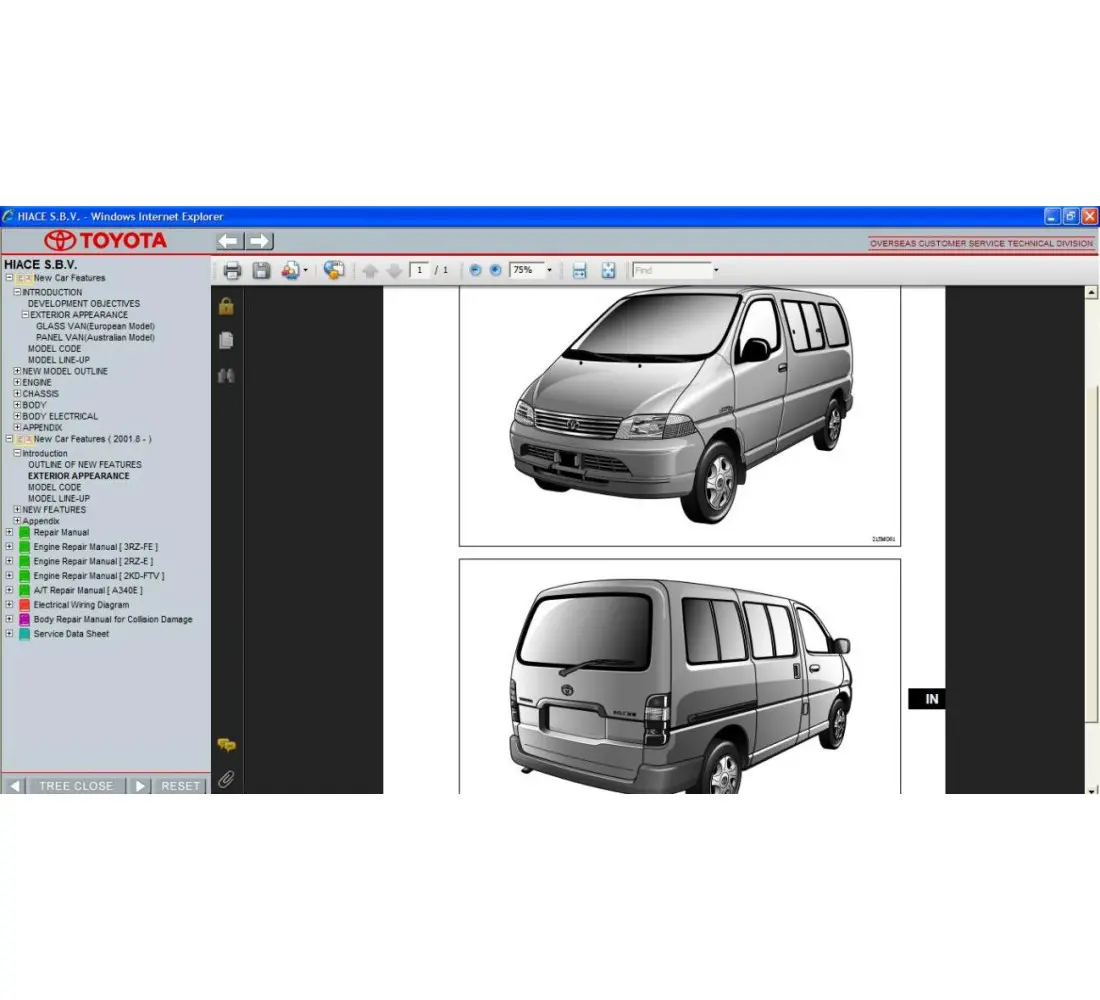

In the world of automotive maintenance, having a comprehensive guide is crucial for ensuring optimal performance and longevity of your vehicle. Such a resource serves as a valuable companion for both novices and seasoned professionals, providing step-by-step instructions, troubleshooting techniques, and best practices.

Whether you’re aiming to enhance your mechanical skills or seeking to solve specific issues, this guide offers an array of detailed insights. From routine inspections to intricate component replacements, every aspect is meticulously covered to empower you in your repair journey.

Furthermore, understanding the intricacies of engine systems can significantly impact your approach to automotive care. Emphasizing the importance of proper techniques and safety measures, this resource ensures that you’re well-equipped to tackle any challenge that may arise under the hood.

Understanding the 2RZ Engine Basics

The engine in question is a robust power unit known for its reliability and efficiency. Designed for versatility, it serves various applications, providing a solid foundation for both performance and durability. Familiarizing oneself with its core components and functionality can significantly enhance the understanding of how this engine operates under different conditions.

Fundamental Components: At the heart of this power unit lies a well-engineered block, featuring a specific number of cylinders arranged to optimize performance. Each cylinder plays a critical role in the combustion process, ensuring that energy is generated effectively. Key components such as pistons, crankshafts, and camshafts work in unison to convert fuel into mechanical energy.

Operational Principles: This engine utilizes a four-stroke cycle, which includes intake, compression, power, and exhaust strokes. Each phase is essential for maintaining the overall efficiency of the unit. During the intake phase, air and fuel mix, followed by compression, where the mixture is compressed to enhance combustion. The power stroke then generates the force needed for movement, and finally, the exhaust phase expels the remaining gases.

Maintenance Considerations: Regular maintenance is vital to ensure optimal performance and longevity. Attention to oil levels, cooling systems, and fuel quality can prevent common issues and prolong the lifespan of the engine. Understanding the intricacies of these aspects allows for better troubleshooting and care.

In summary, grasping the essential elements and operational mechanisms of this engine equips users with the knowledge needed to optimize performance and address potential challenges effectively.

Common Issues with the 2RZ Engine

Engines of this series are known for their reliability, yet they are not without flaws. Over time, certain problems may arise, affecting performance and efficiency. Understanding these common issues can help owners identify potential concerns early and take appropriate action to maintain their vehicles in optimal condition.

Overheating Problems

One of the prevalent challenges faced by these power units is overheating. This can result from a variety of factors, including a malfunctioning thermostat, a leaking radiator, or insufficient coolant levels. Regular checks on the cooling system are essential to prevent severe engine damage.

Oil Leaks

Another frequent issue involves oil leaks, which can occur due to worn gaskets or seals. If left unaddressed, these leaks may lead to low oil levels, ultimately compromising engine lubrication and causing increased wear on internal components. Routine inspections can help detect and resolve these leaks promptly.

Essential Tools for Engine Repair

When it comes to maintaining and restoring vehicle performance, having the right equipment is crucial. A well-equipped workspace not only enhances efficiency but also ensures safety while working on complex machinery. The following are fundamental instruments that every enthusiast and professional should consider in their toolkit.

Wrenches are indispensable for loosening and tightening fasteners. A set of both standard and metric sizes allows for versatility in handling various components. Torque wrenches are particularly important, as they ensure that bolts are tightened to the manufacturer’s specifications, preventing potential damage.

Sockets complement wrenches and enable access to hard-to-reach areas. A comprehensive socket set with an extension bar can make a significant difference in efficiency. Additionally, incorporating ratchet handles speeds up the process of fastening and loosening components.

Diagnostic Tools are essential for identifying issues within the engine. OBD-II scanners can read trouble codes, providing insight into the underlying problems, while compression testers assess the health of the engine cylinders.

Hand Tools, such as pliers, screwdrivers, and hammers, are fundamental for various tasks, from removing parts to making precise adjustments. A sturdy mechanic’s creeper can also enhance comfort and accessibility while working underneath the vehicle.

Incorporating these basic instruments into your setup will significantly improve your capability to tackle engine work effectively. By ensuring you have the right tools, you lay the foundation for successful maintenance and enhancement of your vehicle’s performance.

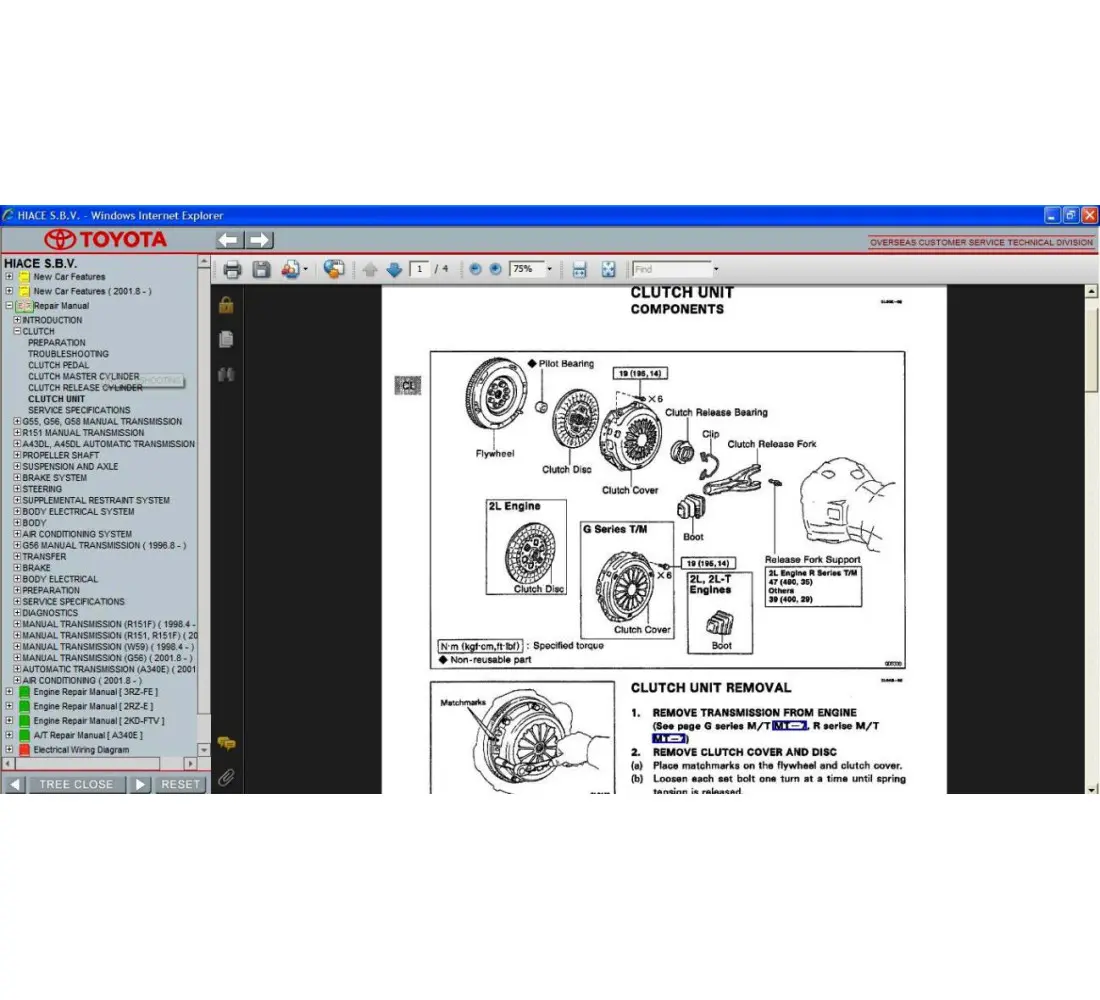

Step-by-Step Repair Procedures

This section outlines a structured approach to addressing common issues encountered in engine maintenance. By following a systematic process, you can effectively diagnose problems and implement solutions, ensuring optimal performance and longevity of your vehicle.

Diagnosis and Preparation

The first stage involves identifying the symptoms and gathering necessary tools. Start by conducting a thorough visual inspection, checking for leaks, unusual noises, or any other irregularities. Once the issues are noted, prepare your workspace and ensure you have all required equipment ready for the task ahead.

Implementation of Solutions

After diagnosing the issues, proceed with the corrective actions. Follow the specified procedures for disassembly and reassembly carefully. During this phase, pay attention to component specifications and torque settings. Always ensure that new parts are compatible and adhere to the manufacturer’s guidelines for optimal results.

By meticulously executing each step, you can achieve reliable outcomes, enhancing the overall functionality of your engine.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your vehicle requires consistent care and attention. Implementing a routine maintenance schedule not only enhances efficiency but also extends the lifespan of various components. Below are essential practices to keep in mind.

- Regular Inspections: Schedule periodic checks to identify wear and tear early. This includes examining belts, hoses, and fluid levels.

- Fluid Changes: Change engine oil, coolant, and transmission fluid at recommended intervals to prevent buildup and ensure smooth operation.

- Tire Care: Monitor tire pressure and tread depth. Rotate tires regularly to promote even wear and extend their life.

- Battery Maintenance: Keep terminals clean and check connections. Test battery health annually to avoid unexpected failures.

- Brake System Check: Inspect brake pads and discs regularly. Address any unusual sounds or decreased responsiveness promptly.

By following these practices, you can significantly improve your vehicle’s reliability and performance over time. Consistent attention to maintenance is key to enjoying a smooth and trouble-free driving experience.

Diagnosis Techniques for Engine Problems

Identifying issues within an engine requires a systematic approach that combines observation, testing, and analysis. By employing various strategies, mechanics can accurately pinpoint the source of malfunctions, leading to efficient troubleshooting and restoration of performance.

Common Symptoms to Observe

Engine problems often manifest through distinct signs. Recognizing these early can significantly aid in diagnosis:

- Unusual noises (knocking, grinding, etc.)

- Inconsistent power delivery

- Excessive smoke from the exhaust

- Unexplained fluid leaks

- Engine warning lights on the dashboard

Diagnostic Tools and Techniques

Utilizing the right tools can streamline the diagnosis process. Here are some essential techniques:

- OBD-II Scanner: Connect this device to retrieve error codes that provide insight into engine performance issues.

- Visual Inspection: Conduct a thorough check of components for wear, damage, or loose connections.

- Compression Testing: Assess the pressure within the cylinders to determine their health and efficiency.

- Fuel Pressure Testing: Measure the fuel system pressure to identify potential delivery problems.

- Smoke Test: Use smoke to detect leaks in the intake system that could affect performance.

By systematically applying these observation techniques and utilizing specialized tools, mechanics can efficiently diagnose and address engine issues, ensuring optimal functionality and longevity.

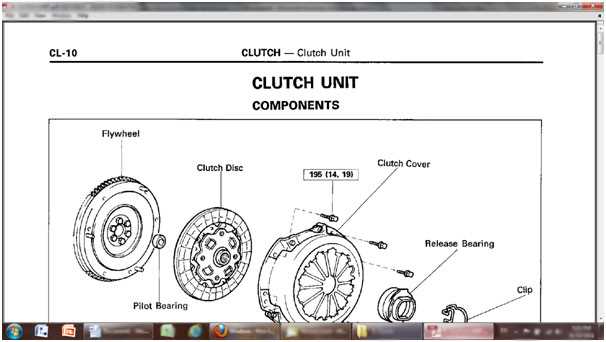

Replacing Parts: A Guide

When it comes to maintaining and enhancing the performance of your vehicle, understanding how to effectively substitute components is crucial. This section provides an overview of the essential steps and considerations to ensure a successful transition, promoting both efficiency and longevity.

Essential Tools and Materials

Before beginning the substitution process, gathering the appropriate tools and materials is vital. This preparation not only facilitates a smoother operation but also minimizes the risk of errors. Here’s a list of common tools and materials you may need:

| Tool/Material | Purpose |

|---|---|

| Wrench Set | To loosen and tighten bolts |

| Screwdrivers | For removing screws |

| Pliers | To grip and pull components |

| Replacement Parts | New components for substitution |

| Grease | To lubricate moving parts |

Step-by-Step Process

Following a systematic approach can greatly enhance the likelihood of a successful replacement. Here are the fundamental steps to consider:

- Identify the component that requires substitution.

- Gather all necessary tools and new parts.

- Ensure the vehicle is on a stable surface and turned off.

- Carefully remove the old component, taking note of any connections.

- Install the new part, ensuring all connections are secure.

- Test the installation by running the vehicle to check functionality.

By adhering to these guidelines, you can confidently replace various components, contributing to the overall performance and reliability of your vehicle.

Upgrades to Enhance Performance

Improving vehicle efficiency and power is a pursuit for many enthusiasts. By implementing various modifications, drivers can unlock their automobile’s potential, leading to a more responsive and exhilarating driving experience. This section explores essential enhancements that can elevate performance levels significantly.

Engine Modifications

One of the most impactful ways to boost performance is through engine upgrades. Components such as high-flow air filters and performance exhaust systems allow for better airflow, enhancing combustion efficiency. Additionally, tuning the engine’s management system can optimize fuel delivery and ignition timing, resulting in noticeable gains in horsepower and torque.

Suspension and Handling Improvements

To complement increased power, enhancing suspension and handling is crucial. Upgrading to sport shocks and coilovers can improve stability and cornering capabilities, making the vehicle more agile on the road. Furthermore, performance tires designed for grip and responsiveness can significantly affect traction and overall driving dynamics, ensuring that power is effectively translated to the pavement.

Resources for Further Learning

Expanding your knowledge in automotive maintenance can greatly enhance your skills and confidence. Numerous resources are available to help you deepen your understanding and effectively tackle various tasks. Whether you are looking for visual guides, comprehensive literature, or community support, a wealth of information is at your fingertips.

Online Platforms

Many websites and forums offer a plethora of articles, videos, and discussions that cater to both beginners and experienced enthusiasts. These platforms often feature step-by-step guides, troubleshooting tips, and user-generated content that can significantly aid your learning journey.

Books and Publications

Investing in well-reviewed books can provide detailed insights into specific topics, techniques, and industry best practices. Printed materials often offer structured information and can serve as valuable references for hands-on projects.

| Resource Type | Examples | Notes |

|---|---|---|

| Online Platforms | YouTube, Forums | Visual and interactive content |

| Books | Textbooks, Guides | In-depth knowledge |

| Workshops | Local Classes | Hands-on experience |

| Community Groups | Clubs, Online Groups | Networking and support |

Importance of Following Repair Manuals

Adhering to comprehensive guides during maintenance tasks is crucial for ensuring optimal performance and longevity of machinery. These resources provide essential instructions, troubleshooting tips, and detailed procedures that help technicians navigate complex processes efficiently.

Utilizing these structured documents not only minimizes the risk of errors but also enhances safety by outlining necessary precautions. Proper guidance aids in identifying specific components and their functions, allowing for accurate assessments and effective solutions.

Moreover, following established protocols fosters consistency in service, which is vital for maintaining the integrity of equipment. This practice also supports knowledge transfer among technicians, as clear documentation aids in training new personnel and preserving best practices.

Ultimately, leveraging these essential resources leads to improved reliability, reduces downtime, and contributes to cost-effectiveness in maintenance operations. Commitment to following these directives ensures that both the machinery and the operators can perform at their best.