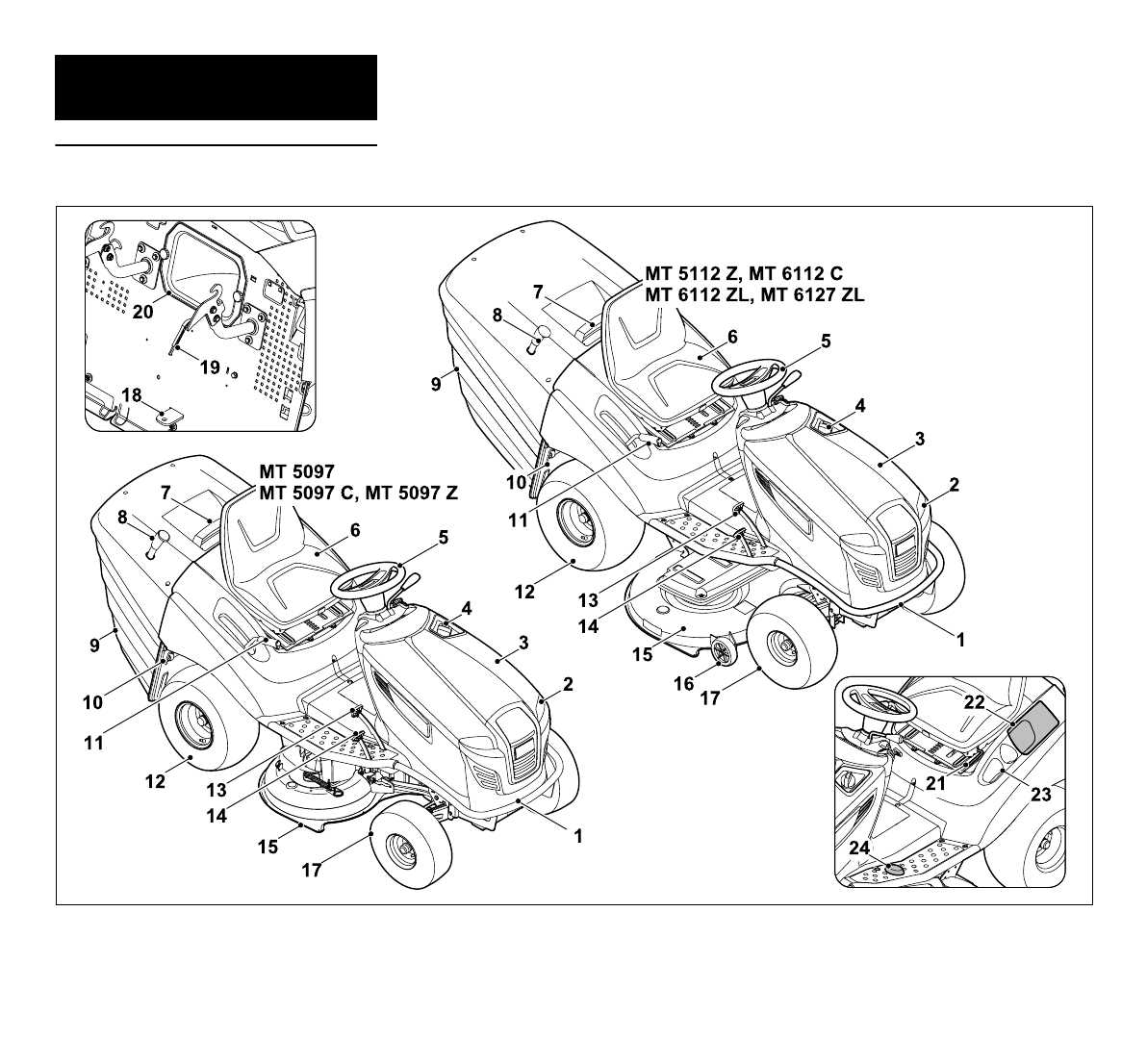

Taking care of your outdoor machinery is essential for ensuring optimal performance and longevity. Proper upkeep can prevent common issues and enhance efficiency, allowing you to enjoy a beautifully maintained landscape without unnecessary interruptions.

In this section, we will explore essential practices and troubleshooting techniques tailored to enhance the functionality of your gardening apparatus. By understanding the intricacies of your equipment, you can address minor concerns before they escalate into significant problems.

Familiarizing yourself with various maintenance procedures empowers you to keep your tools in prime condition. From routine checks to specific adjustments, having a thorough understanding will make your gardening tasks more efficient and enjoyable.

Proper upkeep of outdoor machinery is essential for ensuring its durability and optimal performance over time. By following a consistent maintenance routine, you can significantly extend the life of your equipment while enhancing its efficiency.

Regular Inspection

Conducting routine checks helps identify potential issues before they escalate. Consider the following:

- Examine belts and blades for wear.

- Check fluid levels and top them up as needed.

- Inspect tires for proper inflation and tread wear.

Cleaning and Storage

Keeping your machinery clean is vital for its longevity. Implement these practices:

- Remove grass clippings and debris after each use.

- Store the equipment in a dry, sheltered location.

- Cover the machinery to protect it from dust and moisture.

Understanding the Engine Components

The inner workings of a machine are crucial for its performance and longevity. A thorough comprehension of the various elements that make up the power source can enhance maintenance practices and troubleshooting efforts. Each part plays a specific role in ensuring the system operates smoothly and efficiently.

At the heart of the system lies the combustion chamber, where fuel and air mix to generate power. This area is essential for converting chemical energy into mechanical energy, driving the entire mechanism. Surrounding this chamber, the cylinders house the pistons, which move in a precise manner to facilitate this transformation.

Fuel delivery systems play a vital role in optimizing performance. Components such as fuel injectors and carburetors ensure the right mixture reaches the combustion chamber. Maintaining these systems is important for avoiding performance issues and ensuring efficient energy use.

The ignition system is another key element. It creates the spark that ignites the air-fuel mixture, initiating the power cycle. Regular checks on spark plugs and associated wiring can prevent starting problems and improve overall functionality.

Lastly, the cooling system is crucial for preventing overheating. Components like the radiator and fan help maintain optimal operating temperatures, safeguarding against potential damage. Understanding these elements allows for informed maintenance decisions, enhancing the lifespan and reliability of the equipment.

How to Diagnose Electrical Problems

Identifying issues within an electrical system can be challenging but essential for ensuring optimal performance. By systematically evaluating components, you can pinpoint the source of malfunctions and address them effectively.

Initial Inspection

- Check for visible damage to wires and connectors.

- Ensure all connections are secure and free of corrosion.

- Inspect fuses and circuit breakers for any signs of failure.

Testing Components

- Use a multimeter to measure voltage at different points in the circuit.

- Test switches and relays for continuity to confirm they are functioning.

- Evaluate batteries for charge level and overall health.

Essential Tools for Repairs

When maintaining outdoor machinery, having the right instruments can make a significant difference in efficiency and effectiveness. Proper tools not only simplify tasks but also enhance the quality of work, ensuring that equipment operates smoothly and reliably.

Basic Hand Tools

- Wrenches: Essential for loosening and tightening various fasteners.

- Screwdrivers: Useful for handling different types of screws and adjustments.

- Pliers: Ideal for gripping and manipulating components in tight spaces.

- Socket set: Provides versatility for various nut sizes and quick changes.

Specialized Equipment

- Torque wrench: Ensures bolts are tightened to the correct specifications.

- Feeler gauge: Useful for measuring gap widths and settings.

- Multimeter: Essential for diagnosing electrical issues.

- Cleaning supplies: Brushes, solvents, and rags help maintain cleanliness and function.

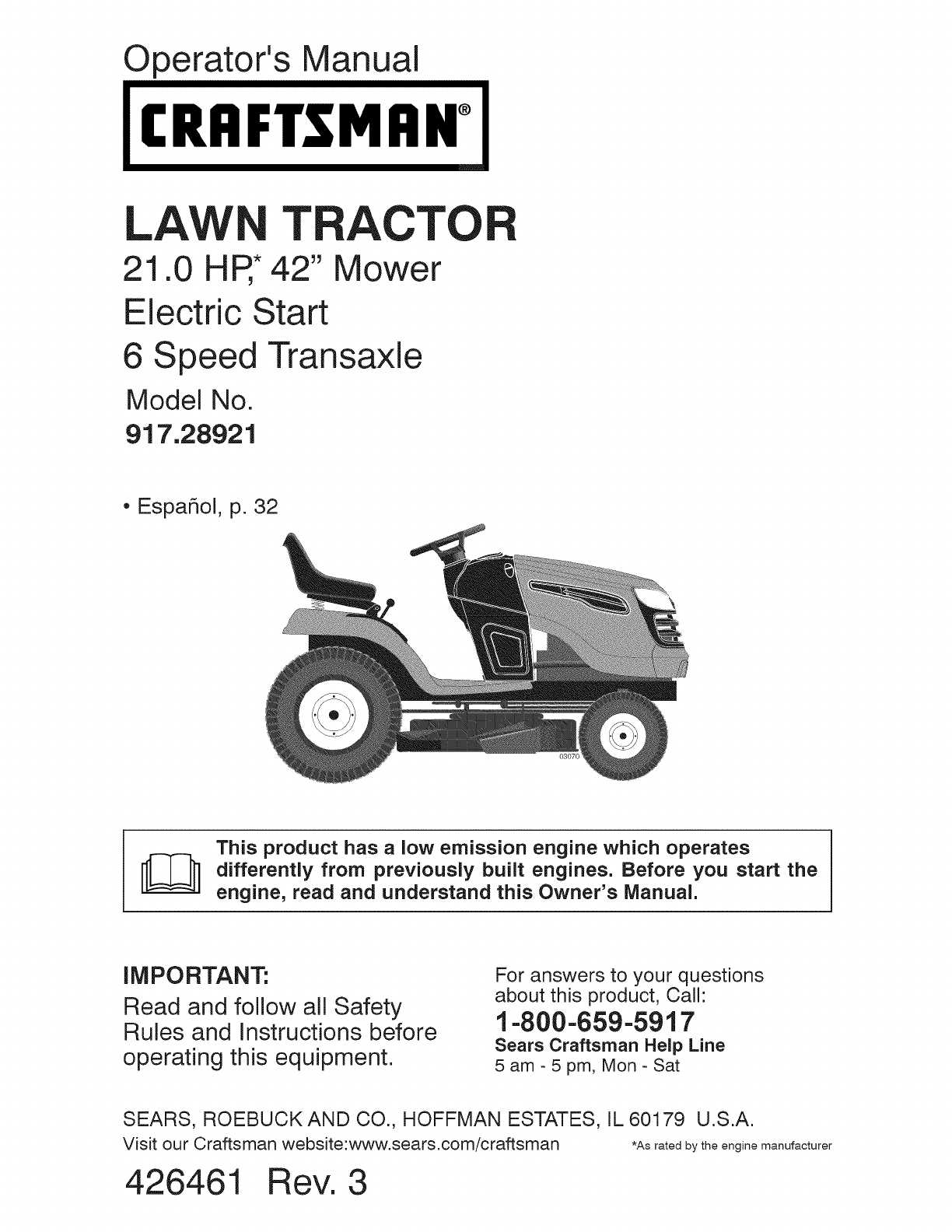

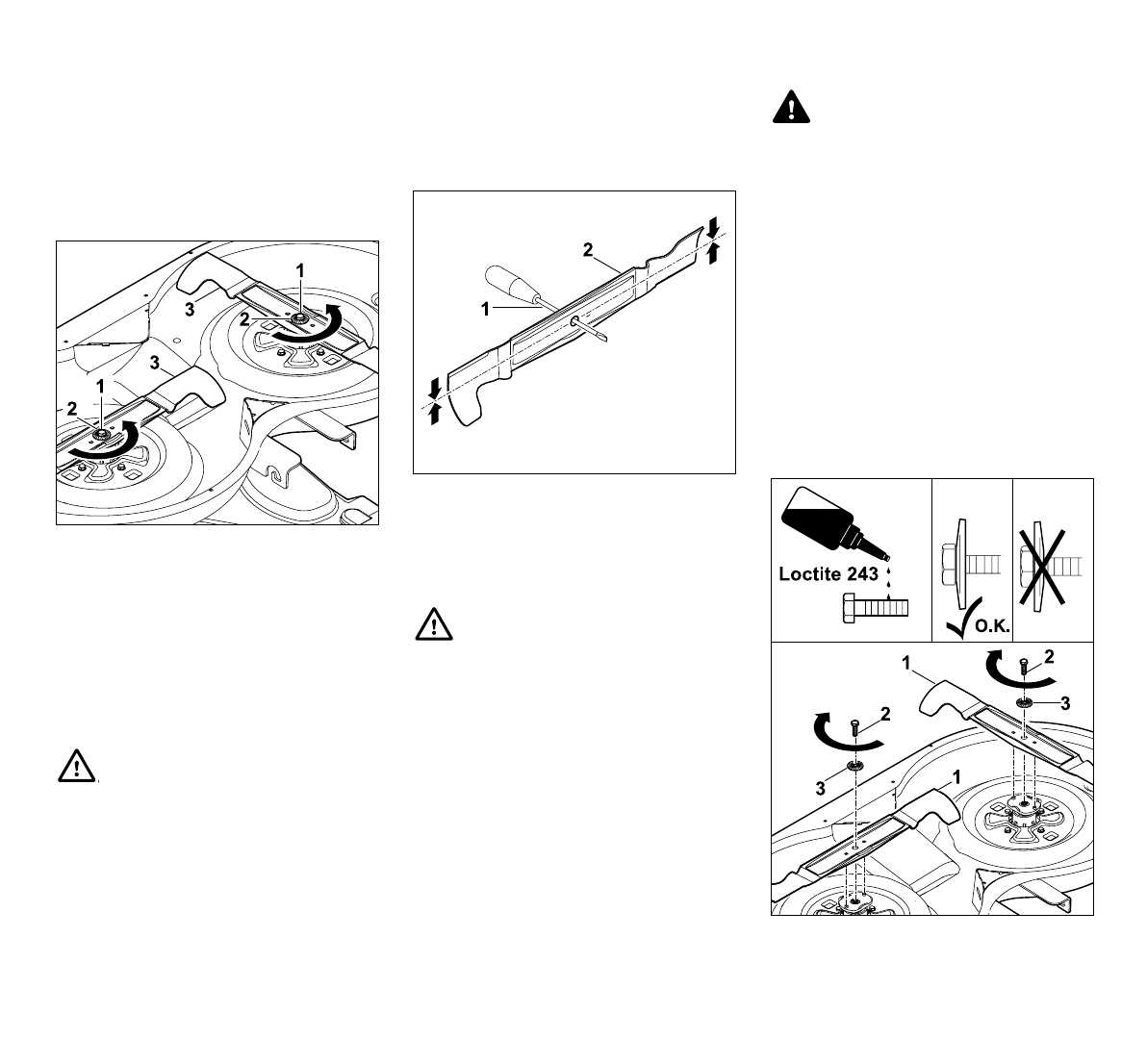

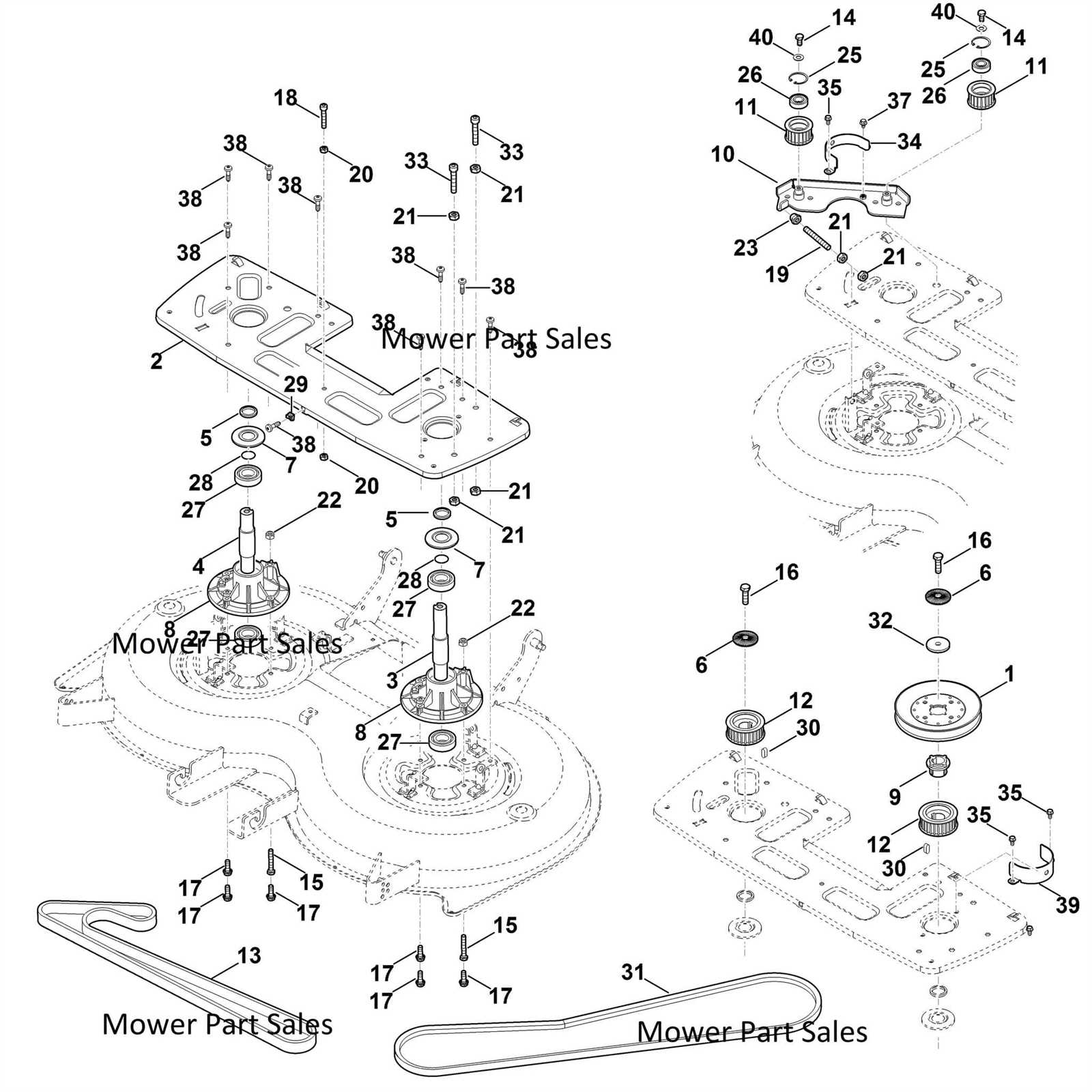

Steps for Changing the Blades

Maintaining the cutting elements of your equipment is essential for optimal performance and longevity. This process involves several key steps to ensure a smooth and safe transition to new cutting components.

1. Gather Necessary Tools: Before starting, collect all required tools, including a socket wrench, safety gloves, and a lifting device to secure the unit.

2. Ensure Safety Precautions: Disconnect the power source to prevent accidental operation. It is crucial to engage safety features to protect yourself during the blade change process.

3. Raise the Equipment: Using the lifting device, elevate the machine to gain easy access to the cutting area. Ensure it is stable and secure before proceeding.

4. Remove Old Blades: Locate the fasteners securing the current blades. Using the socket wrench, carefully unscrew these fasteners and remove the old cutting elements from their mounts.

5. Install New Blades: Position the new blades onto the mounting points, ensuring they align properly. Secure them tightly using the previously removed fasteners to prevent any movement during operation.

6. Lower and Test: Once the new blades are securely attached, lower the equipment back to the ground. Reconnect the power source and conduct a test run to verify proper function and alignment.

Fuel System Maintenance Guidelines

Proper upkeep of the fuel delivery system is essential for optimal performance and longevity of your outdoor equipment. Regular attention to this area can prevent issues and ensure smooth operation, making your tasks more efficient and enjoyable.

Routine Inspections

- Check for any leaks or cracks in fuel lines.

- Inspect the fuel filter and replace it as needed.

- Examine the fuel tank for any debris or contamination.

Fuel Quality Management

- Use fresh fuel to prevent degradation and build-up.

- Store fuel in appropriate containers to minimize contamination.

- Avoid mixing different types of fuel to maintain consistency.

Tire Care and Replacement Advice

Proper maintenance of tires is crucial for ensuring optimal performance and longevity of your equipment. Regular attention to tire condition can prevent issues and enhance efficiency during operation. Below are essential tips for maintaining and replacing tires.

- Regular Inspections: Check for signs of wear, cracks, or foreign objects that may be lodged in the tread.

- Proper Inflation: Maintain the recommended pressure levels to ensure stability and improve fuel efficiency.

- Rotation: Rotate tires periodically to ensure even wear, extending their lifespan.

- Alignment Checks: Ensure that tires are properly aligned to prevent uneven wear and improve handling.

When it’s time to replace tires, consider the following:

- Choosing the Right Size: Always refer to specifications for the correct tire size compatible with your equipment.

- Tread Type: Select tires with appropriate tread patterns suited for your typical terrain and operational needs.

- Quality Over Price: Investing in high-quality tires can lead to better performance and durability.

By adhering to these guidelines, you can enhance the safety and efficiency of your equipment, ensuring smooth operation for years to come.

Handling Transmission Issues

Addressing complications in the power transfer system is crucial for maintaining optimal performance and reliability. These problems can arise from various sources, affecting the overall functionality. Identifying symptoms early can help prevent more severe damage and ensure smoother operation.

Common Symptoms of Transmission Problems

- Unusual noises during operation

- Inconsistent speed or power delivery

- Difficulty shifting gears

- Unresponsive throttle

Troubleshooting Steps

- Inspect fluid levels and condition to ensure proper lubrication.

- Check for any visible leaks around the system.

- Examine connections and cables for wear or damage.

- Test the operation of the throttle control for responsiveness.

Regular maintenance and prompt attention to any issues can significantly extend the lifespan of the transmission system. Always refer to the manufacturer’s guidelines for specific maintenance protocols and troubleshooting tips.

Cleaning and Care of Decks

Maintaining the surface of your cutting equipment is essential for optimal performance and longevity. Regular cleaning helps prevent the accumulation of grass clippings, dirt, and debris, which can affect the effectiveness of the machine and lead to corrosion over time.

First and foremost, ensure that the equipment is turned off and completely cool before starting the cleaning process. Use a brush or scraper to remove any build-up from the deck. Pay special attention to areas where grass tends to accumulate, as these spots can trap moisture and lead to rust.

After scraping, rinse the surface with water to wash away any remaining debris. Avoid using a pressure washer, as the force can damage sensitive components. Instead, a gentle spray from a hose will suffice. Allow the deck to dry thoroughly before storing or using the equipment again.

Additionally, regular inspections for any signs of wear or damage can help catch issues early. Keeping the deck clean not only enhances its appearance but also contributes to a more efficient and effective cutting experience.

Preparing for Seasonal Storage

As the seasons change, it becomes essential to ensure that your equipment is properly prepared for storage. This process not only protects your investment but also enhances its longevity and efficiency for the next use. Taking the time to follow a few key steps can help avoid potential issues that may arise from neglect during the off-season.

Cleaning and Maintenance

Before storing, it’s important to thoroughly clean the machinery to remove any dirt, debris, or grass clippings. This not only prevents corrosion but also keeps pests at bay. After cleaning, check for any wear or damage and perform necessary maintenance tasks such as changing the oil, sharpening blades, and inspecting belts. Addressing these details now can save you time and trouble later.

Fuel and Battery Care

Properly handling fuel is crucial before storage. If the equipment uses gasoline, consider adding a fuel stabilizer to prevent degradation. Emptying the fuel tank completely can also be an option if the machinery will be idle for an extended period. Additionally, if your device is equipped with a battery, disconnect it and store it in a cool, dry place to prolong its lifespan. Keeping these components in good condition will ensure smooth operation when it’s time to use them again.

When to Seek Professional Help

Understanding when to consult an expert is crucial for effective maintenance of your equipment. While some tasks may seem manageable, certain issues can require specialized knowledge and skills. Recognizing the signs that indicate professional assistance is necessary can save time and prevent further complications.

- Persistent Issues: If problems continue despite your attempts to resolve them, it’s a signal to seek expert advice.

- Unusual Noises: Strange sounds during operation can indicate mechanical failures that need professional evaluation.

- Lack of Performance: A noticeable decrease in efficiency or power may suggest underlying issues best handled by a technician.

- Electrical Problems: Any malfunction involving wiring or electrical components often requires specialized expertise.

- Safety Concerns: If you encounter situations that pose a risk to safety, it’s essential to reach out to a professional immediately.

By acknowledging these indicators, you can ensure that your equipment remains in optimal condition while avoiding unnecessary risks.