Ensuring optimal performance and longevity of your vehicle requires a thorough understanding of its components and systems. This section aims to provide essential insights and guidelines for addressing common issues, performing routine checks, and implementing effective solutions. Knowledge of the intricacies involved can significantly enhance the driving experience and safety on the road.

Familiarity with the vehicle’s mechanisms is crucial for any owner or enthusiast. Whether dealing with engine performance, electrical systems, or routine upkeep, a structured approach to problem-solving can lead to successful outcomes. This guide emphasizes the importance of methodical evaluation and preventive measures.

Utilizing available resources to diagnose and resolve challenges can empower individuals to take control of their vehicle’s maintenance. Clear instructions and detailed explanations serve as valuable tools in navigating repairs and enhancements, ensuring that both novices and seasoned individuals can benefit from the information provided.

Overview of 2007 Sprinter Maintenance

Regular upkeep of your vehicle is essential to ensure its longevity and optimal performance. This section provides a concise guide on essential practices and recommendations to maintain your vehicle effectively. By following these guidelines, you can prevent potential issues and enhance your driving experience.

Routine inspections and timely servicing are crucial components of vehicle care. These measures help identify and address any wear and tear, contributing to the overall reliability and efficiency of the vehicle.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 5,000 miles | Use manufacturer-recommended oil type. |

| Tire Rotation | Every 6,000 miles | Check for uneven wear. |

| Brake Inspection | Every 10,000 miles | Replace pads if necessary. |

| Fluid Levels Check | Monthly | Ensure all fluids are at appropriate levels. |

| Air Filter Replacement | Every 15,000 miles | Keep engine running efficiently. |

By adhering to these maintenance practices, vehicle owners can significantly enhance performance and safety. Regular checks not only extend the lifespan of the vehicle but also ensure a smoother and more enjoyable driving experience.

Common Issues and Solutions

This section addresses frequent problems encountered with a specific vehicle model and offers effective solutions to enhance functionality and reliability. Understanding these common issues can aid owners in maintaining optimal performance and prolonging the lifespan of their vehicle.

Electrical System Malfunctions

One of the prevalent challenges involves failures in the electrical system, often leading to difficulties in starting the vehicle or malfunctioning accessories. Checking battery connections and fuses is a crucial first step. If the battery is weak or the alternator is faulty, replacing these components can resolve many issues.

Engine Performance Problems

Another common concern is related to engine performance, which may manifest as reduced power or unusual noises. Regularly inspecting the air filter and fuel system can help identify blockages or leaks. Additionally, ensuring that all sensors are functioning correctly will contribute to smoother operation.

Essential Tools for Repairing Sprinter

Maintaining and servicing vehicles requires a well-equipped toolkit. Having the right instruments not only makes the process efficient but also ensures safety and effectiveness in handling various tasks.

- Wrenches: A variety of sizes is necessary for loosening and tightening different types of bolts.

- Socket Set: This is crucial for accessing hard-to-reach areas and allows for quick removal of fasteners.

- Screwdrivers: A selection of flathead and Phillips screwdrivers is essential for various adjustments and repairs.

- Pliers: These are useful for gripping, twisting, and cutting wires or components.

- Jack and Stands: Safe lifting of the vehicle is critical for performing underbody tasks.

In addition to the basic tools, specialized equipment can enhance your capability:

- Diagnostic Scanner: Helps in identifying issues quickly by reading error codes.

- Torque Wrench: Ensures bolts are tightened to the manufacturer’s specifications.

- Multimeter: Essential for checking electrical components and connections.

- Oil Filter Wrench: Simplifies the removal of oil filters during maintenance.

- Brake Bleeder Kit: Assists in flushing brake lines effectively.

Investing in quality tools is vital for any vehicle enthusiast. A comprehensive set enables effective troubleshooting and extends the lifespan of the vehicle.

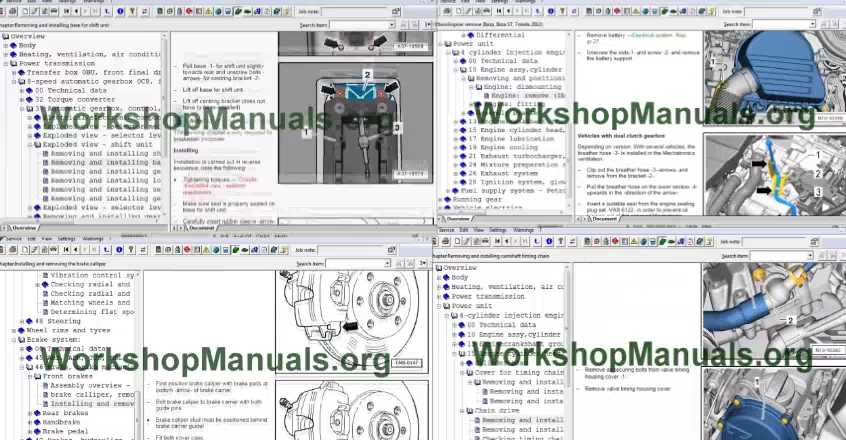

Step-by-Step Diagnostic Procedures

This section outlines a systematic approach to identifying and resolving issues in your vehicle. By following these detailed steps, you can effectively pinpoint the source of problems and ensure optimal performance.

1. Initial Assessment: Begin by gathering information about the symptoms. Listen for unusual noises, check warning lights, and note any irregular behaviors. Documenting these details will aid in the diagnostic process.

2. Visual Inspection: Conduct a thorough visual examination of key components. Look for signs of wear, damage, or loose connections. This step can often reveal issues that require immediate attention.

3. Testing Systems: Utilize diagnostic tools to test various systems within the vehicle. This may include electrical systems, fuel delivery, and ignition components. Record the readings for further analysis.

4. Analyze Results: Review the data collected from your tests. Compare results against manufacturer specifications to determine if any components are functioning outside acceptable limits.

5. Implement Solutions: Once you have identified the issue, proceed with the necessary repairs or adjustments. Ensure all actions are performed according to best practices to prevent further complications.

6. Final Testing: After making repairs, conduct a final series of tests to confirm that the problem has been resolved. Monitoring performance will help ensure reliability going forward.

Engine Troubleshooting Techniques

This section focuses on various approaches to diagnose and resolve issues related to engine performance. Understanding the underlying problems is essential for effective maintenance and ensures optimal functionality.

When faced with engine complications, it is crucial to follow a systematic methodology. Begin by gathering information about the symptoms and any warning indicators present. Utilize diagnostic tools to pinpoint the root cause and determine the best course of action.

| Common Symptoms | Possible Causes | Troubleshooting Steps |

|---|---|---|

| Unusual noises | Worn components | Inspect belts and pulleys |

| Excessive smoke | Oil leaks or combustion issues | Check oil levels and compression |

| Poor acceleration | Fuel delivery problems | Examine fuel filters and injectors |

| Overheating | Cooling system failure | Inspect coolant levels and radiator |

By adhering to these techniques, individuals can efficiently address engine challenges and maintain performance integrity. Consistent evaluation and prompt intervention play a vital role in prolonging engine lifespan.

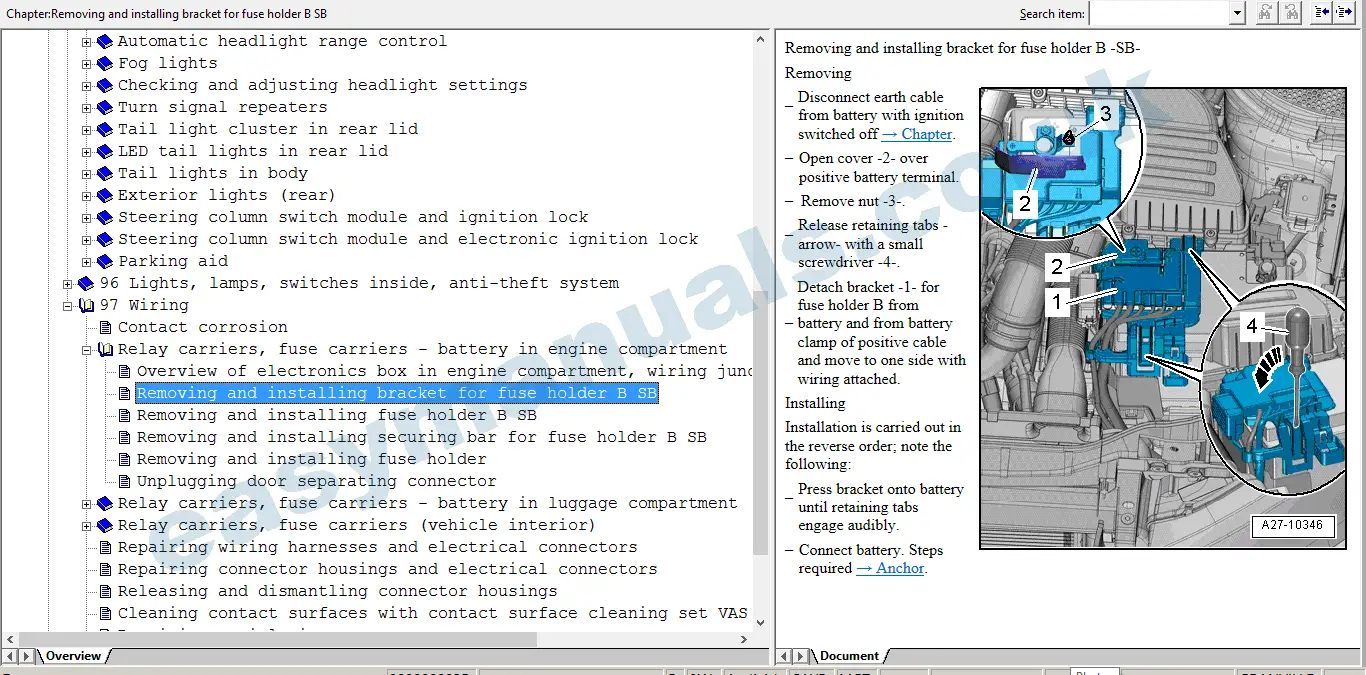

Electrical System Inspection Guide

This section aims to provide a comprehensive approach to assessing the functionality and safety of the electrical components in your vehicle. Regular evaluations are crucial for ensuring reliability and preventing potential issues that could arise from faulty wiring or connections.

Key Components to Inspect

- Batteries: Check for corrosion and ensure secure connections.

- Fuses: Inspect for any blown fuses and replace as necessary.

- Wiring Harness: Look for frayed or damaged wires that could cause shorts.

- Ground Connections: Verify that ground points are clean and tight.

- Switches: Test all switches for proper operation and responsiveness.

Inspection Process

- Begin with a visual inspection of all electrical components.

- Use a multimeter to check voltage levels at the battery and key connections.

- Test the functionality of lights and electronic systems.

- Ensure all connectors are secure and free from debris.

- Document any issues and take corrective actions as needed.

Braking System Maintenance Tips

Ensuring the optimal performance of your vehicle’s stopping mechanism is crucial for safety and reliability. Regular upkeep not only enhances functionality but also extends the lifespan of components.

1. Inspect Brake Pads and Discs: Regularly check the condition of brake pads and discs for wear and tear. Replace them when they show signs of thinning or uneven surfaces.

2. Check Fluid Levels: Monitor the brake fluid level consistently. Low fluid can lead to reduced braking efficiency. Always use the recommended type of fluid for your system.

3. Listen for Unusual Noises: Be attentive to any unusual sounds when applying brakes, such as squeaking or grinding. These can indicate issues that need immediate attention.

4. Maintain Clean Components: Ensure that all braking components are free from dirt and debris. Regular cleaning helps prevent corrosion and maintains effective operation.

5. Monitor Brake Response: Pay attention to how your vehicle responds when braking. If you notice any changes in feel or responsiveness, have the system examined.

6. Perform Regular Inspections: Schedule routine checks with a qualified technician to identify potential problems before they escalate into significant issues.

By adhering to these guidelines, you can ensure a well-functioning braking system that enhances your driving experience while prioritizing safety.

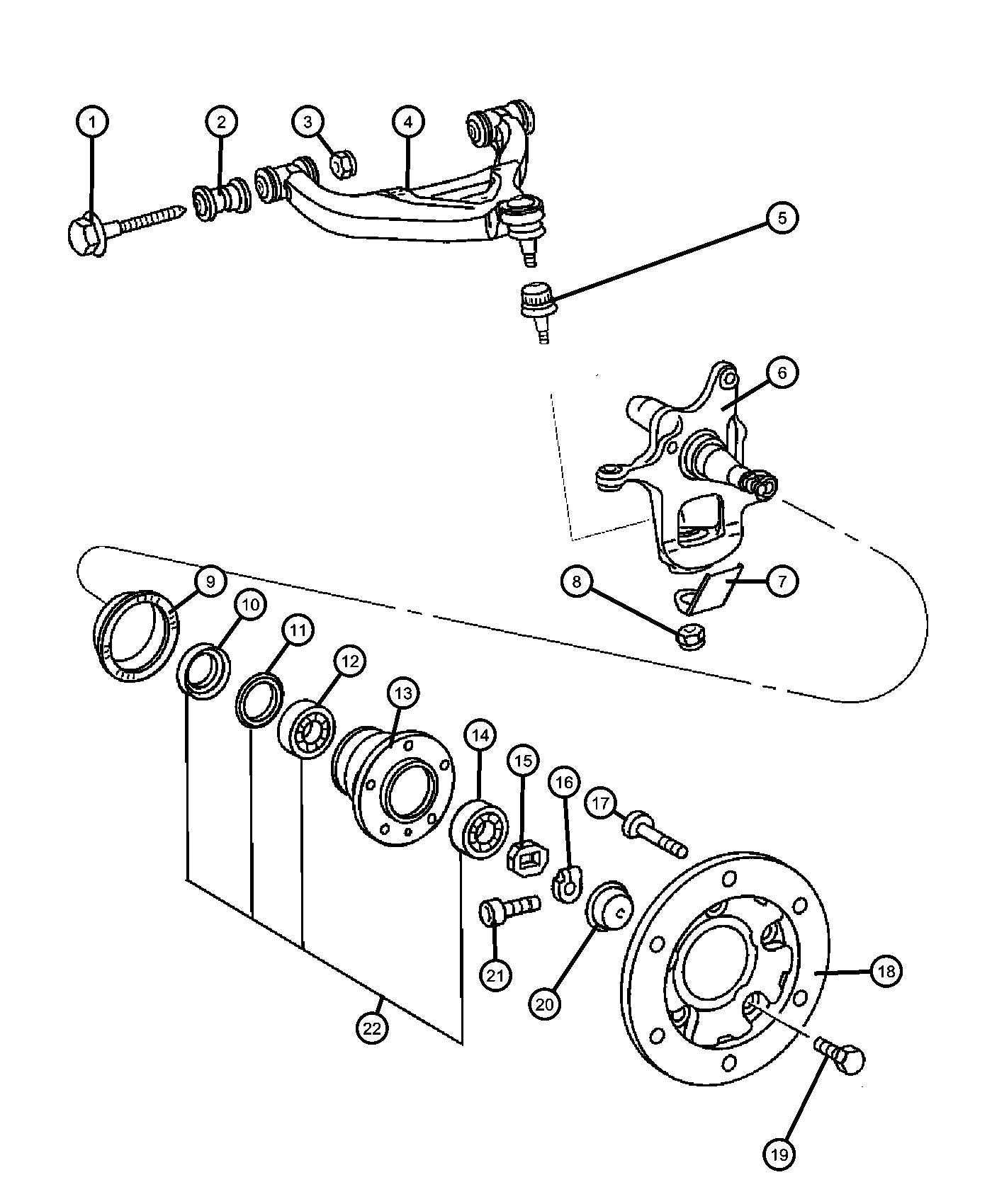

Suspension and Steering Adjustments

This section focuses on the essential modifications required for optimal handling and comfort in a vehicle. Proper alignment and suspension settings significantly influence driving dynamics, contributing to safety and overall performance. Understanding how to adjust these systems can enhance the driving experience and extend the lifespan of the vehicle’s components.

Importance of Proper Alignment

Maintaining accurate alignment is crucial for achieving the best steering response and tire longevity. Misalignment can lead to uneven tire wear, reduced fuel efficiency, and compromised safety. Regular inspections and adjustments can prevent these issues, ensuring smooth operation.

Suspension Settings Overview

Correct suspension settings help absorb road imperfections, providing a comfortable ride. Adjustments can vary based on load and driving conditions, so understanding these variables is key to maintaining optimal performance.

| Adjustment Type | Description |

|---|---|

| Toe Adjustment | Aligns the tires to point inward or outward, affecting handling and tire wear. |

| Camber Adjustment | Adjusts the tilt of the wheels, impacting stability during cornering. |

| Caster Adjustment | Modifies the angle of the steering axis, influencing steering effort and returnability. |

Transmission Care and Repair Methods

Ensuring the longevity and optimal performance of a vehicle’s shifting mechanism requires regular attention and effective techniques. Proper maintenance not only enhances functionality but also prevents costly issues in the long run.

Routine Inspections: Regularly checking for leaks, worn components, and fluid levels is crucial. Keeping an eye on these aspects helps identify problems early and allows for timely interventions.

Fluid Maintenance: Changing the transmission fluid according to the manufacturer’s recommendations is essential. Clean fluid promotes efficient operation and protects internal parts from wear and damage.

Heat Management: Excessive heat can be detrimental. Installing an auxiliary cooler or ensuring proper airflow can significantly reduce overheating risks during operation.

Diagnostic Tools: Utilizing diagnostic equipment can provide insights into performance issues. These tools help pinpoint faults, making it easier to address concerns accurately.

Professional Assistance: When encountering complex issues, consulting with a qualified technician is advisable. Their expertise ensures that any repairs or adjustments are performed correctly and safely.

Fuel System Service Recommendations

Proper maintenance of the fuel delivery system is essential for optimal engine performance and longevity. Regular checks and servicing can prevent common issues that may affect fuel efficiency and engine responsiveness.

Begin by inspecting fuel filters for clogs or contamination, as these components play a critical role in keeping the system clean. It is advisable to replace filters according to the manufacturer’s suggested intervals to ensure a steady flow of fuel.

Next, evaluate the fuel lines for any signs of wear, leaks, or corrosion. Addressing these issues promptly can prevent fuel loss and maintain pressure within the system. Additionally, inspect the fuel pump for functionality and noise, as any irregular sounds may indicate a need for replacement.

Moreover, consider cleaning the fuel injectors periodically to remove deposits that can hinder performance. Using high-quality fuel can also contribute to maintaining a clean system and enhancing overall efficiency.

Lastly, keep an eye on the fuel pressure regulator. Ensuring that it operates within the specified range will help maintain consistent fuel delivery, ultimately supporting smooth engine operation.

Regular Maintenance Schedule Explained

A consistent upkeep plan is essential for ensuring the longevity and reliability of any vehicle. Following a structured schedule not only helps prevent unexpected breakdowns but also enhances overall performance. Understanding the timing and nature of these maintenance tasks is crucial for vehicle owners to keep their transportation in optimal condition.

Key Maintenance Tasks

Several critical procedures should be performed at regular intervals. These tasks encompass various systems within the vehicle, focusing on safety, efficiency, and functionality. Below is a summary of these essential activities.

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 5,000 miles | Replace engine oil and filter to ensure proper lubrication. |

| Tire Rotation | Every 6,000 miles | Rotate tires to promote even wear and extend tire life. |

| Brake Inspection | Every 10,000 miles | Check brake pads and rotors for wear and effectiveness. |

| Fluid Check | Monthly | Inspect levels of coolant, brake fluid, and transmission fluid. |

Benefits of Adhering to the Schedule

Following a regular maintenance schedule leads to numerous advantages. It not only reduces the risk of costly repairs but also enhances fuel efficiency and safety. By staying proactive, owners can enjoy a smoother driving experience and extend the lifespan of their vehicle.

Safety Precautions During Repairs

When engaging in maintenance or troubleshooting tasks on vehicles, it is essential to prioritize safety to prevent accidents and injuries. Following established protocols ensures that the work environment remains secure for both the technician and the vehicle involved.

Before beginning any tasks, it is crucial to wear appropriate protective gear, including gloves, safety glasses, and steel-toed boots. This equipment minimizes the risk of physical harm from sharp tools or heavy components. Additionally, ensure that the workspace is well-ventilated and free of clutter to facilitate safe movement and reduce the chance of mishaps.

Always disconnect the battery and other power sources before conducting any service. This step helps prevent electrical shocks and accidental short circuits. Furthermore, using jack stands or other supports when elevating a vehicle is vital to avoid collapse and ensure stability.

Familiarize yourself with the tools and equipment necessary for the tasks at hand. Using the correct tools not only improves efficiency but also enhances safety by reducing the likelihood of tool-related accidents. It is also advisable to read any accompanying documentation to understand the proper procedures before proceeding.

Lastly, keep a first aid kit accessible and be aware of emergency protocols in case of an accident. Being prepared can make a significant difference in the outcome of an unforeseen situation.