In the world of rugged outdoor adventures, having a reliable resource for vehicle maintenance is essential. This guide serves as a comprehensive reference for enthusiasts seeking to keep their beloved off-road companion in top shape. It covers everything from routine checks to more intricate troubleshooting techniques, ensuring that drivers can navigate challenges with confidence.

Whether you are a seasoned mechanic or a passionate novice, this resource provides invaluable insights into the inner workings of your vehicle. Detailed instructions and diagrams are designed to facilitate understanding, allowing you to tackle repairs and enhancements with ease. By investing time in learning about your machine, you can significantly extend its lifespan and enhance its performance.

Additionally, this guide emphasizes the importance of safety and preventive measures. By following the outlined procedures, owners can avoid common pitfalls and ensure that their vehicle remains a dependable partner on any adventure. Embrace the opportunity to empower yourself with knowledge and skills, transforming your driving experience into one of enjoyment and reliability.

97 Jeep Wrangler Overview

The 1997 model of this iconic off-road vehicle is celebrated for its rugged design and exceptional performance in various terrains. Combining classic styling with modern features, it appeals to enthusiasts who appreciate a blend of tradition and functionality. This model year is often highlighted for its durability and adaptability, making it a preferred choice for both casual drivers and hardcore adventurers.

Key Features

With a robust frame and powerful engine options, this vehicle is engineered to tackle challenging landscapes. Its four-wheel-drive system provides enhanced traction and control, essential for off-road escapades. The spacious interior is designed for comfort, offering ample room for passengers and cargo alike.

Performance and Capabilities

Equipped with a range of powerful engines, this vehicle delivers impressive torque and horsepower, making it capable of handling steep inclines and rough trails. The suspension system is tuned for off-road prowess, ensuring a smooth ride over bumps and obstacles. Owners often praise its reliability and ability to navigate through diverse conditions with ease.

Common Issues with the 97 Model

The 1997 model year is known for several challenges that owners may encounter over time. Understanding these issues can help maintain optimal performance and ensure a smoother driving experience.

Electrical System Problems

One of the frequent complications involves the electrical system. Symptoms may include:

- Intermittent power loss to accessories

- Battery drainage

- Faulty dashboard indicators

Regularly checking the wiring and connections can help prevent these issues.

Transmission Concerns

Another area of concern is related to the transmission. Common signs of trouble include:

- Unusual noises while shifting

- Slipping gears

- Delayed engagement when shifting from park to drive

Maintaining fluid levels and servicing the transmission periodically is essential to prolong its lifespan.

Essential Tools for Repairs

Having the right equipment is crucial for successful maintenance tasks. Whether tackling minor adjustments or more extensive projects, certain instruments can make the process smoother and more efficient. Below is a list of fundamental items that every enthusiast should consider having in their toolkit.

Basic Hand Tools

- Wrenches: A set of various sizes, including both open-end and box-end, is essential for loosening and tightening fasteners.

- Sockets: A socket set with a ratchet is invaluable for accessing hard-to-reach bolts.

- Screwdrivers: Both flathead and Phillips screwdrivers in various sizes should be readily available for different tasks.

- Pliers: Needle-nose and standard pliers are useful for gripping and manipulating components.

Specialized Tools

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Multimeter: A vital tool for diagnosing electrical issues, measuring voltage, and checking continuity.

- Jack and Stands: Essential for lifting the vehicle safely to access the undercarriage for various tasks.

- Oil Filter Wrench: Facilitates easy removal and installation of oil filters during maintenance.

Equipping yourself with these tools will not only enhance your efficiency but also ensure that tasks are completed correctly and safely. With the right instruments at your disposal, you can confidently tackle any challenge that comes your way.

Engine Specifications and Maintenance

This section provides essential information regarding the engine’s characteristics and upkeep requirements. Proper understanding and adherence to these specifications are crucial for optimal performance and longevity of the vehicle.

Maintaining the engine involves regular checks and adherence to specified parameters to ensure reliability and efficiency. Below is a summary of important specifications and recommended maintenance practices:

| Specification | Details |

|---|---|

| Engine Type | Inline 6-cylinder |

| Displacement | 4.0 liters |

| Horsepower | 190 hp at 4,600 RPM |

| Torque | 235 lb-ft at 3,200 RPM |

| Fuel System | Multi-point fuel injection |

| Oil Capacity | 6 quarts (with filter) |

| Recommended Oil Type | API Certification SM or higher, 10W-30 |

| Maintenance Interval | Every 3,000 miles or 3 months |

Regular checks of oil levels, coolant condition, and overall engine health are recommended to prevent potential issues. Additionally, timely replacement of air filters and spark plugs is essential to maintain optimal engine performance.

Transmission Troubleshooting Guide

This section provides essential insights for diagnosing common issues associated with automatic and manual gear-shifting systems in vehicles. Understanding these problems can lead to effective solutions, ensuring optimal performance and longevity of the transmission system.

Common Symptoms of Transmission Issues

- Delayed engagement when shifting gears

- Unusual noises, such as grinding or whining

- Fluid leaks under the vehicle

- Warning lights illuminated on the dashboard

- Unresponsive or erratic gear shifting

Troubleshooting Steps

- Check Fluid Levels: Ensure that the transmission fluid is at the correct level and free of contaminants.

- Inspect for Leaks: Look for any visible signs of fluid leaks around the transmission housing and hoses.

- Examine the Filter: A clogged filter can restrict fluid flow, leading to performance issues.

- Test the Solenoids: Faulty solenoids can disrupt the shifting process; check for proper function.

- Scan for Error Codes: Use a diagnostic tool to read any trouble codes that may indicate specific problems.

Electrical System Diagnostics

The electrical system is crucial for the overall functionality of any vehicle, playing a vital role in starting, operating, and powering various components. Effective diagnostics are essential to identify issues that may hinder performance or cause failure. A systematic approach to troubleshooting electrical components ensures that problems are addressed promptly and accurately.

Begin by visually inspecting wiring and connections for signs of wear, corrosion, or damage. Use a multimeter to measure voltage and continuity throughout the system. Verify the integrity of ground connections, as poor grounding can lead to erratic behavior in electrical components. Test individual components such as the battery, alternator, and starter to confirm their proper operation.

For more complex issues, consider using diagnostic tools like code readers or scanners. These devices can provide error codes that pinpoint specific faults within the electrical network. Additionally, consult wiring diagrams to understand the relationships between different parts of the system, aiding in identifying potential problem areas.

Remember to follow safety protocols while diagnosing electrical systems. Disconnect the battery before working on any components to prevent shock or accidental short circuits. By adhering to these practices, you can ensure a thorough and effective diagnostic process, ultimately leading to reliable performance.

Suspension and Steering Components

The suspension and steering systems are vital for maintaining vehicle stability, comfort, and control. These components work together to absorb shocks from the road and provide precise steering response, ensuring a smooth driving experience.

Key elements of the suspension system include:

- Shock Absorbers: Designed to dampen the impact of bumps and road irregularities, enhancing ride quality.

- Coil Springs: Support the weight of the vehicle and provide elasticity, allowing for vertical movement.

- Control Arms: Connect the wheel hub to the vehicle frame, allowing for controlled movement during suspension travel.

- Ball Joints: Serve as pivot points between the control arms and the steering knuckles, enabling smooth steering action.

The steering system consists of several crucial components, including:

- Steering Gear: Converts the rotational motion of the steering wheel into linear motion to turn the wheels.

- Steering Column: Connects the steering wheel to the steering gear, allowing for driver input.

- Pitman Arm: Transfers motion from the steering gear to the steering linkage.

- Idler Arm: Provides support for the steering linkage and maintains alignment.

Regular inspection and maintenance of these systems are essential for optimal performance. Common issues include worn bushings, leaking shock absorbers, and misaligned components. Addressing these concerns promptly can prevent more severe damage and ensure safe operation.

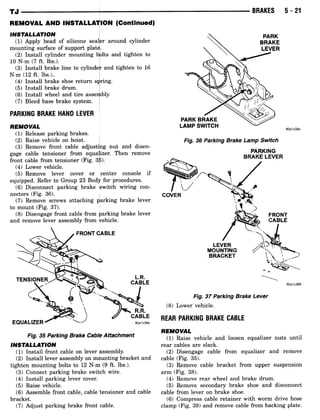

Brake System Inspection Procedures

The braking system is a critical component of vehicle safety, and regular inspection is essential to ensure optimal performance and reliability. This section outlines the necessary steps to evaluate the functionality of the braking apparatus, identifying any potential issues that may require attention.

Visual Inspection

Functional Testing

After the visual assessment, conduct a functional test of the braking system. This includes applying the brakes at various speeds to assess responsiveness and effectiveness. Listen for unusual noises, such as grinding or squeaking, which may indicate worn components. Pay attention to the brake pedal feel; it should remain firm and steady without excessive travel. If any irregularities are noted during testing, further investigation may be necessary to determine the underlying cause.

Bodywork and Frame Repairs

This section focuses on addressing common issues related to the outer structure and chassis of a vehicle. Proper maintenance and restoration of these components are essential for both aesthetics and performance, ensuring longevity and safety on the road.

When tackling body and frame issues, consider the following steps:

- Inspection: Regularly examine the exterior for signs of rust, dents, or misalignment.

- Preparation: Before any work, gather necessary tools and materials, including sandpaper, filler, and paint.

- Repairing Dents: Use a hammer and dolly set to gently reshape affected areas, or consider professional services for deep dents.

- Rust Treatment: Remove rust with a wire brush, apply rust inhibitor, and patch with metal filler if necessary.

- Repainting: After repairs, sand the surface smoothly and apply primer before finishing with paint for a seamless look.

Additionally, addressing frame concerns is critical:

- Frame Straightening: Utilize a frame machine to correct any bends or twists.

- Welding: Inspect welds for integrity, re-welding as needed to ensure structural stability.

- Alignment: After repairs, ensure proper alignment of wheels and chassis components to maintain driving dynamics.

By following these guidelines, individuals can effectively manage and restore the essential elements of a vehicle’s structure, enhancing both safety and visual appeal.

Interior Components and Upgrades

Enhancing the interior space of your vehicle can significantly improve both aesthetics and functionality. From upgrading seating to installing modern infotainment systems, there are numerous options available to elevate the driving experience. This section explores various components and enhancements that can transform the cabin into a more comfortable and stylish environment.

Seating Enhancements

One of the most impactful upgrades involves the seating arrangement. Swapping out factory seats for custom or aftermarket options can provide better support and comfort. Consider investing in ergonomic designs or even heated and cooled seats for added luxury. Additionally, high-quality upholstery materials can enhance both durability and appearance, making your interior feel more premium.

Technology Integration

Modern vehicles often come equipped with advanced technology, but upgrading your existing system can provide new features. Installing a state-of-the-art infotainment system can offer features like GPS navigation, Bluetooth connectivity, and touchscreen interfaces. Moreover, integrating smart accessories such as phone mounts and charging stations can enhance convenience and connectivity while on the road.

Regular Maintenance Schedule

Maintaining your vehicle on a consistent basis is crucial for ensuring its longevity and optimal performance. Following a structured schedule allows for the timely identification of potential issues and helps keep your automobile running smoothly. This section outlines a recommended timeline for routine checks and services that should be performed regularly.

Maintenance Tasks

| Task | Frequency |

|---|---|

| Oil Change | Every 3,000 – 5,000 miles |

| Air Filter Replacement | Every 15,000 – 30,000 miles |

| Brake Inspection | Every 10,000 miles |

| Tire Rotation | Every 5,000 – 7,500 miles |

| Coolant Flush | Every 2 years or 30,000 miles |

Additional Considerations

In addition to the scheduled tasks, it is advisable to perform regular visual inspections of the vehicle’s exterior and interior. Keeping an eye on fluid levels, tire pressure, and overall condition can prevent minor issues from escalating into significant problems. Adhering to this maintenance schedule will contribute to the reliability and safety of your automobile.

Resources for DIY Mechanics

For those who enjoy tackling automotive projects independently, a wealth of materials is essential. These resources not only enhance understanding but also empower enthusiasts to perform tasks confidently. From books to online platforms, the right tools and information can make all the difference in achieving successful outcomes.

Online Communities and Forums

Engaging with online groups and forums can provide invaluable support. Enthusiasts share their experiences, solutions, and tips, creating a rich environment for learning. Websites dedicated to automotive discussions often have sections specifically for troubleshooting and modifications, allowing users to gain insights from others who have faced similar challenges.

Instructional Videos and Tutorials

Visual learning has become increasingly popular among mechanics. Platforms offering tutorial videos can guide users through various tasks step-by-step. These resources often showcase techniques, tools, and common pitfalls, making it easier to grasp complex procedures and improve overall skills.