Understanding the intricacies of vehicle maintenance is essential for every owner aiming to ensure consistent performance and longevity. Navigating the complexities of systems and components requires a solid grasp of the fundamental structure and key connections within the vehicle. This section explores the vital techniques and tools needed for thorough upkeep, focusing on identifying issues early and implementing effective solutions.

Through this guide, readers will gain insight into various systems within the vehicle, including the electrical framework, engine setup, and diagnostics procedures. We emphasize practical knowledge, highlighting the significance of preventative care and proactive checks for avoiding more significant issues down the line. Whether tackling minor fixes or preparing for more involved projects, this resource offers a well-rounded perspective on maintaining optimal vehicle health.

The content covers step-by-step instructions and essential troubleshooting strategies tailored to assist both seasoned enthusiasts and beginners alike. From understanding warning signs to enhancing efficiency through regular inspections, this guide provides valuable knowledge that empowers vehicle owners to handle maintenance confidently and effectively.

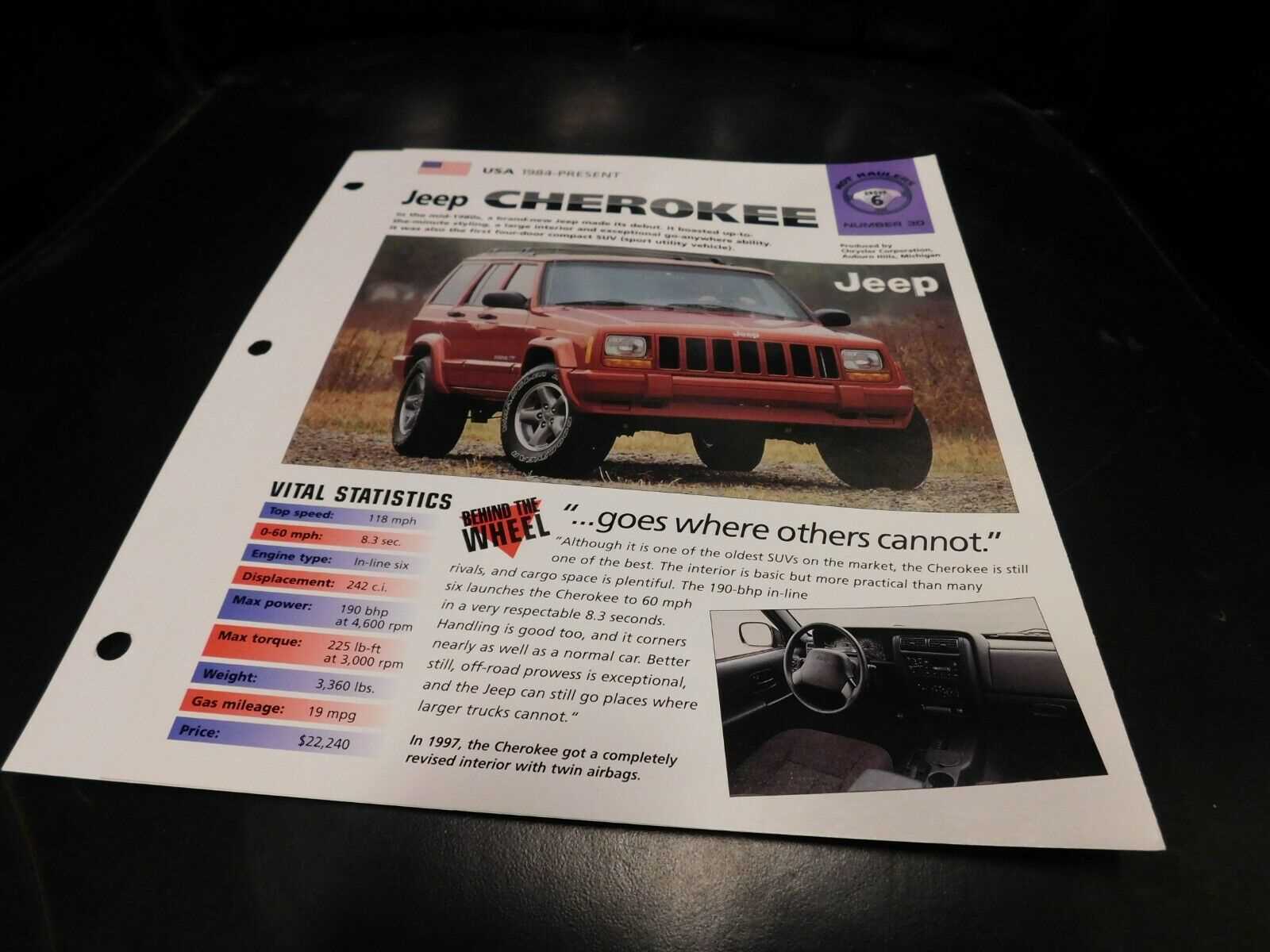

2001 Jeep Cherokee Repair Manual

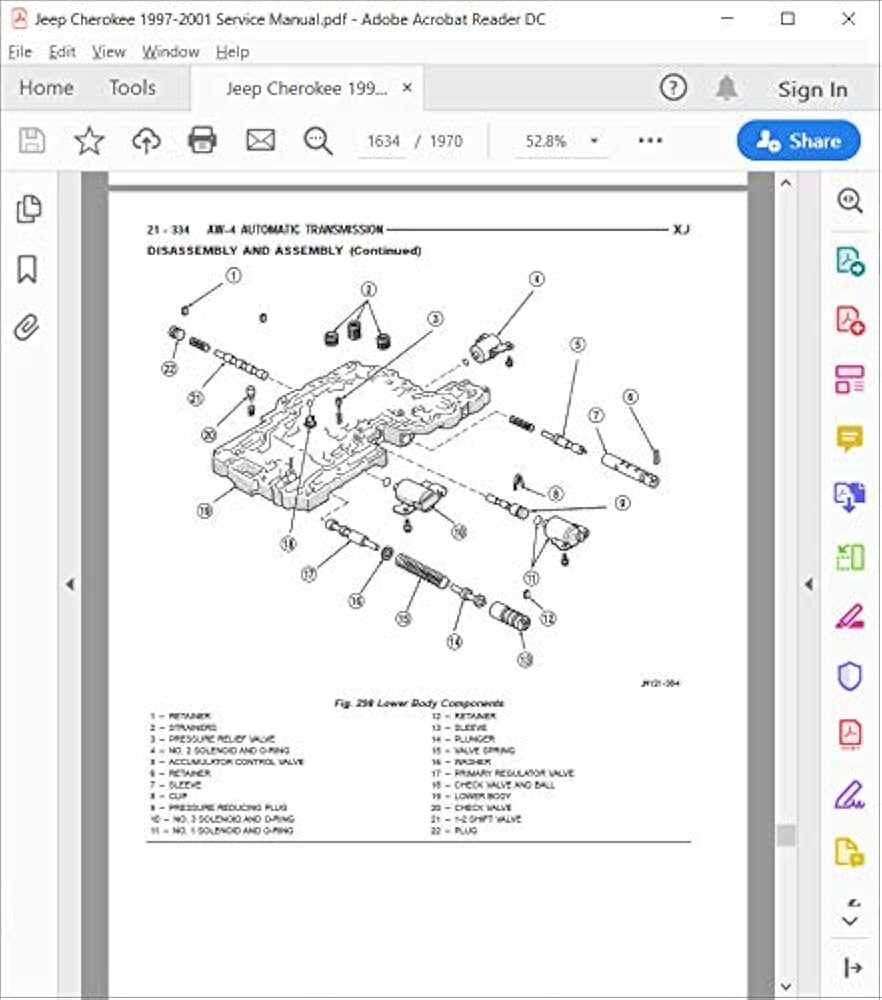

This section offers a comprehensive guide for addressing common issues and performing essential maintenance tasks, tailored for this vehicle model. It provides detailed information to ensure both seasoned mechanics and DIY enthusiasts can approach troubleshooting with confidence. Covering various components, this guide emphasizes a systematic approach to diagnostics and repairs, facilitating a clearer understanding of mechanical and electrical functions.

By following these guidelines, users can gain insights into maintaining peak performance and extending the vehicle’s lifespan. Each aspect, from preliminary inspections to advanced adjustments, is outlined to simplify complex procedures, ensuring clarity and ease for every task.

Engine Maintenance Tips

Proper upkeep of your vehicle’s power source ensures reliable performance and extends the life of essential components. Consistent care can prevent costly issues and improve overall efficiency, making regular checks an important habit for any driver.

Regular Fluid Checks

Maintaining the right fluid levels is key to smooth engine operation. Be sure to inspect and top up the following fluids regularly:

- Engine oil: Crucial for lubrication, preventing overheating and wear on moving parts.

- Coolant: Keeps temperatures stable and prevents the engine from overheating.

- Brake fluid: Essential for responsive braking, aiding safety and control.

Inspect Belts and Hoses

Belts and hoses endure a lot of wear and are critical to engine functions. Examining these parts can help avoid sudden breakdowns.

- Belts: Look for any cracks or frays. Replace them if signs of wear are visible.

- Hoses: Check for leaks or soft spots, as these could lead to coolant loss or overheating.

With regular attention to these areas, you can keep your vehicle in peak condition, enhancing performance and longevity.

Understanding the Electrical System

The electrical system in a vehicle forms the backbone for various components, ensuring they operate in harmony and maintain reliable functionality. It encompasses a network of interconnected circuits, sensors, and power sources that enable critical systems, from lighting and ignition to electronic control units, to perform efficiently. Comprehending this network helps diagnose issues, optimize performance, and ensures each component receives the correct voltage and grounding.

| Component | Function | Common Issues |

|---|---|---|

| Battery | Supplies power to the entire electrical system, especially during startup | Corrosion, low charge, worn terminals |

| Alternator | Recharges the battery and powers electrical components while the engine is running | Loose connections, worn bearings, insufficient charging |

| Fuse Box | Protects circuits by breaking the connection when a surge occurs | Blown fuses, corroded terminals |

| Tool/Material | Purpose |

|---|---|

| Screwdriver Set | For removing screws from trim pieces |

| Pry Tool | To gently detach trim without damaging surfaces |

| Adhesive Cleaner | For removing old adhesive residue |

| Replacement Trim Pieces | New components to install in the vehicle |

| Soft Cloth | To protect surfaces during installation |

Step-by-Step Replacement Process

Follow these steps to successfully replace interior trim:

- Ensure the vehicle is parked on a flat surface and the ignition is off.

- Use the screwdriver to remove any screws securing the trim piece.

- Employ the pry tool to carefully detach the trim from the vehicle’s interior.

- Clean the area where the new trim will be installed, ensuring it is free of debris and old adhesive.

- Align the new trim piece with the existing mounting points and press it into place.

- Reinsert any screws removed earlier to secure the new component.

- Inspect the installation to ensure everything fits properly and functions as intended.

Lighting and Signal Fixes

Ensuring proper illumination and signaling is essential for safe navigation and communication on the road. This section provides insights into diagnosing and resolving common issues associated with lighting and signaling systems. By addressing these concerns, vehicle owners can enhance visibility and maintain compliance with traffic regulations.

Common Issues and Solutions

- Flickering Headlights: Often caused by loose connections or failing bulbs. Inspect the wiring harness and replace any damaged bulbs.

- Dim Lights: Can indicate a weak battery or faulty alternator. Test the battery voltage and examine the charging system.

- Turn Signal Malfunctions: If the signal lights do not function properly, check the flasher relay and the bulbs for continuity.

- Brake Light Failures: Ensure the brake light switch is operational and check the bulbs and wiring for any defects.

Maintenance Tips

- Regularly inspect all lighting elements for signs of wear or damage.

- Clean the lens covers to improve light output.

- Use the correct bulb type and wattage for replacements to avoid overheating.

- Ensure all connections are tight and free of corrosion to maintain a reliable electrical system.

Exhaust System Overview

The exhaust system plays a critical role in managing the emissions produced by the engine, ensuring that harmful gases are effectively routed away from the vehicle. Its design encompasses various components that work in harmony to minimize noise, optimize performance, and enhance fuel efficiency. Understanding the structure and function of each element is essential for maintaining optimal operation.

At its core, the exhaust system consists of parts such as the manifold, catalytic converter, muffler, and tailpipe. The manifold collects exhaust gases from the engine cylinders and directs them into the catalytic converter, where harmful substances are converted into less toxic emissions. Following this, the muffler reduces noise generated by the engine’s operation, while the tailpipe expels the treated gases into the atmosphere.

Regular inspection and maintenance of the exhaust system are vital to prevent issues like leaks, rust, or blockages. These problems can lead to decreased performance, increased emissions, and potential damage to other engine components. A well-functioning exhaust system not only contributes to a cleaner environment but also ensures the vehicle runs smoothly and efficiently.