In the world of small engine maintenance, having access to comprehensive resources is essential for ensuring optimal performance. These resources not only provide detailed information about various components but also offer insights into common issues that may arise during operation. Understanding how to properly service and maintain these machines can greatly enhance their longevity and efficiency.

When faced with technical difficulties or routine upkeep, users benefit from step-by-step instructions that demystify complex processes. These guides encompass a wide range of topics, from assembly and disassembly to troubleshooting and parts replacement. By leveraging such resources, individuals can gain the confidence needed to tackle maintenance tasks effectively.

Whether you are a seasoned professional or a casual user, familiarizing yourself with these informative documents can lead to significant improvements in operational efficiency. Empowering oneself with knowledge equips users to make informed decisions and execute repairs with precision, ultimately leading to a smoother experience in the field.

This section provides a comprehensive approach to identifying and resolving common issues encountered with small engine equipment. By following a systematic method, users can effectively diagnose problems, ensuring optimal performance and longevity of their machinery.

| Step | Description |

|---|---|

| 1 | Check the fuel level and ensure it is fresh and clean. Stale or contaminated fuel can lead to starting issues. |

| 2 | Inspect the air filter for dirt and debris. A clogged filter restricts airflow, affecting engine performance. |

| 3 | Examine the spark plug for wear or damage. Replace it if it appears corroded or fouled. |

| 4 | Look for any visible leaks or damage in the fuel lines. Ensure all connections are secure. |

| 5 | Test the battery and electrical connections. Weak batteries can hinder starting and overall operation. |

| 6 | Perform a visual inspection of all components for signs of wear or damage. Address any concerns immediately. |

Maintenance Tips for Longevity

Regular upkeep is essential for extending the lifespan of your equipment. Proper maintenance not only ensures optimal performance but also prevents costly repairs. Here are some vital strategies to keep your machinery in excellent condition.

Routine Checks

- Inspect the oil levels and change it regularly to keep the engine lubricated.

- Examine air filters for dirt and debris; clean or replace them as needed.

- Check the spark plug condition and replace it if it shows signs of wear.

Seasonal Maintenance

- Prepare your equipment for storage during off-seasons by draining fuel to prevent gumming.

- Clean the exterior to remove dust and grime, which can affect functionality.

- Run the machinery periodically to keep components moving freely and to avoid stagnation.

By following these guidelines, you can significantly enhance the durability of your equipment and ensure it runs smoothly for years to come.

Replacing Engine Parts Effectively

When it comes to maintaining the performance of your machine, timely and efficient replacement of components is crucial. Understanding the steps involved can significantly enhance the longevity and reliability of your engine. Here are key considerations and methods for achieving effective replacements.

Before starting the replacement process, ensure you have the right tools and parts. This preparation sets the foundation for a smooth procedure.

- Gather Necessary Tools: Make sure to have wrenches, screwdrivers, pliers, and any specific tools required for your engine type.

- Select Quality Parts: Using high-quality components ensures better performance and durability.

- Read Instructions: Familiarize yourself with guidelines specific to the components you are replacing.

Once you have prepared, follow these steps for efficient replacement:

- Disconnect Power: Always ensure the machine is turned off and disconnected from any power source.

- Remove Old Parts: Carefully detach the worn-out components using the appropriate tools.

- Install New Parts: Position the new parts correctly and secure them firmly to avoid future issues.

- Test the Engine: After installation, run the engine to check for any abnormalities or performance issues.

By following these guidelines, you can effectively replace engine components, ensuring your machinery operates at its best.

Understanding Engine Specifications

Gaining insight into the specifications of an engine is crucial for ensuring optimal performance and longevity. These parameters define how the engine operates and influence maintenance decisions. A thorough comprehension of these characteristics enables users to make informed choices when troubleshooting or upgrading their machinery.

Specifications typically include key details such as power output, displacement, and torque. Understanding these figures can assist in selecting the appropriate components for repairs and enhancements. Below is a table summarizing common engine specifications.

| Specification | Description |

|---|---|

| Power Output | The maximum power generated by the engine, usually measured in horsepower (HP). |

| Displacement | The total volume of all the cylinders in the engine, typically expressed in cubic centimeters (cc) or liters (L). |

| Torque | The rotational force produced by the engine, measured in foot-pounds (ft-lb) or Newton-meters (Nm). |

| Fuel Type | The type of fuel recommended for optimal performance, which can vary based on engine design. |

| Ignition System | The mechanism responsible for igniting the fuel-air mixture, which can impact starting and efficiency. |

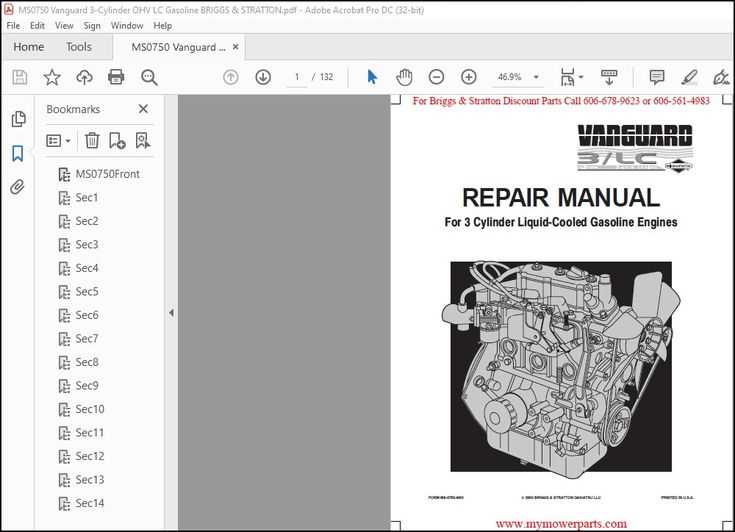

Using Official Repair Manuals

Accessing authorized documentation is crucial for anyone looking to maintain or troubleshoot their equipment effectively. These resources provide detailed information about various models, ensuring that users can follow proper procedures and guidelines for optimal performance.

Utilizing official documentation offers several advantages:

- Comprehensive Information: Authorized guides cover specifications, parts lists, and step-by-step instructions.

- Accurate Troubleshooting: Users can identify and resolve issues quickly using reliable information.

- Consistency: Official materials ensure that users apply the same techniques recommended by manufacturers.

When using these resources, consider the following tips for better results:

- Always verify the model number to ensure the documentation is relevant.

- Familiarize yourself with the terminology used in the manuals for easier comprehension.

- Follow the instructions sequentially to avoid confusion and errors.

In conclusion, relying on authorized documentation is essential for anyone looking to ensure their equipment operates efficiently and lasts longer.

Locating Parts and Accessories

Finding the right components and add-ons for your equipment can greatly enhance its performance and longevity. Whether you are looking to replace a worn part or upgrade your machine with the latest accessories, understanding where to search is essential.

Start by checking reputable online retailers that specialize in outdoor power equipment. These platforms often provide a wide selection of items, including components specific to various models. Additionally, many of these sites offer detailed descriptions and compatibility information, making it easier to identify the correct part for your needs.

Another valuable resource is local distributors or service centers. Visiting these establishments allows you to consult with knowledgeable staff who can assist in identifying the right products. They may also have access to exclusive items not available online.

Don’t overlook the potential of online forums and community groups dedicated to machinery enthusiasts. Engaging with fellow users can provide insights into where to find rare components or tips on the best accessories to enhance functionality.

Safety Precautions During Repairs

When engaging in maintenance or service activities on outdoor power equipment, adhering to safety measures is paramount. Ensuring a safe environment protects not only the individual performing the tasks but also the equipment and surrounding area. These precautions minimize risks and enhance the efficiency of the work being done.

Prior to commencing any service tasks, it is essential to equip oneself with appropriate safety gear. This may include gloves, goggles, and protective clothing to shield against potential hazards. Additionally, maintaining a clean and organized workspace helps prevent accidents and facilitates easier access to tools and parts.

Before starting work, it is crucial to disconnect the power source. This reduces the risk of accidental starts that could lead to injury. Moreover, familiarize yourself with the equipment’s specific requirements and functions, as understanding its mechanisms can aid in performing tasks safely.

FAQs About Engine Maintenance

This section addresses common inquiries regarding the upkeep and service of internal combustion units. Proper maintenance is crucial for ensuring optimal performance and longevity, and understanding the frequently asked questions can help users navigate this essential aspect of engine care.

| Question | Answer |

|---|---|

| How often should I change the oil? | It is recommended to change the oil every 50 hours of operation or at least once a year, whichever comes first. |

| What type of fuel should I use? | Using high-quality unleaded gasoline with an octane rating of 87 or higher is advisable for optimal performance. |

| How do I know if my spark plug needs replacement? | If you experience difficulty starting the engine or notice a decrease in performance, the spark plug may need to be replaced. |

| What maintenance tasks should I perform regularly? | Regular tasks include checking the air filter, inspecting the fuel system, and ensuring all bolts and screws are secure. |

| Can I perform maintenance myself? | Yes, many maintenance tasks can be performed by the user. However, for complex issues, consulting a professional is recommended. |

Online Resources for Further Help

In today’s digital age, there is a wealth of information available online for those seeking assistance with engine maintenance and troubleshooting. Various platforms provide access to a range of helpful content, including instructional videos, detailed articles, and community forums where enthusiasts share their knowledge and experiences.

Official Websites serve as reliable sources, offering access to manufacturer-specific information, guidelines, and troubleshooting tips. These platforms often include a section dedicated to customer support, where users can find FAQs and contact information for professional assistance.

YouTube is another valuable resource, featuring countless video tutorials created by experienced mechanics and hobbyists. These visual aids can simplify complex procedures, making it easier for individuals to follow along and complete tasks accurately.

Additionally, online forums and social media groups dedicated to engine maintenance create a community where individuals can ask questions, share experiences, and receive advice from others who have faced similar challenges. Engaging in these discussions can provide new insights and solutions that may not be found in traditional literature.

For those looking to deepen their understanding, specialized blogs and websites offer articles and guides that cover various topics related to engine care. These resources often delve into specific issues, providing readers with comprehensive information and step-by-step instructions.

By utilizing these online resources, individuals can enhance their knowledge, find solutions to problems, and ultimately improve their skills in maintaining and servicing their engines.

How to Dispose of Engine Oil

Proper disposal of used motor lubricant is crucial for environmental safety. It ensures that harmful substances do not contaminate soil or water sources. By following the correct procedures, you can contribute to a cleaner planet while adhering to local regulations.

Steps for Safe Disposal

When disposing of engine oil, it is important to follow these steps:

| Step | Description |

|---|---|

| 1 | Collect the used oil in a secure container, ensuring it is leak-proof. |

| 2 | Label the container clearly to avoid confusion. |

| 3 | Locate a recycling center or a designated drop-off site in your area. |

| 4 | Follow the specific instructions provided by the facility regarding the drop-off process. |

Environmental Impact

Improper disposal can lead to significant ecological damage, as used oil can leak toxins into the environment. By recycling or disposing of it responsibly, you help to prevent pollution and protect wildlife habitats.