Owning a vehicle requires a solid understanding of its care and upkeep. Each model has its specific maintenance needs, which may involve handling both simple adjustments and more involved technical fixes. A thorough resource can empower owners with the knowledge to ensure their vehicle runs smoothly and safely on the road.

In this guide, we delve into essential tips and instructions that every vehicle owner should know. From routine checks to diagnosing common issues, you’ll find insights that make maintaining and repairing your vehicle straightforward. This information not only helps with solving minor problems but also with preventing them before they escalate into costly repairs.

We also cover methods for enhancing the vehicle’s lifespan through regular service and mindful upkeep. By following structured advice, you can tackle maintenance tasks confidently, gaining a deeper understanding of the mechanisms and best practices that keep your vehicle in top shape.

Overview of 2014 Jeep Compass Maintenance

Regular upkeep ensures the long-term durability and reliability of any vehicle, keeping it running smoothly and efficiently. By following essential care guidelines, vehicle owners can reduce the risk of unexpected issues and enjoy a more consistent driving experience.

Key aspects of ongoing care include monitoring fluid levels, inspecting tires, and maintaining proper engine performance. Frequent checks and timely replacements are vital to prevent wear and enhance the overall safety and performance of the vehicle.

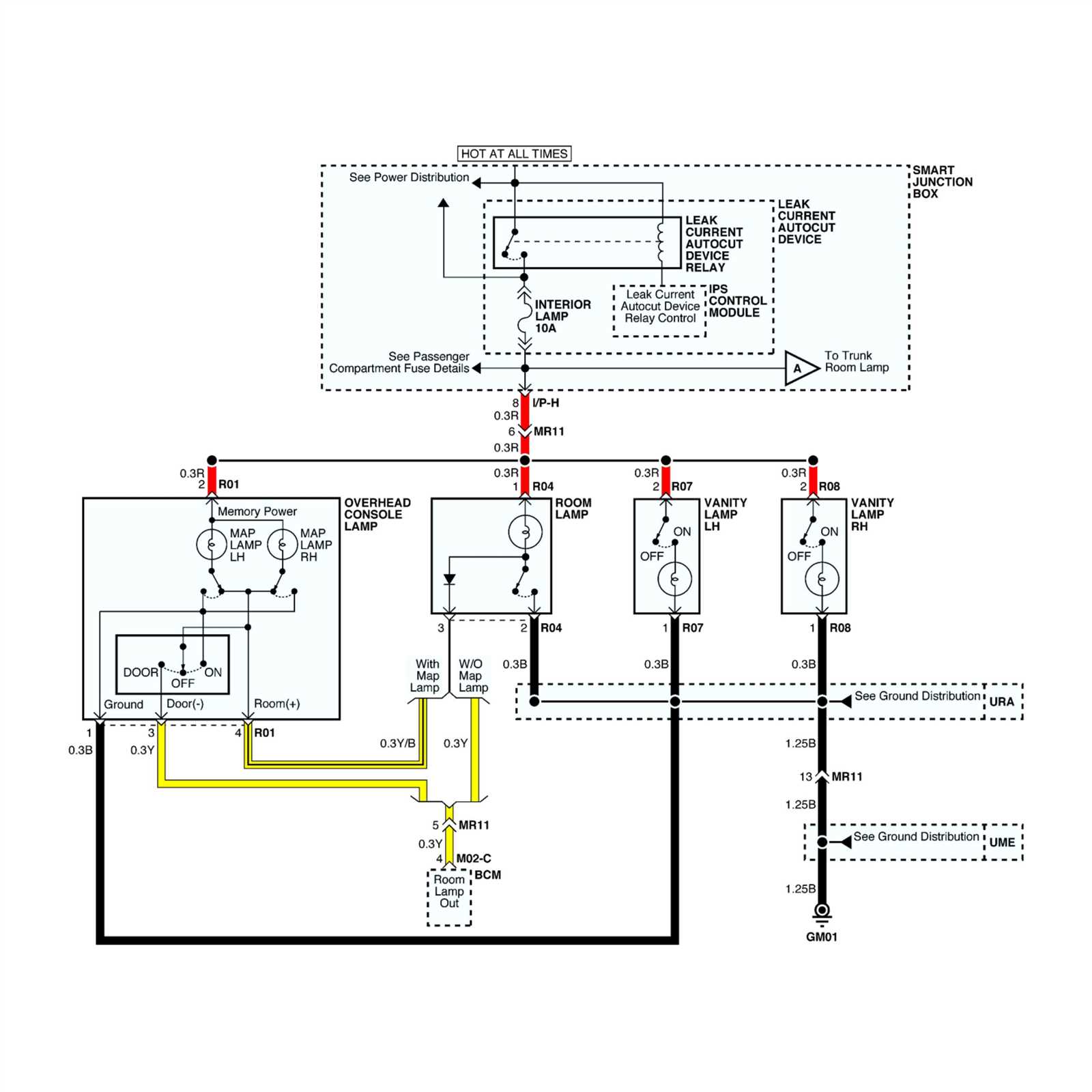

A focus on preventative care not only extends the vehicle’s lifespan but also supports optimal functionality. From assessing brakes to evaluating electrical systems, consistent attention to these areas contributes to a safer and more enjoyable journey.

Essential Tools for Jeep Compass Repairs

To maintain and service a vehicle effectively, having the right equipment is essential. Equipping yourself with a reliable set of tools not only saves time but also enhances the quality and precision of each task. This section highlights some of the must-have items that can help streamline maintenance work and ensure safety and efficiency.

Basic Toolkit Essentials

A basic toolkit is the foundation for any maintenance project. A set of sockets, wrenches, and screwdrivers provides versatility to tackle a range of tasks, from tightening bolts to adjusting parts. Ensuring these tools are made from durable materials will help them withstand extensive use over time.

Specialized Diagnostic Tools

Advanced diagnostic tools are crucial for identifying issues in the vehicle’s system accurately. An OBD-II scanner enables you to read error codes and diagnose potential problems early on. This tool is especially valuable for catching issues that might otherwise go unnoticed until they worsen.

Safety Equipment

Safety gear

Understanding the Jeep Compass Engine System

The engine system in this vehicle model is a complex network designed for efficient power delivery and fuel management. This section explores how various components work together to ensure a smooth, reliable performance. By understanding the basics of the engine’s operation, drivers and mechanics can make informed decisions about maintenance and optimization.

Key Components of the Engine System

The engine comprises multiple parts that work in harmony. Each component plays a role in combustion, cooling, and power distribution, forming a synchronized system. Below is an overview of the main elements and their functions.

| Component | Function | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cylinder | Forms the core where fuel is ignited and power is generated. | |||||||||||||||||||||

| Pistons | Move within the cylinders to compress the fuel-air mixture, facilitating combustion. | |||||||||||||||||||||

| Fuel Injectors | Deliver precise amounts of fuel to the cylinders, optimizing efficiency. | |||||||||||||||||||||

| Camshaft | Controls the intake and exhaust valves to regulate airflow. |

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Check Fluid Level | Monthly | Ensure the level is within the recommended range. |

| Change Fluid | Every 30,000 miles | Use the recommended fluid type for optimal performance. |

Inspecting Transmission Components

Regularly inspecting transmission components for wear and tear can help catch problems early. This includes checking seals, gaskets, and electrical connections.

DIY Guide to Suspension Adjustments

Making modifications to your vehicle’s suspension can significantly enhance its performance and ride quality. This section provides a straightforward approach for enthusiasts looking to fine-tune their vehicle’s suspension system. Understanding the basics of suspension adjustments will enable you to achieve the desired handling characteristics and comfort levels.

Understanding Suspension Components

Before diving into adjustments, it is essential to familiarize yourself with the various components of the suspension system. Key elements include shock absorbers, springs, control arms, and sway bars. Each component plays a crucial role in how your vehicle responds to different driving conditions.

Making Adjustments

Begin by assessing your vehicle’s current setup. Depending on your objectives, you may want to raise or lower the ride height, adjust damping settings, or change spring rates. Use the appropriate tools for each task, ensuring safety and precision throughout the process. Regular checks after making adjustments will help maintain optimal performance.

Tip: Always consult your vehicle’s specifications before proceeding with any modifications to avoid compromising safety or performance.

Cooling System Inspection and Repair

The cooling system is crucial for maintaining optimal engine temperature and preventing overheating. Regular examination of this system ensures effective performance and longevity of the vehicle. This section outlines the key aspects of evaluating and addressing issues within the cooling system, including common components, potential problems, and maintenance tips.

Key Components of the Cooling System

Understanding the primary parts of the cooling system is essential for effective inspection. The major components include the radiator, water pump, thermostat, hoses, and coolant reservoir. Each of these elements plays a vital role in regulating engine temperature and facilitating efficient heat dissipation.

Common Issues and Solutions

Drivers may encounter various problems related to the cooling system, such as leaks, blockages, or overheating. Identifying symptoms early can prevent severe engine damage. Here are some common issues and their corresponding solutions:

| Issue | Symptoms | Recommended Action |

|---|---|---|

| Coolant Leak | Low coolant level, visible puddles | Inspect hoses and connections, replace damaged components |

| Overheating | High temperature gauge reading, steam | Check coolant level, examine thermostat functionality |

| Clogged Radiator | Reduced cooling efficiency, strange noises | Flush the radiator, clear any obstructions |

Step-by-Step Guide to Oil Changes

Performing regular maintenance on your vehicle is essential for its longevity and optimal performance. One of the most crucial tasks is changing the lubricant that keeps the engine components running smoothly. This guide will walk you through the essential steps involved in this process, ensuring your engine remains in top condition.

- Gather Necessary Tools and Materials

- New oil

- Oil filter

- Wrench set

- Oil catch pan

- Funnel

- Gloves and rags

- Prepare the Vehicle

Park your vehicle on a flat surface and turn off the engine. Allow the engine to cool down if it has been running. Engage the parking brake for safety.

- Locate the Oil Drain Plug

Underneath the vehicle, find the oil drain plug. It is usually located at the lowest point of the oil pan.

- Drain the Old Oil

Position the oil catch pan beneath the drain plug. Use a wrench to loosen the plug and allow the old oil to drain completely into the pan.

- Replace the Oil Filter

Locate the oil filter, which is typically above the oil pan. Use an oil filter wrench to remove the old filter. Before installing the new filter, apply a bit of new oil to the rubber gasket of the new filter to ensure a good seal.

- Refill with New Oil

After draining and replacing the filter, replace the drain plug securely. Use a funnel to pour the new oil into the engine through the oil filler cap. Refer to your vehicle’s specifications for the correct amount and type of oil.

- Check Oil Level

After adding the new oil, wait a moment and then use the dipstick to check the oil level. Add more oil if necessary until it reaches the appropriate mark.

- Dispose of Old Oil Properly

Take the old oil and filter to a recycling center or an auto parts store that accepts used oil to ensure proper disposal.

Following these steps will help you maintain your vehicle’s engine health and ensure a smoother driving experience. Regular oil changes are a vital part of vehicle upkeep.

Identifying Common Compass Performance Issues

Understanding the typical performance challenges faced by a vehicle can greatly enhance its longevity and efficiency. Many drivers may encounter various signs that indicate underlying problems, which can manifest in several ways. Recognizing these issues early on allows for timely interventions, preventing further complications and ensuring optimal operation.

One of the most frequent indicators of performance concerns is unusual sounds during operation. These noises can range from grinding to squeaking, often pointing to mechanical wear or inadequate lubrication. Additionally, a noticeable drop in acceleration or sluggish response can suggest issues with the powertrain or fuel system, requiring immediate attention.

Another common issue is irregular handling, which may lead to a lack of control while driving. This could be a result of tire imbalance or suspension problems, which not only affect performance but also compromise safety. Regular inspections of these components are crucial for maintaining stability and comfort on the road.

Finally, monitoring warning lights on the dashboard is essential. Illumination of these indicators often signifies that the vehicle requires diagnostic evaluation. Ignoring these signals can result in more severe issues down the line, making it imperative to address them promptly.

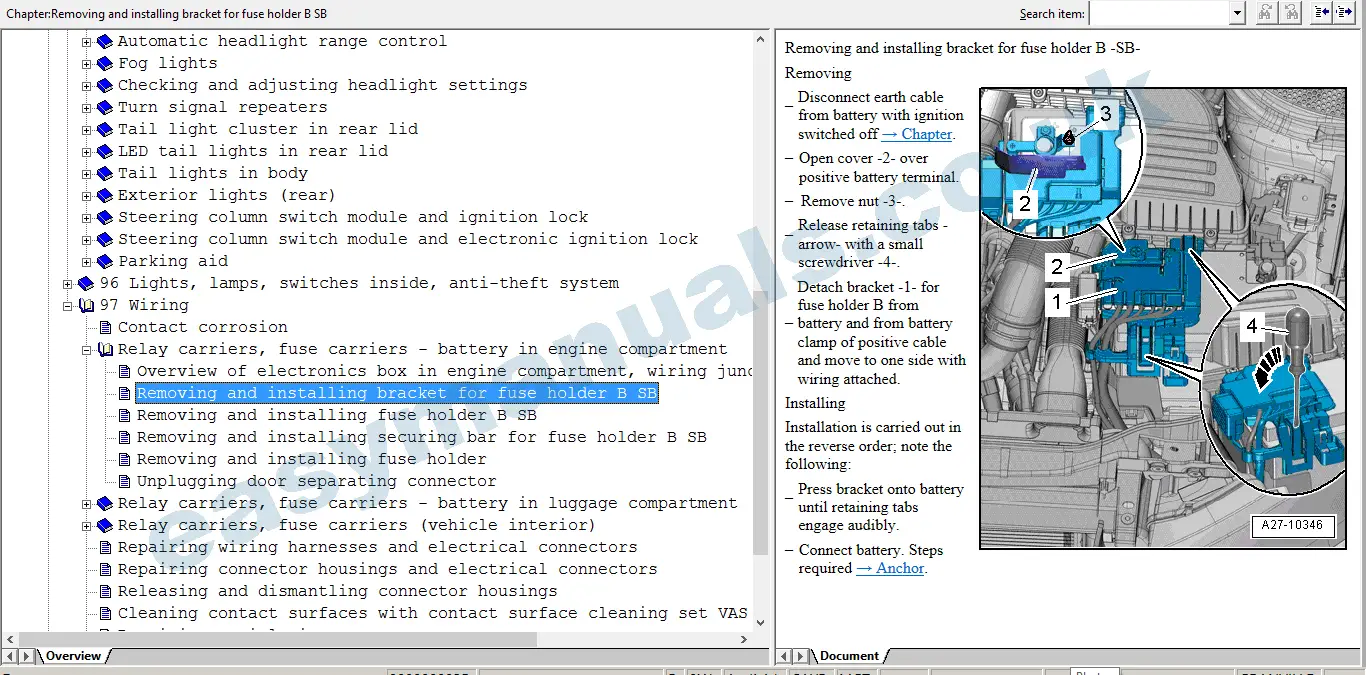

Battery Maintenance and Replacement Tips

Proper upkeep and timely replacement of the power source are crucial for ensuring the longevity and efficiency of your vehicle’s electrical system. Regular attention to the battery can prevent unexpected failures and improve overall performance.

Regular Inspection

Routine checks are essential for identifying potential issues early. Look for signs of corrosion around the terminals, which can hinder electrical flow. Additionally, ensure that the battery is securely mounted and free from any leaks.

Maintaining Charge Levels

Keeping the battery adequately charged is vital. If the vehicle is not used frequently, consider using a trickle charger to maintain optimal charge levels. During colder months, monitor the charge more closely, as low temperatures can reduce battery efficiency.