Outdoor cleaning devices can be a powerful ally when it comes to keeping spaces neat and surfaces pristine. However, even the most dependable equipment may face occasional issues, especially with regular use in tough environments. Understanding how to troubleshoot and refresh these machines ensures they remain efficient and helps avoid unexpected interruptions during tasks.

Frequent use exposes these machines to wear and tear, making them vulnerable to common issues such as diminished output, engine stalling, or irregular performance. Regular care, a keen eye for possible faults, and prompt fixes can help maintain their power and efficiency, maximizing their lifespan and enhancing results.

In this guide, we’ll explore essential steps for diagnosing, adjusting, and fine-tuning outdoor cleaning equipment. This resource is designed to empower users with insights on keeping their tools in peak condition, covering practical methods for various common challenges. By following a few straightforward maintenance steps, you can keep your cleaning companion running smoothly for many years.

Common Issues with Honda Pressure Washers

Powerful outdoor cleaning tools can face a range of challenges after extended use, often related to maintenance needs or environmental factors. Recognizing these common issues can aid in maintaining their efficiency and prolonging their lifespan, saving users from frequent visits to repair centers.

Engine Starting Difficulties: A frequent concern among users is the challenge of getting the motor to start consistently. This issue may stem from a variety of factors, including stale fuel or a dirty air filter. Ensuring that the fuel is fresh and the filter is clear can often resolve this problem quickly.

Water Flow Inconsistencies: Another issue many face is an uneven water output. This could result from clogs or buildup within the nozzle or the water inlet, which can restrict the steady flow needed for optimal performance. Regular cleaning of these parts helps maintain consistent functionality.

Engine Stalling Mid-Use: Some users report that their machine’s motor stalls unexpectedly during use. This might be due to insufficient oil levels or overheating from prolonged operation without breaks. Checking oil levels and following recommended operation intervals helps mitigate these stalling issues.

Leaking or Dripping: Persistent water leaks often indicate worn seals or gaskets that may need replacement. If left unaddressed, these small drips can escalate into more significant issues, affecting overall performance.

Routine care and awareness of these common issues can significantly extend the lifespan and efficiency of your outdoor cleaning tool.

Understanding and Diagnosing Problems

Identifying issues and recognizing potential solutions is key to maintaining the functionality and efficiency of your equipment. By assessing symptoms and carefully observing patterns, you can isolate common malfunctions and locate the root cause of disruptions.

Common Symptoms and Indicators

Equipment performance often declines due to wear or minor malfunctions. Look out for signs such as inconsistent power output, unusual noises, or visible fluid leaks. These clues offer insight into specific areas that may need attention, helping you prioritize solutions.

Step-by-Step Diagnosis

Effective troubleshooting involves a methodical approach. Begin by verifying that essential connections are secure and that all components are free from obstruction. Systematic checks ensure that external factors, such as blockages or loose parts, are not the cause. If issues persist, examining internal elements may reveal the underlying problem.

Professional Insight

Complex issues may require specialized knowledge to resolve. Consulting expert sources or technical references provides a deeper understanding of specific components and helps in making informed choices for maintenance or repairs. Ensuring regular upkeep further reduces the likelihood of recurring issues.

Steps to Check Water Flow

Maintaining a steady water flow is essential for optimal equipment function. Regular checks can help prevent potential blockages and ensure smooth operation. Follow these steps to inspect and improve the water flow effectively.

1. Inspect the Water Source

Begin by ensuring that the water source is open and clear. Check that the water supply is strong, and confirm that any connecting hoses are fully tightened. Loose connections may reduce water flow, impacting performance.

2. Examine the Inlet Screen

The inlet screen helps to filter out any particles or debris that might obstruct the flow. Locate and carefully remove the screen, inspecting it for any buildup. Rinse it thoroughly to eliminate any dirt, allowing for an unobstructed water passage.

3. Check the Hose for Kinks or Leaks

Examine the entire length of the hose, ensuring there are no twists or bends that might restrict water. Look out for any visible leaks. If any damage is found, replace the hose or repair it as necessary.

4. Flush Out Any Trapped Air

Air trapped within the system can interfere with water flow. Hold down the trigger until a consistent stream of water flows smoothly through the nozzle. This will clear out any air, restoring balanced flow.

5. Final Test of Water Flow

Ensuring Proper Water Pressure

For optimal equipment function, maintaining consistent water output is essential. Minor fluctuations in flow can impact both performance and longevity, leading to less effective operation. Proper attention to water supply and regular adjustments can help sustain stable flow and improve overall efficiency.

To address issues related to water output, assess each component involved in flow regulation. Ensuring clear pathways and clean connections is key to reducing interruptions, while routine inspection helps to detect early signs of blockage or wear.

| Checkpoints | Inspection Frequency |

|---|---|

| Supply Hose Condition | Weekly |

| Nozzle Cleanliness | Biweekly |

| Connection Seals | Monthly |

| Water Filter | Monthly |

Following these guidelines can help sustain consistent water flow, ensuring that the equipment operates with reliable power. Regular attention to each element not only maintains stability but also prevents unnecessary wear, saving time and resources in the long run.

Engine Troubleshooting for Honda Models

Identifying and addressing engine performance issues in popular models can enhance functionality and extend their lifespan. Below are key steps to help analyze common symptoms, pinpoint causes, and implement effective solutions.

- Starting Problems: If the engine struggles to start or fails to turn over, check for fuel levels, inspect the ignition system, and ensure the air filter is clean. Issues in these areas are frequent culprits behind starting difficulties.

- Unstable Operation: An erratic idle or sudden stalling may be linked to carburetor adjustments, fuel blockages, or air intake obstructions. Regularly examine these components to maintain a stable engine function.

- Power Loss: If the motor experiences a drop in output or sluggish response, inspect the fuel line for clogs, assess spark plug health, and examine the exhaust system for blockages.

- Overheating Risks: Persistent overheating can indicate issues with cooling vents, oil levels, or the air filter. Ensuring these elements remain unobstructed and properly maintained can prevent further complications.

Through a systematic approach, most engine challenges can be managed, restoring efficient operation. Regular maintenance of key parts, like the carburetor and ignition, minimizes issues and enhances durability.

Identifying Engine-Related Issues

Understanding common challenges related to the motor is crucial for maintaining optimal performance. Various symptoms can indicate underlying problems that may affect the functionality of the equipment. Recognizing these signs early can prevent further complications and ensure efficient operation.

Common Symptoms of Engine Trouble

Pay attention to unusual sounds, such as knocking or grinding, which may suggest internal wear or damage. Additionally, difficulty starting the unit or irregular idling can signify fuel delivery issues or ignition system failures. Excessive smoke or leaks can also point to serious mechanical concerns that require immediate attention.

Steps for Diagnosing Issues

Begin by inspecting fuel levels and quality, as contaminated or insufficient fuel can lead to operational failures. Next, examine the spark plug for signs of wear or fouling, which can hinder ignition. Lastly, check the air filter for clogs that may restrict airflow, affecting engine performance. These assessments can help pinpoint the root cause of the problem.

Cleaning and Replacing Nozzles

Maintaining the functionality of your cleaning equipment is essential for optimal performance. One crucial aspect of upkeep involves the nozzles, which play a significant role in directing and controlling the flow of water. Regular inspection and maintenance ensure that they function effectively, providing the desired cleaning results.

Steps for Cleaning Nozzles

To keep the nozzles in good condition, follow these steps:

| Step | Description |

|---|---|

| 1 | Disconnect the equipment from the power source for safety. |

| 2 | Remove the nozzle from the lance or wand. |

| 3 | Use a soft brush or cloth to clean any debris or buildup. |

| 4 | Rinse the nozzle with clean water to remove any remaining dirt. |

| 5 | Reattach the nozzle securely to the lance. |

Replacing Worn or Damaged Nozzles

If a nozzle is showing signs of wear or damage, it’s important to replace it promptly to maintain performance. Here’s how to do it:

| Step | Description |

|---|---|

| 1 | Assess the nozzle for cracks, chips, or significant wear. |

| 2 | Purchase a suitable replacement that matches the specifications of your device. |

| 3 | Remove the old nozzle by twisting it off the lance. |

| 4 | Attach the new nozzle securely, ensuring a proper fit. |

| 5 | Test the new nozzle to confirm functionality before use. |

Maintaining Optimal Spray Patterns

Achieving effective cleaning results relies heavily on the precision of spray configurations. Proper management of these patterns ensures that surfaces are treated uniformly, maximizing efficiency while minimizing water usage. Understanding how to maintain these optimal settings is crucial for achieving the best possible outcomes in your cleaning tasks.

To ensure that the spray patterns remain effective, consider the following maintenance tips:

- Regularly inspect nozzles for blockages or wear that can alter spray patterns.

- Clean the nozzle tips to remove any debris or buildup that may hinder performance.

- Ensure the right nozzle type is used for specific cleaning tasks, as different patterns serve various purposes.

In addition to physical maintenance, it’s important to monitor pressure settings. Inadequate or excessive pressure can distort spray patterns and impact cleaning efficacy:

- Adjust the pressure according to the surface type being cleaned.

- Test different pressure levels to find the optimal setting for various applications.

- Maintain a consistent distance from the surface to achieve a uniform spray.

By following these guidelines, you can ensure that your cleaning tool operates at its best, delivering consistent and effective results each time.

Fuel System Maintenance Tips

Maintaining the fuel system is crucial for ensuring optimal performance and longevity of your equipment. Proper care not only enhances efficiency but also prevents potential issues that could arise from neglect. Regular attention to the components involved can lead to a smoother operation and extended lifespan of the machine.

Regular Inspection of Components

Performing routine checks on the fuel lines, filters, and injectors is essential. Inspect for leaks or signs of wear that could lead to malfunction. Cleaning the filters periodically will help in maintaining a steady flow of fuel, while examining the injectors for blockages ensures proper combustion.

Use of Quality Fuel

Utilizing high-quality fuel is paramount. Avoid low-grade options that may contain impurities, as these can cause damage to the system over time. Storing fuel properly and ensuring it is fresh can prevent gumming and varnishing, which can hinder performance and cause operational difficulties.

Preventing Fuel-Related Problems

Ensuring optimal performance of your equipment requires careful attention to fuel management. Fuel quality and storage practices play a critical role in preventing complications that can disrupt functionality and lead to costly repairs. By adopting simple strategies, you can significantly enhance the reliability and longevity of your machine.

Regularly inspecting and replacing fuel filters helps eliminate impurities that can affect engine efficiency. Utilizing fresh fuel and avoiding prolonged storage of unused fuel can also minimize the risk of degradation. Additionally, incorporating fuel stabilizers can prolong the life of the fuel and maintain its effectiveness, ensuring your machinery is ready for use whenever needed.

Proper storage conditions are essential as well. Keeping fuel containers sealed and in a cool, dry place protects against contamination and evaporation. Furthermore, routinely checking for leaks and addressing them promptly prevents wastage and potential hazards. By implementing these preventive measures, you will promote a smoother operation and extend the overall lifespan of your equipment.

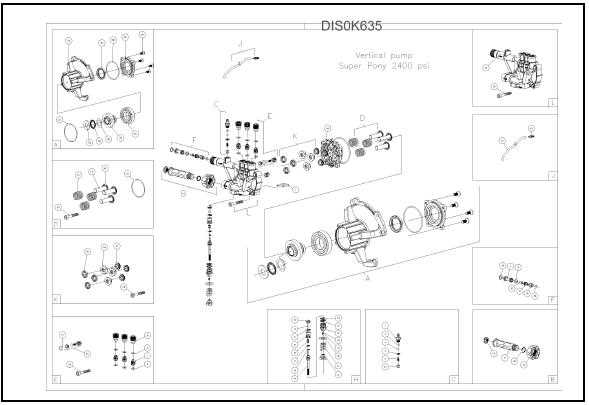

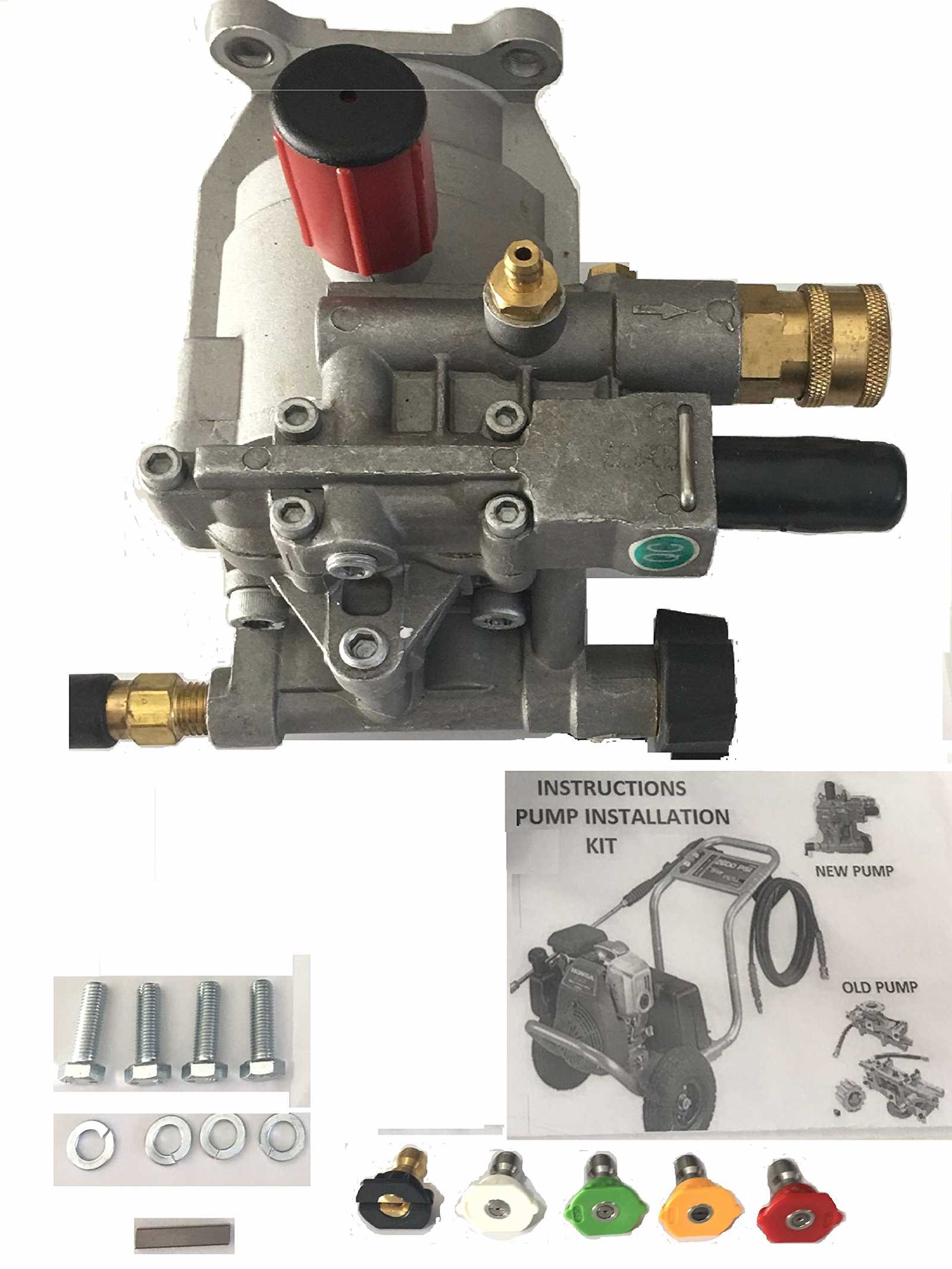

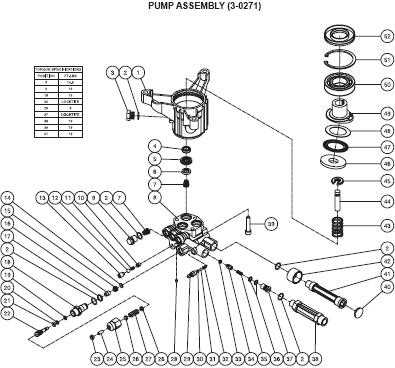

Pump Repairs and Replacement Guide

This section provides a comprehensive overview of servicing and replacing the fluid delivery unit within your cleaning device. Regular maintenance is crucial for ensuring optimal performance and extending the lifespan of the equipment. Understanding common issues and knowing when to replace parts can save time and improve functionality.

Common Issues and Symptoms

When the fluid delivery unit is malfunctioning, several symptoms may arise. Identifying these issues early can prevent further damage and costly repairs. Here are some common problems:

| Issue | Symptoms | Possible Causes |

|---|---|---|

| Leaking fluid | Visible puddles or moisture around the unit | Worn seals or damaged connections |

| No pressure | Weak or inconsistent fluid stream | Clogged filters or air leaks |

| Strange noises | Unusual sounds during operation | Worn bearings or misalignment |

Replacement Steps

When repairs are insufficient, it may be necessary to replace the fluid delivery unit. Follow these steps for an effective replacement:

1. Disconnect the device from its power source and any hoses.

2. Remove the cover to access the unit.

3. Detach the old unit by unscrewing the mounting bolts.

4. Install the new unit by following the reverse order of removal, ensuring all seals are in place.

5. Test the device for proper operation before full use.

Resolving Pump Malfunctions

Understanding and addressing issues related to the water delivery system is essential for maintaining optimal performance. Various factors can contribute to the inefficiency of this vital component, and recognizing symptoms early can prevent further complications. This section provides insights into troubleshooting common problems that may arise, ensuring smooth operation and longevity.

Identifying the signs of malfunction is the first step towards effective resolution. Here are some typical symptoms and their possible causes:

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| No water flow | Clogged intake filter | Inspect and clean the filter |

| Low pressure | Worn-out seals | Replace the seals |

| Inconsistent flow | Air trapped in the system | Bleed the air from the lines |

| Excessive noise | Lack of lubrication | Apply appropriate lubricant |

By following these steps, users can effectively troubleshoot and rectify issues, ensuring that the unit operates at peak efficiency. Regular maintenance checks can also help in identifying potential problems before they escalate.

Fixing Oil Leaks in the Washer

Addressing fluid leaks is crucial for maintaining optimal functionality and longevity of your cleaning device. Such leaks can lead to decreased performance and potential damage if not promptly resolved. This section outlines effective methods to identify and remedy these leaks.

To successfully tackle oil leaks, follow these steps:

- Identify the Source: Examine the device thoroughly to locate the origin of the leak. Common areas include seals, gaskets, and joints.

- Check Seals and Gaskets: Inspect rubber seals and gaskets for wear or damage. If they appear cracked or brittle, they should be replaced.

- Examine Connections: Ensure that all connections, such as hoses and fittings, are secure. Loose connections can be a common source of leakage.

- Use the Right Oil: Verify that you are using the recommended type of fluid for your equipment. Using the wrong type can cause leaks due to improper viscosity.

- Clean the Area: Before applying any sealant or replacements, clean the area around the leak to remove old oil and debris. This ensures better adhesion and a more effective seal.

- Apply Sealant: If the leak persists, consider using a high-quality sealant specifically designed for automotive or machinery use. Follow the manufacturer’s instructions for application.

- Test the Repair: After making the necessary adjustments, run the machine briefly to check for any remaining leaks. Monitor the area for several minutes to confirm the effectiveness of your repairs.

Regular maintenance and inspections can prevent most fluid leaks. By promptly addressing these issues, you can enhance the performance and durability of your equipment.