When the cold months arrive, having a reliable tool to manage snow accumulation becomes essential for many homeowners. Understanding how to keep this machinery in optimal condition not only extends its lifespan but also ensures it operates efficiently during the harshest weather. This section focuses on troubleshooting and upkeep strategies that can empower users to tackle any challenges they may encounter.

Proper maintenance is crucial for maximizing performance and preventing common issues. By familiarizing yourself with key components and operational guidelines, you can address minor problems before they escalate. This approach not only saves time and resources but also enhances safety during use.

In the following segments, we will delve into detailed procedures, offering insights into common repairs and adjustments. Whether you are an experienced user or new to winter machinery, having a comprehensive understanding of your equipment will greatly improve your experience and effectiveness in snow management. Equip yourself with knowledge and enjoy the winter season with confidence!

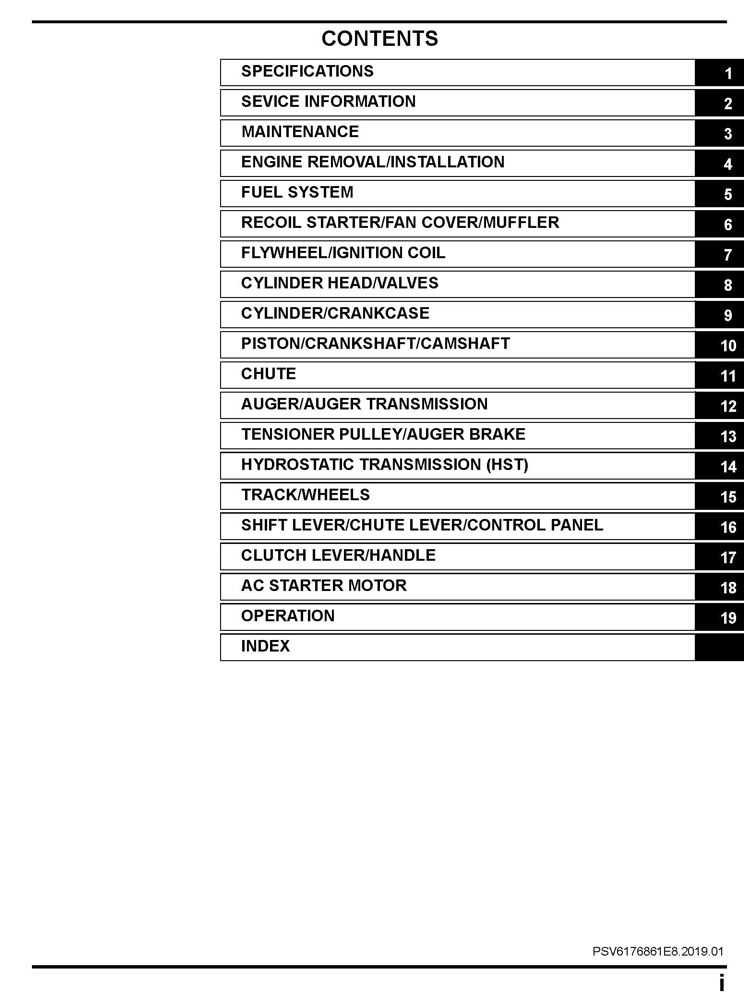

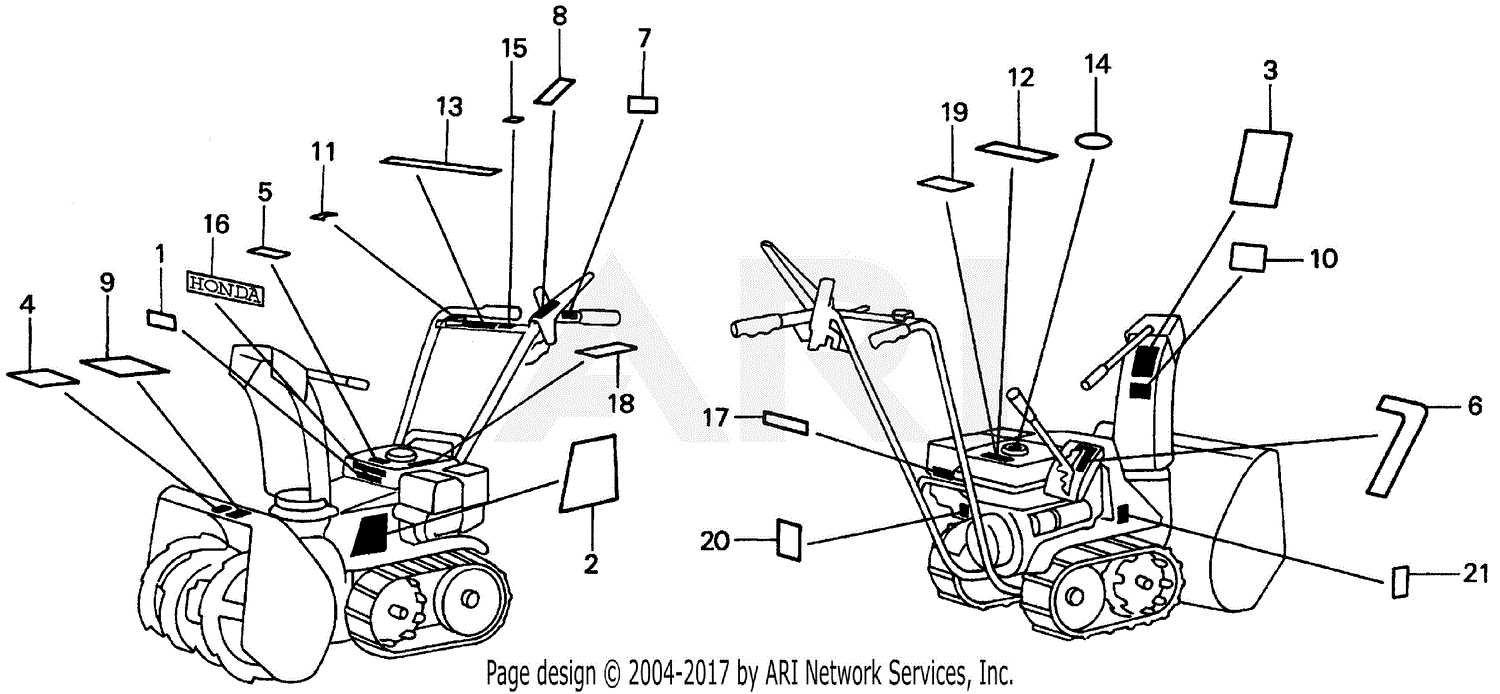

Understanding the Honda HS622 Snowblower

This section delves into the features and functionalities of a specific model designed for clearing snow efficiently. Known for its reliability and performance, this machine is equipped with various components that work together to tackle winter challenges. Familiarizing oneself with its mechanisms can enhance operational effectiveness and longevity.

| Feature | Description |

|---|---|

| Engine Power | Robust engine ensures optimal performance in heavy snowfall. |

| Clearing Width | Wider pathway allows for faster snow removal. |

| Throwing Distance | Adjustable chute for directing snow precisely. |

| Control Features | User-friendly controls for smooth operation. |

| Build Quality | Durable construction for extended use in harsh conditions. |

Understanding these aspects is crucial for anyone looking to maintain efficiency and performance during snowy conditions. Proper handling and care can significantly affect the functionality and lifespan of the equipment.

Common Issues with Honda HS622

When dealing with outdoor equipment designed for snow removal, users may encounter several frequent problems that can affect performance and efficiency. Identifying these challenges early on can help ensure a smoother operation and extend the lifespan of the unit.

Starting Difficulties

One of the most common issues is trouble initiating the engine. This can stem from various factors, such as a drained battery, contaminated fuel, or a clogged air filter. Regular maintenance and inspection of the fuel system and electrical components are essential to prevent this frustration.

Loss of Power

Another prevalent concern is a noticeable reduction in power output. This might be caused by issues such as worn-out belts, dull blades, or engine problems. Ensuring that all parts are in good condition and promptly addressing wear and tear can significantly improve functionality.

By being aware of these typical problems, users can take proactive measures to maintain their equipment and enhance its operational efficiency.

Essential Tools for Repair

When tackling maintenance tasks, having the right equipment at your disposal can make all the difference. Certain instruments are crucial for effectively addressing issues, ensuring that the process is efficient and productive. This section outlines the fundamental tools you should gather before beginning any work, enabling you to achieve optimal results.

First and foremost, a comprehensive set of wrenches and sockets is indispensable for loosening and tightening fasteners. Additionally, screwdrivers in various sizes and types will allow you to navigate different components seamlessly. Pliers are another versatile tool, essential for gripping, twisting, and cutting materials as needed.

Furthermore, a reliable multimeter can aid in diagnosing electrical issues, providing valuable insights into the functioning of various parts. Don’t overlook the importance of a sturdy workbench, as it provides a stable surface for your projects and keeps everything organized. Finally, safety gear such as gloves and goggles should be included to protect yourself during the process.

By assembling these essential tools, you’ll be well-prepared to tackle any maintenance or troubleshooting tasks that arise, ensuring longevity and performance in your equipment.

Step-by-Step Maintenance Guide

Regular upkeep of your equipment is essential to ensure optimal performance and longevity. Following a structured maintenance routine not only prevents potential issues but also enhances efficiency during operation. This guide provides a comprehensive approach to keeping your machinery in excellent condition.

Essential Checks

Begin with a thorough inspection of all components. Check for wear and tear on belts, cables, and other parts. Ensure that the fuel system is clean, and inspect filters for any obstructions. Addressing these issues early can save time and effort later.

Routine Cleaning and Lubrication

Clean the exterior surfaces to remove dirt and debris. Pay special attention to the areas around the motor and moving parts. After cleaning, apply appropriate lubricants to moving components as specified in your guidelines. This not only reduces friction but also prevents rust and corrosion.

Note: Always refer to your specific equipment guidelines for any unique maintenance requirements or specifications.

Engine Troubleshooting Techniques

When dealing with mechanical issues, it is essential to identify the root cause of performance problems. Understanding common symptoms and utilizing effective diagnostic strategies can significantly enhance the efficiency of the repair process.

Observation: Start by closely examining the unit for any visible signs of wear or damage. Listen for unusual noises during operation, which can indicate underlying issues.

Fuel System Check: Ensure that the fuel supply is adequate and uncontaminated. Stale or contaminated fuel can lead to starting difficulties and poor performance.

Ignition Assessment: Investigate the ignition system components, including spark plugs and wiring. A faulty spark plug can hinder the engine’s ability to start or run smoothly.

Airflow Inspection: Evaluate the air intake and exhaust systems. Blockages in these areas can restrict airflow, leading to overheating or inefficient combustion.

Compression Test: Perform a compression test to assess the engine’s internal condition. Low compression readings may suggest wear or damage within the cylinder or piston rings.

By systematically applying these techniques, one can effectively pinpoint issues and implement the necessary corrective measures, ensuring optimal performance of the machinery.

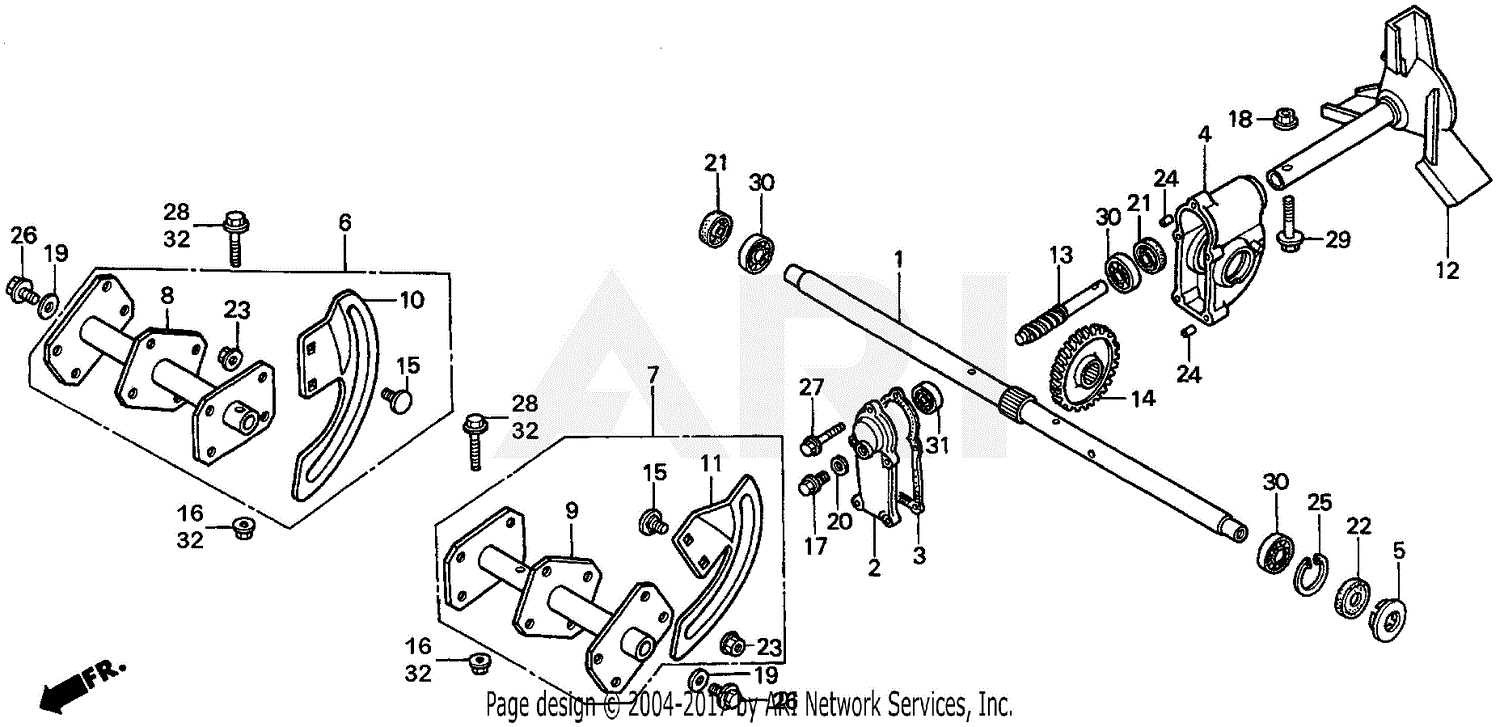

Repairing the Auger Assembly

The auger assembly is a critical component responsible for the efficient movement of snow. Proper maintenance and troubleshooting can enhance performance and prolong its lifespan. Understanding the assembly’s structure and common issues can significantly ease the process of restoration.

Common Issues

Several problems may arise with the auger assembly, including unusual noises, lack of movement, and reduced efficiency. Identifying these issues early can prevent further complications.

Troubleshooting Steps

Follow these steps to address common problems:

| Issue | Possible Cause | Solution |

|---|---|---|

| Unusual Noises | Worn bearings or debris | Inspect and clean or replace bearings |

| Lack of Movement | Broken drive belt | Replace the drive belt |

| Reduced Efficiency | Improper blade alignment | Adjust the blade alignment |

Regular inspections and timely interventions are essential for optimal functionality. By addressing these common issues, users can ensure their equipment remains reliable during winter operations.

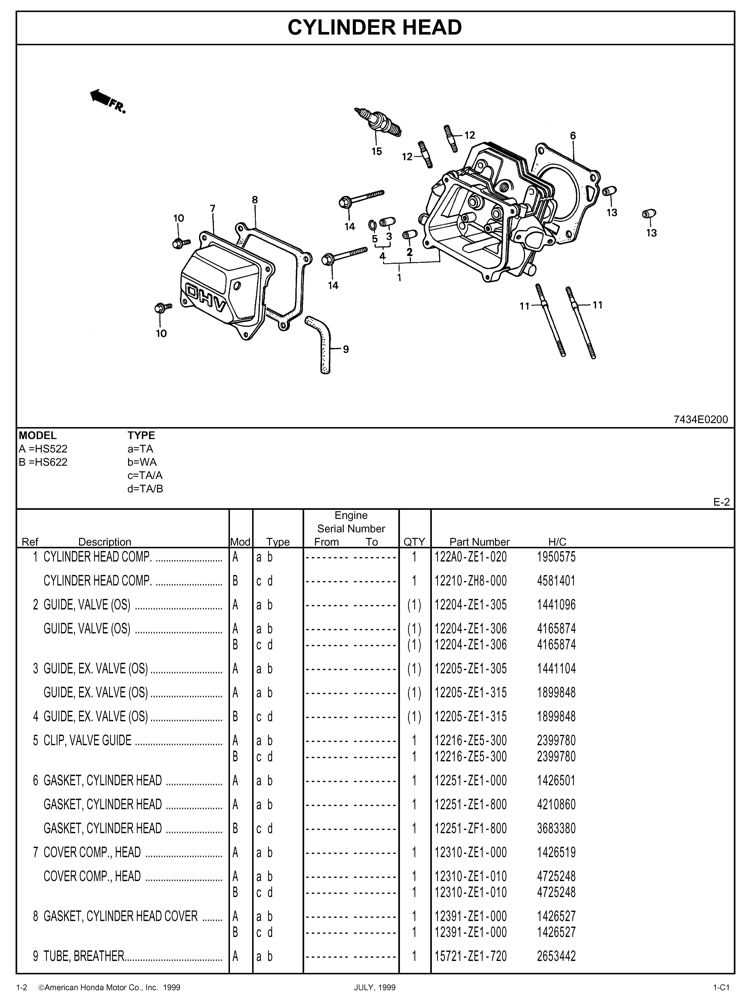

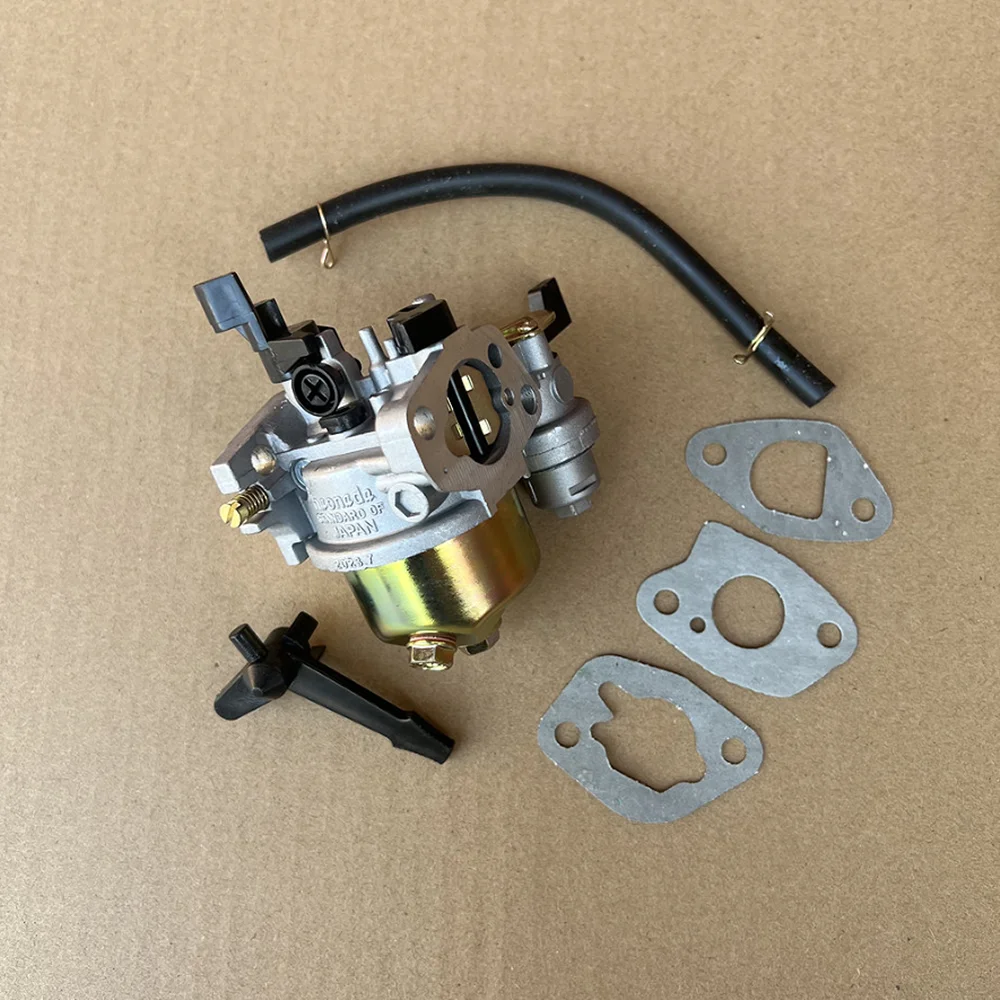

Fixing Fuel System Problems

Addressing issues within the fuel delivery system is crucial for optimal performance of your equipment. Problems may manifest as starting difficulties, irregular engine behavior, or complete failure to run. Identifying and rectifying these concerns can enhance efficiency and extend the lifespan of the machine.

Here are common issues and their potential solutions:

- Clogged Fuel Filter: Replace the filter regularly to ensure clean fuel flow.

- Old or Contaminated Fuel: Drain and refill with fresh fuel to avoid engine problems.

- Fuel Line Obstructions: Inspect and clear any blockages in the lines to restore proper flow.

- Faulty Fuel Pump: Check the pump functionality; replace it if it fails to deliver fuel.

- Carburetor Issues: Clean or rebuild the carburetor to ensure accurate fuel-air mixture.

Regular maintenance and timely interventions can prevent most fuel system issues. Always refer to specific guidelines for thorough diagnostics and actions.

Electrical Components: What to Check

Understanding the functionality of electrical components is crucial for effective maintenance. Proper inspection and testing can help identify issues that may disrupt performance. This section outlines essential elements to examine when troubleshooting electrical systems.

Wiring Integrity

Inspecting the wiring for damage is vital. Look for frayed insulation, corrosion, or loose connections. Damaged wiring can lead to short circuits or power loss, affecting the entire system’s operation. Ensure all connections are secure and free from rust or dirt.

Fuses and Relays

Examine fuses and relays for signs of failure. A blown fuse can interrupt the power supply, while a malfunctioning relay may cause intermittent issues. Replacing these components can often resolve electrical problems. Use a multimeter to check for continuity and ensure proper functionality.

Winter Preparation Tips for Longevity

Ensuring optimal performance of your equipment during the cold months requires careful attention and proactive measures. Proper maintenance not only enhances efficiency but also extends the lifespan of your machinery.

Here are some essential steps to consider for effective winter preparation:

- Inspect Fuel System: Ensure that the fuel tank is clean and filled with the appropriate blend. Consider using a fuel stabilizer to prevent degradation over time.

- Check the Oil Level: Regularly examine the oil level and change it if necessary. Fresh oil helps protect engine components from wear.

- Sharpen Blades: Keeping blades sharp is crucial for effective operation. Dull edges can lead to inefficiency and additional strain on the engine.

- Examine Belts and Cables: Inspect belts and cables for wear and tear. Replace any that show signs of damage to avoid breakdowns during use.

- Clean and Store Properly: After use, clean the exterior and remove any debris. Store the equipment in a dry, sheltered area to prevent rust and corrosion.

By following these guidelines, you can ensure that your machinery remains reliable and ready to tackle the challenges of winter weather.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance on mechanical devices is crucial. Adhering to proper guidelines helps prevent accidents and injuries, creating a secure environment for the task at hand.

Essential Safety Measures

- Wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust.

- Keep the workspace organized to minimize hazards and ensure tools are easily accessible.

- Disconnect power sources before beginning any work to prevent accidental startups.

Handling Tools and Equipment

- Inspect tools for damage before use; do not operate any equipment that is faulty.

- Use tools for their intended purpose only to avoid accidents.

- Store tools safely when not in use to prevent tripping hazards.

- Be aware of your surroundings, ensuring that no one is in the immediate area while operating machinery.

Where to Find Genuine Parts

Locating authentic components is essential for maintaining the performance and longevity of your equipment. Utilizing genuine parts ensures compatibility and reliability, providing peace of mind during operation. Here are some reliable avenues to explore when seeking original replacements.

Authorized Dealers

One of the best ways to secure authentic components is through authorized distributors. These vendors specialize in offering original items that are specifically designed for your machinery. They often have knowledgeable staff who can assist you in finding the right part and provide additional insights on installation and maintenance.

Online Retailers

Another effective option is to browse reputable online platforms that specialize in equipment parts. Many websites cater specifically to owners seeking original components. Ensure you verify the seller’s credentials and check for customer reviews to guarantee that you are purchasing genuine merchandise.

FAQs About HS622 Repairs

This section aims to address common inquiries regarding maintenance and troubleshooting of a specific equipment model. By providing clear answers, users can gain a better understanding of potential issues and solutions that may arise during operation.

What should I do if the engine won’t start?

First, check the fuel level and ensure it’s fresh. Inspect the ignition system for any loose connections or damage. If the problem persists, examine the air filter for clogs, as restricted airflow can prevent starting.

How often should I perform maintenance tasks?

Regular upkeep is essential. It’s recommended to conduct a thorough inspection at the beginning of each season, and perform oil changes and filter replacements as outlined in the guidelines provided by the manufacturer.

What are the signs of wear and tear on the components?

Look for unusual noises, vibrations, or decreased performance during operation. Visual checks for cracks, rust, or other damage can also indicate the need for replacement parts.

Can I fix minor issues myself?

Yes, many users find that basic problems, such as replacing spark plugs or filters, can be handled independently with the right tools and guidance. However, for complex repairs, it’s advisable to consult a professional.

Where can I find replacement parts?

Replacement components can typically be found through authorized dealers, online retailers, or local hardware stores that specialize in similar equipment. Ensure to verify compatibility with your specific model.