Maintaining all-terrain vehicles is essential for ensuring their longevity and optimal performance. This section provides valuable insights into the various aspects of upkeep, troubleshooting, and enhancement for your vehicle. Understanding the intricacies of mechanical systems can empower owners to take proactive steps in preserving their investment.

From routine inspections to complex repairs, having a thorough understanding of each component is crucial. This resource aims to equip enthusiasts and operators with practical knowledge and effective techniques to tackle common challenges. By familiarizing yourself with the systems at play, you can confidently address issues as they arise.

Whether you’re seeking to enhance your vehicle’s capabilities or simply looking to maintain its functionality, this guide serves as a reliable companion. Emphasizing hands-on experience, the following sections delve into essential procedures, tools, and tips that will assist you in your maintenance journey.

Overview of 2004 Polaris Ranger

This section provides a comprehensive examination of a versatile all-terrain vehicle designed for various outdoor applications. Known for its robust construction and reliable performance, this machine is favored by enthusiasts and professionals alike for its adaptability in rugged environments.

Equipped with a powerful engine, it ensures smooth operation and efficient handling, making it suitable for tasks ranging from work to recreation. The vehicle’s spacious cabin accommodates multiple passengers, enhancing its functionality for both leisure and utility purposes.

Additionally, it features advanced suspension systems that provide excellent stability and comfort, allowing users to traverse uneven terrains with ease. This remarkable vehicle combines power, durability, and user-friendly design, making it an ideal choice for those seeking reliability in challenging conditions.

Common Issues and Solutions

This section addresses frequently encountered problems and their corresponding remedies, providing valuable insights for effective troubleshooting and maintenance. By understanding these typical challenges, users can enhance the longevity and performance of their equipment.

| Issue | Description | Solution |

|---|---|---|

| Engine Won’t Start | Unit fails to initiate, often due to battery or ignition problems. | Check battery connections and replace if necessary; inspect the ignition system. |

| Overheating | Excessive heat buildup may lead to performance issues. | Ensure the cooling system is functioning properly; clean any debris blocking airflow. |

| Poor Handling | Difficulty in steering or control, often caused by tire or suspension issues. | Examine tire pressure and tread; inspect suspension components for wear. |

| Electrical Failures | Malfunctions in lighting or other electrical systems can occur. | Inspect wiring for damage; replace faulty fuses and connections as needed. |

Essential Maintenance Procedures

Regular upkeep is vital for ensuring the longevity and performance of your vehicle. By adhering to systematic maintenance routines, you can prevent issues before they arise and keep your equipment operating smoothly.

Here are some key maintenance tasks to consider:

- Fluid Checks: Regularly inspect and replace essential fluids, including engine oil, coolant, and transmission fluid.

- Tire Maintenance: Monitor tire pressure and tread wear. Rotate tires periodically to promote even wear.

- Brake Inspection: Examine brake components for wear and replace pads or discs as necessary to ensure optimal stopping power.

- Battery Care: Check battery terminals for corrosion and ensure secure connections. Test battery performance regularly.

- Filters Replacement: Replace air and fuel filters according to manufacturer recommendations to maintain efficiency.

- Inspection of Belts and Hoses: Look for signs of wear or damage on belts and hoses, and replace them as needed to avoid breakdowns.

Adhering to these fundamental practices will help sustain the performance of your vehicle, allowing you to enjoy reliable operation for years to come.

Electrical System Troubleshooting

Diagnosing issues within the electrical framework of a vehicle is essential for maintaining optimal performance and safety. This process involves systematic checking of various components to identify faults that may disrupt functionality. A thorough understanding of the system’s layout and operation is crucial for effective resolution of electrical problems.

Common Issues and Symptoms

Several common problems can arise in the electrical system, such as intermittent power failures, flickering lights, or malfunctioning accessories. These symptoms often indicate underlying issues, such as faulty wiring, blown fuses, or defective connectors. Recognizing these signs early can prevent further complications and costly repairs.

Troubleshooting Steps

Begin troubleshooting by inspecting all wiring and connections for signs of wear or damage. Utilize a multimeter to check voltage levels at various points throughout the system. Testing fuses and relays should also be a priority, as these components can significantly impact electrical performance. Documenting findings during this process aids in tracking down persistent issues and ensures a comprehensive approach to repairs.

Engine Specifications and Performance

This section delves into the key attributes and operational capabilities of the power unit designed for off-road vehicles. Understanding these elements is essential for enthusiasts and technicians alike, as they influence both functionality and efficiency.

The heart of the vehicle typically features a multi-cylinder configuration, providing a balance between torque and power output. With advancements in engineering, these engines are designed to optimize fuel consumption while delivering robust performance under varying conditions. The integration of electronic fuel injection systems enhances responsiveness and adaptability, ensuring a smooth driving experience.

Power Output: The engine is engineered to deliver impressive horsepower, making it suitable for diverse terrains. This output is crucial for tasks ranging from recreational activities to utility purposes.

Torque Characteristics: A well-calibrated torque curve is essential for off-road applications. The ability to generate substantial low-end torque allows for effective acceleration and maneuverability in challenging environments.

Cooling System: An efficient cooling mechanism is vital to maintain optimal operating temperatures, preventing overheating during extended use. This system is often designed to withstand harsh conditions, ensuring reliability and longevity.

Emissions Control: Modern engines incorporate advanced emissions control technologies, contributing to reduced environmental impact. These innovations align with regulatory standards while maintaining performance levels.

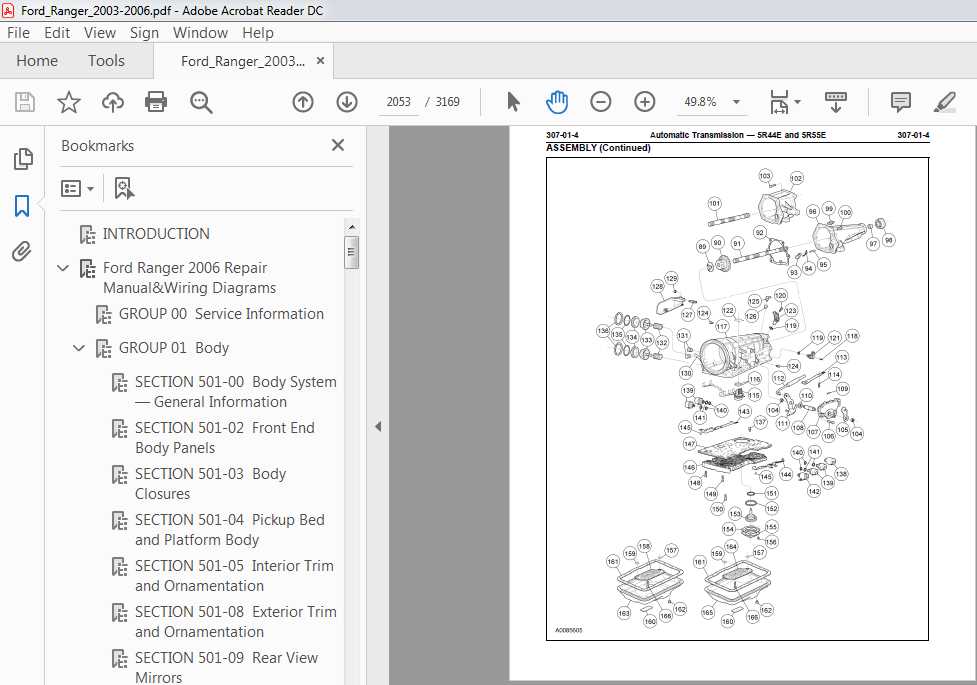

Transmission and Drivetrain Insights

The transmission and drivetrain systems are crucial components that play a significant role in the overall performance and efficiency of any off-road vehicle. Understanding how these systems operate can greatly enhance maintenance practices and troubleshooting efforts.

Key Components of the Drivetrain

- Transmission: Converts engine power into usable torque for driving.

- Drive Shaft: Transfers power from the transmission to the wheels.

- Differential: Allows for variations in wheel speed during turns, improving handling.

- Axles: Connect the wheels to the drivetrain, bearing the vehicle’s weight and torque.

Common Issues and Solutions

- Fluid Leaks: Regularly check for fluid levels and inspect seals and gaskets for wear.

- Strange Noises: Unusual sounds may indicate problems with bearings or gears; seek professional evaluation.

- Shifting Difficulties: Ensure the transmission fluid is at the correct level and quality; consider adjustment or replacement if needed.

- Vibration During Operation: Inspect drive shafts and joints for damage; balance or replace as necessary.

Suspension and Steering Adjustments

Proper alignment and tuning of the suspension and steering components are crucial for ensuring optimal performance and safety of the vehicle. Adjustments in these systems can significantly enhance ride comfort, handling, and overall driving experience. This section covers essential procedures and considerations for fine-tuning these critical elements.

Key Considerations for Suspension Setup

When addressing the suspension system, it’s vital to assess the vehicle’s weight distribution and intended use. Factors such as load capacity and terrain can influence the choice of components and their adjustments. Spring rates and shock absorber settings should be tailored to achieve the desired balance between comfort and stability.

Steering Alignment Techniques

Accurate steering alignment is essential for maintaining directional control. Begin by checking the toe angle and adjusting it to meet the manufacturer’s specifications. Additionally, ensure that the caster and camber angles are correctly set to enhance stability and responsiveness during operation. Regular inspections and adjustments will help mitigate tire wear and improve handling precision.

Bodywork Repair Techniques

Repairing the exterior structure of vehicles requires a range of skills and techniques to restore their original appearance and functionality. Understanding the nuances of various methods is essential for achieving quality results while ensuring the longevity of the materials involved.

Common Techniques

Several widely used approaches exist for addressing exterior damage, including dent removal, surface refinishing, and panel replacement. Each method serves a specific purpose depending on the extent and nature of the damage.

Materials and Tools

The choice of materials and tools is critical in achieving effective results. A variety of options are available, from traditional methods to modern advancements in technology. Proper selection enhances efficiency and ensures a professional finish.

| Technique | Description | Tools Required |

|---|---|---|

| Dent Removal | Method for pulling out dents without damaging the paint. | Dent puller, heat gun |

| Surface Refinishing | Restoration of the original surface finish through sanding and repainting. | Sander, primer, paint |

| Panel Replacement | Complete removal and replacement of damaged sections. | Wrenches, welding equipment |

Safety Guidelines and Best Practices

Ensuring safety while performing maintenance or troubleshooting is paramount for both the operator and the equipment. Following established procedures and employing protective measures can significantly reduce the risk of accidents and enhance the efficiency of the work process.

Before starting any task, familiarize yourself with the specific safety instructions related to the equipment. Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and helmets, to guard against potential hazards. Keep the workspace organized and free from clutter to minimize the chance of slips or falls.

It is essential to use the correct tools for each job, as improper equipment can lead to injuries or damage. Ensure that all tools are in good condition and suitable for the task at hand. Additionally, always disconnect power sources before performing maintenance to prevent accidental startups.

Regularly inspect the equipment for any signs of wear or malfunction. Addressing issues promptly can prevent larger problems from arising. Finally, keep emergency procedures accessible and ensure that all personnel are aware of them, promoting a culture of safety within the team.

Parts Replacement and Upgrades

Maintaining and enhancing your vehicle’s performance often requires attention to component replacements and improvements. Upgrading parts not only boosts efficiency but can also enhance the overall longevity of the machine. Understanding the options available for replacements and the benefits they offer is crucial for any enthusiast or owner.

Choosing Quality Components

When selecting replacement parts, prioritize high-quality components that are designed for compatibility with your specific model. Original equipment manufacturers (OEM) parts ensure reliability, while aftermarket options may provide enhanced performance features. Researching user reviews and consulting experts can aid in making informed choices.

Common Upgrades for Enhanced Performance

Several upgrades can significantly improve functionality. For instance, upgrading the suspension system can enhance stability and handling, especially in rugged terrains. Additionally, performance exhaust systems may improve engine efficiency and sound, while upgraded brakes provide better stopping power. Each upgrade should be considered based on individual needs and usage scenarios.