This section provides essential insights into the upkeep and troubleshooting techniques for compact machinery designed for various industrial tasks. Understanding these processes can enhance the longevity and efficiency of the equipment, ensuring optimal performance in demanding environments.

By delving into detailed procedures, operators and technicians can familiarize themselves with the intricacies of the machinery. Knowledge of standard practices and common issues allows for timely interventions, ultimately reducing downtime and repair costs.

Regular maintenance is crucial for preserving functionality and safety. This guide emphasizes practical steps and considerations, empowering users to tackle challenges with confidence and expertise. Whether performing routine checks or addressing specific concerns, a proactive approach is key to achieving satisfactory results.

This section addresses frequent challenges encountered with compact machinery and offers practical solutions to enhance functionality. Understanding these common problems can lead to better maintenance and prolonged equipment lifespan.

Performance Degradation

One of the most reported issues is a decline in operational efficiency. Factors contributing to this can include wear and tear, inadequate lubrication, or improper adjustments. Regular checks and timely servicing can mitigate these effects.

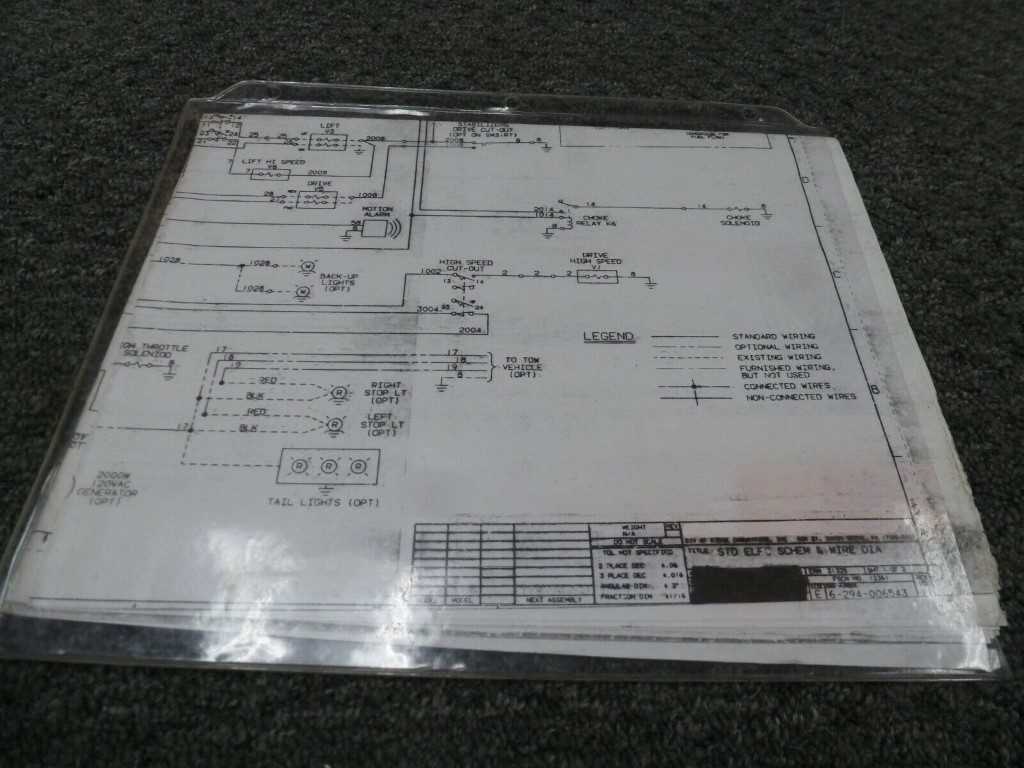

Electrical Malfunctions

Electrical issues often arise, causing disruptions in functionality. Common culprits include loose connections, blown fuses, or faulty sensors. Systematic inspections can help identify and resolve these faults promptly.

| Issue | Symptoms | Solution |

|---|---|---|

| Performance Degradation | Sluggish operation, reduced power | Regular maintenance, lubrication |

| Electrical Malfunctions | Inconsistent power, warning lights | Check connections, replace fuses |

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your machinery requires consistent care and attention. Implementing routine checks and adopting preventive measures can significantly enhance operational capabilities. This section outlines essential practices to maintain peak functionality.

Regular Inspections

Conducting frequent evaluations of your equipment is crucial. Look for signs of wear and tear, loose components, or fluid leaks. Timely identification of potential issues can prevent more extensive damage and costly repairs.

Lubrication and Fluid Levels

Maintaining proper lubrication and monitoring fluid levels are vital for optimal performance. Ensure that all moving parts are adequately lubricated to reduce friction and enhance efficiency. Regularly check and replenish fluids as needed to keep the system running smoothly.

Step-by-Step Repair Procedures

This section outlines the systematic approach to addressing common issues that may arise with heavy machinery. A clear sequence of actions will facilitate efficient troubleshooting and restoration of functionality, ensuring optimal performance.

Preparation and Safety Measures

Before commencing any maintenance tasks, it is essential to prepare the workspace and gather the necessary tools. Ensure that the area is clean and free from hazards. Always wear appropriate safety gear to protect against potential risks during the process.

Diagnostic Steps

Begin with a thorough assessment to identify the underlying problem. Utilize diagnostic tools to gather data on the equipment’s performance. This initial step will guide subsequent actions and ensure that repairs target the root cause effectively.

Essential Tools for Effective Repairs

Having the right instruments is crucial for performing maintenance tasks efficiently. A well-equipped toolkit not only enhances productivity but also ensures that jobs are completed with precision and care. By utilizing appropriate devices, individuals can tackle a variety of challenges that may arise during servicing activities.

Basic Instrumentation

Start with a selection of essential hand tools, such as wrenches, screwdrivers, and pliers. These foundational items are vital for disassembling components and making necessary adjustments. A sturdy toolbox will keep everything organized and accessible, allowing for quick retrieval when needed.

Advanced Equipment

In addition to basic tools, consider investing in specialized equipment like diagnostic devices and hydraulic jacks. These advanced tools facilitate in-depth analysis and repair processes, making it easier to identify issues and apply effective solutions. Utilizing the right combination of instruments can significantly improve the quality of maintenance work.

Safety Precautions During Maintenance

Ensuring a safe environment while conducting upkeep tasks is crucial for both personnel and equipment. By adhering to proper protocols, potential hazards can be minimized, promoting an efficient workflow and preventing accidents.

Personal Protective Equipment

Wearing appropriate gear is essential to safeguard against injuries. This includes helmets, gloves, eye protection, and steel-toed boots. Each piece of equipment plays a vital role in shielding the worker from unforeseen incidents.

Proper Tools and Equipment

Using the right tools enhances safety during service tasks. Ensure that all instruments are in good condition and suited for the job. Regular inspections of tools can prevent malfunctions and reduce risks, fostering a safer working atmosphere.

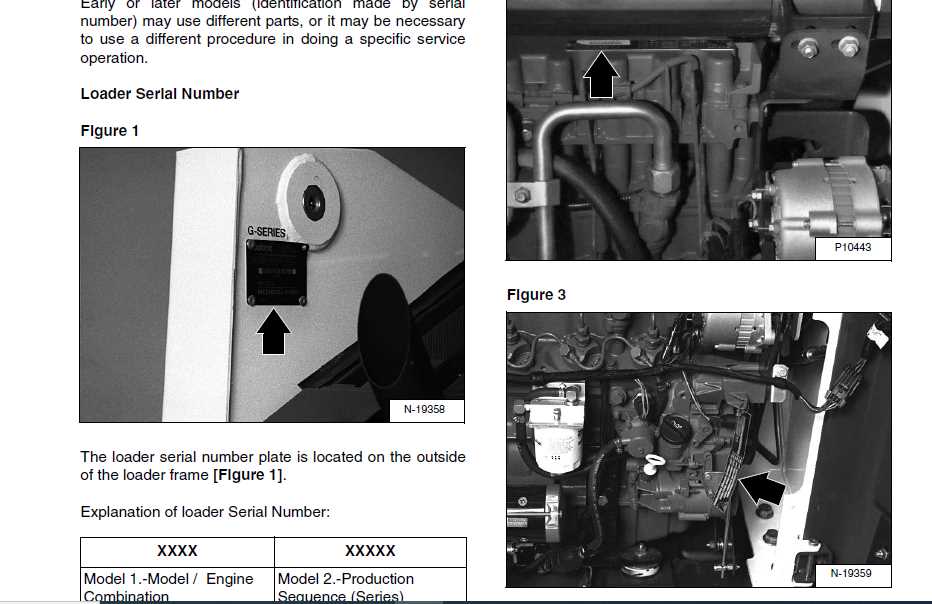

Parts Replacement and Compatibility

Ensuring the proper functioning of machinery often hinges on the correct selection and installation of components. This section emphasizes the importance of selecting compatible parts to maintain performance and longevity. Understanding the intricacies of replacement elements is essential for effective upkeep.

Identifying Suitable Components

When considering part substitutions, it is vital to assess specifications and compatibility. Each component plays a critical role in the overall operation of the equipment, and mismatches can lead to inefficiencies or damage. Always refer to manufacturer guidelines to ensure optimal choices.

Replacement Parts Overview

The following table outlines common components and their suitable alternatives, highlighting the importance of compatibility:

| Component | Original Part Number | Compatible Alternatives |

|---|---|---|

| Hydraulic Filter | 123456 | ABC123, DEF456 |

| Engine Oil Filter | 654321 | XYZ789, LMN012 |

| Drive Belt | 987654 | PQR345, STU678 |

Troubleshooting Electrical Problems

Electrical issues can significantly impact the performance and functionality of machinery. Identifying and resolving these problems requires a systematic approach to ensure efficient operation and prevent further complications.

Common Symptoms

When facing electrical malfunctions, various signs may indicate underlying issues. Inconsistent performance, flickering lights, or unresponsive controls often suggest electrical disturbances. Observing these symptoms can help pinpoint the area requiring attention.

Diagnosis Steps

Begin troubleshooting by inspecting wiring connections for signs of wear or damage. Check for loose or corroded terminals, as these can disrupt the electrical flow. Additionally, utilize a multimeter to measure voltage levels at critical points, ensuring that components are receiving adequate power.

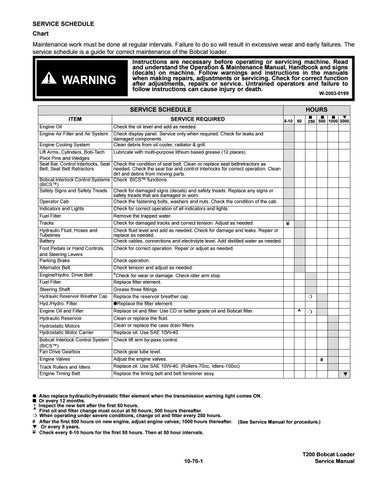

Hydraulic System Maintenance Guide

Proper upkeep of the hydraulic mechanism is crucial for ensuring optimal performance and longevity of the equipment. Regular maintenance helps in identifying potential issues before they escalate, thus minimizing downtime and repair costs. This section outlines essential practices for maintaining the hydraulic system effectively.

Routine Inspection

Conducting frequent inspections is vital for the health of the hydraulic system. Look for signs of leaks, wear, or damage. Regularly check fluid levels and quality to ensure efficient operation.

Fluid Replacement Schedule

Replacing hydraulic fluid according to the manufacturer’s recommendations is essential. Contaminated fluid can lead to system inefficiencies and component failures. Maintain a log of fluid changes to keep track of maintenance history.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect hoses and connections | Monthly | Look for cracks or wear |

| Check fluid level | Weekly | Ensure fluid is at recommended level |

| Replace hydraulic fluid | Every 500 hours | Follow manufacturer’s specifications |

| Clean filters | Every 200 hours | Replace if damaged |

Engine Diagnostics and Repairs

This section focuses on identifying issues within the power unit and the necessary steps for effective solutions. Regular assessment ensures optimal performance and longevity of the machinery.

Common Issues

- Overheating

- Unusual noises

- Reduced power output

- Increased fuel consumption

Diagnostic Steps

- Check coolant levels and quality.

- Inspect for oil leaks.

- Monitor exhaust emissions.

- Test battery and electrical connections.

Once the problems are identified, implementing timely interventions will enhance reliability and prevent further complications.

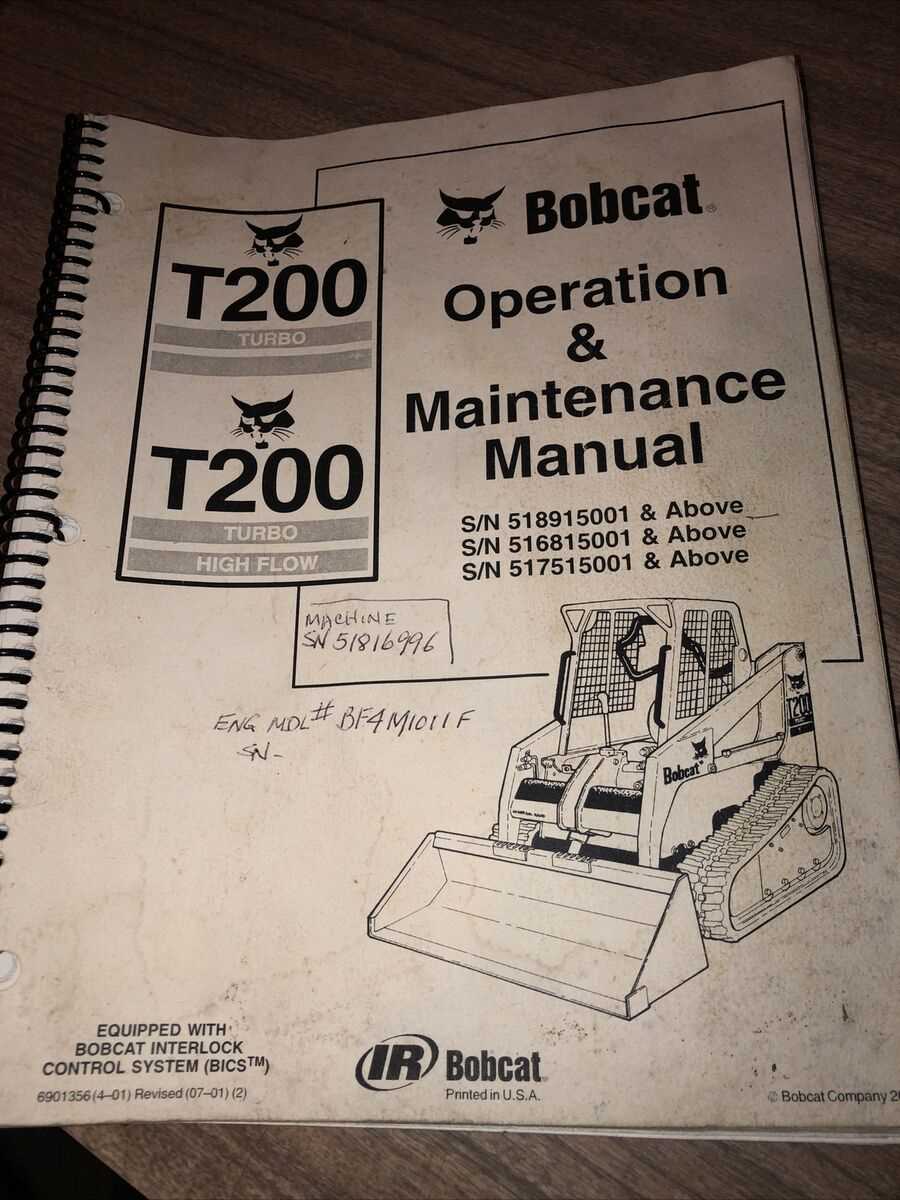

Operator Manual Insights

This section offers valuable information that aids users in maximizing the functionality of their equipment. Understanding the provided guidelines and recommendations can significantly enhance operational efficiency and safety.

Key Features to Consider

- Comprehensive safety protocols

- Operational procedures for various tasks

- Maintenance recommendations to ensure longevity

Tips for Effective Use

- Regularly consult the guidelines for optimal performance.

- Familiarize yourself with safety measures to prevent accidents.

- Follow maintenance schedules to extend the equipment’s lifespan.

Contacting Professional Repair Services

When facing challenges with heavy machinery, seeking assistance from skilled technicians can be essential. These experts possess the knowledge and tools necessary to address various issues effectively. Choosing the right service can ensure a smooth and efficient resolution to any complications.

Before reaching out, consider the following steps:

- Identify the specific problems you are encountering with your equipment.

- Research local service providers with expertise in your machinery type.

- Check online reviews and ratings to gauge the quality of their services.

Once you have gathered information, contacting a service can be straightforward:

- Prepare a list of questions regarding their experience and services offered.

- Provide detailed information about the issues you are experiencing.

- Request a quote or estimate for the work needed.

Establishing clear communication with the service team can lead to a more efficient repair process. Be sure to discuss timelines and any warranties associated with their work.