In the realm of aviation, the integrity and longevity of aircraft are paramount. A comprehensive resource exists to assist technicians in ensuring that airframes and components remain safe and operational. This documentation serves as a crucial reference for identifying issues and implementing appropriate corrective actions, ultimately safeguarding both the aircraft and its occupants.

With a focus on detailed guidance, this resource outlines procedures that are vital for maintaining structural integrity. Technicians can access in-depth descriptions, diagrams, and specifications that illuminate the complexities involved in aircraft upkeep. By leveraging this information, professionals can enhance their understanding of various systems and their interrelationships, fostering a more robust maintenance culture.

Furthermore, the significance of adhering to these guidelines cannot be overstated. They not only promote operational safety but also contribute to the overall efficiency of maintenance processes. By following the recommended protocols, personnel can minimize downtime and ensure that aircraft are always ready for flight, reinforcing the trust placed in aviation systems.

Boeing Structural Repair Manual Overview

This section provides an insight into the comprehensive guide designed for addressing aircraft damage and ensuring safe operations. It serves as a critical resource for aviation professionals, detailing procedures and techniques for restoring aircraft integrity effectively.

Purpose and Importance

The guide is essential for maintaining safety standards and operational readiness. Its primary objectives include:

- Ensuring compliance with aviation regulations.

- Providing standardized procedures for addressing various forms of damage.

- Facilitating effective communication among maintenance teams.

Key Components

Within this resource, several key elements are outlined:

- Damage Assessment: Methods for evaluating the extent of harm.

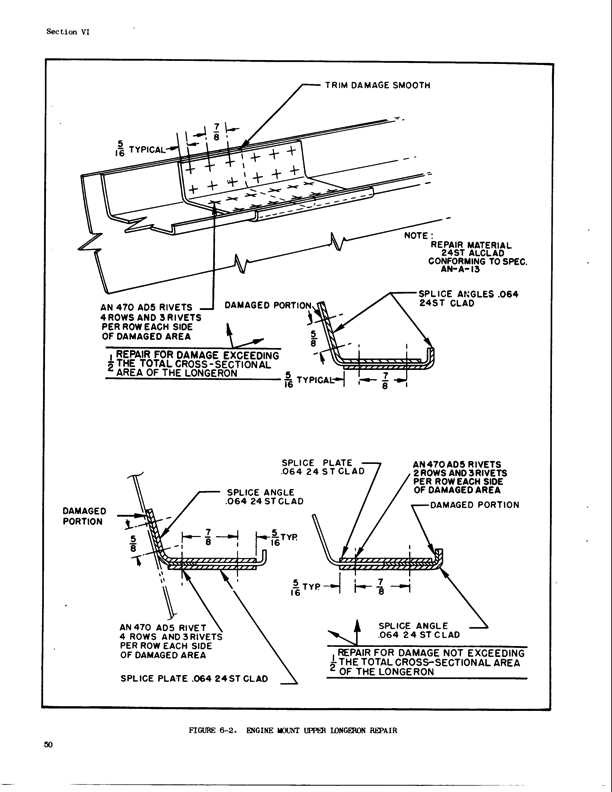

- Restoration Techniques: Step-by-step processes for reestablishing aircraft condition.

- Material Specifications: Guidance on appropriate materials for repairs.

- Safety Protocols: Procedures to ensure worker safety during maintenance tasks.

Importance of Structural Integrity

Ensuring the soundness of an aircraft’s framework is crucial for safety and performance. The resilience of each component plays a vital role in the overall functionality, allowing for reliable operation under various conditions. Neglecting the robustness of these elements can lead to severe consequences, making it essential to adhere to stringent guidelines and protocols.

Consequences of Compromised Strength

Failure to maintain the durability of an aircraft can result in:

- Increased risk of accidents

- Higher maintenance costs

- Decreased operational efficiency

- Loss of passenger confidence

Best Practices for Maintaining Integrity

To uphold the reliability of aircraft frameworks, it is important to follow certain strategies:

- Conduct regular inspections to identify potential weaknesses.

- Utilize advanced materials that enhance overall durability.

- Implement robust testing procedures to evaluate component performance.

- Train personnel in the latest techniques for ensuring component strength.

By prioritizing the stability of every part, the aviation industry can ensure safer skies and more reliable journeys.

Key Components of the Manual

This section delves into the essential elements that comprise a comprehensive guide for aircraft maintenance. These components are vital for ensuring that all procedures are clearly outlined, enabling technicians to perform their tasks effectively and safely.

Documentation and Specifications

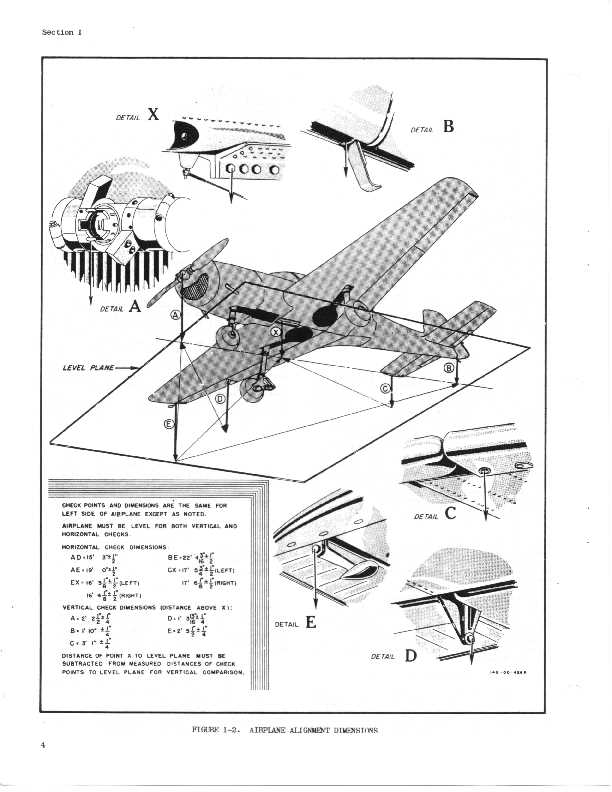

One of the primary features of the guide is the detailed documentation that includes specifications for various aircraft models. This ensures that maintenance personnel have access to precise measurements, materials, and techniques required for any modifications or repairs. Such information is crucial for maintaining structural integrity and operational safety.

Step-by-Step Procedures

The guide also contains step-by-step instructions that outline the processes involved in addressing issues. These systematic procedures help technicians understand the necessary actions, from initial assessment to final inspection, enhancing efficiency and reducing the likelihood of errors. Furthermore, diagrams and illustrations accompany many steps, providing visual support to complement the written instructions.

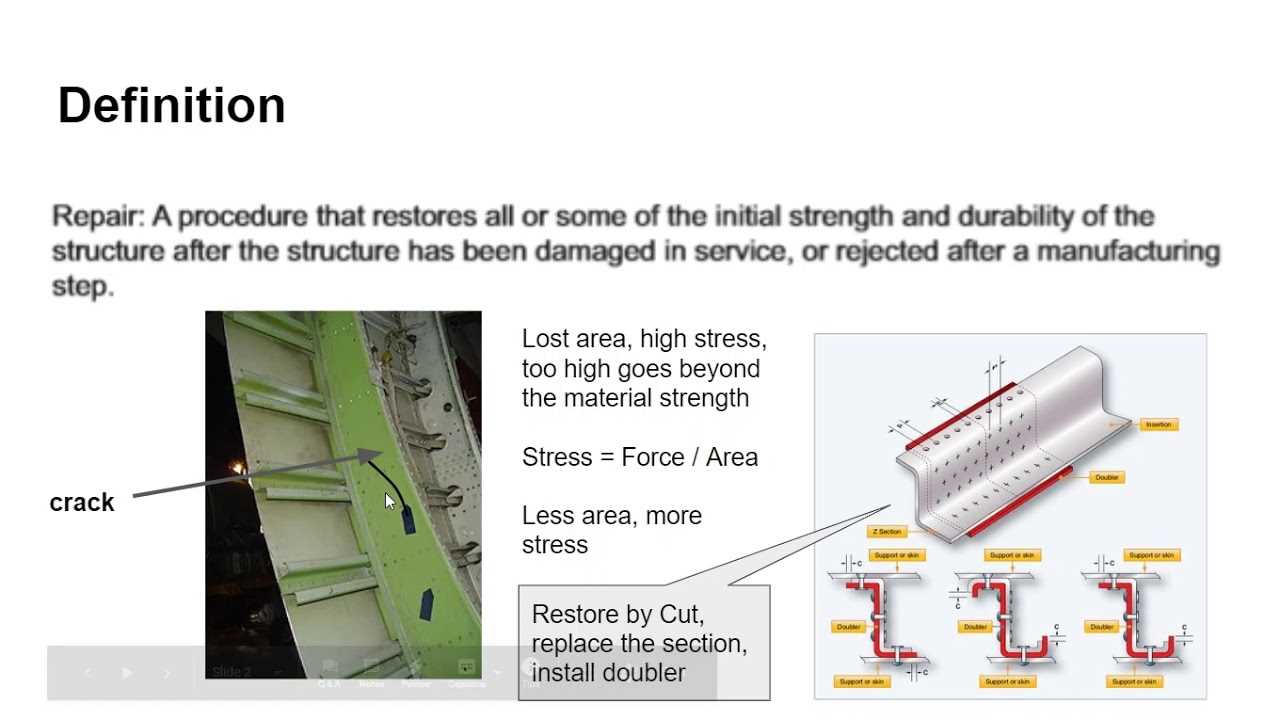

Common Repair Procedures Explained

This section delves into frequently encountered methods for addressing damage in aerospace components. These techniques ensure that the integrity and functionality of structures are maintained, promoting safety and efficiency in operations.

Understanding these approaches is crucial for professionals in the field. Here are some of the standard techniques employed:

- Surface Treatment: Involves cleaning and preparing affected areas to enhance bonding for subsequent repairs.

- Patch Application: Utilizes materials to cover and reinforce damaged sections, restoring structural strength.

- Reinforcement Installation: Adds extra support elements to compromised structures, improving load-bearing capacity.

- Replacement of Components: Involves removing severely damaged parts and substituting them with new or refurbished ones.

- Bonding Techniques: Employs adhesives to join materials, offering a seamless and robust connection.

Each of these methods is guided by specific protocols to ensure compliance with industry standards. Following established procedures is essential for achieving reliable outcomes and maintaining high safety levels in aerospace operations.

Understanding Material Specifications

Material specifications play a crucial role in ensuring the integrity and longevity of components in the aviation industry. These guidelines outline the properties and standards required for various substances used in manufacturing and maintenance processes. A comprehensive understanding of these specifications is essential for achieving optimal performance and safety.

Key aspects of material specifications include:

- Composition: The specific elements and compounds that make up a material, influencing its strength, durability, and weight.

- Mechanical Properties: Characteristics such as tensile strength, fatigue resistance, and hardness that determine how a material will behave under different conditions.

- Corrosion Resistance: The ability of a material to withstand degradation from environmental factors, ensuring its longevity.

- Thermal Properties: How materials react to temperature changes, including their ability to conduct heat and resist thermal expansion.

- Manufacturability: The ease with which a material can be processed, shaped, and assembled into final products.

Understanding these elements helps in making informed decisions during the selection and usage of materials in various applications. Additionally, adherence to specifications ensures compliance with industry standards, ultimately contributing to the overall safety and efficiency of operations.

Safety Guidelines for Technicians

This section emphasizes the importance of adhering to safety protocols to ensure a secure working environment. Proper precautions not only protect personnel but also enhance the overall efficiency of maintenance tasks.

| Guideline | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate gear such as helmets, gloves, and goggles to minimize risks of injury. |

| Tool Inspection | Regularly check all tools for damage or wear before use to prevent accidents. |

| Work Area Cleanliness | Maintain a tidy workspace to reduce hazards and enhance focus during operations. |

| Emergency Procedures | Familiarize yourself with emergency exits and procedures to ensure swift action in case of an incident. |

| Training | Participate in ongoing training to stay updated on safety practices and equipment handling. |

Inspection Techniques for Damage Assessment

Effective evaluation of structural integrity is crucial for maintaining safety and reliability in aviation. Various methodologies exist to identify and assess imperfections, ensuring timely intervention and maintenance.

Visual Inspection

Visual examination is often the first step in damage evaluation. It helps identify surface flaws and anomalies that may require further analysis. Key aspects include:

- Checking for obvious cracks and corrosion

- Inspecting fasteners and joints for looseness

- Looking for signs of wear or fatigue

Non-Destructive Testing (NDT)

NDT techniques provide a deeper understanding of hidden damage without compromising the structure. Common methods include:

- Ultrasonic Testing: Uses high-frequency sound waves to detect internal flaws.

- Magnetic Particle Inspection: Effective for identifying surface and near-surface defects in ferromagnetic materials.

- Radiographic Testing: Employs X-rays or gamma rays to reveal internal features and discontinuities.

Tools Required for Structural Repairs

Effective restoration of airframe components necessitates a precise selection of instruments and equipment. Proper tools not only enhance the efficiency of the work but also ensure the integrity and safety of the aircraft. Understanding the essential gear needed for various tasks is crucial for achieving optimal results in any maintenance operation.

Essential Equipment

When undertaking maintenance tasks, certain categories of tools are indispensable. These include both hand tools and power-operated devices, each serving a specific purpose in the process of inspection and enhancement of airframe elements.

| Tool Type | Description |

|---|---|

| Hand Tools | Basic instruments such as wrenches, pliers, and screwdrivers for manual adjustments and assembly. |

| Power Tools | Electric or pneumatic devices like drills and grinders to facilitate faster and more efficient operations. |

| Measuring Instruments | Calipers, gauges, and levels to ensure precise dimensions and alignments. |

| Safety Gear | Protective equipment such as gloves, goggles, and ear protection to ensure the safety of personnel. |

Specialized Tools

In addition to basic equipment, certain specialized instruments are often required for more complex tasks. These tools enhance precision and are tailored for specific applications, contributing to the overall effectiveness of maintenance practices.

Compliance with Aviation Regulations

Adherence to industry standards is crucial for ensuring the safety and reliability of aircraft operations. Proper alignment with established guidelines not only promotes operational excellence but also enhances public trust in air travel. In the aviation sector, compliance encompasses a variety of protocols that govern maintenance and modifications, thus safeguarding both personnel and passengers.

Key Regulatory Bodies

Several authoritative organizations play a pivotal role in defining and enforcing aviation regulations:

- Federal Aviation Administration (FAA): Oversees civil aviation safety and regulations in the United States.

- European Union Aviation Safety Agency (EASA): Responsible for ensuring aviation safety across Europe.

- International Civil Aviation Organization (ICAO): Sets global standards and recommendations for aviation safety and security.

Importance of Compliance

Ensuring conformity with these regulations provides multiple benefits:

- Safety: Minimizes the risk of accidents and enhances the overall safety of air travel.

- Efficiency: Streamlines maintenance processes and reduces downtime, leading to cost savings.

- Reputation: Builds trust and confidence among passengers and stakeholders in the aviation industry.

Ultimately, a commitment to compliance not only fulfills legal obligations but also fosters a culture of safety and excellence within the aviation community.

Challenges in Repair Processes

The intricacies involved in maintaining and restoring aerospace vehicles present a myriad of obstacles that professionals must navigate. From identifying underlying issues to implementing effective solutions, the journey is often fraught with complexities that demand expertise and precision.

First and foremost, the diversity of materials used in aircraft construction poses significant hurdles. Each component may require distinct techniques and tools for effective restoration, complicating the overall workflow. Additionally, the integration of advanced technologies means that specialists must remain continually educated about evolving methodologies and materials.

Moreover, regulatory compliance adds another layer of difficulty. Adhering to stringent safety standards is paramount, necessitating meticulous documentation and verification throughout the entire process. This can lead to delays, particularly when unexpected issues arise, necessitating further inspections and approvals.

Finally, communication among various teams is crucial yet challenging. Engineers, technicians, and quality assurance personnel must collaborate effectively to ensure that every aspect of the project aligns with safety and performance expectations. Miscommunication can result in costly setbacks and potential safety hazards.

In summary, the landscape of maintaining aerospace vehicles is characterized by a host of challenges that require a combination of specialized knowledge, adherence to regulations, and seamless teamwork to ensure successful outcomes.

Training for Maintenance Personnel

Effective training is essential for professionals involved in the upkeep of aviation systems. It ensures that personnel possess the necessary skills and knowledge to perform their tasks safely and efficiently. A comprehensive training program enhances the overall reliability and longevity of aircraft by equipping maintenance staff with critical insights and practical experience.

Key Training Components

- Understanding of Aircraft Systems

- Hands-On Experience with Tools and Equipment

- Safety Protocols and Emergency Procedures

- Quality Control Measures

- Regulatory Compliance

Training Methods

- Classroom Instruction

- Simulation and Virtual Training

- On-the-Job Training

- Workshops and Seminars

- Continuous Education Programs

By investing in these training methodologies, organizations can foster a highly skilled workforce capable of addressing various maintenance challenges and contributing to the safety and efficiency of aviation operations.

Case Studies of Successful Repairs

This section presents a series of examples that highlight effective interventions in aerospace structures. Each case illustrates the application of innovative techniques and the successful restoration of airworthy conditions, demonstrating the critical role of meticulous procedures and skilled personnel.

-

Case 1: Wing Spar Reinforcement

In this instance, a significant issue was identified in a wing spar. The solution involved:

- Comprehensive assessment of damage.

- Designing a custom reinforcement scheme.

- Utilizing advanced composite materials for added strength.

This approach not only restored structural integrity but also enhanced overall performance.

-

Case 2: Fuselage Skin Replacement

A critical area of fuselage skin suffered extensive corrosion. The intervention included:

- Thorough evaluation of surrounding areas to prevent future issues.

- Precise removal of the damaged skin sections.

- Installation of new, lightweight skin using specialized adhesives.

The result was a seamless integration that extended the lifespan of the aircraft.

-

Case 3: Landing Gear Component Overhaul

A major challenge arose with a landing gear component showing signs of fatigue. The response involved:

- Detailed inspection to pinpoint wear and tear.

- Precision machining of replacement parts.

- Rigorous testing post-installation to ensure safety and reliability.

This meticulous process not only resolved the immediate issue but also reinforced confidence in operational safety.

These examples exemplify the importance of strategic planning and expert execution in maintaining aircraft integrity. Each successful outcome contributes to the advancement of industry standards and practices.

Future Developments in Repair Techniques

Innovations in maintenance methodologies are set to transform the aviation industry. As technology advances, new strategies will emerge, enhancing the efficiency and safety of airframe restoration processes.

- Advanced Materials: The use of composite and lightweight materials is expected to increase, offering superior strength and resistance to corrosion.

- Automation: Robotics and automated systems are likely to streamline tasks, reducing human error and improving precision.

- Real-Time Monitoring: Integration of IoT devices will facilitate continuous assessment of aircraft conditions, enabling proactive interventions.

- Virtual Reality: Training using immersive technology will enhance skill development, allowing technicians to practice complex procedures safely.

- 3D Printing: On-demand production of components will reduce lead times and inventory costs, providing tailored solutions for specific needs.

These advancements promise not only to enhance the quality of interventions but also to significantly reduce downtime and operational costs in the aviation sector.