In every household, keeping the environment clean and fresh is essential for comfort and health. To maintain such an atmosphere, effective upkeep of your cleaning equipment is crucial. When issues arise or performance starts to dwindle, it helps to have a reliable source of information to bring the device back to optimal functioning.

This guide provides a detailed overview of routine care and problem-solving techniques. From examining the essential components to addressing specific malfunctions, you’ll find practical steps to keep your device performing at its best. By understanding these straightforward procedures, you’ll extend the service life of your equipment and ensure consistent results.

Whether you’re a first-time user or experienced in managing household appliances, this resource is designed to be intuitive and clear. Each section covers distinct aspects, enabling you to identify issues quickly and apply solutions with confidence. Let’s delve into the key methods that help retain the efficiency of your home assistant over time.

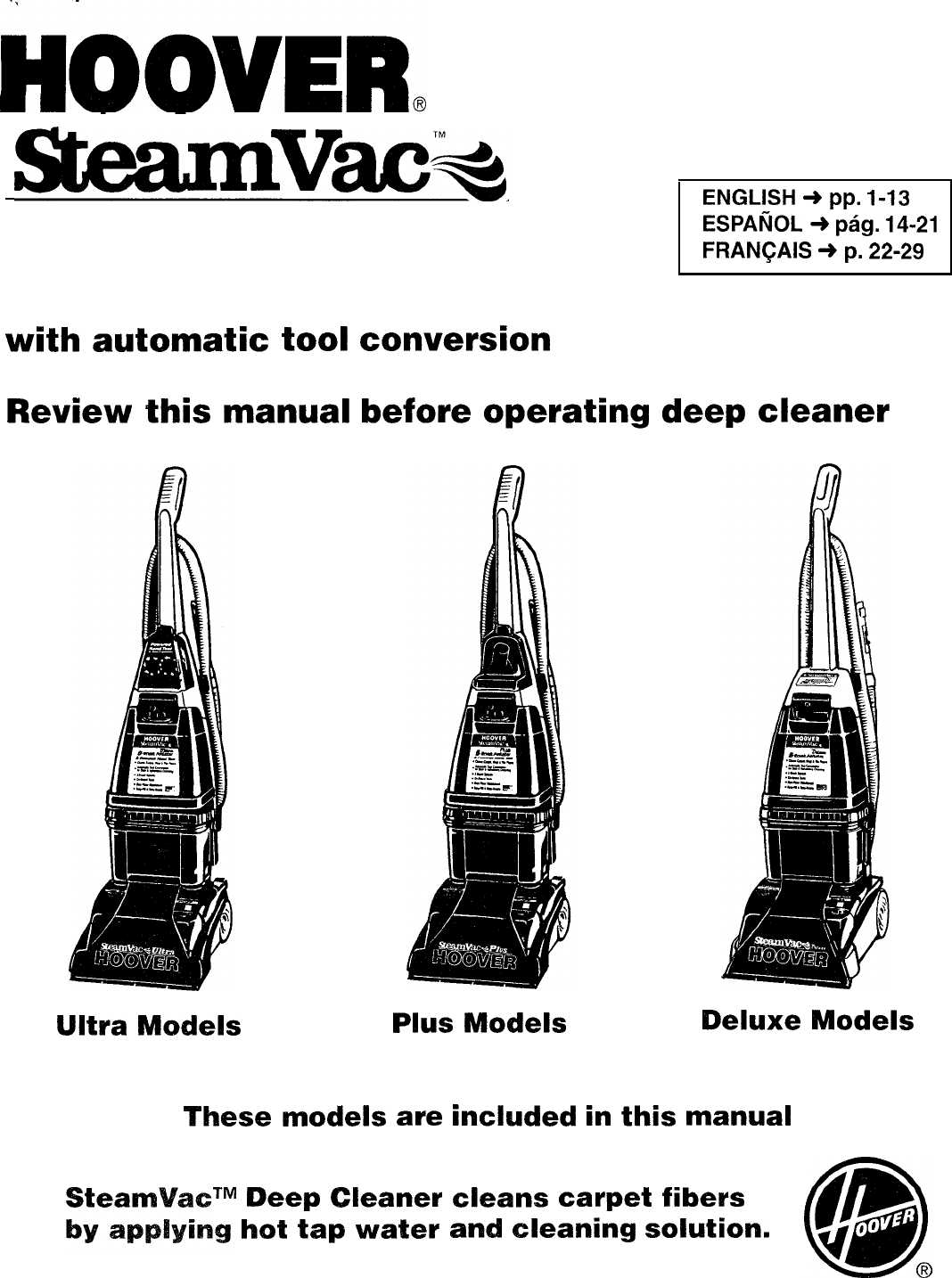

Hoover Vacuum Cleaner Repair Manual

In this section, we provide guidance on restoring functionality and improving the performance of home cleaning equipment. The focus is on understanding how common issues may impact operation and what steps can be taken to address them effectively.

We’ll cover a range of troubleshooting techniques, from resolving minor blockages to addressing power inconsistencies, all aimed at maximizing efficiency and extending the device’s life span. By exploring these practical steps, users can approach issues with confidence, ensuring that their equipment performs optimally with minimal downtime.

Regular maintenance is also essential to avoid potential complications. Here, you’ll find advice on simple preventive measures and component checks that can make a noticeable difference in overall reliability and usability. With proper care and attention, any user can help keep their cleaning tool in excellent working condition for years to come.

Identifying Common Hoover Vacuum Issues

Understanding the typical challenges with these cleaning appliances can help maintain efficient performance and prolong their life. Recognizing specific issues early on allows for straightforward troubleshooting and prevention of more significant malfunctions. This section highlights some frequently encountered problems and their primary causes.

Power and Suction Problems

Power-related issues and decreased suction are common among home cleaning devices. If the machine struggles to turn on or maintain suction, blockages in the hose, filter obstructions, or a damaged power cord could be the reason. Regular maintenance and component inspection are key to preventing these malfunctions.

Brush Roll and Belt Issues

A malfunctioning brush roll or broken belt can reduce cleaning efficiency, especially on carpets. Signs include an unresponsive roller or unusual sounds during operation. Checking for tangled hair or debris around the brush and ensuring the belt is intact can resolve these issues.

| Problem Type | Possible Cause | Solution |

|---|

| Step | Description | ||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. Access the Motor Housing | Un

Fixing Power Cord ProblemsIssues with the power cord can hinder the performance of your cleaning device, making it essential to address them promptly. Understanding the common problems associated with power cords can help you identify and resolve these issues effectively. Identifying DamageBegin by examining the cord for visible signs of wear or damage. Look for frayed edges, cuts, or exposed wires. Any visible damage may indicate that the cord needs replacement to ensure safety and functionality. Testing the Connection

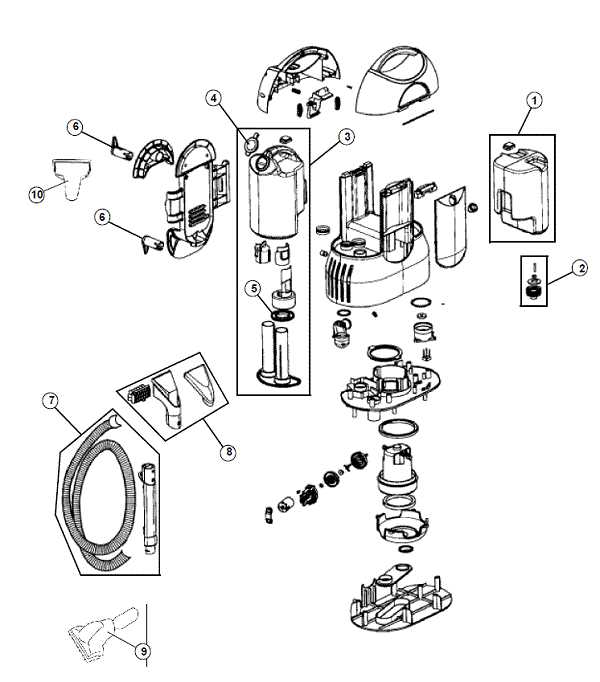

If the device does not turn on, check the connection points. Ensure that the plug is firmly inserted into the outlet. Additionally, you can test the outlet with another device to confirm it is functioning correctly. Sometimes, the problem lies not with the cord but with the electrical supply. Cleaning and Replacing FiltersMaintaining optimal performance of your device involves regular attention to its filtration system. Keeping filters clean is essential for ensuring efficient airflow and preventing dust accumulation, which can hinder functionality. Understanding how to properly clean and replace these components will not only prolong the life of the appliance but also improve its effectiveness. Importance of Regular MaintenanceRegular maintenance of the filtration elements is crucial for effective operation. Over time, filters can become clogged with debris, reducing suction power and increasing energy consumption. By performing routine checks, you can ensure that your device continues to operate at peak efficiency. Steps for Cleaning and ReplacementTo maintain the filtration system, begin by removing the filter according to the manufacturer’s instructions. Gently tap or brush off loose dirt and debris. For thorough cleaning, rinse the filter under warm water and allow it to air dry completely before reinserting it. If the filter is worn or damaged, consider replacing it with a new one to ensure optimal performance. Always refer to the guidelines provided to choose the correct replacement. Troubleshooting Suction Loss

Loss of suction can be a frustrating issue, affecting the performance of your cleaning device. Identifying the underlying cause is essential for restoring efficiency and ensuring a thorough cleaning experience. This section outlines common factors that may contribute to reduced suction and offers practical solutions. Begin by checking the following components:

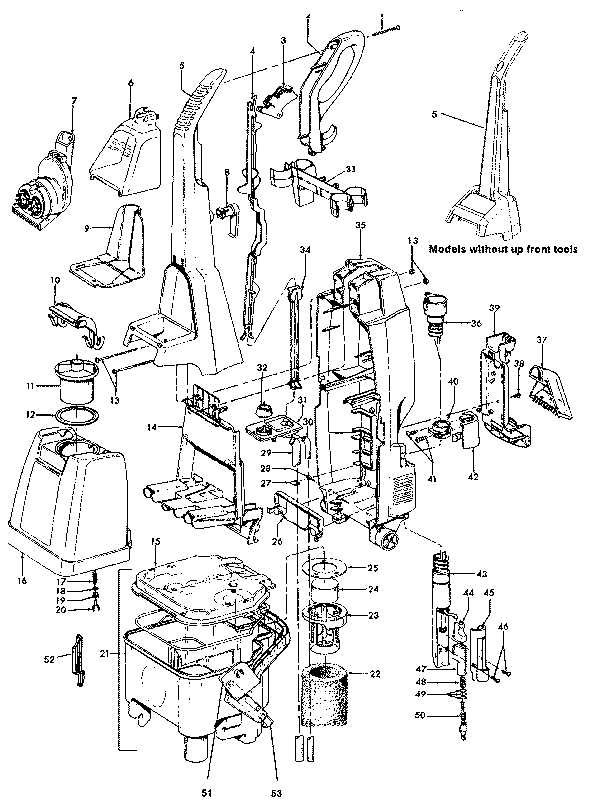

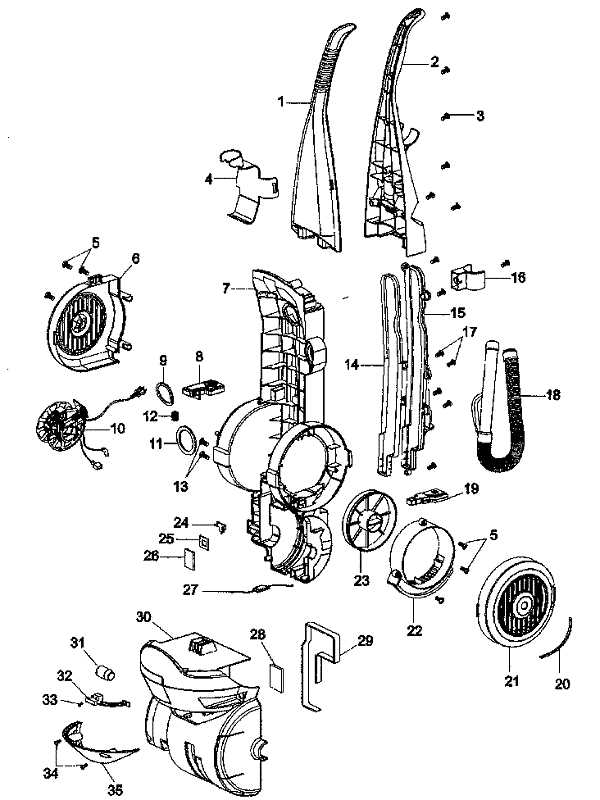

By systematically examining these elements, you can often pinpoint the cause of diminished performance and take corrective action to enhance the functionality of your device. Repairing a Damaged Brush RollThe brush roll plays a crucial role in maintaining the effectiveness of your cleaning device. A malfunctioning brush can lead to suboptimal performance, making it essential to address any issues promptly. This section will guide you through the steps necessary to restore the functionality of a compromised brush roll. Identifying DamageBefore proceeding with any restoration efforts, it is important to determine the nature and extent of the damage. Common signs of a problematic brush roll include unusual noises, decreased suction power, or visible wear and tear. Inspect the brush carefully for frayed bristles, obstructions, or any signs of warping. Tools NeededGathering the right tools can streamline the process. Below is a list of essential items:

By following these steps and using the appropriate tools, you can effectively restore the functionality of the brush roll, ensuring your cleaning equipment operates at its best. Addressing Belt Slipping Issues

Belt slipping can lead to decreased efficiency in cleaning devices, making it essential to identify and resolve this problem. Understanding the underlying causes of belt slippage can help users maintain optimal performance and prolong the life of their equipment. This section outlines common reasons for this issue and offers effective solutions. Common Causes of Belt SlippingThere are several factors that may contribute to belt slipping in cleaning apparatuses. These include wear and tear, incorrect tension, and debris accumulation. Regular maintenance is vital to prevent these issues from arising. Below is a summary of the most common causes:

Solutions for Belt SlippingTo resolve belt slipping issues, consider the following actions:

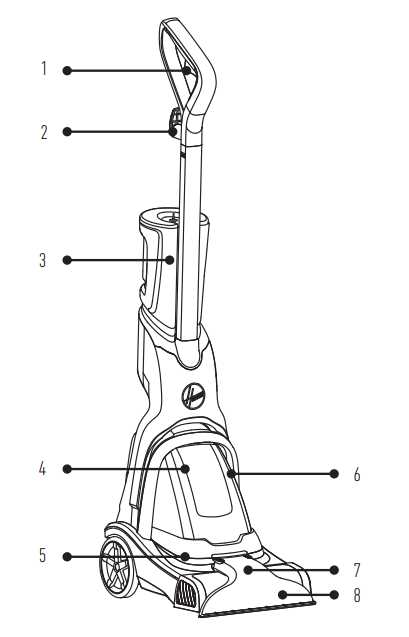

Guidelines for Reassembling the VacuumReassembling the device after maintenance is a crucial step to ensure its effective functioning. Proper assembly not only guarantees optimal performance but also prolongs the lifespan of the unit. Following these guidelines will help facilitate a smooth reassembly process. Before starting the reassembly, ensure you have all components and tools ready. This preparation will make the task more manageable. Follow these steps for efficient assembly:

By adhering to these practices, you can ensure the equipment is reassembled correctly, ready for future use. Maintenance Tips for LongevityEnsuring the prolonged functionality of your cleaning device requires consistent attention and care. By adopting a few simple practices, you can enhance its performance and lifespan, leading to more efficient operations over time. Regular Cleaning and InspectionRoutine cleaning and inspection of your equipment are essential for optimal performance. Here are some recommendations:

Proper Usage TechniquesUsing your device correctly can significantly impact its durability. Consider the following tips:

|