When it comes to ensuring the longevity and performance of a beloved off-road vehicle, having access to detailed information is crucial. This section provides essential insights and practical tips for enthusiasts who wish to maintain their vehicles in top condition. From common issues to advanced troubleshooting techniques, every aspect of upkeep is covered to enhance your driving experience.

Understanding the intricacies of your vehicle’s systems can significantly reduce the time and cost associated with repairs. With the right knowledge, owners can diagnose problems accurately and implement effective solutions. Whether you’re dealing with engine complications or electrical malfunctions, this resource aims to empower you with the skills necessary for effective maintenance.

Additionally, familiarity with repair techniques not only saves money but also fosters a deeper connection with your vehicle. Exploring the nuances of each component can unveil opportunities for customization and performance enhancement. This guide serves as a roadmap for both novice and seasoned mechanics alike, equipping you with the confidence to tackle any challenge on your journey.

Essential Tools for Jeep Wrangler Repairs

When it comes to maintaining and fixing your off-road vehicle, having the right equipment is crucial. Proper tools not only make tasks easier but also ensure that each job is completed efficiently and effectively. Here’s a guide to some of the fundamental instruments you’ll need for optimal performance.

- Socket Set: A comprehensive socket set is indispensable for loosening and tightening bolts and nuts of various sizes.

- Wrenches: Adjustable and fixed wrenches allow for flexibility when working on different components.

- Screwdriver Set: A variety of screwdrivers, both flathead and Phillips, are necessary for accessing different parts.

- Pliers: Needle-nose and regular pliers help grip and manipulate small items.

- Jack and Stands: For lifting your vehicle safely, a sturdy jack paired with jack stands is essential.

Additionally, consider incorporating these specialized tools:

- Torque Wrench: Ensures bolts are tightened to the manufacturer’s specifications, preventing damage.

- Diagnostic Scanner: Helps in troubleshooting electronic issues by reading error codes.

- Multimeter: Ideal for checking electrical systems and diagnosing faults.

- Fluid Pump: Facilitates the easy transfer of oils and fluids without spills.

With the right toolkit, you’ll be well-equipped to handle various tasks and keep your vehicle in prime condition for all your adventures.

Common Issues with 1995 Jeep Wrangler

This section explores frequently encountered problems that owners of a specific off-road vehicle may face. Understanding these common challenges can help in maintaining performance and ensuring a smooth driving experience. Being aware of potential issues allows for proactive measures to prevent further complications.

Electrical Problems

Electrical issues are often reported, affecting various components. Symptoms can range from faulty lights to power window malfunctions. Regular inspections of wiring and connections are essential to ensure reliability.

Engine and Transmission Concerns

Owners frequently note challenges with engine performance and transmission shifting. Common signs include rough idling and delayed gear changes. Routine maintenance and timely repairs can mitigate these problems.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Electrical Failures | Flickering lights, unresponsive windows | Check wiring, replace faulty fuses |

| Engine Performance | Rough idling, reduced power | Regular tune-ups, check fuel system |

| Transmission Problems | Delayed shifts, slipping gears | Fluid replacement, inspect transmission components |

Step-by-Step Maintenance Guide

Maintaining your vehicle is essential for ensuring its longevity and optimal performance. This guide provides a clear and structured approach to keeping your automobile in top condition, focusing on routine checks and necessary procedures to enhance reliability.

-

Regular Inspections:

- Check fluid levels (oil, coolant, brake fluid).

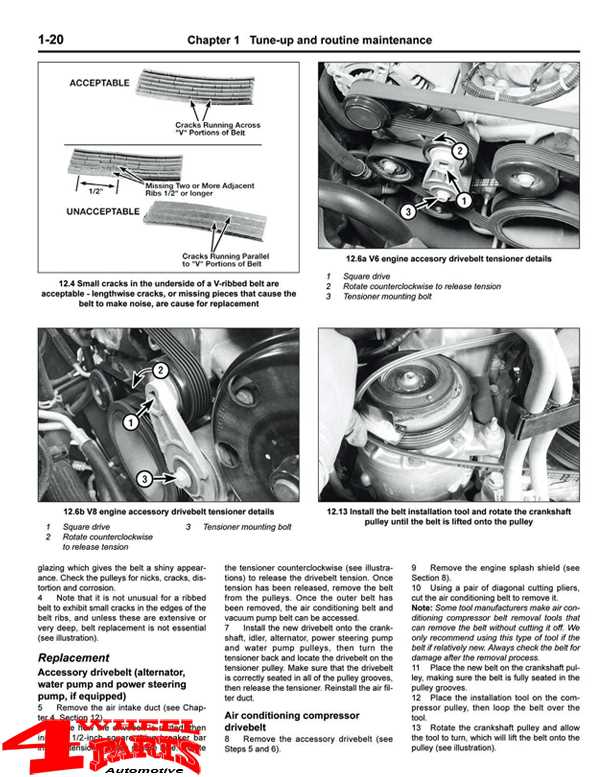

- Inspect belts and hoses for wear and tear.

- Examine tires for pressure and tread depth.

-

Oil Changes:

- Replace oil and oil filter every 3,000 to 5,000 miles.

- Use the recommended oil type for optimal performance.

-

Brake Maintenance:

- Inspect brake pads and rotors regularly.

- Replace brake fluid as recommended in the specifications.

-

Battery Care:

- Check battery terminals for corrosion.

- Ensure the battery is securely mounted.

-

Filter Replacements:

- Replace air filter to maintain engine efficiency.

- Change fuel filter as per the manufacturer’s guidelines.

-

Cooling System Checks:

- Inspect radiator and hoses for leaks.

- Flush coolant system as needed to prevent overheating.

Following these systematic steps can significantly enhance the performance and reliability of your vehicle, ensuring it serves you well for years to come.

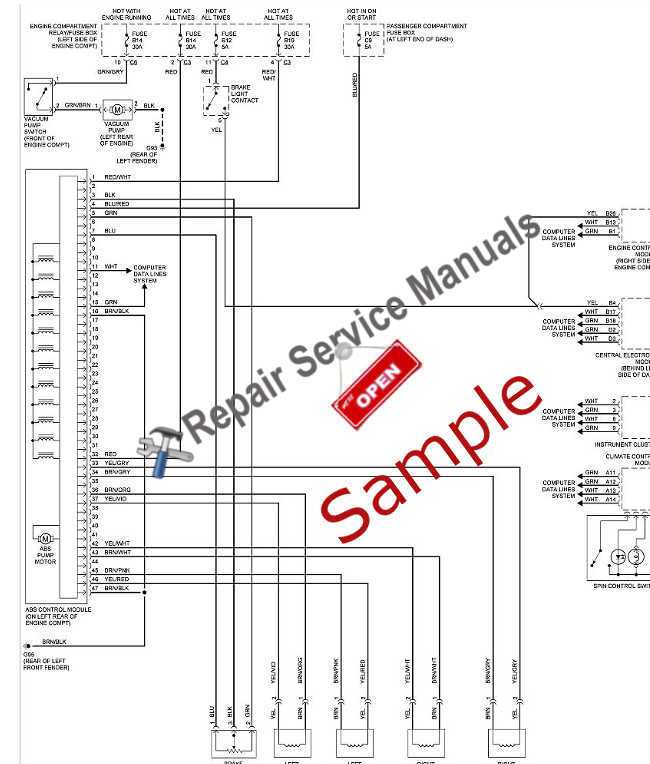

Understanding the Wrangler’s Electrical System

The electrical framework of this iconic off-road vehicle is crucial for its performance and functionality. It encompasses various components that work together to ensure seamless operation of essential features, such as lighting, ignition, and onboard diagnostics. A solid grasp of this system can aid in troubleshooting issues and enhancing overall reliability.

Key Components

Several critical elements make up the electrical setup, each serving specific functions that contribute to the vehicle’s overall performance. Below is a breakdown of these components:

| Component | Description |

|---|---|

| Battery | Supplies power to the entire electrical system and starts the engine. |

| Alternator | Recharges the battery while the engine is running and powers electrical accessories. |

| Fuses | Protect electrical circuits by breaking the connection if too much current flows. |

| Wiring Harness | A network of wires that connects various components and allows for electrical flow. |

Troubleshooting Common Issues

Understanding potential problems within the electrical system can prevent breakdowns and costly repairs. Common issues include faulty connections, blown fuses, and battery failure. Regular inspections and maintenance are essential to ensure optimal performance and longevity.

Engine Troubleshooting Tips

When facing issues with your vehicle’s power unit, it’s essential to approach the problem methodically. Understanding common symptoms and potential causes can help you diagnose issues effectively. This section offers practical guidance for identifying and resolving engine-related concerns.

Start by paying attention to any unusual noises. Knocking, pinging, or excessive vibrations can indicate underlying problems. Regularly check the engine oil level and quality; low or dirty oil can lead to severe damage. Overheating is another critical sign. Ensure that the cooling system is functioning correctly and look for leaks or blockages.

Next, monitor the performance during acceleration. If you experience hesitation or stalling, the fuel system might require inspection. Clogged filters or malfunctioning injectors can significantly impact engine efficiency. Also, keep an eye on warning lights on the dashboard. These indicators can provide vital information about malfunctions.

Lastly, ensure that all electrical connections are secure. Loose or corroded wires can disrupt the ignition and fuel systems, leading to starting difficulties. Regular maintenance and timely diagnostics will help keep your power unit running smoothly and prolong its lifespan.

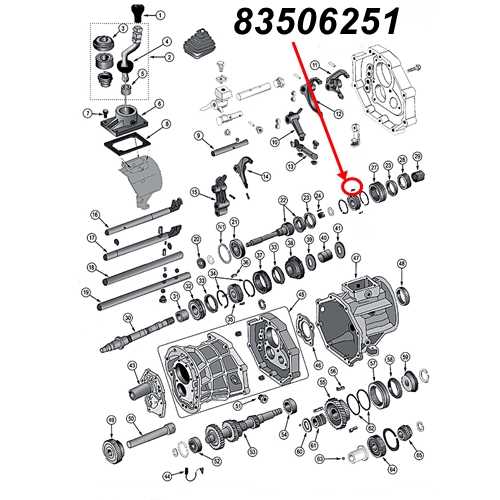

Transmission Care for Jeep Owners

Maintaining the functionality of your vehicle’s gear system is essential for optimal performance and longevity. Regular attention to this critical component can prevent costly repairs and ensure a smoother driving experience. Understanding the signs of wear and tear, as well as the necessary maintenance routines, can significantly enhance your ride’s reliability.

Routine Maintenance Checklist

To keep your gear mechanism in top condition, follow these essential maintenance steps:

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Fluid Level Check | Monthly | Ensure fluid is at the correct level for optimal operation. |

| Fluid Replacement | Every 30,000 miles | Use manufacturer-recommended fluid type. |

| Inspection of Hoses and Seals | Every 6 months | Look for cracks or leaks to prevent fluid loss. |

| Diagnostic Check | Annually | Identify any potential issues before they escalate. |

Signs of Trouble

Being aware of warning signals can help you address issues before they become serious. Look out for unusual noises, difficulty shifting gears, or warning lights on your dashboard. Early detection can save time and money, ensuring your vehicle remains dependable for years to come.

Bodywork Repair Techniques

Addressing exterior damage on vehicles requires a blend of skill and knowledge. Various methods can be employed to restore surfaces, ensuring both functionality and aesthetic appeal. This section explores effective techniques that can help bring your vehicle back to its prime condition.

Panel Replacement

One of the most common methods involves replacing damaged sections with new panels. This process includes carefully removing the affected area, preparing the surrounding surface, and fitting a new panel. Proper alignment and secure attachment are essential for achieving a seamless finish.

Painting and Finishing

Once the bodywork is complete, the next step is to refine the appearance. This involves sanding, priming, and painting the surface to match the original color. Techniques such as blending paint and applying clear coat are crucial for ensuring a smooth and durable finish that withstands the test of time.

Suspension Upgrades and Maintenance

Enhancing the suspension system of your vehicle can significantly improve handling, comfort, and off-road capabilities. Proper upkeep and upgrades are essential for ensuring that the ride quality remains optimal and that the components can withstand various driving conditions. This section covers key aspects of suspension enhancements and necessary maintenance procedures to keep your vehicle performing at its best.

| Component | Upgrade Options | Maintenance Tips |

|---|---|---|

| Shocks and Struts | High-performance or adjustable dampers | Inspect for leaks and test responsiveness regularly |

| Coil Springs | Heavy-duty or lifted springs | Check for sagging and rust; replace if damaged |

| Sway Bars | Upgraded anti-roll bars | Ensure mounting points are secure and inspect bushings |

| Control Arms | Longer or reinforced arms for lift kits | Lubricate bushings and check for wear |

| Ball Joints | Upgraded or adjustable options | Monitor for play and replace if necessary |

Regular inspections and timely upgrades not only enhance driving dynamics but also prolong the lifespan of suspension components. By addressing wear and considering improvements, you ensure a smoother, safer ride whether on or off the beaten path.

Finding Replacement Parts Effectively

Locating suitable components for your vehicle can often feel overwhelming. However, with the right approach, you can streamline the process and ensure that you obtain high-quality pieces that meet your needs. This section outlines practical strategies for sourcing these essential items efficiently.

- Research Online: Utilize various websites that specialize in automotive parts. Look for reviews and ratings to gauge the reliability of the suppliers.

- Visit Local Auto Shops: Building relationships with local retailers can provide you with insights on the best sources for parts.

- Join Online Communities: Engage with forums and social media groups dedicated to automotive enthusiasts. Members often share valuable tips on where to find rare components.

Additionally, consider the following methods:

- Check Salvage Yards: These places can be treasure troves for used parts that are still in good condition.

- Utilize Parts Catalogs: Many manufacturers offer catalogs that list available components for specific vehicle models.

- Explore Online Marketplaces: Websites that allow individuals to sell parts can provide competitive pricing and unique items.

By employing these techniques, you can navigate the search for replacement components more effectively, saving time and ensuring your vehicle remains in optimal condition.

DIY vs. Professional Repairs

The choice between tackling tasks yourself and hiring an expert often hinges on several factors, including skill level, available time, and complexity of the job. Each approach has its own set of advantages and drawbacks, making it essential to evaluate your specific situation before making a decision.

Advantages of DIY

Engaging in hands-on work can be highly rewarding. It not only saves money but also allows for personal involvement in the maintenance of your vehicle. With the right resources and determination, enthusiasts can gain valuable experience and enhance their mechanical skills. Additionally, the sense of accomplishment after completing a project can boost confidence and foster a deeper connection with the vehicle.

Benefits of Professional Assistance

On the other hand, enlisting a skilled technician can provide peace of mind. Professionals bring expertise and specialized tools, ensuring that tasks are completed efficiently and correctly. This is especially beneficial for complex issues that require diagnostic equipment or extensive experience. Moreover, relying on experts often includes warranties on the work performed, offering additional security for vehicle owners.

Ultimately, the decision should reflect your capabilities and the specific needs of your vehicle.