In the world of compact construction equipment, ensuring optimal performance and longevity is crucial. This section delves into essential procedures and techniques that aid operators and technicians in maintaining their machinery. By following structured guidelines, users can enhance the efficiency and reliability of their equipment.

Understanding the intricacies of various components and systems is vital for effective upkeep. This guide highlights critical aspects such as troubleshooting common issues, performing routine inspections, and executing detailed servicing tasks. Each section provides valuable insights that empower users to tackle mechanical challenges confidently.

With an emphasis on practical solutions and best practices, this resource serves as an indispensable companion for anyone involved in the operation and maintenance of heavy machinery. Whether you are a seasoned professional or a novice, mastering these techniques will ensure that your equipment remains in peak condition.

Understanding the Bobcat 643

This section delves into the functionality and features of a compact, versatile machine designed for a variety of tasks. With its robust construction and powerful engine, it serves as an essential tool for construction, landscaping, and agriculture. Its design allows for exceptional maneuverability, making it suitable for both large and tight spaces.

Key Features

Equipped with an array of capabilities, this compact loader is engineered to tackle demanding jobs efficiently. The notable aspects include its lifting capacity, ease of operation, and adaptability to various attachments.

| Feature | Description |

|---|---|

| Lifting Capacity | Can lift heavy loads, enhancing productivity on job sites. |

| Versatility | Compatible with multiple attachments for different applications. |

| Maneuverability | Designed for tight spaces, allowing operation in confined areas. |

| Durability | Built with strong materials to withstand tough working conditions. |

Applications

This machine excels in a wide range of environments, from construction sites to agricultural fields. Its ability to perform various tasks makes it a valuable asset for both professionals and hobbyists.

Common Issues with Bobcat 643

This section highlights frequent problems encountered with a specific model of compact machinery, providing insights into symptoms, causes, and potential solutions. Understanding these issues can help operators maintain optimal performance and extend the lifespan of the equipment.

Hydraulic System Troubles

The hydraulic system is crucial for the functionality of the machine. Common hydraulic issues include:

- Fluid leaks, which may originate from hoses or connections.

- Inadequate power, often due to low fluid levels or contamination.

- Unresponsive controls, potentially caused by air trapped in the system.

Engine Performance Problems

Engine-related difficulties can significantly impact overall operation. Typical symptoms include:

- Difficulty starting, which might be due to battery issues or fuel delivery problems.

- Overheating, often caused by radiator blockages or low coolant levels.

- Excessive noise, potentially indicating wear in internal components or exhaust issues.

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of your equipment requires consistent attention and care. Implementing effective maintenance practices can significantly extend the life of your machinery, minimize downtime, and enhance productivity. Below are some essential tips to keep your unit in optimal condition.

Regular Inspections

Routine checks are crucial for identifying potential issues before they escalate. Focus on the following components:

- Fluid levels: Regularly check and refill hydraulic fluid, oil, and coolant.

- Belts and hoses: Inspect for wear, cracks, or fraying.

- Filters: Change air and fuel filters according to the manufacturer’s recommendations.

Cleaning Practices

Keeping your machine clean is essential for both functionality and longevity. Consider these cleaning tips:

- Remove debris: Regularly clear dirt and debris from the engine compartment and undercarriage.

- Wash exterior: Use a pressure washer to maintain a clean exterior without damaging sensitive components.

- Inspect for rust: Regularly check for and address any signs of corrosion.

By following these maintenance strategies, you can help ensure that your machinery remains reliable and efficient for many years to come.

Essential Tools for Repairs

When undertaking maintenance or restoration tasks on machinery, having the right instruments at hand is crucial for achieving optimal results. The effectiveness and efficiency of any project can greatly depend on the selection of appropriate tools, which not only enhance performance but also ensure safety during the process.

Basic Hand Tools are indispensable for any mechanical task. Items such as wrenches, screwdrivers, and pliers form the foundation of a well-equipped workspace. These tools facilitate the disassembly and assembly of various components, allowing for thorough inspections and adjustments.

Power Tools also play a significant role in expediting repair processes. Devices such as drills and impact drivers can save considerable time and effort, making them valuable assets for both professional technicians and DIY enthusiasts. Proper usage of these tools ensures precision and reduces the risk of damage to sensitive parts.

Diagnostic Equipment is essential for identifying underlying issues. Instruments like multimeters and pressure gauges help in assessing the condition of electrical and hydraulic systems. Utilizing these tools effectively can prevent unnecessary parts replacement and extend the lifespan of the machinery.

Safety Gear should never be overlooked. Items such as gloves, goggles, and ear protection are vital for safeguarding oneself during any repair task. Prioritizing safety not only protects the individual but also promotes a more efficient working environment.

In conclusion, equipping oneself with a comprehensive set of tools tailored for specific tasks enhances the overall repair experience. By combining basic hand tools, power equipment, diagnostic instruments, and safety gear, one can approach maintenance with confidence and skill.

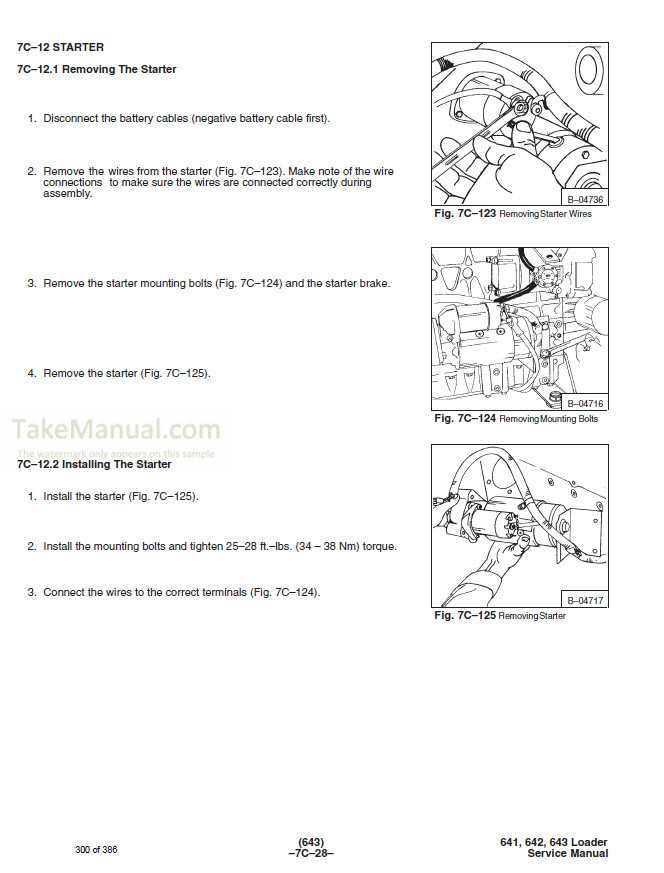

Step-by-Step Repair Procedures

This section provides detailed guidelines for effectively addressing various mechanical issues. Following a systematic approach ensures that each task is handled efficiently, minimizing downtime and enhancing performance.

1. Preparation: Before commencing any work, gather all necessary tools and components. Ensure you have a clean workspace to facilitate the process.

2. Diagnostics: Identify the specific problem by conducting a thorough assessment. Check for visible signs of wear or damage, and utilize diagnostic tools if needed.

3. Disassembly: Carefully dismantle the components that require attention. Keep track of all parts and fasteners to avoid confusion during reassembly.

4. Inspection: Examine each part for defects or irregularities. Look for cracks, corrosion, or other issues that may need addressing.

5. Replacement: If any components are found to be faulty, replace them with high-quality alternatives. Ensure compatibility with the existing system.

6. Reassembly: Reassemble the unit meticulously, following the reverse order of disassembly. Double-check that all parts are secured and properly aligned.

7. Testing: Once reassembled, conduct a series of tests to confirm that the system operates as expected. Monitor for any unusual noises or performance issues.

8. Maintenance: After successful repairs, establish a regular maintenance routine to prevent future issues. This can include lubrication, cleaning, and periodic inspections.

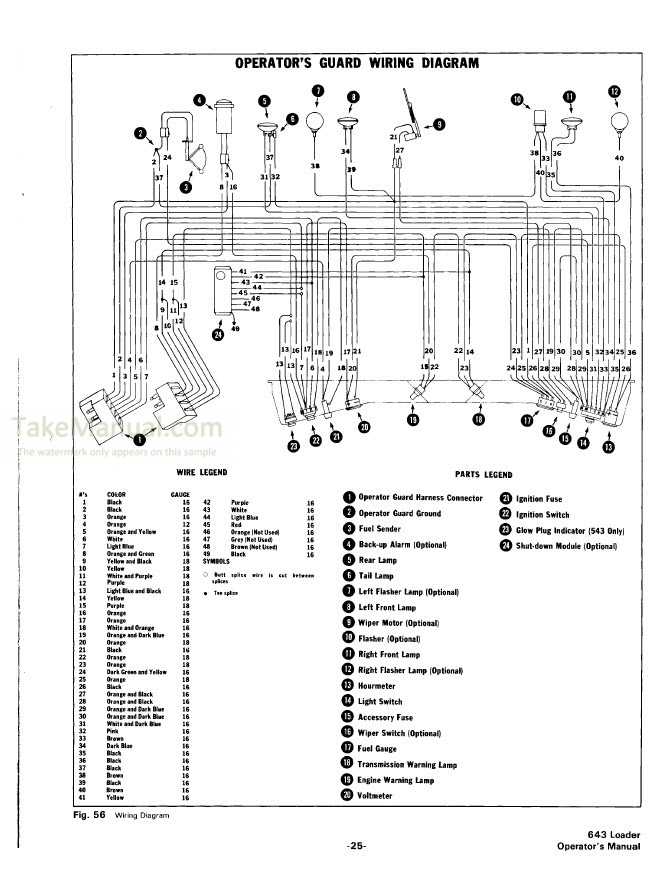

Electrical System Troubleshooting

The electrical system of any machinery is crucial for its optimal performance. Diagnosing issues within this system involves a systematic approach to identify faults and ensure all components function correctly. By following specific steps, operators can efficiently resolve electrical problems, enhancing the overall reliability of the equipment.

Common symptoms of electrical malfunctions include unexpected shutdowns, failure to start, and inconsistent operation of electrical components. Identifying the root cause requires checking various elements such as batteries, wiring, and connectors. The following table summarizes typical issues and recommended actions to address them.

| Issue | Symptoms | Recommended Action |

|---|---|---|

| Dead Battery | Machine won’t start | Charge or replace battery |

| Faulty Wiring | Intermittent electrical failures | Inspect and repair damaged wires |

| Loose Connections | Components not functioning | Tighten or replace connectors |

| Blown Fuses | Power loss in specific areas | Replace fuses and check for overloads |

| Defective Switches | Inconsistent operation | Test and replace faulty switches |

By addressing these common issues, operators can maintain the electrical integrity of their machinery, ensuring efficient and reliable operation. Regular inspections and prompt attention to electrical components are essential for preventing further complications.

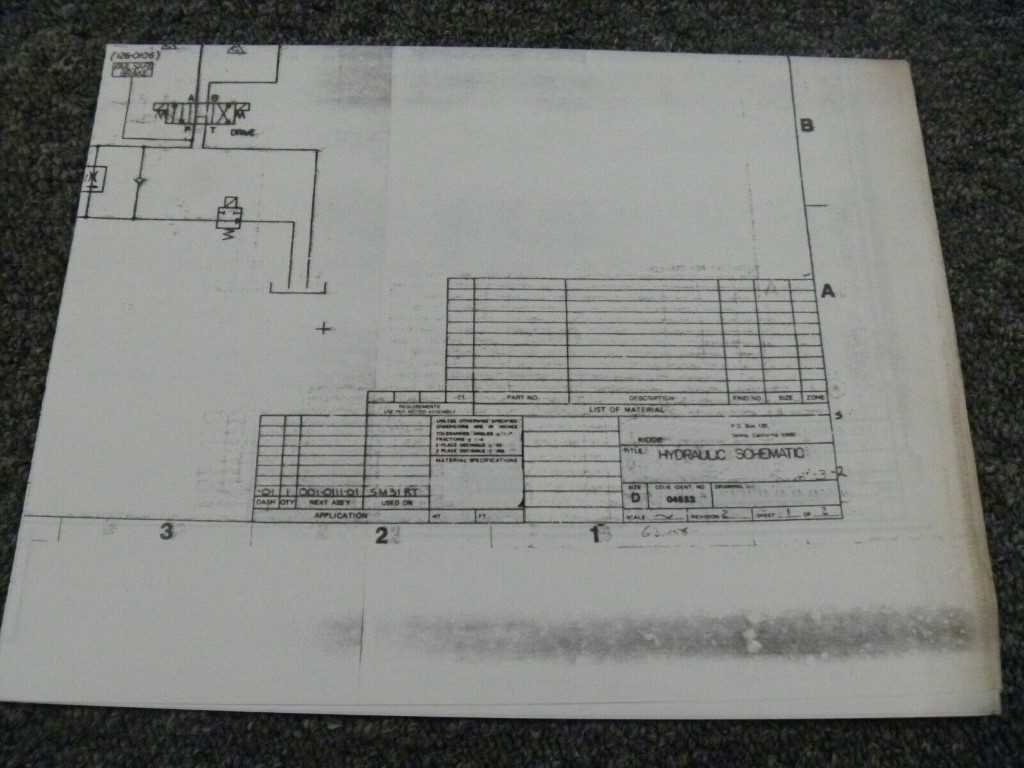

Hydraulic Components Overview

The hydraulic system is a vital aspect of many machines, facilitating efficient movement and operation through fluid dynamics. Understanding the various elements that comprise this system is essential for optimal functionality and maintenance. Each component plays a critical role in ensuring that the entire mechanism operates smoothly and effectively.

Main Hydraulic Components

This section outlines the primary elements involved in hydraulic systems, highlighting their functions and importance in overall performance.

| Component | Function |

|---|---|

| Hydraulic Pump | Converts mechanical energy into hydraulic energy, creating fluid flow. |

| Hydraulic Cylinder | Transforms hydraulic energy into linear motion, enabling lifting and pushing actions. |

| Hydraulic Motor | Converts hydraulic energy into rotational motion for driving various attachments. |

| Control Valves | Regulate fluid flow and direction, ensuring proper operation of the system. |

| Hydraulic Fluid | Transmits power throughout the system and lubricates components. |

Importance of Regular Maintenance

Finding Replacement Parts Easily

Locating the right components for your equipment can often feel daunting, but with the right approach, it becomes a straightforward process. This section will guide you through effective strategies to streamline your search and ensure you obtain high-quality parts that meet your needs.

Utilizing Online Resources

The internet offers a wealth of resources for sourcing components. Numerous websites specialize in machinery parts, providing detailed catalogs and search functionalities. By entering the specific model or part number, you can quickly narrow down your options. Always check for customer reviews and ratings to ensure the reliability of the supplier.

Networking with Local Dealers

Establishing connections with local distributors or dealers can be incredibly beneficial. These professionals often have access to a wide range of stock and can provide personalized assistance in finding the right parts. Additionally, they may offer insights into compatibility and performance, enhancing your overall experience.

By leveraging these strategies, you can simplify the process of finding replacement components and ensure that your machinery remains in top condition.

Safety Precautions During Repairs

Ensuring safety during maintenance activities is crucial to prevent accidents and injuries. Proper awareness of potential hazards and adherence to recommended protocols can significantly reduce risks associated with equipment handling. Following safety guidelines not only protects the individual performing the work but also preserves the integrity of the machinery involved.

Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and hard hats to shield against debris and hazardous substances. It’s vital to inspect your gear regularly to confirm it remains in good condition.

Before commencing any work, disconnect power sources to avoid unexpected machinery activation. Ensure that all moving parts are securely immobilized, and perform checks to confirm that tools are in proper working order.

Maintain a clean and organized workspace to reduce the risk of slips, trips, and falls. Keep tools and materials neatly stored, and remove any clutter that could obstruct movement or cause distractions during tasks.

Be aware of your surroundings and communicate clearly with anyone nearby. Establish a safety zone if necessary, ensuring that only authorized personnel are present during the maintenance process. Regular safety briefings can foster a culture of vigilance among team members.

In case of an emergency, know the location of first aid kits and fire extinguishers. Familiarize yourself with emergency procedures and ensure that all personnel understand their roles in such situations.

By prioritizing safety and adhering to established protocols, individuals can effectively minimize risks and ensure a smoother and more secure maintenance experience.

Resources for Further Assistance

When facing challenges with machinery maintenance, having access to reliable information and support is crucial. Numerous resources are available to help users troubleshoot issues and enhance their understanding of equipment operations. This section outlines various options for obtaining additional guidance and assistance.

Online Forums and Communities

Engaging with online platforms can provide valuable insights and shared experiences from fellow users. Consider the following:

- Dedicated machinery forums where enthusiasts discuss common problems and solutions.

- Social media groups focused on equipment care and technical advice.

- Specialized subreddits that cover maintenance topics and offer peer support.

Official Websites and Customer Support

Manufacturers often offer resources that can enhance your knowledge and help with specific inquiries:

- Access to technical specifications and troubleshooting guides directly from the manufacturer’s site.

- Customer service hotlines where experts can provide personalized assistance.

- Downloadable content, including diagrams and operational tips, that can aid in effective equipment management.