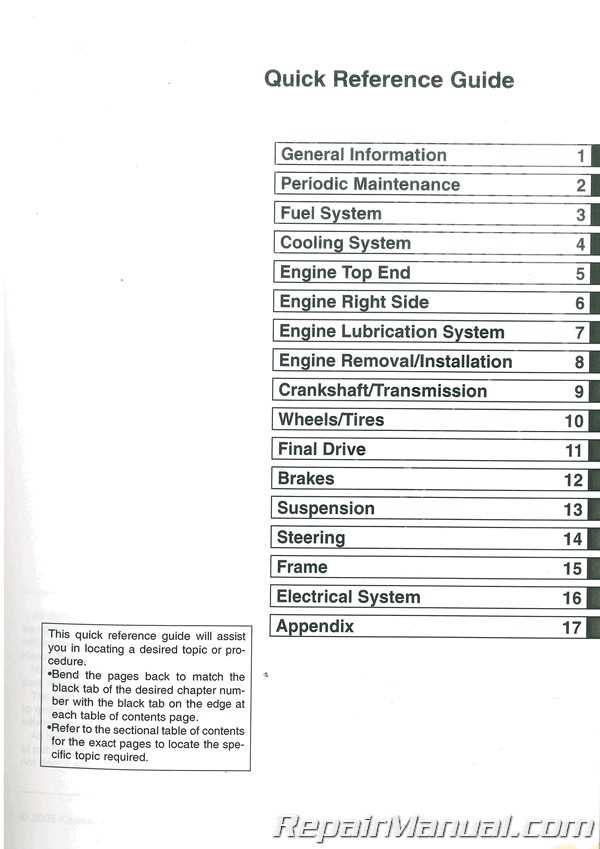

Maintaining a high-performance motorcycle is essential for ensuring optimal functionality and longevity. Every rider understands the significance of regular upkeep to enhance performance, safety, and overall enjoyment of the ride. This section delves into the intricacies of servicing a popular off-road machine, offering insights that both novice and experienced mechanics will find invaluable.

Proper knowledge of the various components and systems of the bike can prevent costly repairs and extend its lifespan. With a focus on systematic procedures, this guide provides step-by-step instructions, troubleshooting tips, and essential maintenance techniques. Whether it’s tackling engine issues or adjusting suspension, having a thorough understanding of your vehicle is crucial.

From routine checks to more complex repairs, being equipped with the right information allows riders to take control of their machines confidently. This resource aims to empower motorcycle enthusiasts with the expertise needed to keep their rides in peak condition, ensuring that every journey is both thrilling and safe.

Understanding the 2006 KX250F

This section provides an insightful overview of a high-performance off-road motorcycle, emphasizing its design, engineering, and features. This machine is renowned for its agility and power, making it a favorite among enthusiasts and competitive riders alike. The combination of advanced technology and robust construction delivers an exceptional riding experience, suitable for various terrains.

Key Features

One of the standout characteristics of this model is its lightweight frame, which enhances maneuverability and responsiveness. The powerful engine is designed to offer optimal performance, providing both speed and torque when needed. Additionally, the suspension system plays a crucial role in handling rough trails, ensuring stability and comfort during rides.

Maintenance Considerations

Regular upkeep is essential to maintain the performance and longevity of this motorcycle. Key areas for attention include the engine, suspension components, and braking system. Ensuring that these parts are regularly checked and serviced can prevent potential issues and enhance the overall riding experience.

Common Issues with the KX250F

When it comes to off-road bikes, enthusiasts often encounter various challenges that can affect performance and reliability. Understanding these frequent problems is crucial for maintaining optimal functionality and ensuring a smooth riding experience. This section delves into some of the typical concerns that riders may face.

Engine Performance

A notable issue riders may experience involves engine performance, particularly with the fuel delivery system. Inconsistent throttle response can lead to frustrating rides, often traced back to clogged injectors or air leaks in the intake system. Regular cleaning and maintenance can mitigate these problems.

Suspension and Handling

Another common concern relates to the suspension system. Riders often report excessive sagging or inadequate rebound, which can compromise handling and comfort. Adjusting the settings according to the rider’s weight and riding style is essential for achieving the best performance from the suspension.

Essential Tools for Repairing KX250F

When it comes to maintaining and fixing a high-performance motorcycle, having the right set of instruments is crucial. The following list highlights the necessary gear that every enthusiast should have at hand to ensure effective and efficient servicing.

- Socket Set: A comprehensive socket set with various sizes will facilitate the removal and installation of nuts and bolts.

- Torque Wrench: This tool ensures that components are tightened to the manufacturer’s specifications, preventing damage and ensuring safety.

- Wrenches: Both adjustable and fixed wrenches are essential for various tasks, from simple adjustments to complex assemblies.

- Screwdrivers: A selection of Phillips and flathead screwdrivers will cover most needs for disassembling and reassembling parts.

- Pliers: Needle-nose and standard pliers are invaluable for gripping, bending, and cutting wires or small components.

- Oil and Grease: Quality lubricants are necessary for maintaining the longevity of moving parts.

- Cleaning Supplies: Brushes, rags, and solvents are essential for keeping the machine in pristine condition.

- Feeler Gauges: Useful for measuring gaps and ensuring precise adjustments in engine components.

- Stand: A sturdy stand will help stabilize the bike while working on it, providing easier access to various areas.

Having these essential tools at your disposal will not only streamline the process but also enhance your ability to diagnose and address any issues effectively.

Step-by-Step Maintenance Procedures

Proper upkeep of your two-wheeled machine is essential for optimal performance and longevity. This section outlines essential procedures that ensure your vehicle runs smoothly and efficiently. Following these systematic steps will help you identify potential issues before they escalate, thereby enhancing your riding experience.

Routine Checks

Conducting regular inspections is vital for maintaining the health of your bike. These checks can help in early detection of wear and tear. Here are some key areas to focus on:

| Component | Frequency | Action |

|---|---|---|

| Oil Level | Every Ride | Inspect and top up if necessary |

| Air Filter | Every Month | Clean or replace as needed |

| Tire Pressure | Weekly | Check and adjust to specifications |

| Brakes | Monthly | Inspect pads and fluid levels |

Fluid Changes

Regular fluid replacement is critical to keeping your engine and transmission functioning properly. Here’s a brief guideline:

| Fluid Type | Interval | Procedure |

|---|---|---|

| Engine Oil | Every 20-30 Hours | Drain, replace, and check filter |

| Coolant | Every 2 Years | Flush and replace with new fluid |

| Brake Fluid | Annually | Flush and replace with fresh fluid |

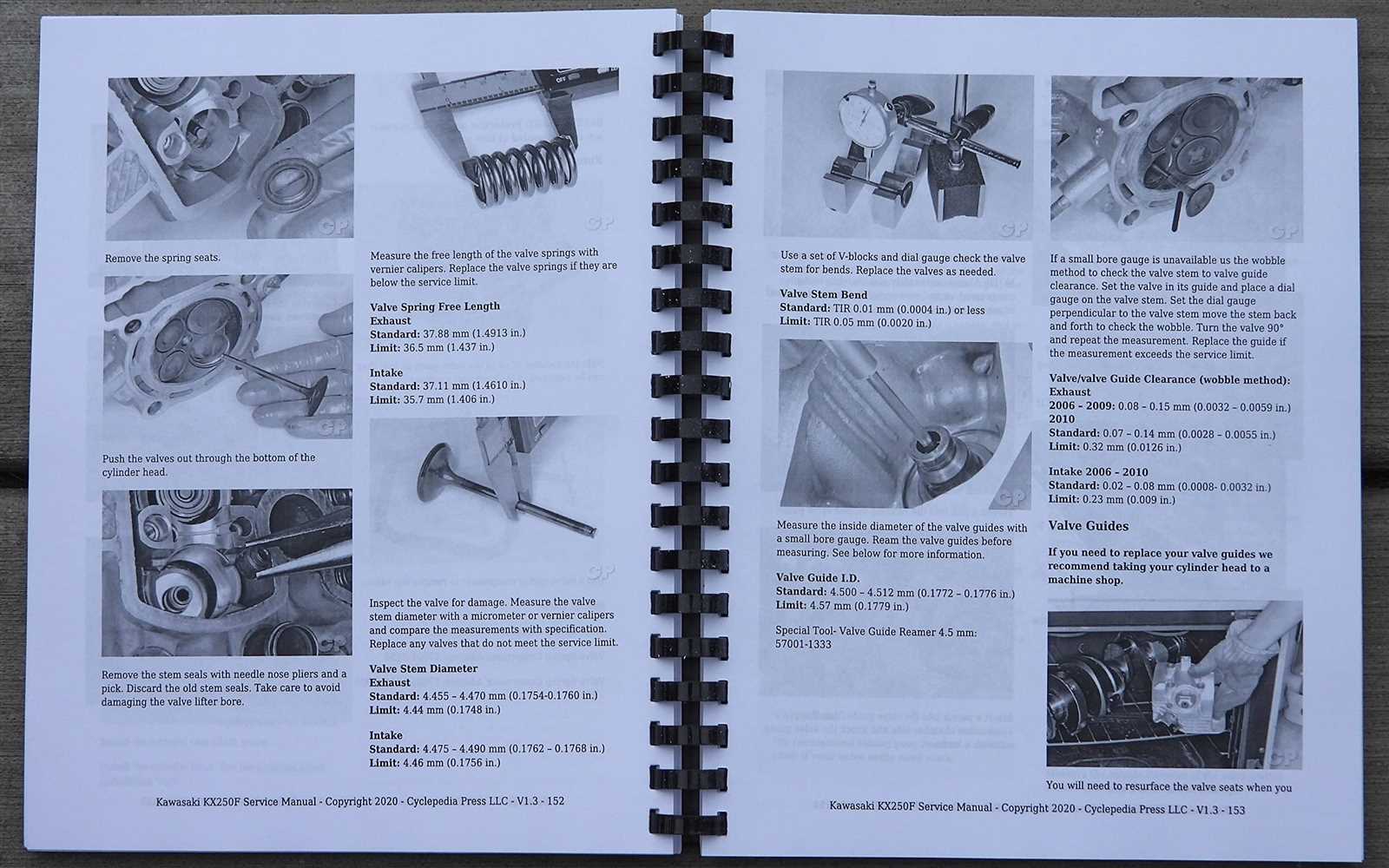

Engine Components and Their Functions

The engine is a complex assembly of various parts, each playing a crucial role in the overall performance and efficiency of the machine. Understanding these components and their functions is essential for effective maintenance and optimal operation.

Cylinder: This is the chamber where fuel and air mix and ignite, generating power. It is central to the engine’s function.

Piston: Moving within the cylinder, the piston compresses the air-fuel mixture and transfers the resulting energy to the crankshaft.

Crankshaft: This component converts the linear motion of the piston into rotational motion, ultimately driving the vehicle’s wheels.

Valves: These open and close at precise moments to control the intake of air and fuel, as well as the exhaust of gases, ensuring efficient combustion.

Camshaft: Responsible for operating the valves, the camshaft is synchronized with the crankshaft to optimize timing during the engine’s cycle.

Timing Chain/Belt: This element connects the crankshaft and camshaft, ensuring they operate in harmony, critical for the engine’s timing.

Fuel Injector: It delivers the precise amount of fuel into the combustion chamber, playing a key role in maintaining optimal engine performance.

Exhaust System: This system directs and treats the gases produced during combustion, reducing harmful emissions and noise.

Each component works in harmony, creating a powerful engine capable of delivering ultimate performance when properly maintained.

Diagnosing Electrical Problems

Identifying issues within the electrical system of a motorcycle can be a challenging yet essential task for ensuring optimal performance. A systematic approach is key to isolating faults effectively, enabling a rider to maintain their machine in top condition. Understanding the common symptoms and utilizing appropriate diagnostic techniques will facilitate quicker resolutions to electrical malfunctions.

Common Symptoms of Electrical Issues

Motorcycles may exhibit various signs when electrical problems arise. Frequent starting difficulties, flickering lights, or erratic behavior of the gauge cluster are typical indicators. Inspecting the battery and connections is often the first step, as a weak or poorly connected battery can lead to widespread failures in the electrical system.

Diagnostic Steps to Follow

Begin by checking the fuses for any signs of damage or blown components. Replacing faulty fuses can sometimes resolve the issue immediately. Next, utilize a multimeter to measure voltage levels throughout the system. This will help in identifying weak spots or shorts. Additionally, examining wiring harnesses for fraying or corrosion can uncover hidden problems that may affect the electrical integrity of the motorcycle.

Suspension Setup and Adjustments

Achieving optimal performance from your motorcycle requires careful attention to the suspension system. Proper setup and adjustments can significantly enhance handling, stability, and rider comfort. This section delves into the essential aspects of tuning the suspension to suit various riding styles and conditions, ensuring a smoother and more controlled experience on the track or trail.

Understanding Suspension Components is crucial. The primary elements include forks at the front and a shock absorber at the rear. Each component plays a vital role in how the bike interacts with the terrain. Familiarizing yourself with the settings and adjustments available for these parts is the first step toward an effective setup.

Initial Setup involves setting the correct sag, which is the distance the suspension compresses under the weight of the rider. This measurement is critical as it influences the bike’s balance and responsiveness. Aim for approximately 30% of the total suspension travel for the rider’s weight. Adjusting preload can help achieve the desired sag, ensuring the bike performs optimally under varying conditions.

Damping Adjustments are another vital area to focus on. Both compression and rebound damping settings control how quickly the suspension responds to bumps and dips. For softer terrain, a more forgiving setup may be preferable, while stiffer settings can be beneficial for smoother tracks. Experiment with these settings to find the perfect balance that suits your riding style.

Regular Maintenance of suspension components is essential for consistent performance. Inspecting seals, oil levels, and bushings can prevent wear and tear, ensuring that adjustments remain effective. Keeping the system clean and well-lubricated will prolong its lifespan and improve reliability.

By taking the time to fine-tune the suspension system, riders can enjoy enhanced control, comfort, and confidence on their journeys. Whether navigating tight corners or tackling rough trails, a well-adjusted suspension can make all the difference.

Replacing the KX250F Chain and Sprockets

Maintaining optimal performance and safety of your off-road machine often involves replacing the drive components. The chain and sprockets play a crucial role in transferring power from the engine to the wheels. Regular inspections and timely replacements can prevent excessive wear and improve overall ride quality.

Before beginning the replacement process, gather the necessary tools and parts:

- New chain

- New front and rear sprockets

- Chain breaker tool

- Wrench set

- Torque wrench

- Socket set

- Lubricant

Follow these steps for a successful replacement:

- Start by lifting the machine securely on a stand to access the rear wheel.

- Remove the rear wheel by loosening the axle nut and sliding the wheel out of the swingarm.

- Detach the old chain by breaking it with the chain tool or using a quick link if applicable.

- Remove the rear sprocket by unscrewing the bolts and sliding it off the hub.

- Proceed to the front sprocket by removing the cover and unscrewing the retaining bolts.

- Install the new front sprocket, ensuring proper alignment and torque specifications.

- Attach the new rear sprocket, making sure it is securely fastened.

- Thread the new chain through the rear sprocket and around the front sprocket, connecting it properly.

- Reinstall the rear wheel, ensuring the chain tension is adjusted correctly.

- Lubricate the chain and check all components for proper alignment and security.

After completing the installation, it’s advisable to take a short test ride to ensure everything functions smoothly. Regular maintenance of these components will enhance the longevity and performance of your vehicle.

Upgrading Performance Parts

Enhancing the capabilities of your motorcycle involves selecting the right performance components that can significantly improve handling, speed, and overall ride quality. By focusing on key areas such as the engine, suspension, and exhaust system, riders can unlock the full potential of their machine.

One of the most impactful upgrades is to the engine. Replacing the stock air filter with a high-flow version allows for better airflow, leading to increased horsepower. Additionally, a performance-oriented fuel map can optimize engine efficiency, ensuring that the bike runs smoothly under various conditions.

Suspension upgrades are equally essential. High-quality fork springs and shock absorbers can enhance stability and control, especially during aggressive riding. Adjusting these components according to personal riding style and terrain can lead to a more responsive and enjoyable experience.

Lastly, the exhaust system plays a crucial role in performance enhancement. A lighter, less restrictive exhaust can improve both power output and sound, giving the bike a more aggressive tone while also shedding unnecessary weight. Together, these upgrades can transform your ride, providing a blend of power, agility, and excitement on every adventure.

Safety Tips for DIY Repairs

Engaging in do-it-yourself maintenance can be rewarding, but it also comes with its own set of risks. Prioritizing safety ensures that the process is not only effective but also minimizes the likelihood of accidents. Understanding and following essential precautions can significantly enhance your repair experience.

| Tip | Description |

|---|---|

| Wear Protective Gear | Always use safety glasses, gloves, and appropriate clothing to protect yourself from debris and sharp objects. |

| Work in a Well-Ventilated Area | Ensure good airflow when using chemicals or tools that produce fumes to avoid inhalation hazards. |

| Keep a First Aid Kit Handy | Have basic medical supplies nearby to address minor injuries promptly. |

| Understand Your Tools | Familiarize yourself with the tools you are using to prevent misuse and potential injuries. |

| Follow Instructions Carefully | Adhere to guidelines and steps thoroughly to avoid mistakes that could lead to dangerous situations. |

| Disconnect Power Sources | Always unplug or disconnect batteries before starting any maintenance work to prevent accidental activation. |

| Be Mindful of Your Surroundings | Ensure your workspace is clear of obstacles to reduce the risk of tripping or falling. |