This section provides a comprehensive overview of essential practices for ensuring the longevity and optimal performance of small engines. Whether you are a seasoned technician or a novice enthusiast, understanding the intricacies of engine upkeep can significantly enhance your operational efficiency.

From basic adjustments to advanced diagnostics, mastering the art of engine care is crucial. This guide delves into various aspects, including routine checks, common issues, and practical solutions that empower users to tackle problems effectively. With a focus on clear, actionable steps, it aims to simplify the maintenance process and boost confidence in handling engine-related tasks.

By following the outlined strategies, individuals can not only extend the lifespan of their machinery but also achieve a greater understanding of the underlying mechanics. This knowledge fosters a proactive approach to maintenance, ensuring that any potential challenges are addressed before they escalate.

Overview of Honda GXV140 Engine

This section provides a comprehensive examination of a widely utilized power unit known for its reliability and efficiency. The design and engineering of this engine make it suitable for various applications, ensuring optimal performance in demanding environments.

Key Features

Notable characteristics of this engine include a compact layout, which facilitates easy integration into various machinery. Additionally, the incorporation of advanced technology enhances fuel efficiency and minimizes emissions, making it an environmentally friendly choice. The durable construction is engineered to withstand rigorous use, providing longevity and dependability.

Applications

This power unit is commonly employed in outdoor equipment and machinery, such as lawn mowers, generators, and other tools. Its versatility allows it to function effectively across a range of settings, catering to both professional and residential needs. With a focus on performance and user satisfaction, this engine stands out in the competitive market.

Common Issues and Symptoms

Understanding typical complications that may arise with small engines is essential for effective troubleshooting. These problems often manifest in various ways, affecting performance and reliability. Recognizing the signs can lead to timely interventions, minimizing potential damage and enhancing longevity.

Performance Deterioration

A noticeable decline in engine efficiency can indicate underlying issues. Symptoms such as reduced power output, difficulty starting, or stalling during operation may point to fuel delivery problems or air intake obstructions. Regular maintenance checks are crucial to identify and rectify these concerns promptly.

Unusual Noises

Strange sounds during operation often signal mechanical issues. Rattling, knocking, or excessive vibrations can suggest worn components or misalignment. Addressing these auditory warnings quickly can prevent further damage and ensure smooth functionality.

Essential Tools for Repairs

When tackling maintenance tasks on small engines, having the right instruments is crucial for ensuring efficiency and accuracy. These implements not only facilitate the process but also enhance safety, allowing for a more streamlined approach to troubleshooting and fixing issues.

Basic Hand Tools

Begin with a collection of fundamental hand tools. A set of wrenches and sockets in various sizes is vital for loosening and tightening bolts and nuts. Additionally, screwdrivers with both flat and Phillips heads will assist in accessing various components. Pliers, especially needle-nose varieties, are useful for gripping and manipulating small parts.

Specialized Equipment

For more complex tasks, specific equipment becomes necessary. A torque wrench is essential for applying precise force to fasteners, preventing over-tightening. A multimeter aids in diagnosing electrical issues, ensuring that circuits are functioning correctly. Lastly, a compression tester can be invaluable in assessing the health of the engine, providing insights into its performance and longevity.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring the longevity and efficient operation of your engine. Regular upkeep not only enhances performance but also prevents costly repairs down the line.

Follow these essential steps for optimal maintenance:

- Check and change the oil:

- Locate the oil drain plug and remove it.

- Allow old oil to fully drain.

- Replace with fresh oil, ensuring the correct viscosity.

lessCopy code

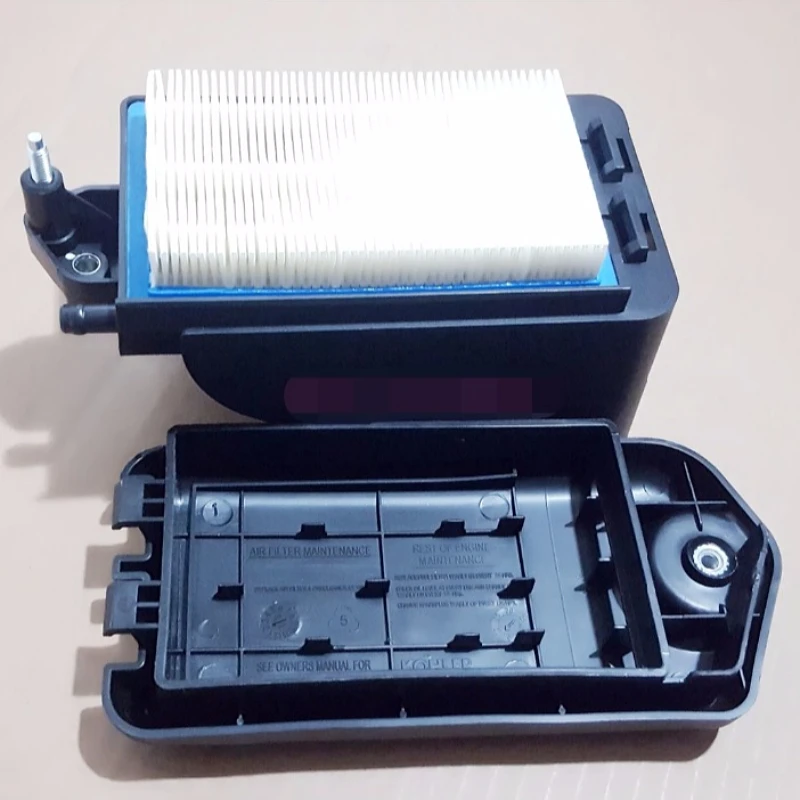

- Remove the air filter from its housing.

- Inspect for dirt and debris.

- Clean or replace as necessary to maintain airflow.

- Remove the spark plug using a wrench.

- Inspect for wear or deposits.

- Clean or replace if needed to ensure proper ignition.

- Inspect fuel lines for leaks or cracks.

- Replace any damaged components immediately.

- Ensure the fuel is clean and fresh.

- Go through all accessible fasteners.

- Tighten any loose bolts to prevent vibration issues.

By adhering to this structured approach, you can maintain peak performance and extend the life of your engine significantly.

How to Change Oil Properly

Regular maintenance of your small engine is essential for optimal performance and longevity. One critical aspect of this upkeep is the proper replacement of lubricating fluid. Ensuring that the engine is well-lubricated reduces wear and tear and helps prevent overheating, making it vital to understand the correct procedure for changing oil.

Gather Necessary Tools and Materials

Before starting the process, collect the required items. You will need a suitable lubricant, an oil filter if applicable, a wrench or socket set, an oil drain pan, a funnel, and a cloth for cleaning. Having everything on hand will streamline the task and prevent interruptions.

Step-by-Step Procedure

Begin by warming up the engine slightly. This makes the oil less viscous, allowing it to drain more easily. Once warmed, turn off the engine and allow it to cool for a few minutes. Position the oil drain pan under the engine’s drain plug, then remove the plug using the appropriate tool. Let the old lubricant fully drain into the pan.

After draining, replace the drain plug securely. If your setup includes a filter, remove the old filter and install a new one, ensuring a tight seal. Finally, pour the new lubricant into the engine through the funnel, checking the dipstick to achieve the correct level. Wipe away any spills and dispose of the old oil responsibly.

By following these steps, you can effectively maintain your engine’s health and enhance its performance.

Adjusting the Valves Correctly

Properly calibrating the valve mechanism is essential for maintaining optimal engine performance. This process ensures that the timing and clearance of the valves align perfectly with the specifications, promoting efficient operation and reducing wear on internal components.

To begin, ensure the engine is cool and the spark plug is removed. This will allow for safe access to the valve assembly. Next, rotate the crankshaft to position the piston at the top of its compression stroke. This alignment allows for accurate measurement of the valve clearance.

Utilize a feeler gauge to assess the gap between the rocker arm and the valve stem. Consult the specific tolerances for the engine to determine if adjustments are necessary. If the clearance is outside the recommended range, carefully loosen the lock nut on the adjustment screw. Turn the screw to achieve the desired gap, then re-tighten the lock nut securely.

After adjustments, rotate the crankshaft a couple of times to ensure everything is functioning correctly. Recheck the valve clearance to confirm that the adjustments have remained stable. Completing this process not only enhances engine efficiency but also extends the longevity of its components.

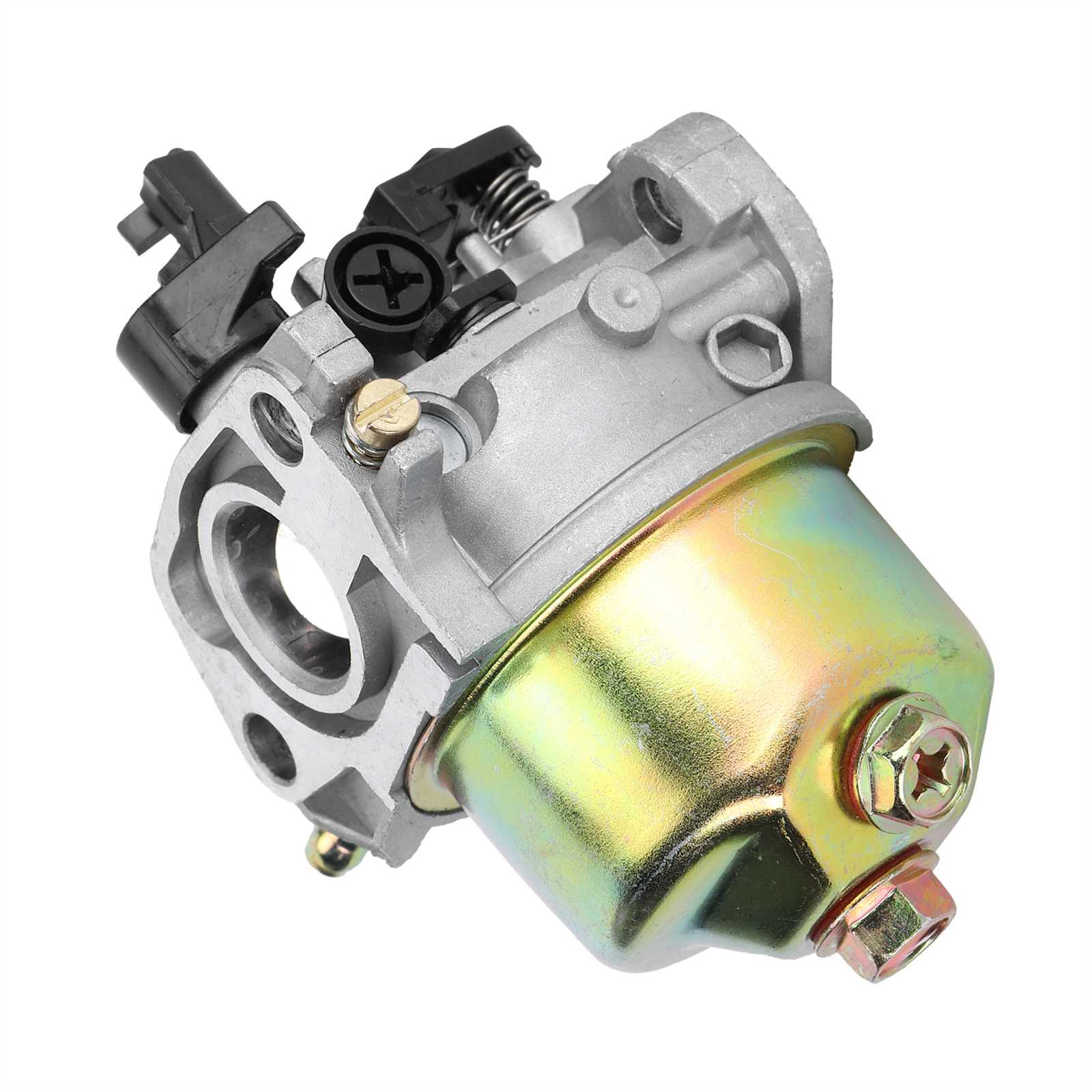

Fuel System Cleaning Techniques

Maintaining optimal performance of combustion engines requires regular attention to the fuel delivery components. Over time, deposits and contaminants can accumulate, affecting efficiency and overall functionality. Implementing effective cleaning methods can restore performance and prolong the lifespan of the system.

Fuel Injector Cleaning is a crucial step. Specialized cleaning solutions can be introduced into the fuel system to dissolve deposits. This process may involve removing the injectors for a thorough ultrasonic cleaning, ensuring every passage is free from obstructions.

Fuel Filter Replacement should not be overlooked. A clogged filter can restrict fuel flow, leading to performance issues. Regularly replacing this component ensures that impurities are kept at bay, allowing for a steady and clean fuel supply to the engine.

Cleaning the Fuel Tank is equally important. Sediments and rust can accumulate over time. Draining and cleaning the tank with appropriate solvents can help prevent these materials from entering the fuel lines and damaging components.

Adding Fuel Additives is another method to consider. These products are designed to clean the entire fuel system while being used, helping to break down carbon deposits and improve combustion efficiency. Regular use can lead to noticeable improvements in engine responsiveness.

By incorporating these cleaning techniques, one can enhance the reliability and efficiency of the fuel delivery system, ensuring smooth operation and optimal performance of the engine.

Replacing Spark Plug Instructions

Replacing the spark component is a crucial maintenance task that ensures efficient engine operation. A worn or damaged spark element can lead to poor performance, reduced fuel efficiency, and difficulty starting. This guide provides step-by-step instructions for performing this task safely and effectively.

Tools and Materials Needed

Before beginning the replacement process, gather the following tools and materials:

| Tool/Material | Purpose |

|---|---|

| Socket wrench | To remove the old spark element |

| New spark component | To replace the old one |

| Gap gauge | To ensure proper spacing between electrodes |

| Anti-seize compound | To apply on threads for easier removal in the future |

Replacement Procedure

Follow these steps to successfully replace the spark element:

- Ensure the engine is turned off and cooled down.

- Locate the spark component, which is typically found on the top or side of the engine.

- Using the socket wrench, carefully unscrew and remove the old spark element.

- Inspect the old component for signs of wear or damage.

- Check the gap on the new spark component using the gap gauge, adjusting as necessary.

- Apply a small amount of anti-seize compound to the threads of the new spark element.

- Install the new spark element by screwing it in gently and securely with the socket wrench.

- Start the engine to ensure it runs smoothly.

Troubleshooting Starting Problems

Experiencing difficulty initiating an engine can be frustrating. Various factors might contribute to this issue, ranging from fuel supply to electrical components. Identifying the root cause is essential for effective resolution.

Checking Fuel Supply

Ensure that there is an adequate amount of fuel in the tank. Inspect the fuel line for blockages or leaks, as these can prevent the engine from receiving the necessary fuel. Additionally, verify that the fuel is fresh and free from contaminants, which can affect performance.

Inspecting Electrical Components

Examine the ignition system for potential faults. Check the spark plug for wear and ensure it is properly connected. A faulty battery can also impede the starting process; confirm that it is fully charged and connections are secure. Lastly, review any fuses that may have blown, as this could disrupt the electrical flow.

Cooling System Maintenance Tips

Proper upkeep of the cooling mechanism is essential for ensuring optimal performance and longevity of your engine. Regular attention to this system helps prevent overheating and enhances efficiency. Following a few straightforward guidelines can keep the cooling system functioning effectively.

Regular Inspection

Frequent checks of the coolant level are crucial. Ensure that the fluid is within the recommended range to avoid potential issues. Look for any signs of leaks or deterioration in hoses and connections, as these can lead to significant problems if left unattended.

Fluid Replacement

Changing the cooling fluid at regular intervals is vital. Over time, the coolant can lose its effectiveness due to contamination. Refer to the manufacturer’s guidelines for the appropriate type and frequency of replacement. Utilizing the correct mixture of coolant and water can significantly enhance thermal performance.

Maintaining your engine’s cooling system is key to its overall reliability and functionality.

Understanding Electrical Components

Electrical elements play a crucial role in the functionality of various machines. These components ensure the proper flow of energy and facilitate the operation of numerous systems. Understanding their functions and interconnections is essential for effective maintenance and troubleshooting.

Key Components

- Battery: Stores energy for starting the engine and powering electrical systems.

- Alternator: Converts mechanical energy into electrical energy, keeping the battery charged.

- Ignition Coil: Transforms low voltage into high voltage to ignite the fuel-air mixture.

- Wiring Harness: A collection of wires and connectors that transmits electrical signals throughout the system.

Common Issues

- Battery Failure: Symptoms include difficulty starting and dim lights.

- Faulty Alternator: Can lead to battery drain and electrical malfunctions.

- Ignition Problems: May result in misfires or failure to start.

Recognizing these components and potential issues can enhance the understanding of system performance and aid in effective problem-solving strategies.

Safe Practices During Repairs

Ensuring a secure environment while conducting maintenance is essential for both the technician and the equipment involved. By adhering to established protocols, one can minimize risks and promote a smoother workflow. This section outlines fundamental guidelines that should be followed to enhance safety and efficiency during servicing tasks.

Personal Protective Equipment

The use of appropriate protective gear is crucial in safeguarding against potential hazards. This includes items such as gloves, goggles, and sturdy footwear. Proper attire not only protects from physical injuries but also shields against harmful substances that may be encountered during the servicing process.

Workspace Organization

A well-organized workspace contributes significantly to safe practices. Keeping tools and materials neatly arranged reduces the likelihood of accidents. It is advisable to maintain a clutter-free environment, ensuring that pathways are clear and that equipment is stored properly when not in use.

| Safety Tip | Description |

|---|---|

| Use Protective Gear | Always wear gloves and goggles to protect against injuries. |

| Keep Area Clean | Maintain a tidy workspace to prevent tripping hazards. |

| Follow Guidelines | Adhere to operational protocols for equipment handling. |

| Be Aware of Surroundings | Stay vigilant of your environment and potential risks. |