Understanding the intricacies of vehicle upkeep is essential for any owner seeking to maintain performance and longevity. This section provides valuable insights into the procedures and practices necessary for keeping your automobile in optimal condition. With a focus on detailed information, it aims to equip readers with the knowledge required for effective maintenance.

Access to reliable resources can significantly simplify the process of troubleshooting and repairing various issues. By utilizing this guide, owners can enhance their familiarity with the components and systems of their vehicles. Empowerment through knowledge not only facilitates smoother operation but also contributes to cost-effective ownership.

Furthermore, regular inspections and timely interventions can prevent minor concerns from escalating into major problems. With proper guidance, anyone can learn to identify potential issues and apply appropriate solutions. This approach fosters a deeper understanding of the vehicle, encouraging proactive care and informed decision-making.

Diagnosing issues within a powertrain system requires a systematic approach. Identifying symptoms accurately can save time and resources during the repair process. This section outlines effective strategies for troubleshooting common engine problems.

Common Symptoms and Their Causes

- Starting Issues: Difficulty starting may indicate battery problems, faulty ignition components, or fuel delivery issues.

- Unusual Noises: Sounds like knocking or pinging can signal internal damage or improper combustion.

- Overheating: High temperatures could result from coolant leaks, a malfunctioning thermostat, or radiator blockages.

Troubleshooting Steps

- Begin with a visual inspection of all components and connections.

- Use diagnostic tools to retrieve error codes from the engine control unit.

- Conduct a systematic test of individual systems, including fuel, ignition, and exhaust.

- Review the results and compare them with manufacturer specifications.

- Make adjustments or repairs as necessary based on findings.

Electrical System Diagnostics

The assessment of electrical systems in vehicles is crucial for ensuring optimal performance and reliability. This section provides an overview of methods and techniques to effectively diagnose issues related to electrical components. By understanding the underlying principles, technicians can identify faults and implement appropriate solutions.

Common Electrical Issues

Several problems can arise within the electrical systems of vehicles. Recognizing these issues is the first step toward effective troubleshooting. Common electrical concerns include:

- Dead batteries

- Faulty alternators

- Wiring faults

- Defective sensors

- Malfunctioning switches

Diagnostic Tools and Techniques

Utilizing the right tools and techniques can significantly enhance the diagnostic process. Key methods include:

- Visual Inspection: Check for damaged wires or loose connections.

- Multimeter Testing: Measure voltage, current, and resistance in circuits.

- Scan Tool Utilization: Access diagnostic trouble codes from the vehicle’s computer.

- Continuity Testing: Ensure circuits are complete and functioning properly.

By applying these techniques, technicians can efficiently diagnose and resolve electrical issues, ensuring the vehicle operates smoothly.

Transmission Service Procedures

Effective maintenance of a vehicle’s transmission system is crucial for optimal performance and longevity. This section outlines essential practices to ensure the smooth operation of the transmission, focusing on preventive measures and servicing techniques that can help avoid common issues.

Fluid Replacement and Inspection

Regularly checking and replacing transmission fluid is vital for maintaining functionality. Fluid quality directly affects the system’s efficiency, so it is recommended to inspect for discoloration or debris. Using the manufacturer-recommended fluid can prevent potential damage.

Filter Maintenance

The transmission filter plays a key role in keeping the system clean. Periodic replacement of the filter is necessary to avoid clogging, which can lead to performance degradation. Ensuring that the filter is free from contaminants is essential for maintaining optimal fluid flow and overall transmission health.

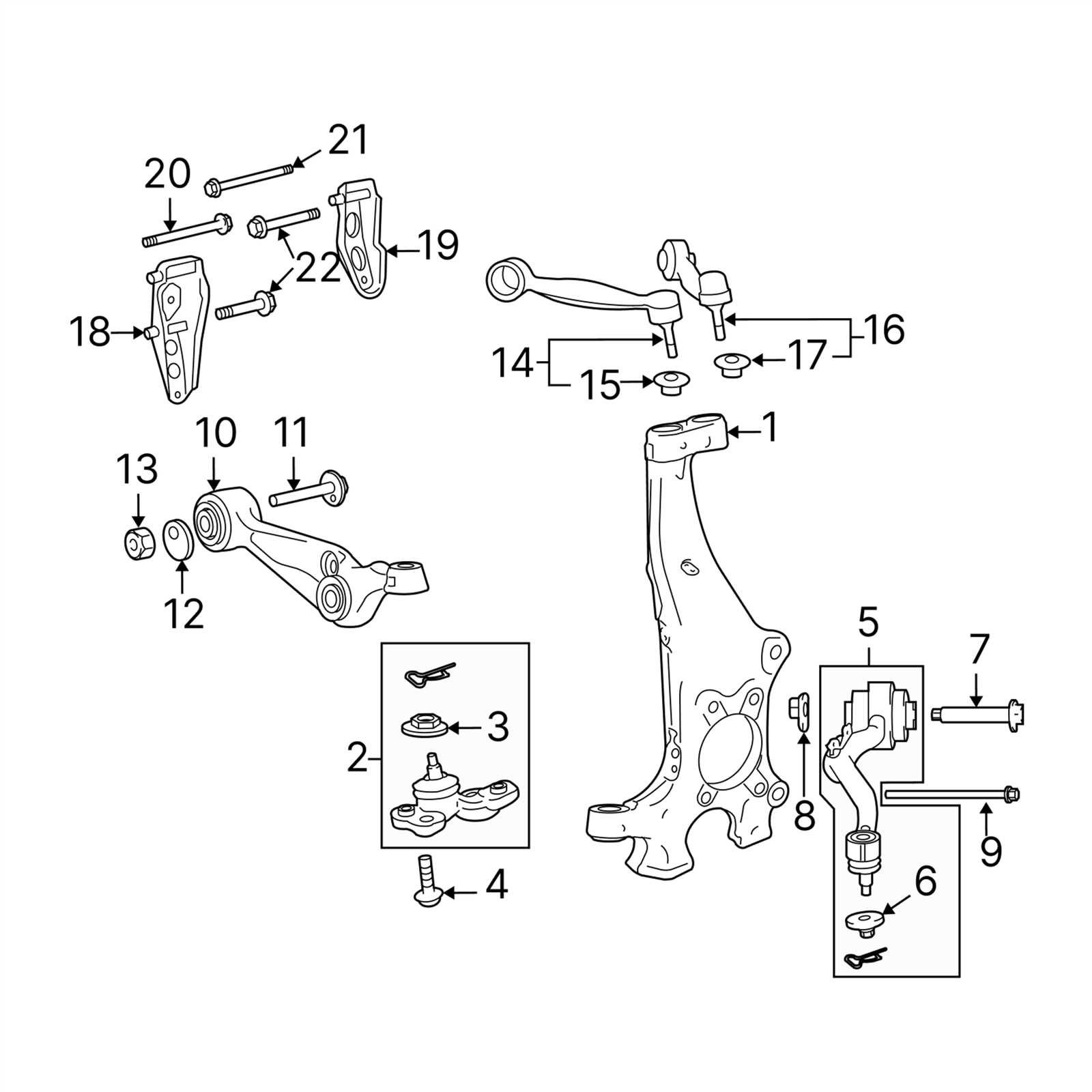

Suspension and Steering Insights

This section explores the critical aspects of vehicle dynamics, focusing on the components that ensure a smooth and controlled driving experience. Proper understanding of these systems contributes significantly to safety and comfort on the road.

Key Components of Suspension

- Shock Absorbers: Essential for minimizing vibrations and maintaining contact with the road.

- Springs: Support the vehicle’s weight and absorb impacts from uneven surfaces.

- Control Arms: Allow for movement of the wheels while maintaining alignment with the chassis.

Steering Mechanisms Overview

- Rack and Pinion: Commonly used for its responsiveness and compact design.

- Power Steering: Enhances maneuverability, making it easier to turn the wheel.

- Steering Linkage: Connects the steering wheel to the wheels, ensuring precise control.

Maintaining these components is vital for optimal performance. Regular checks can prevent wear and enhance safety, leading to a better overall driving experience.

Brake System Repair Steps

Maintaining the braking mechanism is essential for ensuring safety and optimal performance in any vehicle. This section outlines the necessary procedures for effectively addressing issues within this critical system. Understanding each step helps in diagnosing problems and performing necessary adjustments or replacements efficiently.

Preparation and Tools Required

Before beginning the process, gather all necessary tools and materials. This preparation ensures a smooth workflow and minimizes interruptions.

| Tool/Material | Description |

|---|---|

| Jack and Jack Stands | To lift the vehicle securely. |

| Wrenches | For loosening and tightening bolts. |

| Brake Fluid | To refill and maintain proper levels. |

| Replacement Pads | For replacing worn components. |

Step-by-Step Procedure

Follow these steps to address issues with the braking system effectively:

- Lift the vehicle using the jack and secure it with jack stands.

- Remove the wheel to access the braking components.

- Inspect the pads for wear and replace if necessary.

- Check the rotors for damage and resurface or replace as needed.

- Ensure all bolts are tightened to manufacturer specifications.

- Refill brake fluid and bleed the system to remove any air.

- Reattach the wheel and lower the vehicle.

Cooling System Maintenance Tips

Proper upkeep of the temperature control system is essential for optimal vehicle performance. Regular checks and maintenance help prevent overheating and extend the life of engine components. Here are some key strategies to ensure your cooling system operates efficiently.

First, inspect coolant levels frequently. Maintaining the appropriate amount of fluid is crucial for effective heat dissipation. Additionally, regularly examine hoses and connections for signs of wear or leaks, as these can compromise system integrity.

Key Maintenance Activities

| Task | Frequency | Description |

|---|---|---|

| Coolant Level Check | Monthly | Ensure coolant is at the recommended level. |

| Hose Inspection | Every 6 Months | Look for cracks, bulges, or leaks in hoses. |

| Radiator Cleaning | Annually | Remove debris to improve airflow and cooling efficiency. |

| Fluid Replacement | Every 2 Years | Replace old coolant to prevent corrosion and maintain effectiveness. |

By adhering to these maintenance guidelines, you can help ensure the longevity and reliability of your vehicle’s temperature management system.

Fuel System Inspection Protocols

Ensuring the optimal performance of a vehicle’s fuel delivery system is crucial for maintaining efficiency and reliability. This section outlines essential procedures to examine various components of the fuel system, allowing for early detection of potential issues and facilitating effective maintenance practices.

Initial Assessment Steps

Begin by performing a visual inspection of the fuel system components. Follow these steps:

- Check for any visible leaks in fuel lines, connections, and filters.

- Inspect the fuel tank for signs of corrosion or damage.

- Examine the fuel pump for proper mounting and any irregular sounds during operation.

Functional Testing Procedures

After the initial assessment, conduct functional tests to ensure the system operates correctly. This includes:

- Measure fuel pressure using a gauge to confirm it meets manufacturer specifications.

- Check the fuel filter for clogs by removing and inspecting it.

- Test the fuel injectors for proper spray patterns and functionality.

By adhering to these protocols, one can enhance the reliability of the fuel system and prolong the lifespan of the vehicle.

Exhaust System Upkeep

Maintaining the exhaust system is essential for ensuring optimal performance and longevity of your vehicle. Regular inspections and prompt attention to any issues can help avoid costly repairs and improve fuel efficiency.

Here are key aspects to consider for effective upkeep:

- Routine Inspections: Regularly check for leaks, rust, and damage.

- Clear Blockages: Ensure that the exhaust pathway is free from obstructions.

- Replace Damaged Components: Address any worn or broken parts immediately to maintain efficiency.

- Monitor Emissions: Keep an eye on the vehicle’s emissions output to identify potential problems early.

By adhering to these maintenance practices, you can enhance the overall function of the exhaust system and contribute to a smoother driving experience.

Interior and Exterior Care

Maintaining the appearance and functionality of your vehicle is essential for its longevity and performance. Proper care for both the inside and outside can enhance your driving experience and protect your investment. This section will cover effective methods to ensure your automobile remains in top condition.

For the interior, regular cleaning and protection of surfaces can prevent wear and tear. Here are some key practices:

| Task | Frequency | Tips |

|---|---|---|

| Vacuum carpets and seats | Weekly | Use a brush attachment for better results. |

| Wipe down surfaces | Bi-weekly | Use a microfiber cloth and appropriate cleaner. |

| Condition leather seats | Monthly | Apply a conditioner to prevent cracking. |

For the exterior, routine washing and waxing are crucial to protect the finish and paint. Consider these recommendations:

| Task | Frequency | Tips |

|---|---|---|

| Wash exterior | Monthly | Use a pH-balanced soap to avoid damage. |

| Apply wax | Every 3 months | Choose a high-quality wax for better protection. |

| Inspect tires and wheels | Monthly | Look for signs of wear and clean regularly. |

Tools and Equipment Recommendations

Having the right tools and equipment is essential for effective vehicle maintenance and troubleshooting. A well-equipped workspace not only enhances efficiency but also ensures safety during various procedures. Below is a selection of recommended items that can facilitate optimal performance and reliability when working on automotive systems.

Start with basic hand tools such as wrenches, screwdrivers, and pliers. A comprehensive socket set is also crucial for tackling a variety of fasteners. Additionally, investing in a high-quality jack and jack stands will provide secure access to the vehicle’s undercarriage, allowing for thorough inspections and repairs.

For electrical work, consider a multimeter and wire strippers to diagnose and address wiring issues effectively. Diagnostic scanners can greatly assist in identifying error codes and system malfunctions, streamlining the troubleshooting process. Finally, safety gear such as gloves and goggles is essential to protect yourself while working.

Safety Precautions During Repairs

Ensuring safety while working on vehicles is paramount. Adhering to specific guidelines helps prevent accidents and injuries, creating a secure environment for both the technician and the vehicle. Proper preparation and awareness of potential hazards are essential to facilitate a smooth workflow.

Essential Protective Gear

Wearing appropriate personal protective equipment (PPE) is crucial. Items such as gloves, goggles, and steel-toed boots provide necessary protection against injuries. Using ear protection can also be beneficial when working with loud machinery.

Work Area Organization

A tidy workspace significantly reduces the risk of accidents. Ensure that tools are stored properly, and any spills are cleaned immediately to prevent slips. Maintaining a clear area around the vehicle allows for safer movement and efficient work practices.