In the realm of outdoor power equipment, ensuring optimal functionality is paramount for achieving the best performance. Effective upkeep not only prolongs the lifespan of machinery but also enhances operational efficiency. Familiarity with essential procedures can empower users to address common issues, reducing downtime and enhancing productivity.

For those looking to enhance their skills in managing snow-clearing machines, a comprehensive guide to diagnostics and fixes can be invaluable. It offers step-by-step instructions that facilitate understanding of the intricacies involved in machinery operation. By following these guidelines, operators can confidently tackle various challenges that may arise during use.

Moreover, having access to well-structured resources equips individuals with the knowledge needed to perform routine checks and necessary adjustments. This proactive approach not only safeguards the equipment from potential malfunctions but also ensures a smoother experience in adverse weather conditions. Engaging with practical advice can transform the maintenance process into a straightforward task, ultimately leading to a more enjoyable and effective operation.

Ariens ST724 Overview

This section provides a comprehensive look at a specific model designed for snow removal tasks. It highlights its features, performance, and overall utility, making it an ideal choice for both residential and commercial use.

Equipped with a powerful engine, this machine ensures efficient operation even in harsh winter conditions. Key attributes include:

- Robust construction for durability

- User-friendly controls for easy maneuverability

- Multiple speed settings to adapt to various snow depths

- Wide clearing path to cover large areas quickly

Additionally, the design emphasizes ease of maintenance, allowing users to keep the unit in optimal working condition without extensive effort. Features such as:

- Accessible components for quick service

- Reliable starting system for convenience

- Adjustable skid shoes for tailored performance on different surfaces

Overall, this machine stands out as a reliable solution for tackling snow accumulation, ensuring that users can manage winter weather effectively.

Common Issues with Ariens ST724

When operating a snow-clearing machine, various challenges may arise that can hinder its performance. Understanding these common problems can help users maintain efficiency and prolong the life of their equipment. Below are some frequent issues encountered by users of this particular model.

| Issue | Description | Potential Solutions |

|---|---|---|

| Engine Won’t Start | The engine may fail to start due to fuel issues or battery problems. | Check fuel level and quality; inspect the battery for charge and connections. |

| Reduced Power | Users may experience a lack of power during operation. | Inspect the air filter and spark plug; ensure that they are clean and functioning. |

| Auger Jam | The auger can become obstructed, preventing it from rotating properly. | Clear any debris or ice; check for damaged components. |

| Uneven Snow Discharge | Snow may not be thrown evenly, affecting clearing efficiency. | Adjust the chute angle; inspect for clogs or blockages. |

| Strange Noises | Unusual sounds may indicate mechanical issues. | Examine belts and gears for wear; lubricate moving parts as necessary. |

Tools Needed for Repairs

When tackling maintenance tasks, having the right instruments at your disposal is crucial for achieving successful outcomes. A well-equipped toolkit not only streamlines the process but also ensures that each task can be performed safely and efficiently. Whether you are fixing mechanical components or performing routine checks, certain tools will enhance your ability to address various issues effectively.

Essential items include wrenches and screwdrivers of various sizes, which are fundamental for loosening and tightening fasteners. Pliers are also invaluable for gripping, twisting, or cutting wires. Additionally, a torque wrench is beneficial for applying the correct amount of force to bolts, preventing over-tightening that can lead to damage.

Safety gear, such as gloves and goggles, should not be overlooked, as they protect you from potential hazards during the work. A quality multimeter is essential for diagnosing electrical problems, while a jack or lifting device allows for easier access to hard-to-reach areas. Having these tools on hand will not only facilitate smoother operations but also improve the overall quality of your maintenance tasks.

Step-by-Step Repair Guide

This section provides a comprehensive approach to fixing common issues with your snow removal equipment. By following these detailed instructions, you can effectively address problems and ensure optimal performance.

Begin by gathering the necessary tools and parts. A well-organized workspace will facilitate the process. Ensure that you have safety gear, including gloves and goggles, to protect yourself while working.

Next, identify the specific issue you are facing. Common problems may include difficulty starting, unusual noises, or ineffective snow clearing. Once the problem is pinpointed, consult the troubleshooting section for guidance on potential causes and solutions.

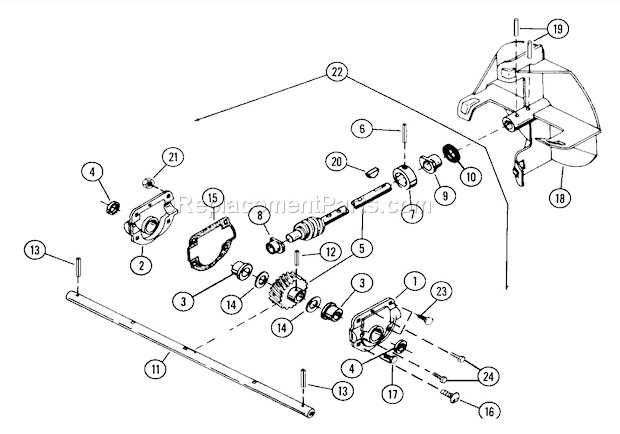

After diagnosing the issue, disassemble the relevant components carefully. Take note of how parts fit together to ease reassembly. Clean each part thoroughly to remove any debris or buildup that may hinder performance.

Replace any worn or damaged parts as necessary. Ensure that new components are compatible with your machine. Proper installation is crucial for functionality, so refer to diagrams or guides to assist with positioning.

Once reassembly is complete, conduct a thorough inspection to confirm that everything is securely attached. Finally, test the equipment in a controlled environment to verify that it operates smoothly and effectively.

Following these steps will help you maintain your machine in peak condition, ensuring reliable performance throughout the winter season.

Maintenance Tips for Longevity

Ensuring the prolonged functionality of your equipment requires regular attention and care. Adopting a proactive maintenance routine not only enhances performance but also significantly extends the lifespan of your machinery. By following a few essential practices, you can keep your unit running smoothly and efficiently for many seasons.

Regular Inspections

Conducting routine checks is crucial for identifying potential issues before they escalate. Look for signs of wear and tear, such as frayed belts or loose components. Cleanliness also plays a vital role; keep the machine free of debris and buildup to avoid unnecessary strain on its parts.

Fluid Changes and Lubrication

Maintaining proper fluid levels is essential for optimal performance. Regularly check and change oils or fluids as specified by the manufacturer. Additionally, lubricating moving parts reduces friction and prevents overheating, thus contributing to smoother operation. Implementing these practices can significantly enhance the reliability and longevity of your equipment.

Safety Precautions When Repairing

Ensuring safety during maintenance tasks is crucial for both the technician and the equipment involved. Adhering to established guidelines minimizes the risk of accidents and enhances overall efficiency. A well-informed approach not only protects individuals but also prolongs the lifespan of the machinery being serviced.

Before initiating any work, it’s essential to gather the necessary personal protective equipment (PPE). This includes items such as gloves, goggles, and appropriate footwear. Additionally, a clean and organized workspace significantly reduces hazards.

| Safety Measure | Description |

|---|---|

| Disconnect Power Source | Always unplug the device or disconnect the battery to prevent accidental activation. |

| Use Proper Tools | Utilize tools specifically designed for the task to avoid injuries and equipment damage. |

| Maintain Ventilation | Ensure adequate airflow in the workspace to prevent the buildup of harmful fumes. |

| Follow Manufacturer Guidelines | Refer to official instructions to understand the specific requirements for maintenance. |

| Be Aware of Surroundings | Keep the work area clear of clutter and be mindful of others nearby to avoid accidents. |

Implementing these precautions is vital for creating a safe environment during maintenance tasks. Prioritizing safety not only protects individuals but also ensures the reliability and functionality of the machinery. Always remain vigilant and proactive in identifying potential risks.

Finding Replacement Parts

Locating the right components for your equipment can significantly enhance its performance and longevity. Whether you are looking for specific pieces or general accessories, knowing where to search is crucial.

Here are some effective strategies to find the necessary parts:

- Manufacturer’s Website: Start with the official site, as it often offers a comprehensive catalog of available components.

- Authorized Dealers: Contact local dealers who specialize in your equipment brand. They can provide genuine parts and valuable advice.

- Online Marketplaces: Websites such as eBay and Amazon frequently have a wide range of parts from various sellers, including both new and used options.

- Forums and Community Groups: Engage with online communities. Enthusiasts often share sources for hard-to-find items.

- Salvage Yards: Check out local salvage yards that may have disassembled units, providing a cost-effective option for used parts.

Additionally, it’s wise to compare prices and read reviews before making a purchase to ensure you are getting a reliable component. Being patient and thorough in your search will yield the best results.

Diagnosing Engine Problems

Identifying issues with an engine requires a systematic approach to pinpoint the source of the malfunction. By following a structured process, you can effectively determine the underlying problems that may be affecting performance or functionality. It is essential to consider various factors such as unusual noises, starting difficulties, or power loss during your diagnosis.

Start by conducting a visual inspection. Check for any obvious signs of damage, loose connections, or leaks. Pay close attention to the fuel system, electrical components, and the condition of belts and hoses. Identifying external problems can often lead to a quicker resolution.

Next, observe the engine behavior. Note any irregularities during operation, such as misfiring, stalling, or reduced power output. These symptoms can provide valuable clues about what might be wrong. For instance, if the engine struggles to start, it may indicate issues with the ignition system or fuel delivery.

Utilize diagnostic tools when available. Equipment like multimeters or compression testers can assist in evaluating electrical systems or the integrity of the combustion chamber. Analyzing error codes from the engine’s control unit can also reveal specific faults, allowing for targeted troubleshooting.

Lastly, consult reliable sources for guidance on common issues associated with similar engines. User forums, technical guides, or expert advice can enhance your understanding and provide insights into potential fixes. By combining careful observation with technical knowledge, you can effectively diagnose and address engine problems.

Winter Preparation and Care

Preparing your snow removal equipment for the colder months is essential to ensure optimal performance and longevity. Proper maintenance and attention to detail can make all the difference when facing harsh winter conditions. This section covers key steps to get your machine ready for snow clearing and how to keep it in excellent condition throughout the season.

Essential Maintenance Steps

Prior to the first snowfall, it is crucial to perform a series of maintenance checks. These include inspecting the engine, belts, and augers, as well as ensuring that all fluids are at appropriate levels. A thorough cleaning can also prevent rust and damage, allowing for smoother operation.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Before season | Replace with fresh oil to ensure engine efficiency. |

| Inspect Belts | Monthly | Check for wear and tear; replace if necessary. |

| Clean Fuel System | Before season | Remove impurities to prevent engine issues. |

| Test Battery | Before season | Ensure battery holds charge for reliable starts. |

Ongoing Care During Winter

Once the snow season is underway, regular checks will help maintain performance. It’s important to monitor for any unusual sounds or changes in operation. Additionally, storing equipment properly when not in use can help protect it from the elements and prolong its life.

Customer Support Resources

Access to effective assistance is crucial for ensuring optimal performance and longevity of your equipment. This section outlines various avenues through which users can obtain guidance and support, enhancing their overall experience.

Contact Options

There are several ways to reach out for help. Users can choose from phone support, online chat, or email communication to get the necessary information.

| Contact Method | Description | Availability |

|---|---|---|

| Phone Support | Direct conversation with a representative for immediate assistance. | Mon-Fri, 8 AM – 6 PM EST |

| Online Chat | Real-time messaging with a support agent for quick queries. | Mon-Sun, 9 AM – 9 PM EST |

| Email Support | Detailed assistance via email, suitable for non-urgent questions. | 24/7 |

Online Resources

In addition to direct support, users can access a wealth of online resources. These include FAQs, troubleshooting guides, and community forums where they can share experiences and solutions.