Fixing Dryer Drum Problems

Addressing issues related to the rotating compartment of a laundry appliance is essential for maintaining optimal performance. Over time, various complications can arise, leading to inefficient operation or even complete failure. Understanding the potential causes and remedies can help in restoring functionality and extending the lifespan of the unit.

Common problems that may affect the rotating compartment include:

- Noisy Operation: Unusual sounds during the cycle may indicate worn bearings or foreign objects caught in the compartment.

- Inconsistent Rotation: A failure to spin at the appropriate speed can stem from belt issues or motor malfunctions.

- Physical Damage: Cracks or dents in the compartment can result in uneven movement and potential clothing damage.

To effectively resolve these issues, consider the following steps:

- Inspect for Foreign Objects: Check for items lodged inside the compartment that may disrupt rotation.

- Examine the Belt: Ensure that the belt is intact and properly tensioned. Replace it if frayed or broken.

- Check Bearings: Inspect the bearings for wear and tear. Lubricate or replace them as necessary.

- Look for Damage: Assess the compartment for cracks or warping, and replace if needed.

By following these guidelines, it is possible to identify and rectify issues, ensuring the effective performance of the appliance and preventing further complications down the line.

Troubleshooting Electrical Connections

Ensuring proper functionality of appliances often requires a thorough examination of their electrical components. Issues with power supply or connections can lead to malfunctions that may appear as more complex problems. This section focuses on identifying and resolving common electrical issues that may arise, enabling a smoother operation of your appliance.

Before delving into repairs, it’s crucial to conduct a systematic inspection of the electrical connections. This includes checking for loose wires, damaged plugs, or any signs of wear that could hinder performance. Below is a guide to help you through the diagnostic process:

| Issue |

Possible Causes |

Solutions |

| No Power |

Blown fuse, tripped circuit breaker, faulty outlet |

Replace the fuse, reset the breaker, or test the outlet with another device |

| Intermittent Functionality |

Loose connections, damaged wiring |

Tighten all connections and replace any frayed wires |

| Burning Smell |

Overheating components, short circuit |

Immediately unplug the unit and inspect for burnt wires or components; seek professional assistance if needed |

By following these guidelines, you can effectively troubleshoot electrical issues, ensuring optimal performance and longevity of your appliance. Regular maintenance and inspections will further prevent future complications.

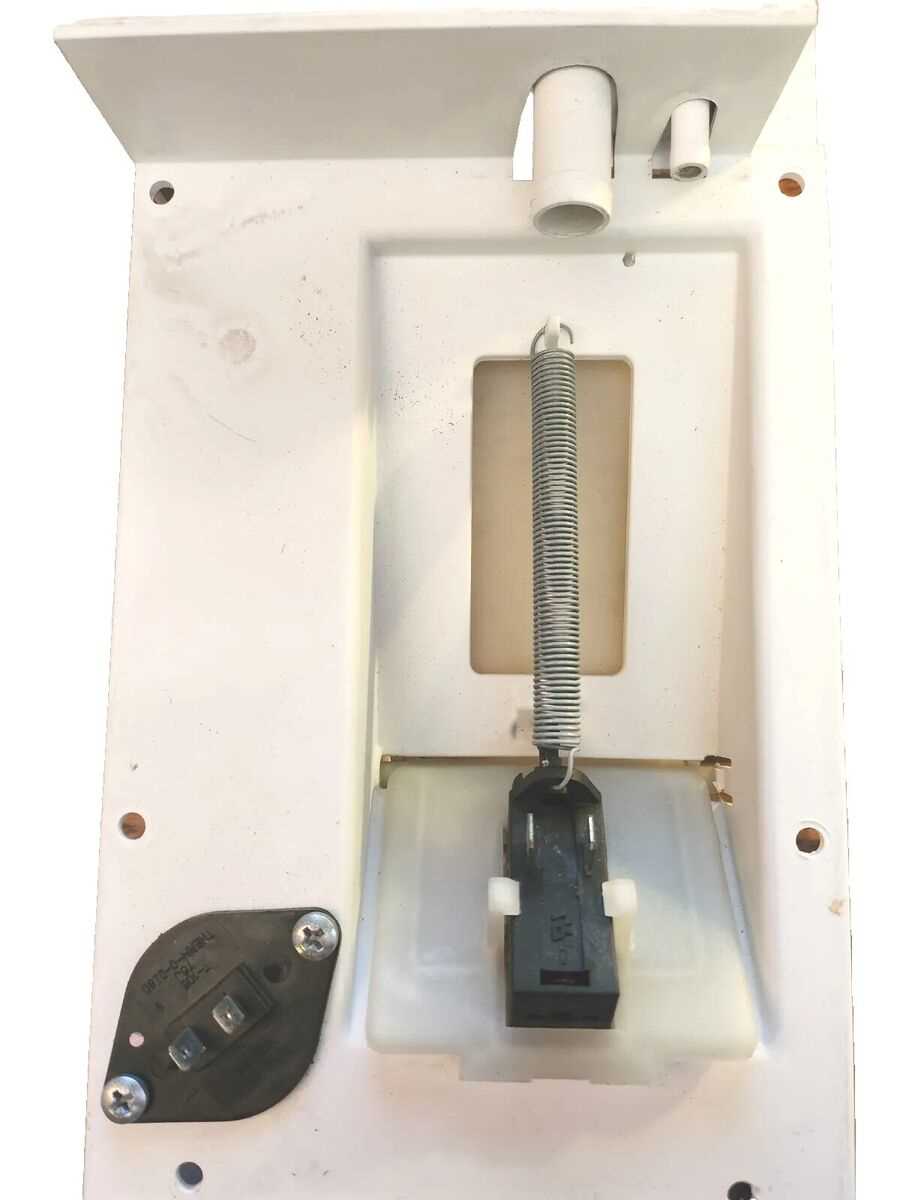

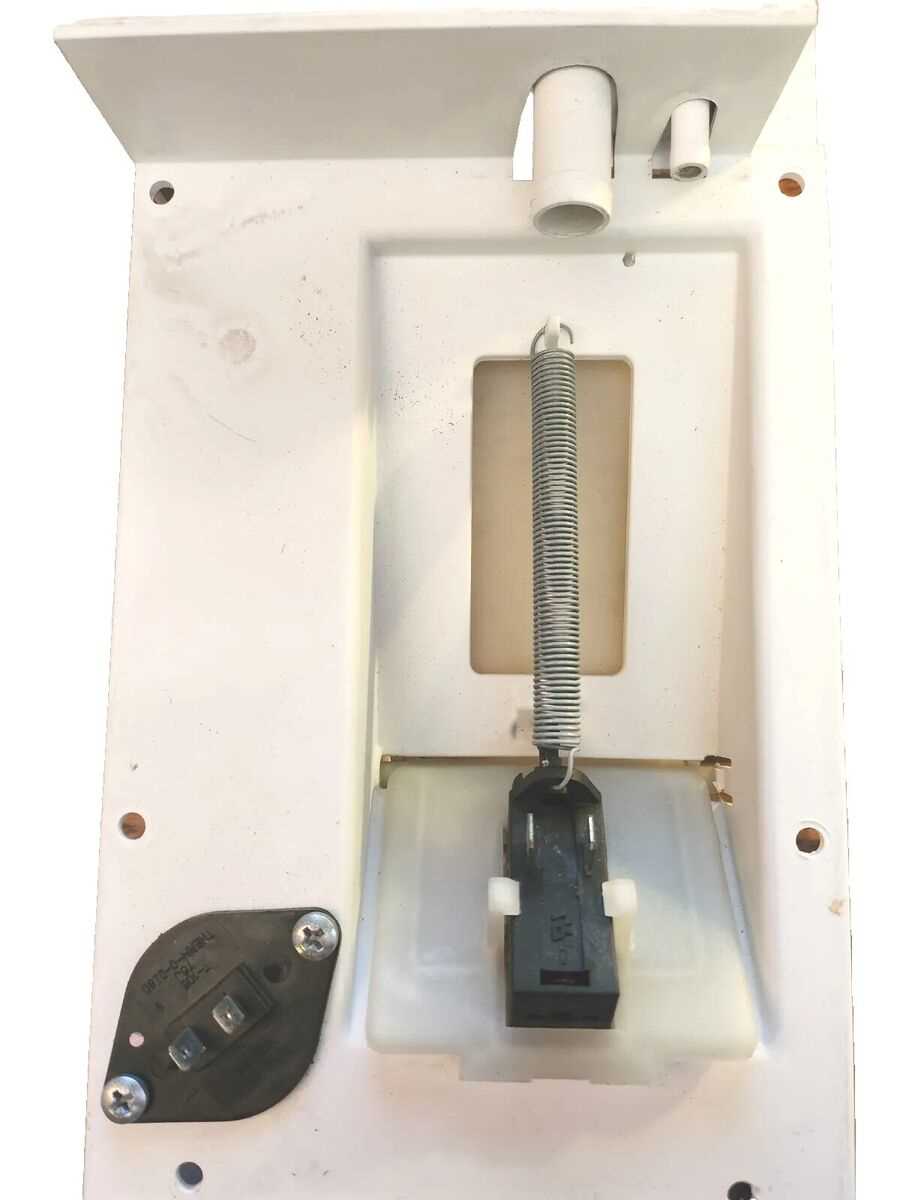

Checking and Replacing Thermostats

Thermostats play a critical role in maintaining the optimal operating temperature of your appliance. When these components malfunction, they can lead to improper heating, resulting in inefficient performance or even damage. Regular checks and timely replacements are essential to ensure the unit operates effectively and safely.

Identifying Symptoms of Malfunction

Common signs that a thermostat may be failing include inconsistent temperature regulation, the appliance not heating at all, or excessive heating that could indicate a risk of overheating. If you notice any of these issues, it is crucial to investigate further.

Steps for Checking and Replacing

To begin the inspection, disconnect the appliance from the power source for safety. Remove the access panel to locate the thermostat. Use a multimeter to test the component for continuity; if it does not show continuity, replacement is necessary. When installing a new thermostat, ensure it is compatible with your specific model. Secure it in place and reassemble the unit before restoring power.

Regular maintenance, including thermostat checks, will extend the lifespan of your appliance and enhance its efficiency. If uncertain about any steps, consulting a professional is advisable.

Repairing the Motor Assembly

The motor assembly is a crucial component responsible for driving the drum and facilitating the drying process. Addressing issues with this unit can significantly enhance the efficiency of the appliance. This section outlines essential steps and considerations for diagnosing and resolving problems related to the motor assembly.

Before starting any work, ensure that the appliance is disconnected from the power source. This step is vital for safety and prevents potential hazards during the process.

- Inspect the Motor: Begin by examining the motor for visible signs of wear or damage. Look for frayed wires, burn marks, or any unusual sounds when the unit is powered on.

- Check the Capacitor: The capacitor is essential for providing the initial boost of power to the motor. If the motor struggles to start, testing or replacing the capacitor may be necessary.

- Examine the Belt: A worn or damaged drive belt can impede motor function. Ensure that the belt is intact and properly aligned.

After identifying potential issues, proceed with the following troubleshooting steps:

- Remove the Motor: Detach the motor from its housing by loosening the screws and carefully disconnecting any wiring harnesses.

- Clean the Assembly: Accumulated lint and debris can hinder motor performance. Use a vacuum or soft brush to clear any obstructions.

- Test the Motor: Utilize a multimeter to check for continuity and verify that the motor is functioning correctly.

- Reassemble: Once repairs or replacements are completed, carefully reassemble the motor assembly, ensuring all components are securely fastened.

Finally, reconnect the power source and conduct a test run to confirm that the motor operates smoothly and efficiently. Regular maintenance can help prolong the lifespan of the motor assembly and improve overall performance.

Cleaning the Vent and Lint Filter

Proper maintenance of the ventilation system and lint filter is essential for optimal performance and safety. Accumulated lint and debris can impede airflow, causing inefficient operation and potential hazards. Regularly addressing these components ensures the appliance operates smoothly and prolongs its lifespan.

Start by removing the lint filter, typically located near the door. Gently pull it out and clear away any lint build-up. A soft brush or cloth can help remove stubborn fibers. After cleaning, rinse the filter under warm water if it’s heavily soiled. Allow it to dry completely before reinserting it.

Next, check the venting system. Disconnect the vent hose from the rear of the appliance. Inspect it for lint accumulation and clear any blockages using a vacuum or a lint brush. Ensure the venting path is straight and unobstructed, as kinks or bends can hinder airflow.

After servicing the lint filter and vent, reconnect the vent hose securely. Regular cleaning of these areas not only enhances performance but also reduces the risk of fire hazards associated with lint buildup. Schedule this maintenance at least once every six months to ensure efficiency and safety.

Preventative Maintenance Tips

Regular upkeep is essential for ensuring the longevity and optimal performance of your household appliance. Implementing simple maintenance practices can prevent unexpected breakdowns, enhance efficiency, and extend the lifespan of the equipment. This section highlights key strategies to keep your unit in top condition.

Routine Cleaning

Keeping the appliance clean is crucial. Regularly remove lint buildup from the filter and vent to improve airflow and reduce the risk of fire hazards. Additionally, periodically clean the drum and exterior surfaces to maintain hygiene and appearance.

Regular Inspections

Conducting routine inspections can help identify potential issues before they escalate. Check the hoses and connections for any signs of wear or damage. Ensure that all electrical components are functioning properly and address any irregularities immediately.

| Maintenance Task |

Frequency |

| Clean lint filter |

After each use |

| Inspect hoses |

Monthly |

| Deep clean drum |

Every 3 months |

| Check electrical components |

Every 6 months |

When to Consult a Technician

Understanding when to seek professional assistance can save both time and resources. While some issues can be addressed with basic troubleshooting, there are situations where expert intervention is necessary. Recognizing these scenarios is crucial for effective resolution and maintaining the longevity of your appliance.

Signs You Need Professional Help

Certain indicators suggest that a trained technician should be called. If you notice persistent problems despite following troubleshooting steps, it may be time to consult an expert. Here are common signs:

| Issue |

Indication |

| Unusual Noises |

Grinding, squeaking, or banging sounds may indicate internal damage. |

| Persistent Error Codes |

Repeated error messages that don’t clear after resets require professional diagnosis. |

| Heating Problems |

If the appliance fails to heat or overheat, it poses a risk of malfunction. |

| Inconsistent Performance |

Fluctuations in efficiency can signify underlying issues that need attention. |

Benefits of Consulting a Professional

Engaging a skilled technician can lead to a thorough evaluation and effective solutions. Professionals have the expertise to identify problems that may not be apparent to the average user. Additionally, they possess the tools and knowledge necessary for safe and efficient repairs, ultimately ensuring your appliance functions optimally.