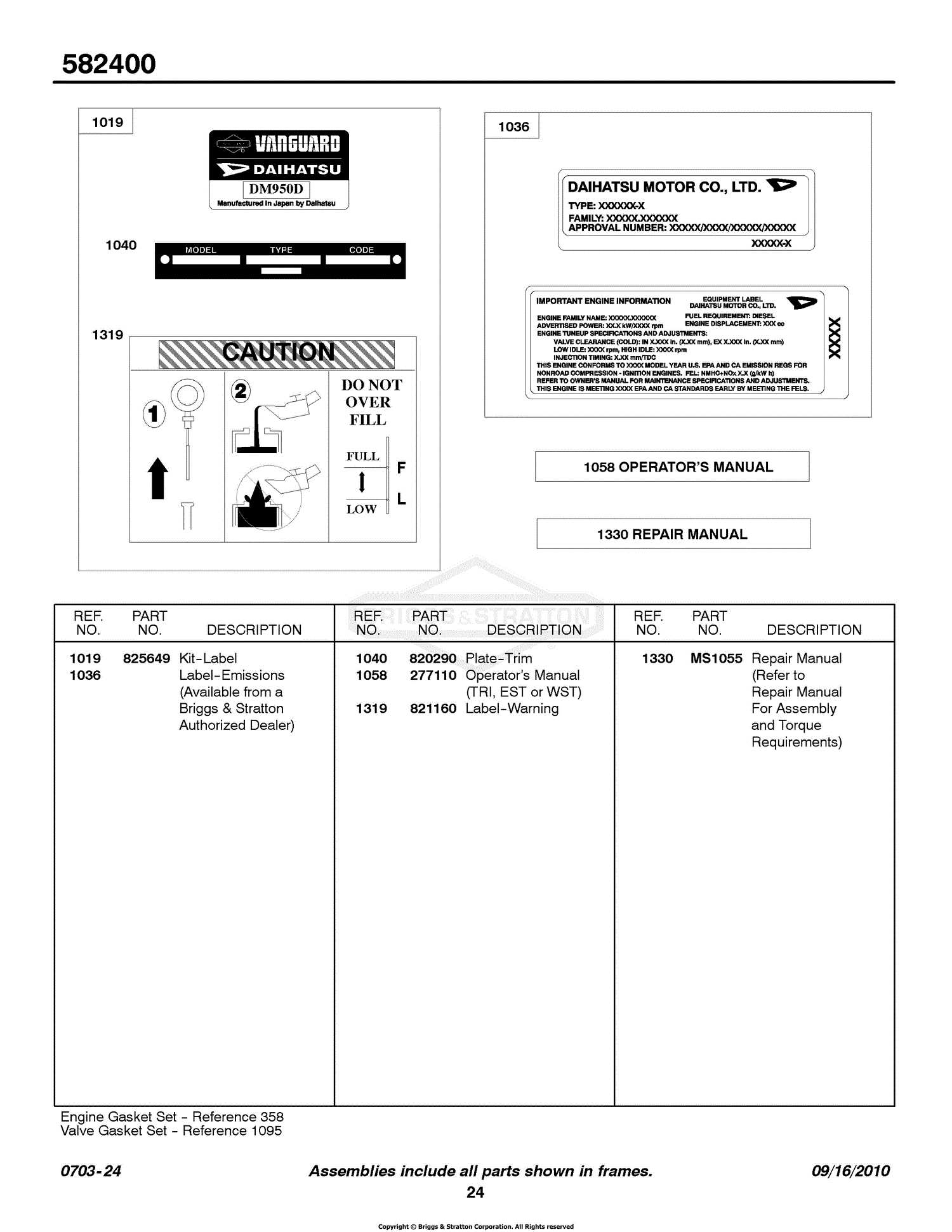

Overview of Briggs Repair Manual 1330

This section provides a comprehensive insight into a resource designed for maintenance and troubleshooting. The document serves as a vital tool for individuals seeking to enhance their understanding of equipment functionality and service procedures.

The guide encompasses a range of topics, from fundamental operational principles to advanced diagnostics. It aims to empower users with the knowledge necessary to perform effective upkeep and resolve common issues that may arise during usage.

| Key Features | Description |

|---|---|

| Detailed Procedures | Step-by-step instructions for various tasks to ensure efficient handling. |

| Component Identification | Visual aids and descriptions to help users recognize essential parts. |

| Troubleshooting Tips | Guidelines for diagnosing and fixing frequent problems effectively. |

| Maintenance Schedules | Recommendations for regular checks to prolong equipment life. |

This resource not only fosters a deeper comprehension but also promotes confidence in performing necessary tasks, ensuring longevity and optimal performance of the machinery involved.

Key Features of the Manual

This guide is designed to provide users with comprehensive insights into the maintenance and troubleshooting of various equipment. It serves as an essential resource for understanding the intricacies involved in keeping machinery in optimal condition. The content is structured to facilitate both novice and experienced users, ensuring accessibility and clarity throughout.

Comprehensive Troubleshooting

One of the standout attributes of this guide is its thorough troubleshooting section. It addresses common issues that may arise, offering step-by-step solutions and detailed explanations. This empowers users to identify problems quickly and implement effective fixes without unnecessary delays.

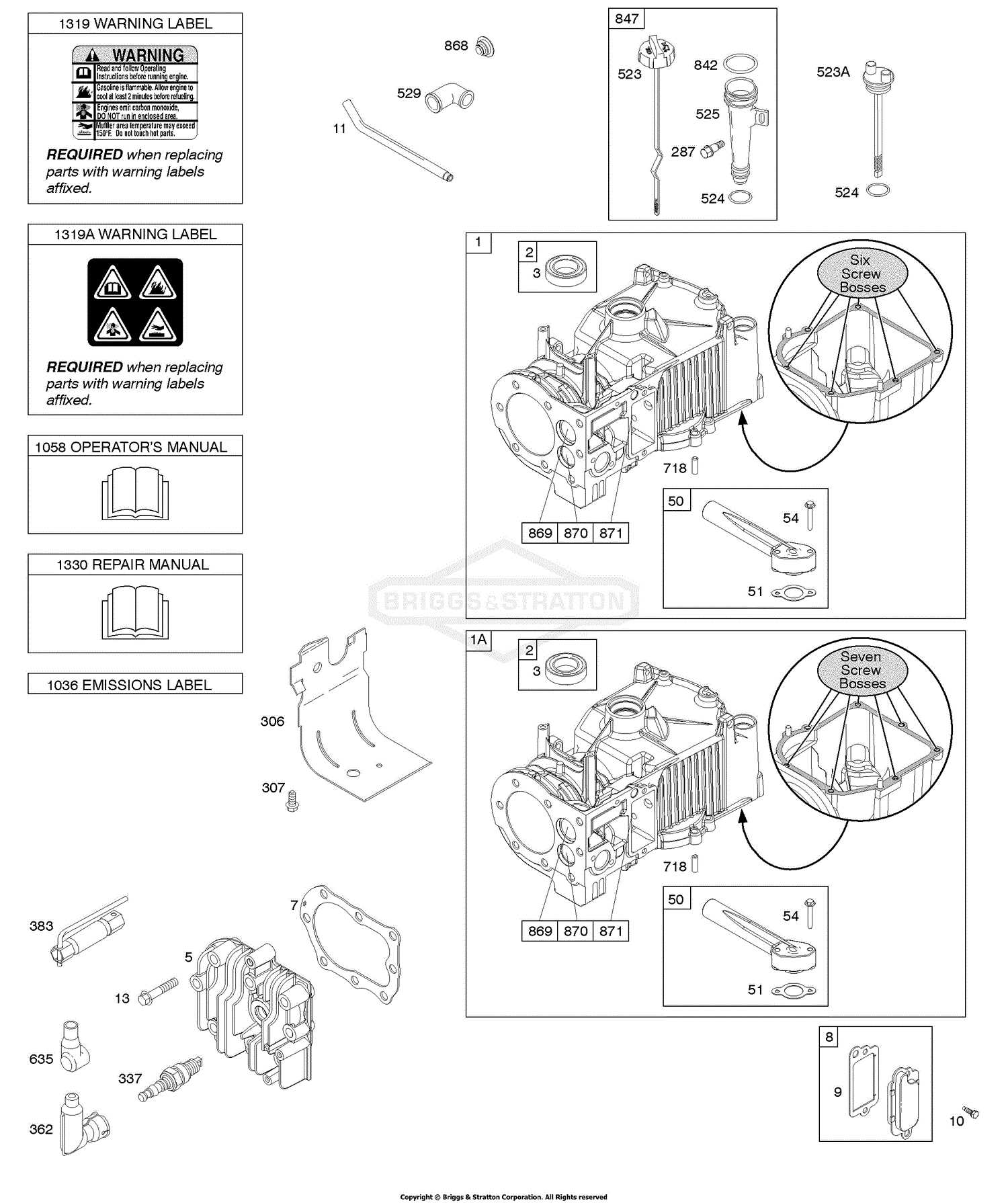

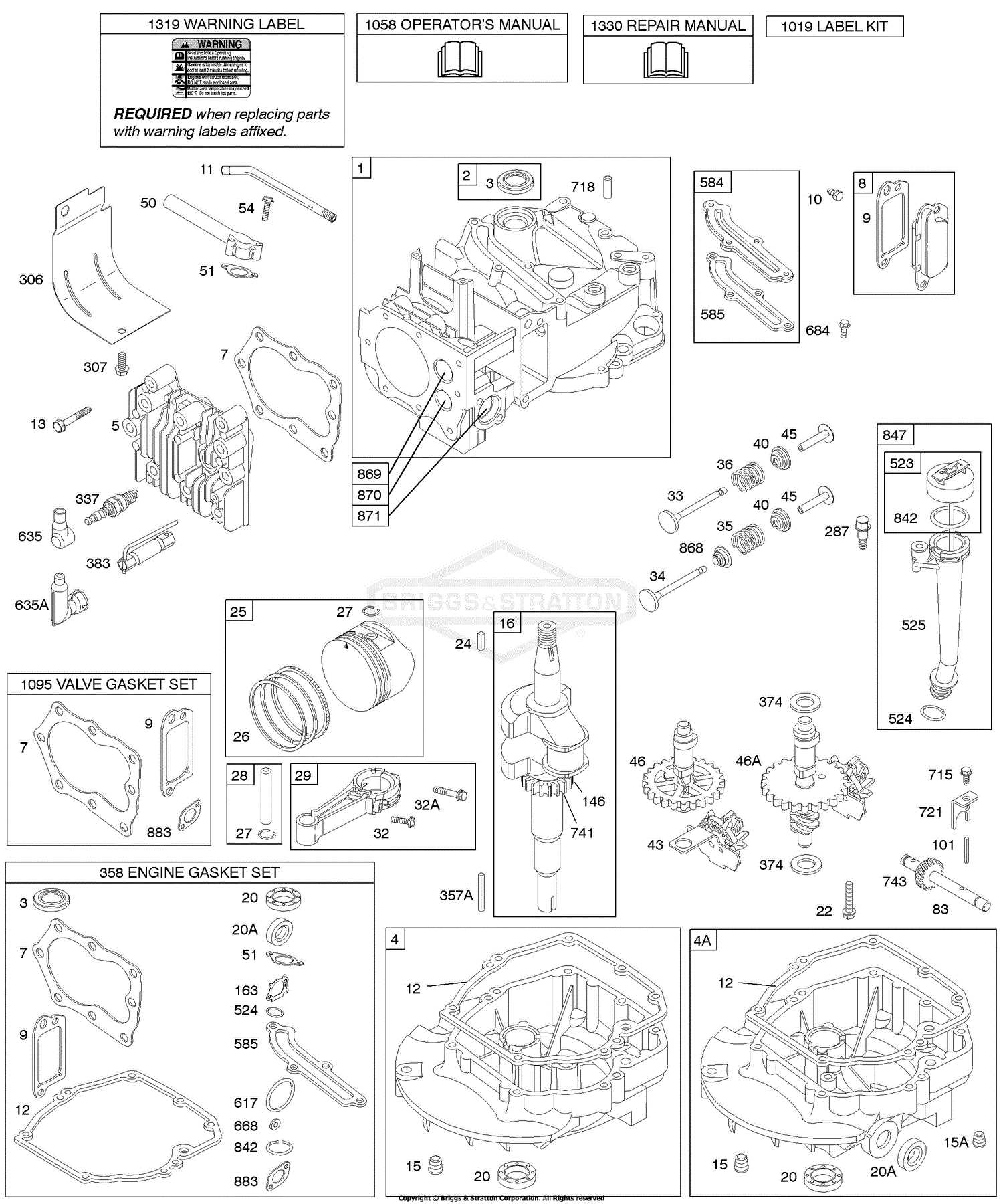

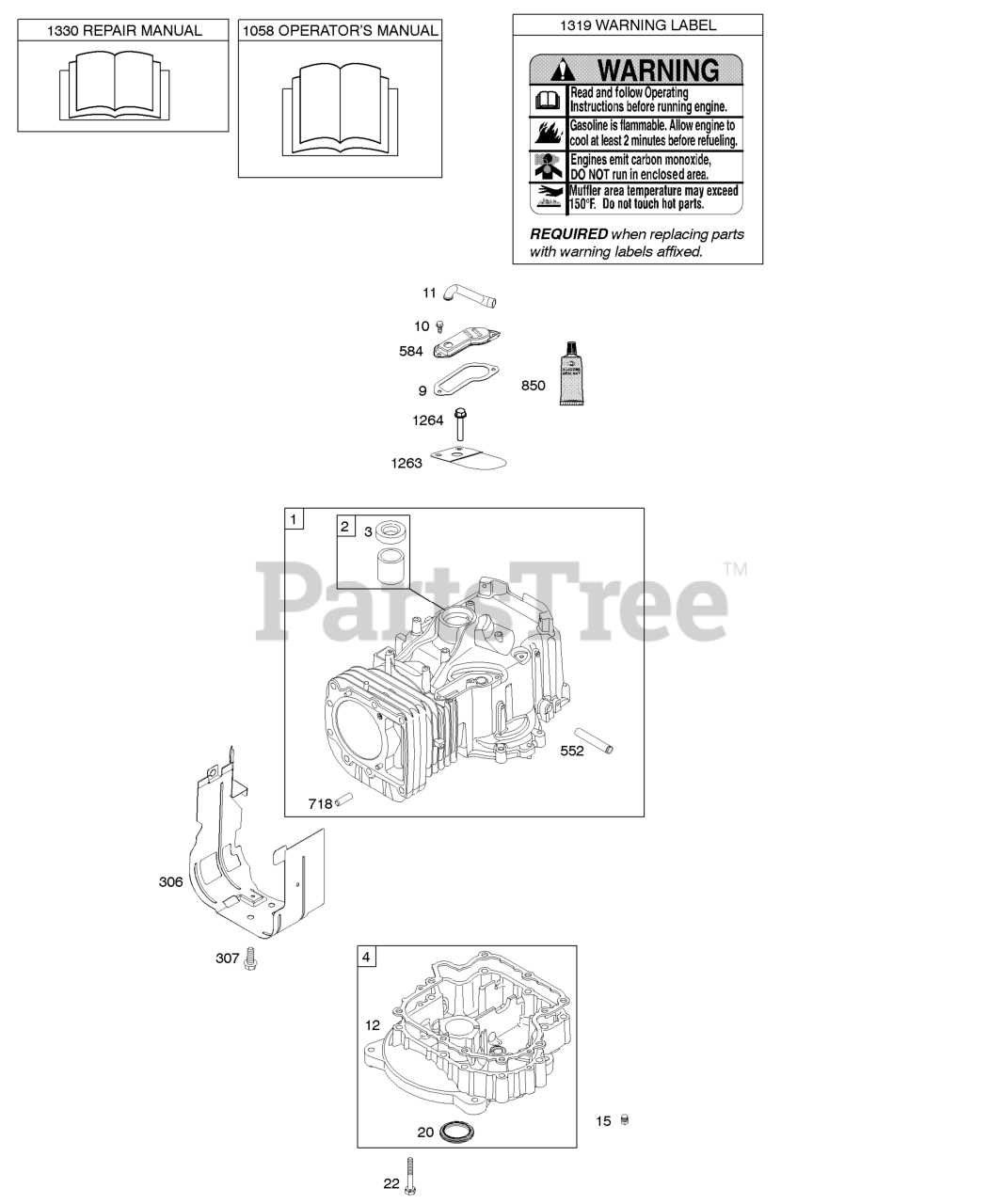

Detailed Diagrams and Illustrations

The inclusion of detailed diagrams and illustrations enhances user comprehension. Visual aids complement the written instructions, allowing for easier navigation of complex components. This feature significantly reduces the likelihood of errors during the maintenance process, ensuring that users can follow along with confidence.

Understanding Maintenance Requirements

Proper upkeep of machinery is essential for optimal performance and longevity. Understanding the necessary tasks and intervals can help prevent unexpected failures and ensure that equipment operates smoothly. A structured maintenance approach not only enhances efficiency but also contributes to safety.

- Regular inspections: Frequent evaluations help identify potential issues before they escalate.

- Scheduled servicing: Adhering to a timeline for maintenance tasks promotes consistency and reliability.

- Fluid changes: Replacing oils and lubricants is crucial for reducing wear and tear.

To effectively manage maintenance, consider the following key aspects:

- Documentation: Keep a log of all maintenance activities to track what has been done and what is due.

- Tools and equipment: Utilize the appropriate tools to ensure tasks are completed correctly and efficiently.

- Training: Ensure that personnel are well-trained to perform maintenance tasks safely and effectively.

By prioritizing these components, individuals can safeguard their investments and maintain peak operational performance.

Common Troubleshooting Techniques

When dealing with mechanical equipment, encountering issues is not uncommon. Understanding effective methods for identifying and resolving these problems can greatly enhance efficiency and extend the lifespan of the machinery. Here, we explore various strategies that can aid in diagnosing faults and implementing solutions effectively.

Visual Inspection

A thorough visual assessment is often the first step in the diagnostic process. Look for obvious signs of wear, damage, or disconnection. Check for loose components, leaks, or corrosion. This simple technique can quickly reveal issues that may require further investigation or immediate action.

Systematic Testing

After initial observations, conducting systematic tests can provide deeper insights into functionality. Start with basic checks such as power supply and connections. Utilize diagnostic tools where applicable to measure performance metrics. This methodical approach helps isolate problems and ensures that all potential issues are addressed.

Remember: Staying organized during troubleshooting is crucial. Keep detailed notes on your findings and the steps you’ve taken, as this information will be invaluable for future reference or if professional assistance is needed.

Parts and Tools Needed for Repairs

To effectively address maintenance tasks and ensure optimal performance of your equipment, it is crucial to have the right components and instruments on hand. This section outlines the essential items that will facilitate a smooth and efficient process.

| Component/Tool | Purpose |

|---|---|

| Wrenches | For loosening and tightening bolts and nuts. |

| Screwdrivers | To remove and install screws in various parts. |

| Socket set | For quick and efficient fastening of different sizes of fasteners. |

| Replacement filters | To ensure clean air and fuel flow, enhancing performance. |

| Oil | For lubrication and maintaining engine health. |

| Fuel | To ensure proper functioning and efficiency of the engine. |

| Cleaning supplies | For removing dirt and debris from components. |

| Safety gear | To protect yourself during maintenance activities. |

Having these essential items readily available will greatly enhance your ability to perform maintenance tasks effectively, ensuring that your machinery operates smoothly and reliably.

Step-by-Step Repair Procedures

This section outlines the systematic approach for addressing common issues encountered in various machines. By following these guidelines, you can effectively diagnose and resolve problems, ensuring optimal performance and longevity.

-

Preparation:

- Gather necessary tools and equipment.

- Ensure a clean workspace to facilitate the process.

- Review safety precautions to prevent accidents.

-

Diagnosis:

- Identify the symptoms and gather information.

- Perform visual inspections for obvious signs of wear or damage.

- Use diagnostic tools to pinpoint specific issues.

-

Disassembly:

- Carefully take apart components to access the problematic areas.

- Label and organize parts to ensure smooth reassembly.

- Follow a structured order to avoid missing steps.

-

Repair:

- Replace or fix damaged parts as necessary.

- Apply lubricants and clean surfaces to enhance functionality.

- Ensure all adjustments meet manufacturer specifications.

-

Reassembly:

- Carefully put components back together in the reverse order of disassembly.

- Double-check connections and fastenings to ensure stability.

- Test the assembly before finalizing the process.

-

Testing:

- Run the machine under normal operating conditions.

- Monitor performance for any irregularities.

- Make adjustments as needed based on testing outcomes.

Following these structured steps will help you effectively address issues and maintain peak performance in your equipment.

Safety Precautions During Repairs

Ensuring a secure environment while conducting maintenance tasks is essential for both the technician and the equipment involved. Adhering to safety measures minimizes the risk of accidents and injuries, creating a more efficient working atmosphere. Proper preparation and awareness of potential hazards play a crucial role in achieving successful outcomes.

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Always wear appropriate gear such as gloves, goggles, and masks to protect against debris and hazardous materials. |

| Work Environment | Keep the workspace clean and well-lit. Ensure that tools and materials are organized to prevent tripping or falling. |

| Electrical Safety | Disconnect power sources before beginning any task. Use insulated tools when working with electrical components. |

| Read Instructions | Thoroughly review all provided guidelines before starting. Understanding the procedures helps avoid mistakes. |

| Emergency Preparedness | Have a first aid kit accessible and be aware of emergency contacts. Know the location of fire extinguishers and exits. |

Implementing these safety practices fosters a proactive approach to maintenance activities. Awareness and readiness to address potential risks can lead to more effective and enjoyable working experiences.

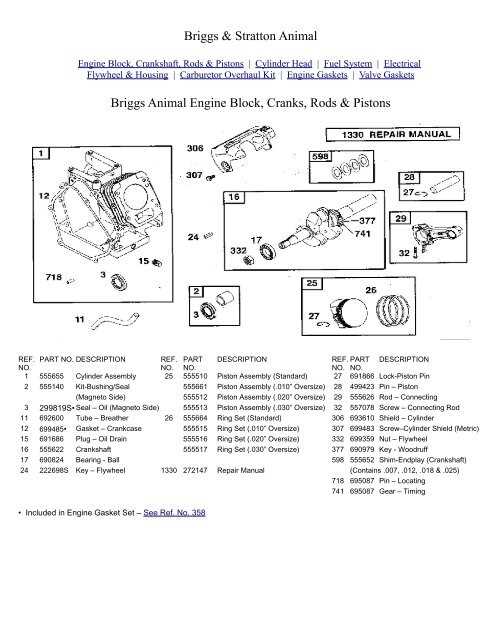

Understanding Engine Components

Grasping the intricate parts of an engine is essential for anyone looking to enhance performance or troubleshoot issues. Each component plays a vital role in ensuring smooth operation and efficiency. By familiarizing yourself with these elements, you can better appreciate how they interact and contribute to the overall functionality of the machine.

Key Components and Their Functions

Engines consist of several crucial elements, including the cylinder, piston, crankshaft, and valves. The cylinder serves as the chamber where fuel and air mix and combust, driving the piston. This motion is then transferred to the crankshaft, which converts linear movement into rotational energy. Valves control the intake and exhaust processes, regulating airflow and maintaining optimal performance.

Importance of Maintenance

Regular upkeep of these components is vital for longevity and efficiency. Neglecting even one part can lead to diminished performance or complete breakdown. Understanding each component’s role empowers users to perform necessary checks and balances, ensuring that the engine operates at peak performance for years to come.

Typical Problems with Briggs Engines

Engines from this brand are known for their reliability, yet they can encounter several common issues over time. Understanding these potential problems can aid in timely maintenance and troubleshooting, ensuring optimal performance.

- Starting Difficulties:

- Fuel delivery problems

- Clogged air filters

- Weak batteries or faulty ignition systems

- Overheating:

- Insufficient cooling due to debris

- Low oil levels or poor oil quality

- Malfunctioning cooling fins

- Unusual Noises:

- Worn bearings or internal components

- Loose or damaged exhaust systems

- Vibrations from misaligned parts

- Excessive Smoke:

- Oil leaks into the combustion chamber

- Faulty valve seals

- Improper fuel mixtures

Identifying and addressing these issues early can significantly enhance the longevity and efficiency of your engine.

How to Replace Essential Parts

Replacing key components is crucial for maintaining the optimal performance of your equipment. Understanding the process can save time and enhance longevity. This guide will walk you through the necessary steps to effectively swap out vital elements.

Before starting, ensure you have the appropriate tools and replacement parts ready. Here’s a step-by-step approach:

- Preparation:

- Disconnect the power source to avoid accidents.

- Gather all necessary tools, such as wrenches, screwdrivers, and pliers.

- Refer to the specifications of the parts you need to replace.

- Access the Component:

- Remove any covers or panels that obstruct access to the part.

- Keep track of screws and fasteners for reassembly.

- Remove the Old Part:

- Carefully disconnect any electrical connectors or hoses.

- Unscrew or unbolt the part from its position.

- Check for any wear or damage in surrounding areas.

- Install the New Component:

- Position the new part in place, ensuring it aligns correctly.

- Secure it using the original screws or bolts.

- Reconnect any electrical connections or hoses.

- Final Checks:

- Replace any covers or panels that were removed.

- Reconnect the power source and test the equipment to ensure proper function.

By following these guidelines, you can successfully replace essential parts and keep your machinery running smoothly.

Maintenance Schedules for Longevity

Establishing a regular upkeep routine is essential for maximizing the lifespan of any machinery. By adhering to a systematic schedule, users can ensure optimal performance and prevent costly failures. Consistency in maintenance tasks fosters reliability and efficiency.

| Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 50 hours | Use high-quality lubricant. |

| Filter Replacement | Every 100 hours | Check for blockages regularly. |

| Spark Plug Inspection | Every 200 hours | Replace if worn or fouled. |

| Clean Air Filter | Every 25 hours | Ensure proper airflow. |

| Visual Inspection | Before each use | Look for leaks or damages. |

Tips for Efficient Repairs

Effective maintenance not only enhances the longevity of equipment but also ensures optimal performance. By following specific strategies, one can streamline the process and achieve better results with minimal effort.

Preparation is Key

- Gather all necessary tools and materials beforehand to avoid interruptions.

- Review any relevant documentation to familiarize yourself with the system.

- Ensure you have a clean and organized workspace to facilitate smooth operations.

Step-by-Step Approach

- Start with a thorough assessment to identify the issues accurately.

- Prioritize tasks based on urgency and complexity.

- Follow a logical sequence to avoid confusion and maintain focus.

- Test the system periodically after each task to confirm progress.

Implementing these practices can lead to quicker resolutions and a more satisfying experience in maintaining your equipment.

Resources for Additional Support

When tackling maintenance and troubleshooting tasks, having access to various resources can significantly enhance your understanding and effectiveness. Whether you seek expert advice, detailed instructions, or community support, numerous options are available to assist you in overcoming challenges.

Here are some valuable resources to consider:

- Online Forums: Participate in dedicated forums where enthusiasts and professionals share their experiences and solutions. These platforms often provide insights into common issues and effective fixes.

- Video Tutorials: Explore video platforms for step-by-step guides. Visual demonstrations can simplify complex tasks and give you confidence in executing repairs.

- Technical Guides: Seek out comprehensive guides that delve into specific models or types of equipment. These documents often contain troubleshooting tips and detailed procedures.

- Local Workshops: Consider attending workshops or classes hosted by professionals. Hands-on training can deepen your skills and understanding of various maintenance techniques.

- Customer Support: Don’t hesitate to reach out to manufacturers or retailers for assistance. Their support teams can provide tailored advice based on your specific situation.

Utilizing these resources can empower you to address any issues effectively and enhance your overall knowledge in the field.