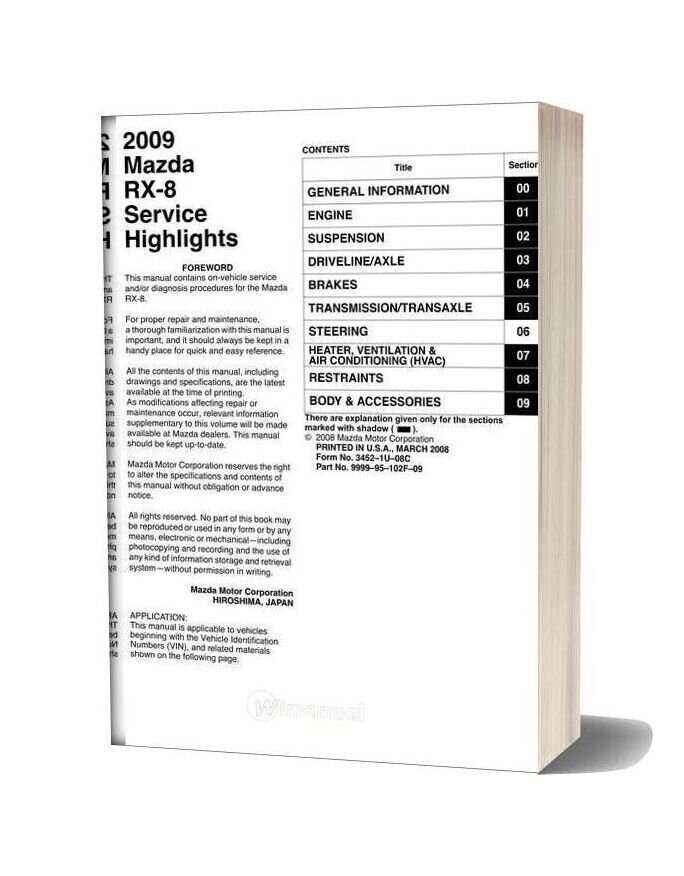

In the realm of automotive care, understanding the intricacies of vehicle upkeep is essential for enthusiasts and everyday drivers alike. This section delves into the vital practices that ensure optimal performance and longevity of a specific model known for its unique design and engineering. By familiarizing oneself with essential maintenance tasks, owners can enhance the driving experience and preserve the vehicle’s value.

Equipped with detailed insights, this resource aims to empower individuals with the knowledge needed to navigate common issues and challenges. From basic troubleshooting to more complex procedures, readers will find a wealth of information designed to aid in managing their vehicle efficiently. Emphasizing proactive measures, this guide encourages a hands-on approach to automotive care, fostering a deeper connection between the owner and their machine.

Essential Tools for RX-8 Maintenance

Maintaining a vehicle effectively requires a variety of essential implements to ensure proper functioning and longevity. Each tool serves a specific purpose, aiding in the upkeep and troubleshooting of various components. Familiarity with these implements can significantly enhance the maintenance process and facilitate timely interventions.

Basic Hand Tools

Having a comprehensive set of hand tools is fundamental for any vehicle owner. Common items include wrenches, sockets, and screwdrivers, which are indispensable for performing routine tasks such as tightening bolts and replacing components. A sturdy toolset will allow you to tackle most maintenance challenges with ease.

Diagnostic Equipment

Modern vehicles often require diagnostic devices to identify underlying issues effectively. These gadgets can read error codes from the onboard computer, helping pinpoint malfunctions that might not be immediately visible. Investing in quality diagnostic equipment can save time and effort, ensuring accurate assessments of vehicle performance.

Common Problems with Mazda RX-8

The rotary engine vehicle is known for its unique design and performance characteristics, but it can also present various challenges for owners. Understanding these issues can help enthusiasts and drivers maintain their vehicles effectively and enjoy a smooth driving experience.

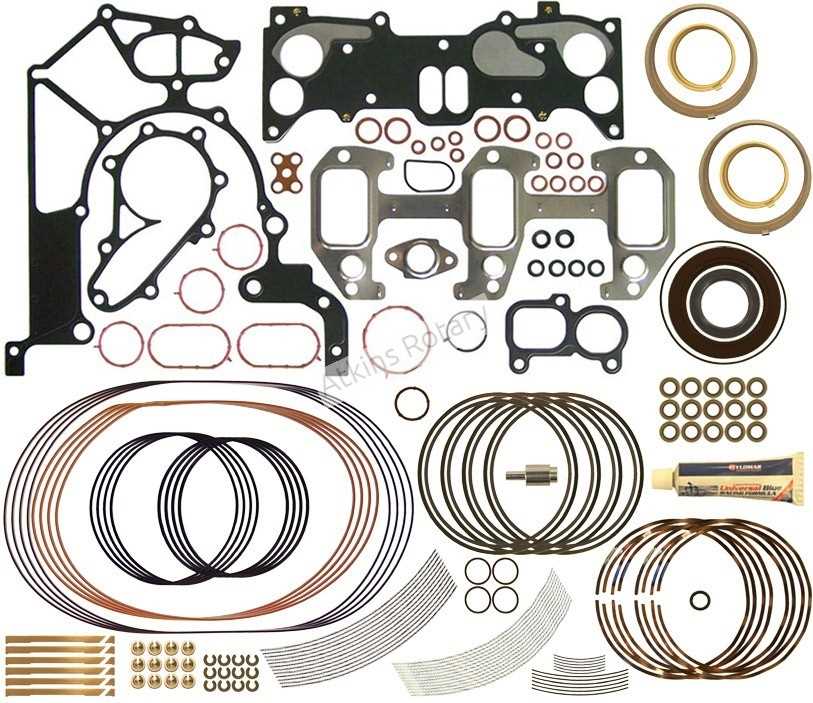

Engine Issues

One of the most prevalent concerns is related to the engine. Many users report problems with oil consumption and sealing failures, which can lead to decreased performance and reliability. Regular monitoring of oil levels is crucial, as excessive consumption may indicate underlying complications.

Electrical and Fuel System Problems

Another area of concern involves electrical systems and fuel delivery. Drivers may encounter difficulties with starting the vehicle or notice warning lights activating unexpectedly. Issues with fuel injectors and electrical components can affect overall functionality, making timely inspections and maintenance vital.

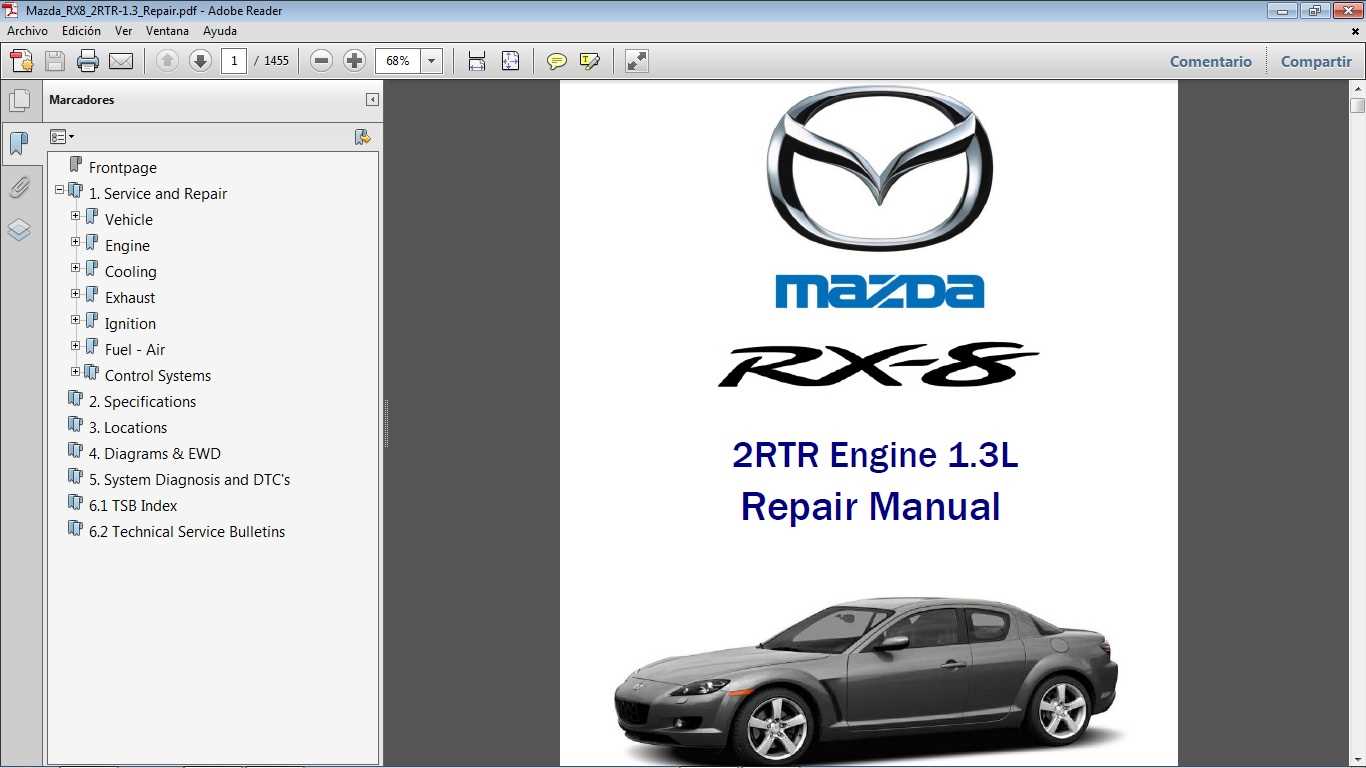

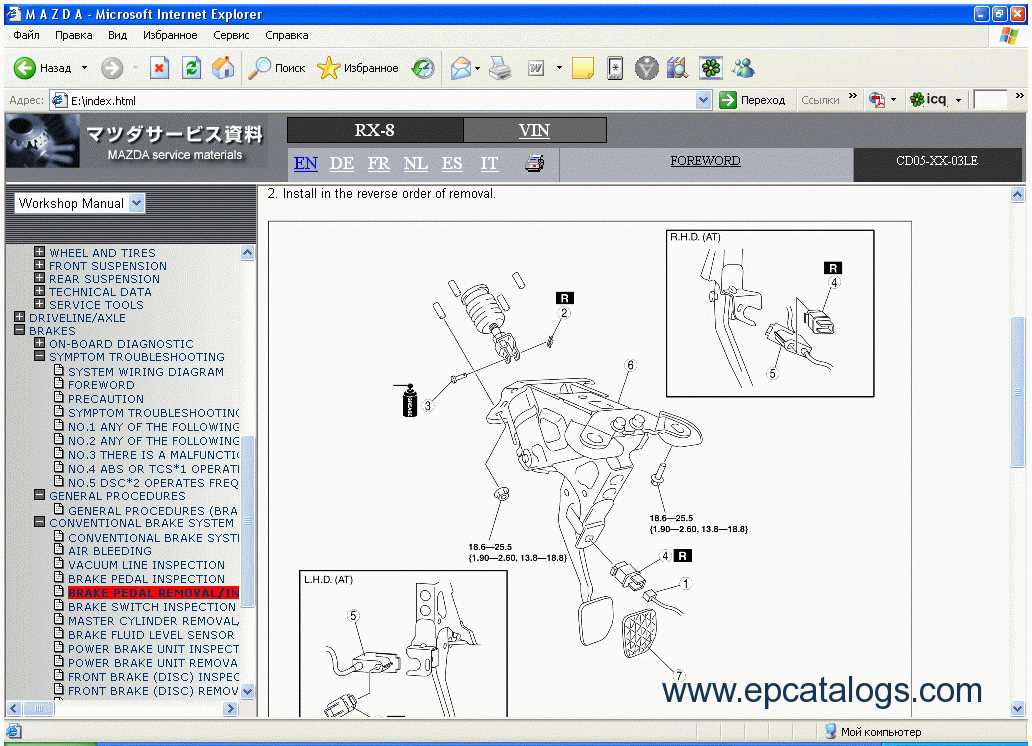

Step-by-Step Repair Procedures

This section outlines a detailed approach to addressing common issues that may arise in a specific vehicle model. By following these sequential instructions, enthusiasts and technicians alike can effectively troubleshoot and rectify problems, ensuring optimal performance and longevity of the automobile. The focus is on practical steps that facilitate understanding and execution of necessary tasks.

Initially, it is essential to gather all required tools and materials before starting any work. This preparation not only streamlines the process but also minimizes potential disruptions. Ensure that the workspace is clean and well-lit, providing a safe environment for undertaking the maintenance tasks.

Next, identify the specific issue that needs attention. This may involve performing a preliminary assessment, including visual inspections and diagnostic checks. Once the problem is clearly defined, reference the detailed steps associated with that particular challenge.

As you proceed, adhere closely to the recommended techniques, which often include disassembly of components, careful handling of parts, and reassembly with precision. Each stage should be executed methodically, allowing for adjustments and checks along the way to confirm progress and accuracy.

Finally, after completing the necessary actions, it is advisable to conduct a thorough review. Test the functionality of the affected areas to ensure everything operates as intended. This final step is crucial for confirming that the issues have been effectively resolved, contributing to the overall reliability of the vehicle.

Understanding the Engine Components

The engine is the heart of any vehicle, comprising various elements that work together to produce power and ensure efficient operation. Each component plays a crucial role in the overall functionality, influencing performance, fuel efficiency, and reliability.

Key Parts of the Engine

Among the primary elements are the cylinders, which house the combustion process, and the crankshaft, responsible for converting linear motion into rotational force. Additionally, the valves regulate the intake of air and the exhaust of gases, while the piston moves within the cylinders, creating the necessary pressure for combustion.

Supporting Systems

Supporting systems, such as the cooling and lubrication systems, are vital for maintaining optimal operating conditions. The cooling system prevents overheating, while the lubrication system reduces friction between moving parts, ensuring longevity and efficient performance.

Electrical System Troubleshooting Tips

Addressing issues within the electrical framework of a vehicle can often seem daunting. However, by employing systematic approaches and techniques, you can effectively identify and resolve common problems. This section provides practical advice to help you navigate electrical challenges with confidence.

Common Symptoms of Electrical Issues

- Dim or flickering lights

- Unresponsive dashboard indicators

- Difficulty starting the engine

- Malfunctioning audio system

- Inconsistent power supply to accessories

Troubleshooting Steps

- Check the Battery: Ensure that the battery terminals are clean and securely connected. A weak or dead battery can cause various electrical failures.

- Inspect Fuses: Examine the fuses in the fuse box for any signs of damage or burning. Replacing blown fuses can restore functionality to affected components.

- Examine Wiring: Look for frayed or damaged wires that may be causing short circuits. Pay attention to areas where wires may be exposed to heat or moving parts.

- Test the Alternator: Ensure that the alternator is charging the battery properly. A malfunctioning alternator can lead to electrical system failures.

- Use a Multimeter: Utilize a multimeter to measure voltage, current, and resistance. This tool can help pinpoint issues within the electrical system.

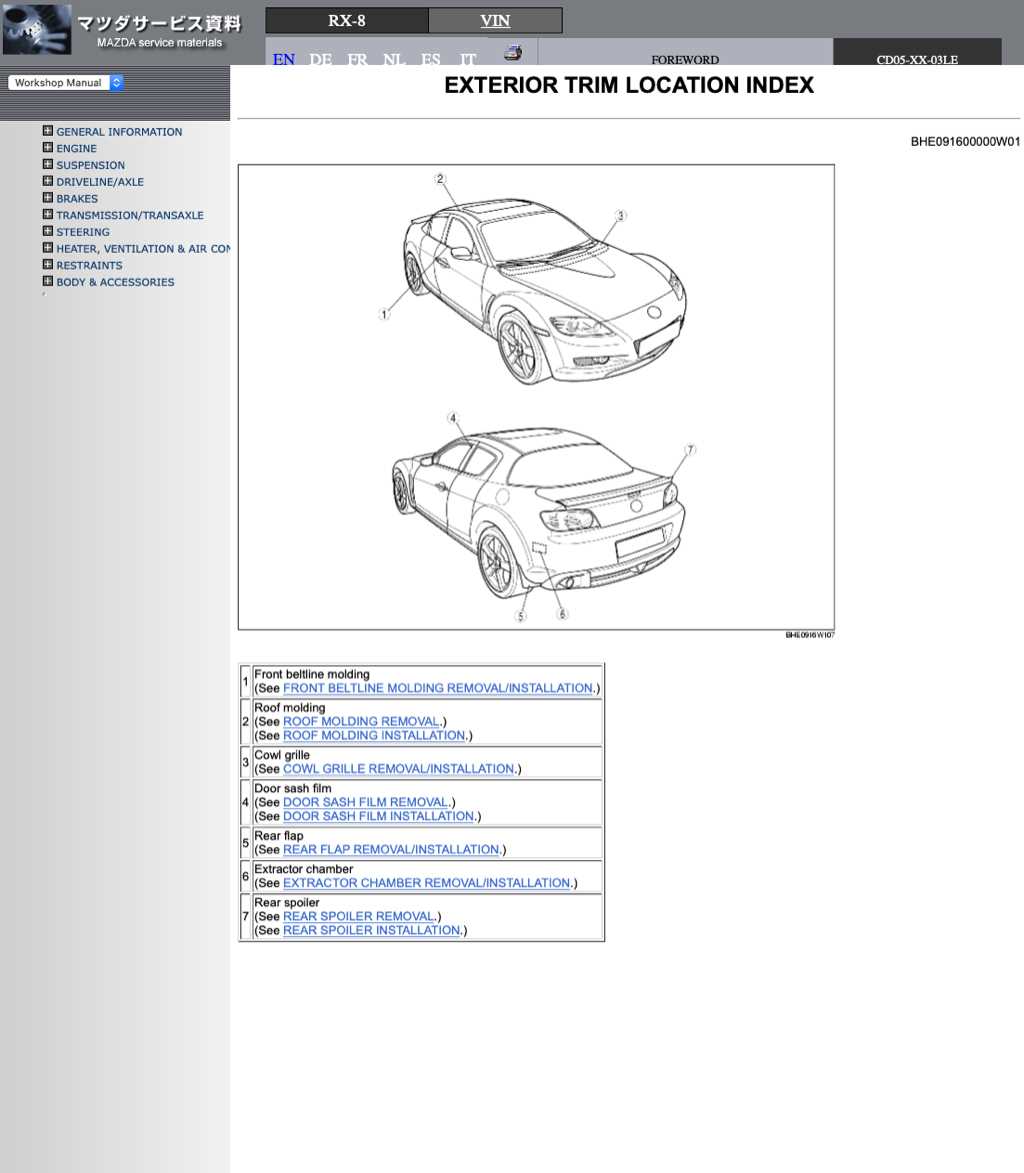

Suspension and Brake System Care

Proper maintenance of the suspension and braking components is essential for ensuring a smooth and safe driving experience. Regular checks can help identify potential issues before they escalate, contributing to vehicle longevity and performance.

- Inspecting Suspension Components:

- Check for signs of wear or damage on shock absorbers and struts.

- Examine control arms and bushings for any cracks or deterioration.

- Ensure that springs are intact and free from corrosion.

- Brake System Maintenance:

- Regularly assess brake pads and rotors for thickness and even wear.

- Inspect brake fluid levels and top up if necessary.

- Look for leaks in the brake lines and connections.

- Alignment and Balancing:

- Check wheel alignment periodically to prevent uneven tire wear.

- Balance tires to enhance stability and handling.

Timely attention to these aspects can significantly improve the vehicle’s handling characteristics and overall safety on the road.

Fluid Replacement and Maintenance Schedule

Regular upkeep of essential liquids is crucial for optimal vehicle performance and longevity. A well-structured schedule for fluid changes ensures that all systems function efficiently and helps prevent potential issues. This section outlines the key types of fluids that require attention and provides a suggested timetable for their replacement.

Types of Fluids

The primary fluids that need regular monitoring include engine oil, transmission fluid, coolant, brake fluid, and power steering fluid. Each of these plays a vital role in maintaining the overall health of the vehicle. Proper levels and conditions of these liquids are essential for effective operation and safety.

Recommended Replacement Intervals

It is advisable to replace engine oil every 5,000 to 7,500 miles, while transmission fluid should be checked and replaced approximately every 30,000 to 60,000 miles, depending on driving conditions. Coolant should be refreshed every two years or as specified by the manufacturer, whereas brake fluid typically requires changing every two years. Power steering fluid should also be inspected regularly and replaced as needed to ensure smooth steering performance.

How to Diagnose Engine Issues

Identifying problems with the engine can be a challenging task. It requires a systematic approach to pinpoint the root causes of unusual sounds, performance drops, or warning lights. By following a structured method, one can effectively assess the situation and determine necessary actions.

Initial Checks

Before delving into more complex diagnostics, start with basic inspections:

- Check the oil level and condition.

- Inspect the coolant level and look for leaks.

- Listen for any abnormal noises when the engine is running.

- Examine the exhaust for unusual colors or smells.

Utilizing Diagnostic Tools

Employing specialized equipment can greatly enhance the diagnostic process:

- Connect an onboard diagnostics (OBD) scanner to read error codes.

- Use a multimeter to check electrical components.

- Monitor engine parameters such as temperature and pressure.

- Perform a compression test to evaluate the engine’s health.

Performance Upgrades for RX-8

Enhancing the capabilities of a sports coupe involves various modifications that can significantly boost its performance. These upgrades can range from improving engine efficiency to optimizing handling and responsiveness. By focusing on key areas, enthusiasts can transform their vehicle into a more dynamic and thrilling driving experience.

Engine Modifications

One of the most impactful areas for enhancement is the engine. Upgrading components such as air intake systems and exhaust systems can lead to improved airflow, resulting in increased horsepower. Additionally, tuning the engine management system can optimize fuel delivery and ignition timing, further maximizing performance.

Suspension and Handling Improvements

To complement the increased power, enhancing the suspension is essential for better handling. Installing upgraded shocks and springs can significantly improve ride quality and cornering capabilities. Furthermore, performance tires can provide better grip, ensuring that the vehicle maintains stability during aggressive driving.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is essential for both the technician and the vehicle. Proper precautions help prevent accidents and injuries while promoting a secure working environment. Adhering to safety guidelines is crucial for successful outcomes.

Essential Safety Gear

Before starting any maintenance work, it is important to equip oneself with the appropriate safety gear:

- Gloves: Protect hands from chemicals and sharp objects.

- Safety glasses: Shield eyes from debris and fluids.

- Steel-toed boots: Prevent foot injuries from heavy components.

- Overalls: Keep clothing clean and reduce exposure to hazardous materials.

Workplace Safety Tips

Creating a safe working environment is key to successful tasks:

- Ensure adequate ventilation in enclosed spaces to avoid inhalation of harmful fumes.

- Keep the workspace organized to reduce the risk of trips and falls.

- Use proper lifting techniques or equipment when handling heavy parts.

- Disconnect the battery and secure the vehicle to prevent unintended movement.