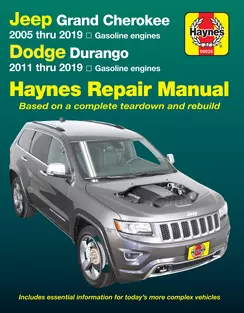

Maintaining high-performance engines is crucial for ensuring optimal functionality and longevity. Understanding the intricacies of these power units can significantly enhance driving experiences and prevent potential issues down the line. This section aims to provide detailed insights and practical knowledge necessary for anyone looking to delve into engine care and troubleshooting.

From routine checks to advanced diagnostics, this guide encompasses various aspects of engine upkeep. Each component plays a vital role in the overall performance, and knowing how to properly service and address common problems is essential. Whether you are a seasoned mechanic or a passionate car enthusiast, the information provided here will serve as a valuable resource.

Moreover, engaging with the nuances of engine technology can empower users to make informed decisions regarding maintenance and upgrades. By familiarizing yourself with essential techniques and strategies, you can ensure that your engine not only performs at its best but also remains reliable for years to come. Embrace the opportunity to expand your knowledge and enhance your vehicle’s performance through effective maintenance practices.

Understanding the 5.7 HEMI Engine

This section aims to provide a comprehensive overview of a specific engine design known for its performance and efficiency. Characterized by its unique combustion chamber shape, this powertrain has become a popular choice among automotive enthusiasts and professionals alike. Its engineering features facilitate a balance of power and fuel economy, making it suitable for a variety of vehicles.

Key Features

The engine’s architecture includes a series of innovative components that contribute to its remarkable capabilities. For instance, the configuration allows for optimized airflow, enhancing both horsepower and torque. Additionally, advanced technology in fuel delivery and ignition systems ensures that the engine operates smoothly across different driving conditions.

Performance and Efficiency

One of the standout attributes of this engine type is its ability to deliver robust performance while maintaining commendable fuel efficiency. The design incorporates strategies such as variable valve timing and cylinder deactivation, which help to maximize energy usage. This results in an engine that not only excels in power but also minimizes environmental impact, appealing to a broad range of drivers.

In summary, the discussed powertrain exemplifies a successful blend of engineering prowess and practical functionality, catering to both performance seekers and everyday users.

Common Issues with HEMI Engines

High-performance powertrains are known for their impressive capabilities, but they can also encounter specific challenges over time. Understanding these common problems can help owners maintain their vehicles and enhance longevity.

- Oil Consumption: Many enthusiasts report excessive oil usage, which can lead to diminished performance and engine damage if not addressed promptly.

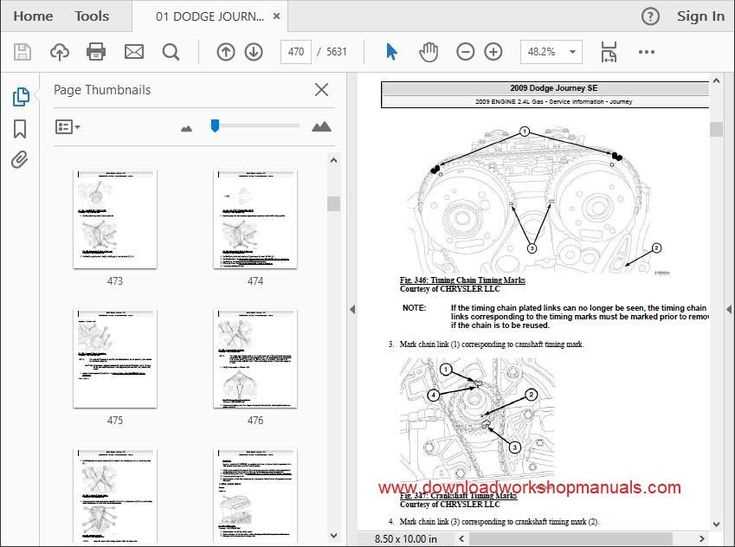

- Timing Chain Stretch: Over time, the timing chain can stretch, causing misalignment and potential engine knocking or failure.

- Coolant Leaks: Issues with gaskets or seals may lead to coolant leaks, resulting in overheating and possible engine failure.

- Valve Seat Recession: This problem can cause poor compression and rough idling, necessitating more serious engine work.

- Electrical Problems: Faulty sensors or wiring can disrupt the engine management system, leading to performance issues and warning lights.

Regular maintenance and timely inspections can help mitigate these issues, ensuring a smooth and efficient operation.

Essential Tools for HEMI Repairs

When tackling engine maintenance and enhancements, having the right instruments is crucial for achieving optimal results. This section highlights the must-have equipment that ensures efficiency and precision during various tasks.

- Socket Set: A comprehensive socket set is vital for loosening and tightening bolts with ease. Look for a variety of sizes to accommodate different fasteners.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, preventing potential damage from over-tightening.

- Engine Stand: For those undertaking more extensive work, an engine stand allows for easy access and mobility while handling the engine.

- Oil Filter Wrench: Essential for removing and installing oil filters without causing damage, this tool simplifies a common task.

- Compression Tester: This device assesses the condition of the engine by measuring the pressure in each cylinder, helping diagnose issues efficiently.

Investing in these tools not only enhances the quality of your work but also ensures that you are well-prepared for any challenges that may arise during the process.

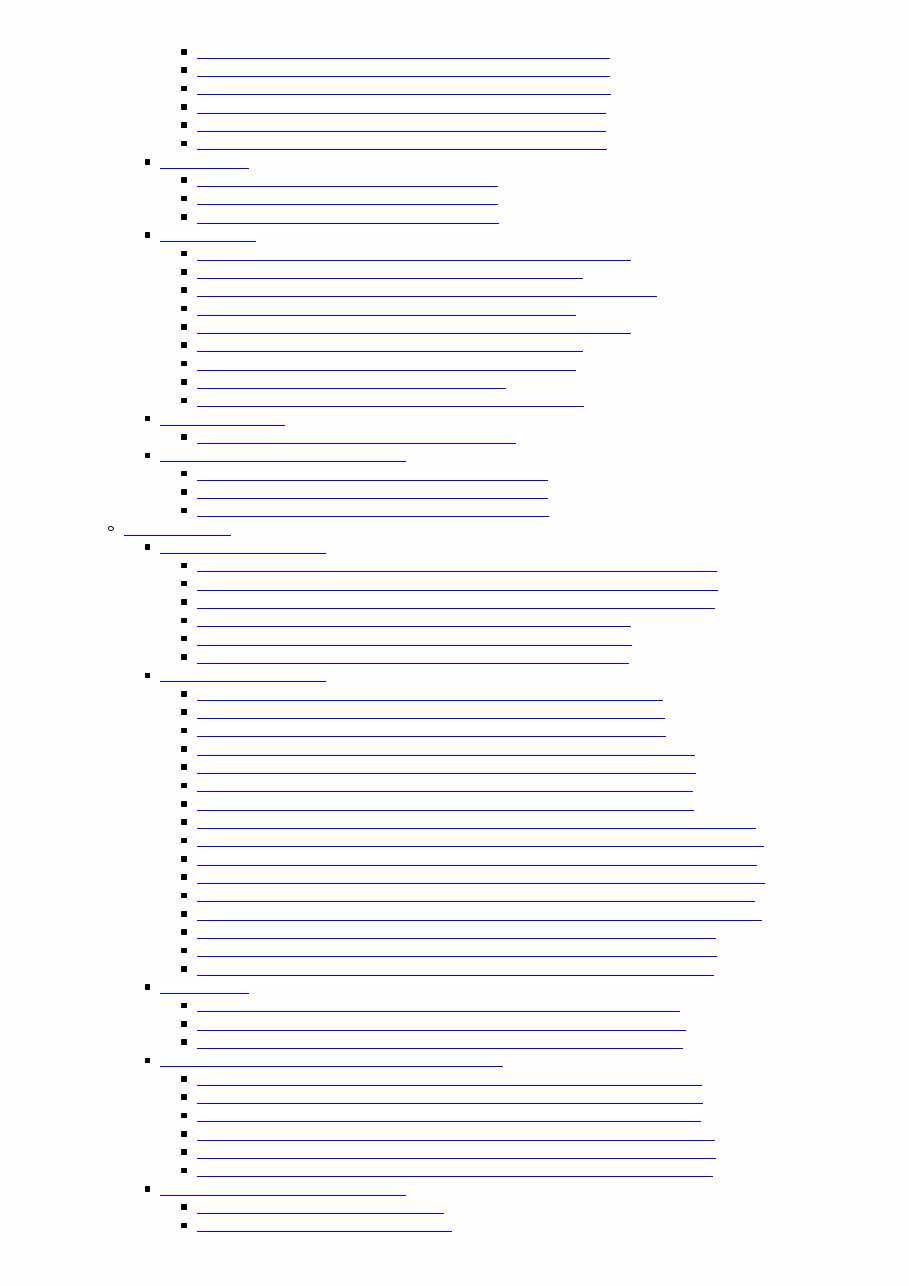

Step-by-Step Repair Procedures

This section outlines the essential methods for troubleshooting and fixing engine issues effectively. Following a structured approach can significantly enhance the efficiency and accuracy of the work involved. Here, we will break down the process into manageable steps to ensure a smooth workflow.

- Gather Necessary Tools and Materials

- Wrenches and sockets

- Torque specifications

- Replacement components

- Fluid and sealants

cssCopy code

- Disconnect the battery to prevent electrical issues.

- Use protective gear to safeguard against hazards.

- Work in a well-ventilated area.

- Start with the intake manifold.

- Take off the valve covers carefully.

- Detach any additional parts blocking access.

- Check for wear and tear on the gaskets.

- Examine the valves for any signs of damage.

- Assess the condition of the pistons and cylinder walls.

- Install new gaskets as needed.

- Replace any broken or worn components.

- Ensure all parts are cleaned before reassembly.

- Carefully reattach the valve covers and intake manifold.

- Follow torque specifications during reassembly.

- Double-check connections and fittings for tightness.

- Reconnect the battery.

- Run diagnostic tests to identify any remaining issues.

- Take the vehicle for a test drive to ensure everything functions correctly.

By adhering to these steps, the process of diagnosing and addressing engine issues can be conducted with greater precision and care.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for maximizing the lifespan of your vehicle’s engine. Adopting a proactive maintenance routine not only enhances performance but also helps prevent costly repairs in the future. Below are key strategies to ensure your engine remains in optimal condition for years to come.

Regular Fluid Checks

Maintaining the right fluid levels is critical for the health of your engine. Here are some fluids to monitor:

- Engine oil: Change it regularly to keep parts lubricated.

- Coolant: Ensure it’s at the appropriate level to prevent overheating.

- Transmission fluid: Check for proper levels to facilitate smooth gear shifts.

Scheduled Inspections

Consistent inspections can catch potential issues before they escalate. Follow these guidelines:

- Check belts and hoses for wear and tear.

- Inspect filters and replace them as needed.

- Monitor battery health and clean terminals to prevent corrosion.

By implementing these maintenance tips, you can significantly extend the life of your engine and enjoy reliable performance on the road.

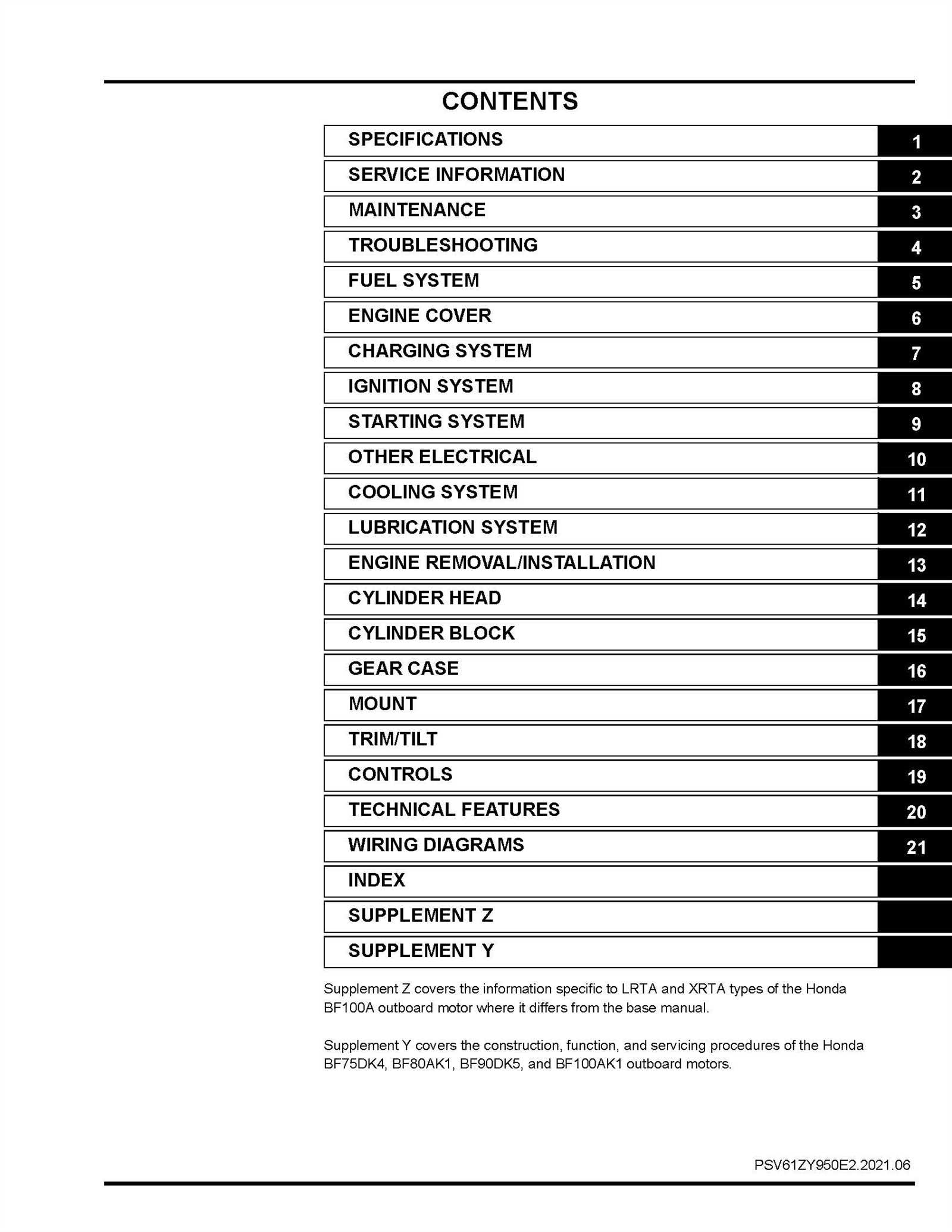

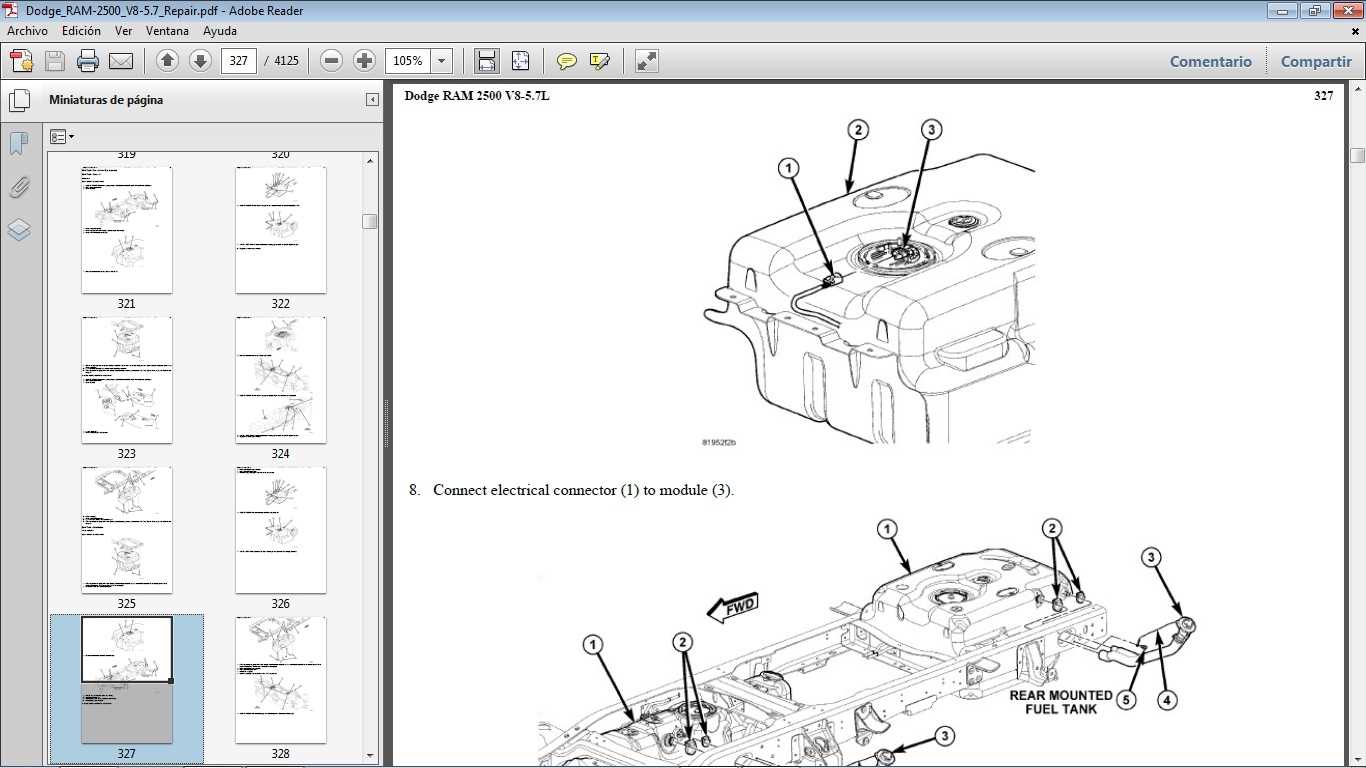

Understanding Engine Components and Functions

An engine operates as a complex assembly of various parts that work together to convert fuel into mechanical energy. Each component plays a crucial role in ensuring optimal performance and efficiency, making it essential to understand their functions and interrelations.

The primary components of an engine can be categorized as follows:

- Fuel System:

- Fuel tank

- Fuel pump

- Injectors

- Air Intake System:

- Air filter

- Intake manifold

- Throttle body

- Combustion Chamber:

- Pistons

- Cylinders

- Valves

- Exhaust System:

- Exhaust manifold

- Catalytic converter

- Exhaust pipes

- Lubrication System:

- Oil pump

- Oil filter

- Oil pan

Each component not only serves its own purpose but also interacts with others, creating a seamless operation that is vital for performance. Understanding these parts and their functions is fundamental for anyone looking to maintain or troubleshoot an engine effectively.

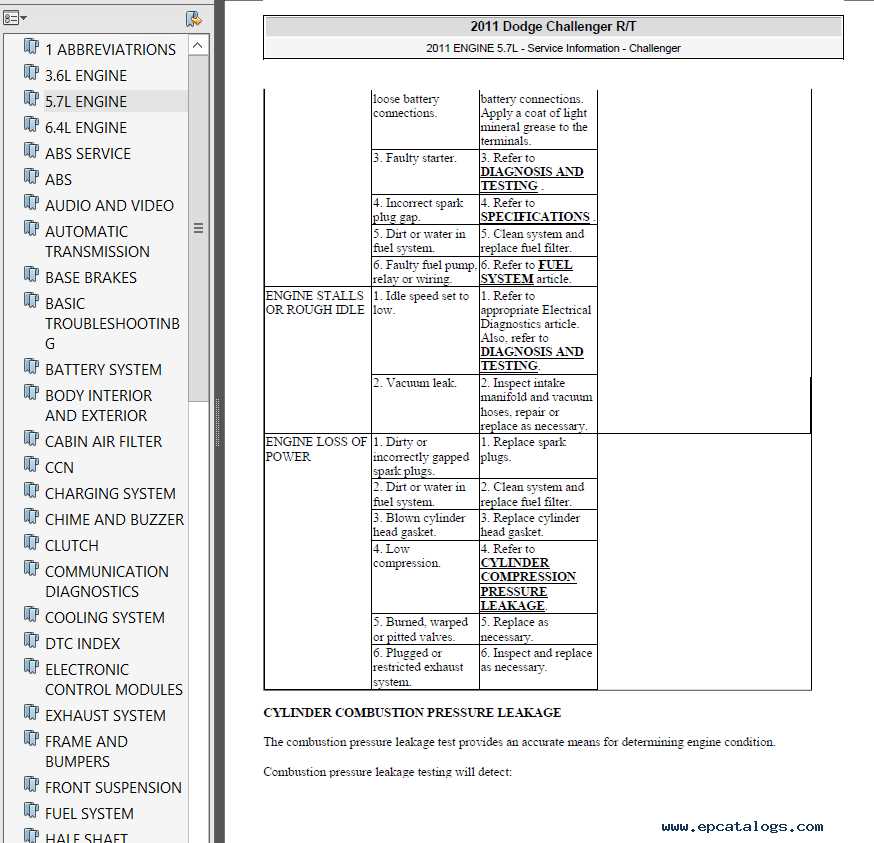

Troubleshooting HEMI Performance Problems

Identifying and resolving performance issues in high-performance engines requires a systematic approach. Various factors can contribute to a decline in power, efficiency, or responsiveness. Understanding these elements can help pinpoint the root cause and facilitate effective solutions.

Common symptoms of performance degradation may include reduced acceleration, unusual noises, or poor fuel economy. These signs can often be traced back to issues with fuel delivery, ignition systems, or airflow. Below is a table outlining potential problems and their corresponding troubleshooting steps.

| Symptoms | Possible Causes | Troubleshooting Steps |

|---|---|---|

| Poor acceleration | Clogged fuel injectors | Inspect and clean injectors; check fuel filter. |

| Unusual engine noises | Worn components | Check for signs of wear; inspect belts and pulleys. |

| Decreased fuel efficiency | Faulty sensors | Test and replace faulty oxygen or mass airflow sensors. |

| Rough idle | Vacuum leaks | Inspect vacuum lines and gaskets for leaks. |

| Engine misfires | Ignition system issues | Examine spark plugs, wires, and coils; replace as needed. |

By methodically addressing each symptom and investigating the underlying causes, enthusiasts and technicians can restore optimal performance and reliability. Regular maintenance and timely intervention are crucial to preventing more significant issues down the line.

Upgrading HEMI Engine Parts

Enhancing the performance of your powertrain can significantly elevate your vehicle’s capabilities. Upgrading components can lead to improved horsepower, torque, and overall efficiency. This section explores various parts that can be optimized for better output and responsiveness.

Essential Components for Enhancement

- Intake Systems: Improving air intake can boost engine efficiency. Consider high-performance air filters and intake manifolds.

- Exhaust Systems: Upgrading exhaust headers and systems can reduce back pressure, allowing for better airflow and increased power.

- Tuning Software: Custom tuning can optimize fuel maps and ignition timing, maximizing performance gains.

Performance Enhancements

- Camshaft: Installing a performance camshaft can enhance valve timing and lift, contributing to higher RPM performance.

- Pistons and Rods: Forged pistons and connecting rods can withstand greater stresses, making them ideal for high-performance builds.

- Forced Induction: Adding superchargers or turbochargers can significantly increase power output by forcing more air into the combustion chamber.

By carefully selecting and upgrading these components, enthusiasts can unlock the full potential of their engine, achieving an exhilarating driving experience and enhanced reliability.

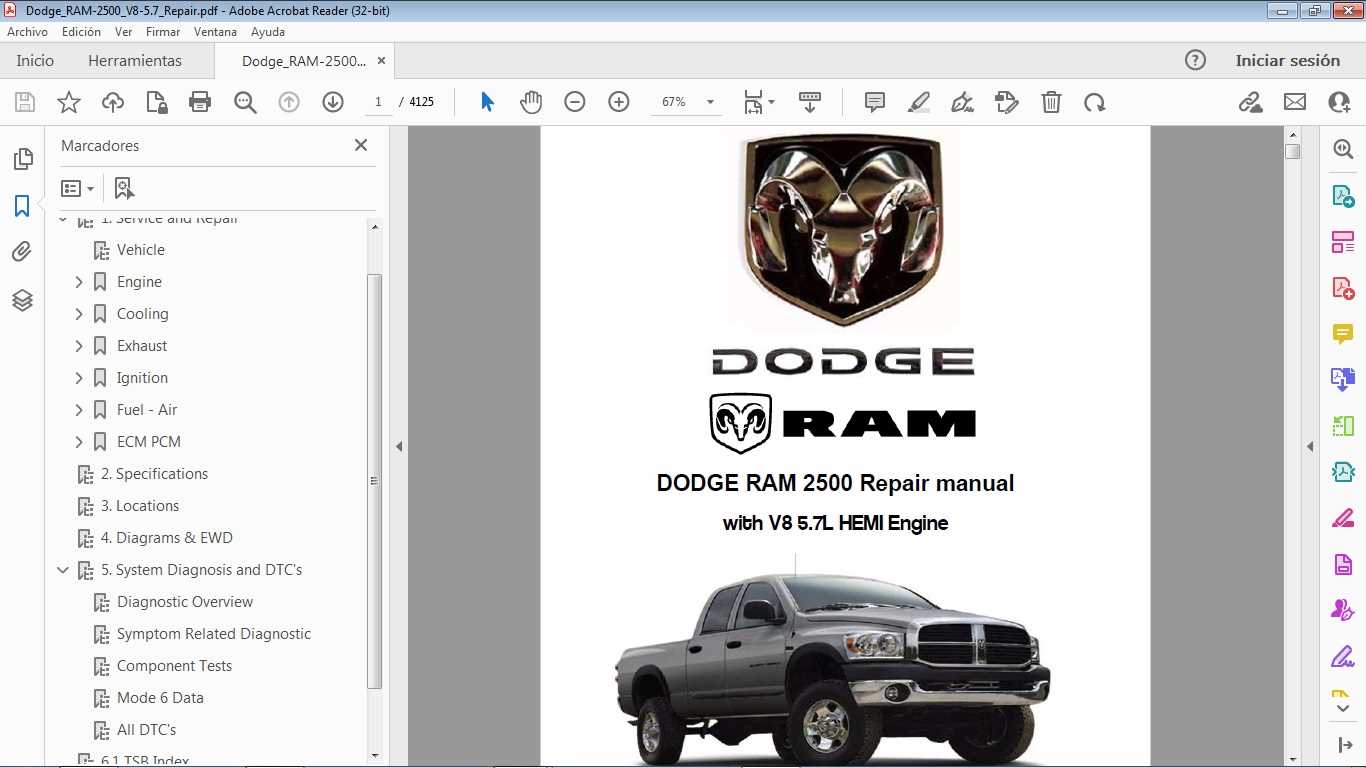

HEMI Engine Specifications Overview

This section provides an in-depth examination of the technical characteristics and design elements of a well-known American powertrain. Understanding these specifications is essential for enthusiasts and professionals alike, as it lays the foundation for performance assessment and maintenance practices.

Displacement: The total engine displacement plays a crucial role in determining the engine’s power output and efficiency. This specific engine boasts a substantial displacement, allowing it to generate impressive torque and horsepower figures.

Cylinder Configuration: The design features a distinctive arrangement of cylinders that enhances performance and fuel efficiency. The architecture is engineered to optimize airflow, contributing to overall engine responsiveness and power delivery.

Fuel System: This power unit utilizes a sophisticated fuel delivery system that ensures optimal combustion efficiency. By employing advanced technologies, it maximizes fuel economy while minimizing emissions.

Compression Ratio: A key factor in engine performance, the compression ratio significantly influences power generation and efficiency. This particular engine achieves a high compression ratio, which translates to enhanced power output and improved thermal efficiency.

Valvetrain: The engine features an innovative valvetrain system that promotes efficient airflow and enhances performance at various RPM levels. This design choice is crucial for achieving both low-end torque and high-end power.

Cooling System: Effective temperature management is vital for engine longevity and performance. The cooling system is designed to maintain optimal operating temperatures, ensuring reliability under various driving conditions.

Overall, a comprehensive understanding of these specifications is essential for anyone involved with this iconic engine. It not only aids in performance tuning but also ensures that maintenance and service practices are aligned with the engine’s design and capabilities.

Safety Precautions During Repairs

Ensuring a secure environment while performing maintenance tasks is essential for both personal safety and the successful completion of the work. Adhering to specific guidelines minimizes risks and enhances efficiency, allowing for a smooth and effective process.

Before starting any work, it is crucial to wear appropriate protective gear. This includes safety goggles to shield the eyes from debris, gloves to protect the hands from sharp objects and chemicals, and sturdy footwear to prevent injuries from heavy components. Additionally, a well-ventilated area is necessary when handling volatile substances to avoid inhalation of harmful fumes.

Properly securing the vehicle is vital. Always use jack stands instead of relying solely on hydraulic jacks, ensuring stability and preventing accidents. Keeping the workspace organized helps avoid tripping hazards and allows for easy access to tools and parts.

It is also important to disconnect the battery before initiating any electrical work. This precaution prevents accidental shocks and protects sensitive components from damage. Familiarizing oneself with the specific tools and equipment used in the process enhances safety and effectiveness.

Finally, maintaining a clear line of communication with others in the vicinity can significantly reduce the likelihood of mishaps. Informing those around you about ongoing tasks ensures everyone is aware of potential hazards. By following these safety measures, individuals can create a productive and secure environment for all maintenance activities.

Comparing HEMI Models and Variants

In the realm of high-performance automotive engines, there exists a diverse array of models and variants, each offering unique characteristics and capabilities. Understanding the distinctions among these powerplants is essential for enthusiasts and potential buyers alike, as each variant serves different needs and preferences. From horsepower and torque figures to design features and technological advancements, the comparison of these engine types reveals a rich tapestry of engineering excellence.

Performance Characteristics

The performance metrics of different variants play a pivotal role in their appeal. While some are tailored for maximum power output, others may prioritize fuel efficiency or torque delivery. For instance, a variant designed for racing applications often boasts higher compression ratios and advanced tuning, resulting in impressive acceleration and responsiveness. Conversely, models aimed at everyday driving might focus on a balanced blend of power and economy, making them suitable for a broader audience.

Technological Innovations

Each engine type is also influenced by technological advancements that enhance performance and reliability. Notably, features such as variable valve timing, direct fuel injection, and advanced cooling systems can significantly impact the driving experience. These innovations not only improve engine efficiency but also contribute to reduced emissions, aligning with modern automotive standards. Evaluating these technological differences can provide deeper insights into the overall performance and suitability of each variant for specific driving conditions.

Resources for HEMI Enthusiasts

For those passionate about high-performance engines, finding reliable sources of information and community support is essential. A wealth of materials is available, ranging from technical documents to forums, ensuring enthusiasts have the resources they need to enhance their knowledge and skills.

Online Communities

Participating in forums and social media groups can greatly benefit enthusiasts looking to share experiences and gather tips. Platforms such as Reddit and dedicated car forums offer a space for discussions, troubleshooting, and sharing modifications. Engaging with others who share similar interests fosters a sense of community and provides invaluable insights.

Technical Documentation

Access to comprehensive guides and specifications is crucial for anyone working on engine modifications. Various websites offer downloadable resources that cover everything from basic maintenance to advanced upgrades. Utilizing these documents allows enthusiasts to better understand their engines and execute projects with confidence.

In summary, whether you are seeking camaraderie or technical expertise, a myriad of resources exists to support your journey in the world of performance engines. Embrace these tools to elevate your passion and knowledge.