Owning a vehicle often comes with the responsibility of understanding its intricacies. This comprehensive resource aims to equip enthusiasts and everyday drivers alike with the knowledge required to maintain their automobiles efficiently. With an emphasis on practical advice, it covers a range of topics crucial for ensuring longevity and optimal performance.

Whether you’re a seasoned mechanic or a novice looking to deepen your understanding, having access to detailed information can make all the difference. This guide delves into various components of a specific model, providing step-by-step instructions and insights that simplify complex tasks. Emphasis is placed on preventive care and troubleshooting, empowering individuals to address common issues confidently.

Additionally, this resource underscores the importance of routine checks and maintenance, helping vehicle owners identify potential problems before they escalate. By fostering a proactive approach, it not only enhances safety but also contributes to the overall driving experience. With this knowledge at your fingertips, you can ensure that your vehicle remains reliable for years to come.

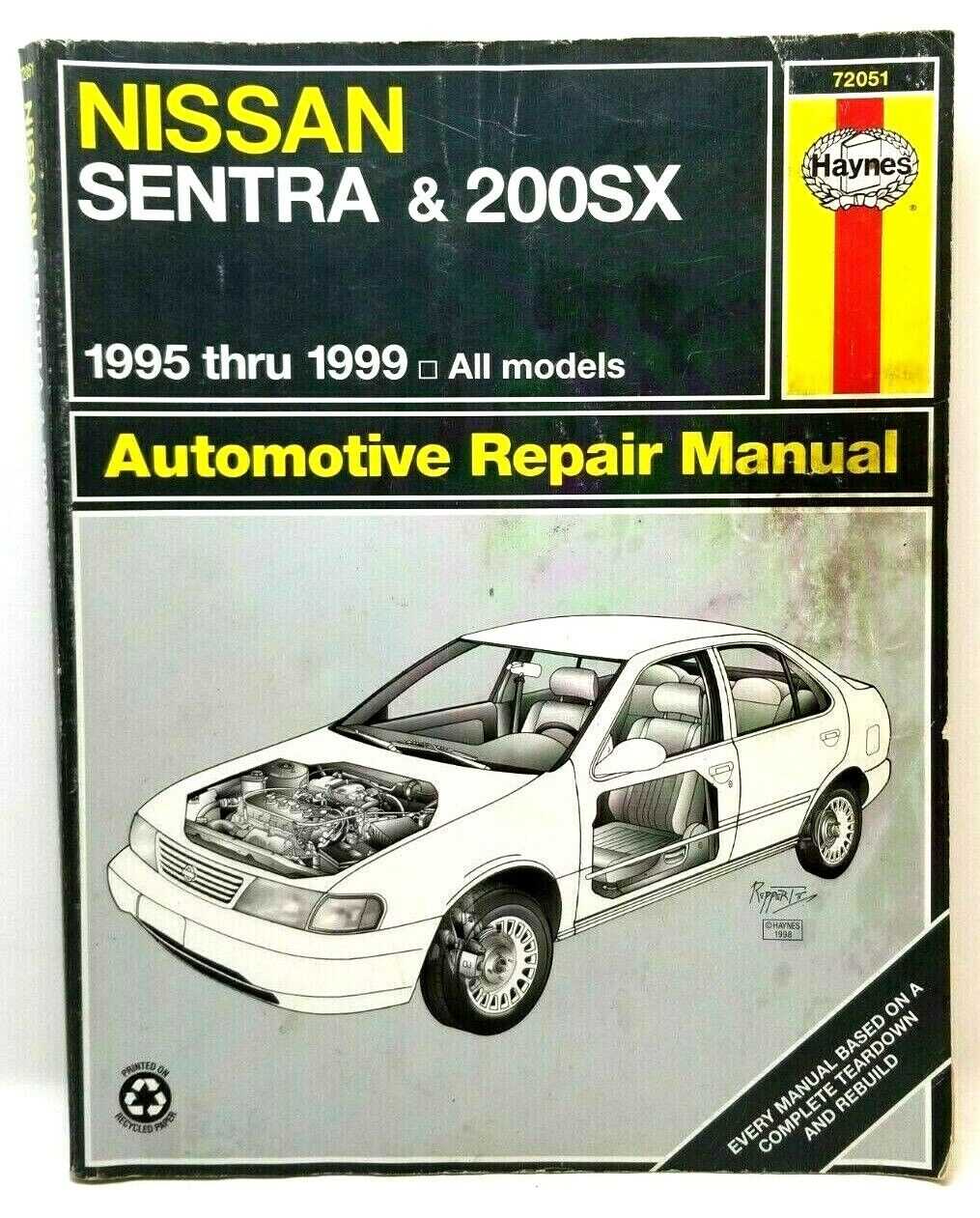

Nissan Sentra 1998 Overview

This section provides a comprehensive examination of a popular compact automobile known for its reliability and efficiency. Designed to cater to the needs of everyday drivers, this model blends practicality with a user-friendly experience, making it a favorite among commuters and small families alike.

Under the hood, this vehicle boasts a selection of engines that deliver adequate power while maintaining excellent fuel economy. The balance between performance and sustainability has made it a sensible choice for those conscious of their fuel consumption. Safety features are thoughtfully integrated, ensuring peace of mind on the road.

The interior is characterized by a spacious layout, providing comfort for both the driver and passengers. With a straightforward dashboard design, accessibility to controls and features is seamless. Technology options, while modest by modern standards, offer essential functionality that enhances the driving experience.

In terms of maintenance, this model is known for its straightforward servicing requirements, making it an ideal option for those who prefer to handle basic upkeep themselves. Overall, this vehicle stands as a testament to durability and practical engineering, appealing to a wide audience.

Common Issues in 1998 Models

Vehicles from this era often encounter a variety of challenges that can impact their performance and longevity. Understanding these common problems can help owners address issues proactively, ensuring a smoother driving experience.

| Issue | Description |

|---|---|

| Transmission Problems | Shifting difficulties and unexpected slipping can occur, often due to worn components or fluid issues. |

| Electrical Failures | Malfunctions in wiring or electronic systems may lead to problems with lights, windows, and other accessories. |

| Cooling System Leaks | Leaks in the radiator or hoses can result in overheating, necessitating timely repairs to prevent engine damage. |

| Suspension Wear | Components like struts and bushings may wear out, affecting ride quality and handling characteristics. |

| Brake Issues | Worn pads and rotors can lead to reduced stopping power and increased noise during operation. |

Essential Tools for Repairs

Having the right instruments is crucial for maintaining and fixing vehicles effectively. A well-equipped workspace not only enhances efficiency but also ensures safety during various tasks. Familiarity with essential tools empowers enthusiasts to tackle challenges with confidence.

Basic Hand Tools are the foundation of any toolkit. Wrenches, screwdrivers, and pliers are indispensable for loosening and tightening components. A set of both metric and standard sizes will provide versatility for different tasks.

Power Tools can significantly expedite processes. An electric or pneumatic impact wrench can save time when dealing with stubborn fasteners. Similarly, a drill is essential for making precise holes or driving screws quickly.

Diagnostic Equipment is vital for troubleshooting. A code reader or scanner allows users to access error codes and understand underlying issues, helping in making informed decisions about repairs.

Safety Gear should never be overlooked. Protective eyewear, gloves, and masks are essential to safeguard against debris and chemicals, ensuring a secure working environment.

Lastly, a reliable workbench and adequate lighting are necessary to create an organized and safe space. Having everything within reach promotes productivity and reduces frustration during maintenance tasks.

Engine Maintenance Guidelines

Regular upkeep of your vehicle’s powertrain is essential for optimal performance and longevity. Adopting a systematic approach to engine care not only enhances efficiency but also prevents costly repairs in the future.

Here are some key practices to follow:

- Oil Changes: Regularly check and change the engine oil to ensure proper lubrication. Use the recommended oil type and change it based on mileage or time intervals.

- Air Filter Replacement: Inspect the air filter periodically. A clean air filter improves airflow and fuel efficiency, while a clogged one can lead to performance issues.

- Coolant Levels: Maintain appropriate coolant levels to prevent overheating. Regularly check for leaks and flush the system as needed.

- Fuel System Care: Use high-quality fuel and consider periodic fuel injector cleaning to maintain performance and fuel economy.

- Belt and Hose Inspection: Examine belts and hoses for signs of wear, such as cracks or fraying. Replace them as necessary to avoid breakdowns.

- Regular Tune-Ups: Schedule routine tune-ups to check ignition systems, timing, and other essential components for optimal functioning.

By following these guidelines, you can ensure that the engine remains in excellent condition, providing reliable service for years to come.

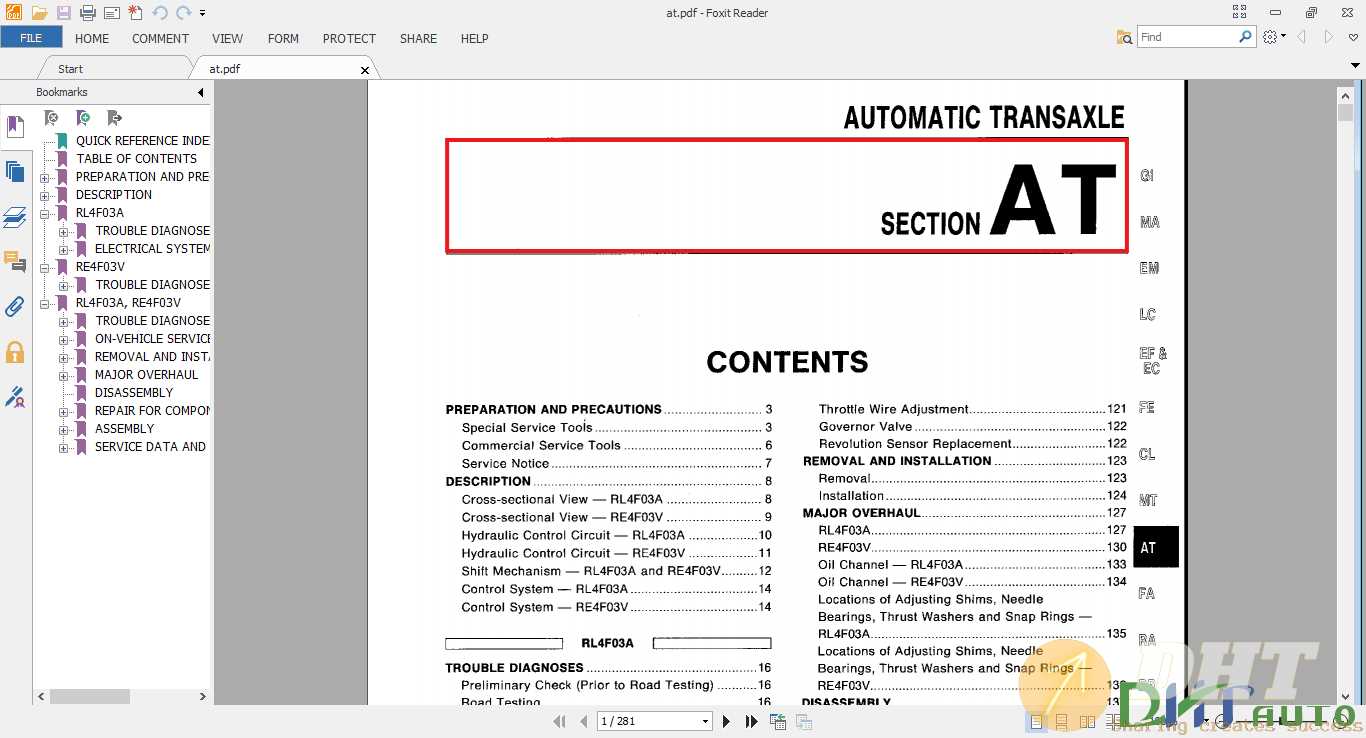

Transmission Troubleshooting Tips

When experiencing issues with the gear-shifting system of your vehicle, it’s crucial to diagnose the problem accurately. Understanding the common signs of malfunction can save you time and money while ensuring optimal performance.

Common Symptoms of Transmission Issues

Several indicators may suggest that your transmission requires attention. Pay close attention to slipping gears, where the vehicle unexpectedly shifts out of gear, or delayed engagement, which occurs when there’s a lag in response when shifting from park to drive. Additionally, unusual noises, such as grinding or whining, can signify underlying problems that need to be addressed.

Initial Diagnostic Steps

Begin troubleshooting by checking the transmission fluid level and condition. Low fluid levels or contaminated fluid can lead to performance issues. If the fluid appears dark or has a burnt smell, it may need to be replaced. Additionally, examining for any visible leaks around the transmission casing can help identify potential problems early. If these basic checks do not resolve the issue, consulting a professional may be necessary for a thorough inspection and more advanced diagnostics.

Electrical System Diagnostics

The electrical system in a vehicle plays a crucial role in its overall functionality and performance. Diagnosing issues within this system requires a systematic approach to identify faults that may affect various components, such as the battery, alternator, and wiring harnesses. Effective diagnostics not only ensure the reliability of the vehicle but also enhance safety and efficiency.

Common Symptoms of Electrical Issues

Recognizing the signs of electrical malfunctions is the first step in troubleshooting. Typical symptoms include dimming or flickering lights, difficulty starting the engine, and erratic behavior of electronic components. Frequent blown fuses or warning lights on the dashboard may also indicate underlying problems that necessitate further investigation.

Diagnostic Tools and Techniques

Utilizing the appropriate tools is essential for accurate diagnosis. A multimeter can measure voltage, current, and resistance, helping to pinpoint faulty connections or components. OBD-II scanners can provide diagnostic trouble codes that assist in identifying specific issues within the electrical system. It is important to follow a logical sequence when testing components to avoid unnecessary replacements and ensure a thorough evaluation.

Brake System Inspection Procedures

The brake system is a critical component of any vehicle, ensuring safe and reliable stopping performance. Regular inspection of this system is essential for maintaining optimal functionality and preventing potential failures. The following procedures outline the steps necessary to thoroughly evaluate the condition of the braking components.

Visual Inspection: Begin by examining the brake components for any visible signs of wear or damage. Look for cracks, corrosion, or leaks in the brake lines and check the condition of the pads and rotors. Ensure that all hardware is securely fastened and free of any obstructions.

Brake Pad Thickness: Measure the thickness of the brake pads using a caliper. Pads should generally be replaced when they reach a thickness of 3mm or less. Uneven wear patterns may indicate issues with calipers or suspension components.

Rotor Condition: Inspect the rotors for scoring, warping, or excessive rust. Use a dial indicator to check for any runout. Rotors should be replaced if they are below the manufacturer’s specified minimum thickness or show significant wear.

Fluid Level and Quality: Check the brake fluid level in the reservoir. If it’s low, investigate for leaks. Additionally, assess the fluid’s condition; it should be clear and free from contaminants. Cloudy or dark fluid may require a complete flush and replacement.

Brake Pedal Feel: Assess the brake pedal’s response. A soft or spongy feel may indicate air in the hydraulic lines, while a hard pedal could suggest an issue with the brake booster. Test the pedal for any unusual movements or noises during operation.

Performance Testing: Conduct a test drive to evaluate the overall braking performance. Pay attention to any vibrations, pulling to one side, or unusual sounds when applying the brakes. These symptoms can indicate problems that require further investigation.

Following these procedures will help ensure that the brake system remains in good condition, providing safety and reliability during operation.

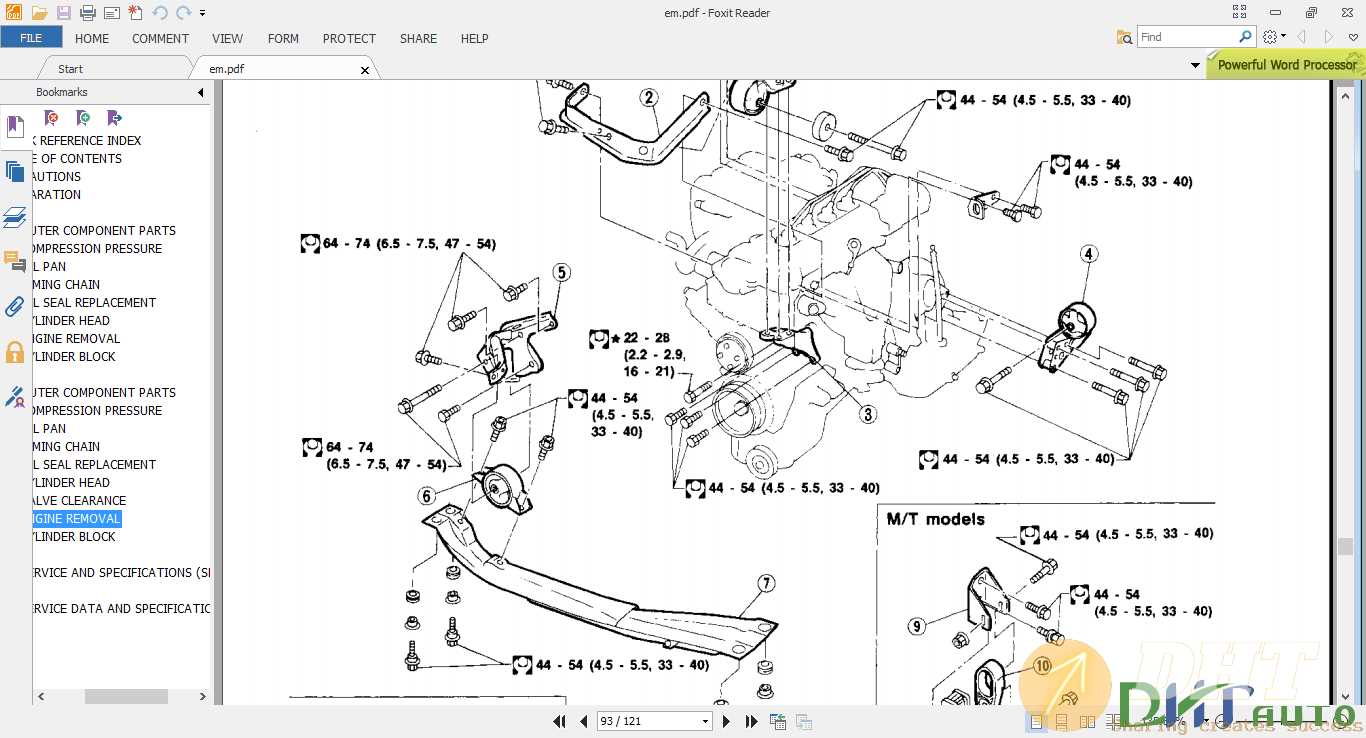

Suspension and Steering Repairs

This section addresses the essential aspects of maintaining and restoring the components responsible for vehicle stability and control. Proper attention to these systems ensures a smooth driving experience, enhances safety, and prolongs the lifespan of your automobile. Understanding the intricacies of these parts will empower you to tackle common issues effectively.

Common Issues and Symptoms

Drivers may encounter a variety of problems related to suspension and steering systems. Symptoms such as unusual noises, uneven tire wear, or a drifting sensation while driving can indicate underlying issues. It’s crucial to diagnose these signs early to prevent further damage and ensure optimal handling and comfort.

Maintenance and Replacement Tips

Regular inspections of components like shock absorbers, struts, and tie rods are vital for identifying wear and tear. Replacing worn parts promptly can improve ride quality and steering responsiveness. When performing maintenance, always refer to the specifications for torque settings and alignment to achieve the best results.

Cooling System Maintenance Practices

Proper upkeep of the cooling system is crucial for optimal engine performance and longevity. Regular maintenance ensures that the engine operates within the ideal temperature range, preventing overheating and associated damages. Adopting effective practices can help detect potential issues early and prolong the lifespan of the cooling components.

One fundamental aspect of maintenance is regularly checking the coolant level and condition. It’s essential to use the recommended type of coolant and to replace it according to the manufacturer’s guidelines. Flushing the system periodically removes contaminants and prevents corrosion, contributing to the overall efficiency of the cooling system.

Inspecting hoses and connections for signs of wear or leaks is also vital. Cracked or brittle hoses can lead to coolant loss and subsequent overheating. Replacing worn components proactively helps maintain system integrity and prevents unexpected breakdowns.

Additionally, examining the radiator and ensuring it is free from debris enhances airflow and cooling efficiency. A clean radiator can significantly impact the system’s ability to dissipate heat. Furthermore, checking the operation of the thermostat and water pump is necessary, as these components are critical for regulating engine temperature.

Lastly, being attentive to any unusual sounds or changes in engine performance can signal cooling system issues. Addressing these signs promptly can save time and money in the long run, ensuring reliable vehicle operation.

Fuel System Troubleshooting Steps

Troubleshooting the fuel delivery system is essential for maintaining optimal engine performance. When issues arise, it’s crucial to methodically identify and resolve the root causes to ensure efficient operation and prevent further complications.

Step 1: Initial Inspection

Begin by visually inspecting the entire fuel system. Check for any signs of leaks, damaged hoses, or loose connections. A thorough examination can reveal obvious issues that may be affecting fuel flow.

Step 2: Fuel Pressure Test

Utilize a fuel pressure gauge to measure the pressure within the system. Compare the readings against the manufacturer’s specifications. Inadequate pressure may indicate a failing pump, clogged filter, or malfunctioning regulator.

Step 3: Fuel Filter Evaluation

Inspect the fuel filter for blockages. A clogged filter can significantly restrict fuel flow. Replace it if necessary, and consider scheduling regular maintenance to prevent future issues.

Step 4: Injector Functionality Check

Examine the fuel injectors to ensure they are functioning correctly. Listen for a clicking sound while the engine is running, and perform a cleaning or replacement if any are found to be faulty.

Step 5: Electrical System Analysis

Evaluate the electrical components related to the fuel system, including the fuel pump relay and wiring. A malfunctioning electrical connection can hinder pump operation, leading to fuel delivery problems.

Step 6: Diagnostic Testing

Use an OBD-II scanner to check for any diagnostic trouble codes (DTCs) related to the fuel system. This information can provide valuable insights into underlying issues that may not be immediately apparent.

By following these systematic steps, you can effectively troubleshoot fuel system concerns, ensuring your vehicle runs smoothly and efficiently.

Bodywork and Interior Fixes

Maintaining the aesthetics and functionality of a vehicle’s exterior and interior is essential for both safety and comfort. Addressing issues such as dents, scratches, and worn-out upholstery not only enhances the overall appearance but also contributes to the longevity of the automobile. This section focuses on essential repairs that can restore your car’s appeal and ensure a pleasant driving experience.

Exterior Repairs

Common challenges with bodywork include paint damage and minor dents. For superficial scratches, polishing compounds can effectively restore the original finish. For deeper imperfections, touch-up paint might be necessary. Dents can often be removed using techniques like the heat method or specialized tools, providing a cost-effective solution to maintaining a flawless exterior.

Interior Maintenance

Inside the vehicle, upholstery wear and tear is prevalent over time. Stains can be tackled with appropriate cleaners specific to the material, while seams and stitching may require reinforcement or patching to prevent further damage. Replacing floor mats and ensuring proper care for dashboard components can significantly enhance the overall interior ambiance.

Regular upkeep of both bodywork and interior elements not only preserves the vehicle’s value but also creates a more enjoyable environment for all passengers. Whether tackling minor repairs or planning significant renovations, a well-maintained automobile reflects the owner’s commitment to quality and safety.

DIY Maintenance vs. Professional Help

When it comes to keeping your vehicle in optimal condition, there are two primary approaches: tackling tasks yourself or enlisting the expertise of a qualified technician. Each option has its merits and drawbacks, depending on your skills, tools, and comfort level with mechanical work.

Do-it-yourself maintenance can be a rewarding experience, allowing you to save money and gain a deeper understanding of your vehicle’s inner workings. With the right resources and guidance, even beginners can successfully perform routine tasks such as oil changes, air filter replacements, and brake inspections. However, this path requires time, effort, and sometimes a steep learning curve to ensure that all procedures are done correctly.

On the other hand, seeking professional assistance guarantees that your vehicle receives expert care. Technicians possess specialized knowledge, experience, and access to advanced tools, ensuring repairs are performed accurately and efficiently. This option can be particularly beneficial for complex issues that may be beyond the capabilities of an average owner. Nonetheless, it often comes at a higher financial cost and may require you to trust someone else with your vehicle’s maintenance.

Ultimately, the choice between DIY and professional help hinges on individual preferences, budget constraints, and the specific requirements of the vehicle. Balancing both methods can lead to a well-maintained vehicle and a rewarding experience in automotive care.