In the realm of small engine technology, understanding the intricacies of your machinery is essential for optimal performance. This section focuses on troubleshooting, adjustments, and essential upkeep to enhance the longevity of your engine system. By familiarizing yourself with various components and their functions, you can ensure smooth operation and mitigate potential issues.

Engine care involves a series of procedures that, when followed correctly, can lead to improved efficiency and reliability. From examining fuel systems to inspecting ignition components, each step plays a critical role in maintaining the overall health of the unit. This guide provides a comprehensive overview, empowering users to tackle common challenges effectively.

Whether you are a seasoned technician or a novice enthusiast, gaining insights into operational specifics is invaluable. Emphasizing preventative measures can save time and resources in the long run. Understanding how to address typical malfunctions not only boosts confidence but also enhances your skills in managing and caring for your machinery.

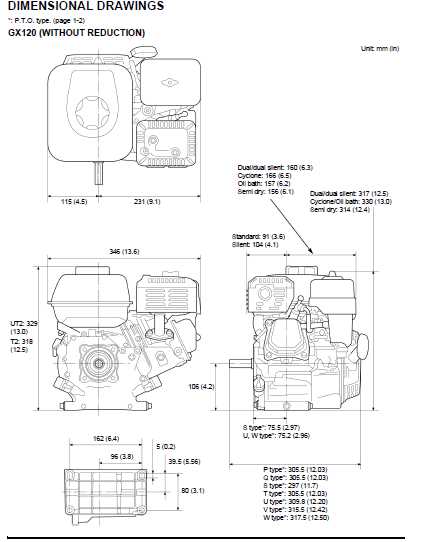

This section provides a comprehensive introduction to a powerful small engine commonly used in various outdoor equipment. Understanding its design, features, and applications is essential for effective maintenance and troubleshooting.

- Engine Specifications: Explore key specifications such as displacement, power output, and torque ratings.

- Construction Features: Discuss materials used and engineering design that enhances durability and performance.

- Typical Applications: Identify common uses in gardening tools, lawn mowers, and other equipment.

- Fuel System Overview: Explain the fuel delivery method and types of fuel recommended for optimal performance.

- Cooling Mechanism: Describe the cooling system, including air cooling features that prevent overheating.

- Ignition System: Detail the ignition technology and its importance in starting and operation.

- Maintenance Requirements: Outline regular maintenance tasks essential for prolonging engine life.

- Troubleshooting Common Issues: Provide insights into common problems and their potential solutions.

- Performance Enhancements: Suggest modifications and upgrades that can improve efficiency and power.

- Replacement Parts: List essential components that may need replacement and tips on sourcing them.

Common Issues with GXV620 Engines

Engines of this type are known for their reliability, yet they may experience certain complications that can impact performance. Understanding these common issues can aid in maintaining efficiency and prolonging the lifespan of the machinery.

- Starting Difficulties: One prevalent issue involves challenges with ignition. This can stem from a variety of factors, including a faulty spark plug or fuel delivery problems.

- Overheating: Engines can overheat due to inadequate cooling or blocked air passages. Regular maintenance of the cooling system is essential to prevent this problem.

- Excessive Vibration: Unusual vibrations may indicate imbalances in the engine components or issues with the mounting hardware. This should be addressed promptly to avoid further damage.

- Oil Leaks: Leaks can occur at various points, often due to worn gaskets or seals. Regular inspection can help catch these issues early.

- Poor Performance: A noticeable decline in power can be attributed to fuel system blockages or air filter contamination, both of which should be checked periodically.

lessCopy code

Identifying these common issues early can facilitate timely interventions, ensuring optimal operation and longevity of the engine.

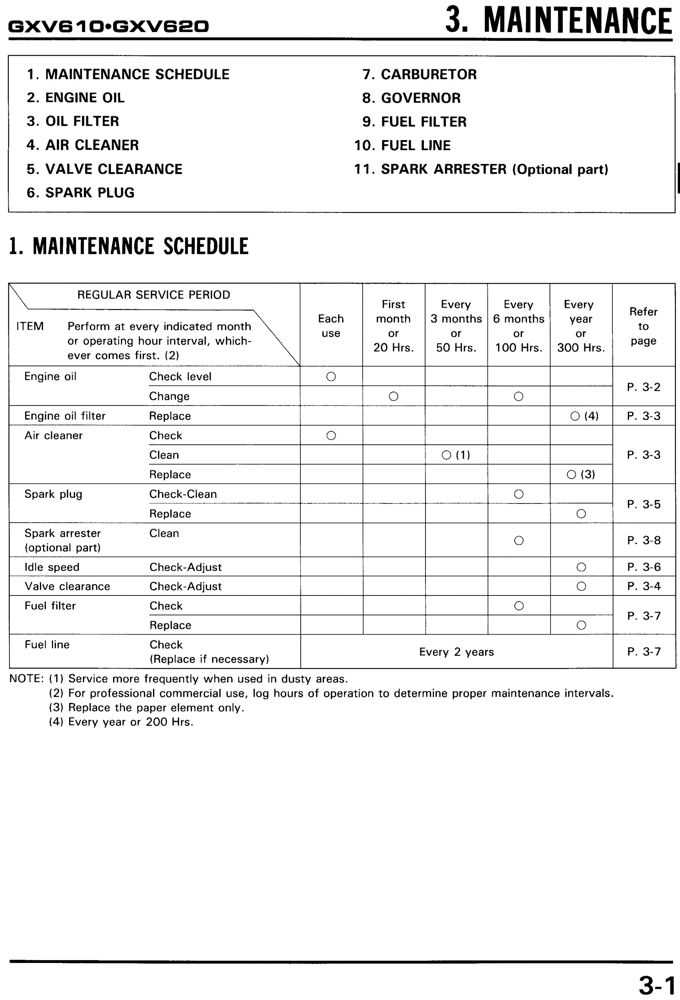

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring the longevity and optimal performance of your engine. This guide provides a comprehensive overview of essential procedures that will help you maintain your equipment effectively. By following these steps, you can minimize downtime and enhance reliability.

1. Check Oil Levels

Start by inspecting the oil level. Ensure the engine is on a level surface and remove the dipstick. Wipe it clean, reinsert, and then check the level. If the oil is low, top it up with the recommended type to prevent wear and tear.

2. Air Filter Maintenance

Remove the air filter and inspect it for dirt and debris. A clean filter is crucial for optimal airflow. If it’s dirty, either clean it if it’s reusable or replace it with a new one to ensure proper performance.

3. Spark Plug Inspection

Check the spark plug for wear and carbon buildup. A worn plug can lead to poor ignition. Replace it if necessary, ensuring the gap is set to the manufacturer’s specifications for efficient combustion.

4. Fuel System Care

Inspect the fuel lines and connections for leaks or cracks. Ensure the fuel filter is clean, and replace it if it shows signs of clogging. Use fresh fuel to prevent starting issues.

5. Battery Maintenance

If applicable, check the battery connections for corrosion and ensure they are tight. Clean any buildup on the terminals and check the fluid level in the battery, topping up as needed.

Following these maintenance steps will help you keep your engine running smoothly and efficiently, ultimately prolonging its life and performance.

Essential Tools for Repairs

When undertaking maintenance tasks, having the right equipment at your disposal is crucial for achieving optimal results. Proper tools not only enhance efficiency but also ensure safety during the process. This section highlights the necessary instruments that can make any service task smoother and more effective.

Basic Hand Tools

Start with a solid set of hand tools. A combination of wrenches, screwdrivers, and pliers will cover most basic needs. Having both metric and imperial sizes is advantageous, as it allows for versatility in handling various components. Additionally, a sturdy ratchet set can significantly reduce the time spent loosening and tightening fasteners.

Diagnostic Equipment

To accurately identify issues, incorporating diagnostic tools is essential. A multimeter helps in checking electrical systems, while a compression tester assesses engine performance. These devices provide valuable insights, enabling efficient troubleshooting and ensuring that repairs address the root causes of problems.

Understanding Engine Components

Engines are intricate machines composed of various parts that work together to convert fuel into mechanical energy. Each component plays a vital role in the overall functionality, ensuring smooth operation and efficiency. A comprehensive understanding of these elements is essential for effective maintenance and troubleshooting.

| Component | Function |

|---|---|

| Cylinder | Houses the piston and is where the combustion process occurs. |

| Piston | Moves up and down within the cylinder, converting pressure from combustion into mechanical motion. |

| Crankshaft | Transforms the linear motion of the piston into rotational motion, driving the engine’s output. |

| Camshaft | Controls the timing of valve openings and closings, allowing air and fuel to enter and exhaust gases to exit. |

| Valves | Regulate the flow of air and fuel into the combustion chamber and the expulsion of exhaust gases. |

| Ignition System | Ignites the air-fuel mixture, initiating the combustion process. |

| Fuel System | Delivers the correct amount of fuel to the combustion chamber for efficient burning. |

Familiarity with these components allows for better diagnosis of issues and enhances the overall lifespan of the engine. Understanding how they interact contributes significantly to effective operation and maintenance practices.

Fuel System Troubleshooting Tips

Ensuring optimal performance of an engine often requires addressing issues within its fuel delivery mechanism. Various problems can arise, affecting the efficiency and operation of the system. Here are some practical steps to diagnose and resolve common fuel-related challenges.

- Check Fuel Quality: Always start by inspecting the fuel used. Contaminated or old fuel can lead to performance issues. Consider replacing it with fresh fuel to eliminate this potential problem.

- Inspect Fuel Lines: Look for cracks, leaks, or blockages in the fuel lines. Any damage can disrupt the flow, leading to inadequate fuel supply.

- Examine the Fuel Filter: A clogged filter can restrict fuel flow. Regularly inspect and replace the fuel filter as part of routine maintenance.

- Test the Fuel Pump: Ensure that the fuel pump is operating correctly. Listen for unusual noises and verify the pressure is within the manufacturer’s specifications.

- Check for Air Leaks: Inspect all connections for potential air leaks that could disrupt fuel delivery. Tighten or replace any loose or damaged fittings.

- Evaluate the Carburetor: If applicable, ensure the carburetor is clean and functioning properly. Adjustments may be necessary for optimal performance.

- Assess Injector Functionality: If equipped with injectors, ensure they are clean and spraying fuel correctly. Consider using a cleaning solution if deposits are present.

lessCopy code

By following these troubleshooting steps, issues within the fuel delivery system can be effectively identified and resolved, ensuring the engine operates smoothly and efficiently.

Electrical System Diagnostics

This section focuses on the evaluation and troubleshooting of the electrical components within small engine systems. Proper diagnostics are essential for identifying issues that may hinder performance or lead to complete failure. Understanding the interplay between various electrical parts can greatly enhance maintenance efficiency and operational reliability.

The diagnostic process typically involves a systematic approach to testing and analyzing the electrical circuitry. Key steps include visual inspections, voltage measurements, and continuity tests. Each component must be assessed to ensure it functions correctly within the overall system.

| Component | Test Method | Normal Range |

|---|---|---|

| Battery | Voltage Check | 12.6 – 12.8 V |

| Starter Motor | Current Draw | 150 – 250 A |

| Alternator | Output Voltage | 13.5 – 14.5 V |

| Wiring Harness | Continuity Test | 0 Ohms |

By following these diagnostic protocols, one can efficiently pinpoint electrical malfunctions, ensuring timely repairs and optimal engine performance. Regular checks and maintenance of the electrical system contribute significantly to the longevity and reliability of the equipment.

Replacing Spark Plugs and Filters

Maintaining optimal performance in small engines often involves regular checks and replacements of key components. Two critical parts that should be addressed periodically are the ignition devices and air filtration units. Ensuring these elements are functioning correctly can lead to enhanced efficiency and longevity of the equipment.

Steps for Replacing Spark Plugs

Begin by gathering the necessary tools, including a spark plug socket, ratchet, and a gap gauge. Ensure the engine is cool before proceeding. Locate the ignition components, usually situated on the side or top of the engine. Remove the ignition wire by gently pulling it off the plug. Using the socket, unscrew the old plug and discard it. Before installing the new plug, check its gap using the gauge to ensure it meets specifications. Install the new spark plug by hand, followed by tightening it with the socket, and finally, reattach the ignition wire securely.

Changing Air Filters

Next, focus on the air filtration system. Begin by locating the filter housing, which is typically secured with clips or screws. Remove the housing cover to access the filter. Carefully take out the old filter and inspect the housing for any debris. Clean the area if necessary. Insert the new filter, ensuring it fits snugly into place. Replace the housing cover, securing it with the clips or screws. Regularly replacing air filters helps maintain proper airflow and performance, ultimately leading to a smoother operation.

Cooling System Maintenance Procedures

Regular upkeep of the cooling mechanism is essential for ensuring optimal performance and longevity of the engine. This section outlines key steps for maintaining this critical system, emphasizing the importance of keeping it clean and functional to prevent overheating and related issues.

The primary components of the cooling system require attention, including the radiator, hoses, and coolant. Periodic checks and replacements are vital to avoid any potential failures that could lead to engine damage.

| Procedure | Description | Frequency |

|---|---|---|

| Inspect Hoses | Check for cracks, leaks, or wear. Replace if necessary. | Every 50 hours of operation |

| Flush Cooling System | Remove old coolant and debris. Refill with fresh coolant. | Annually |

| Check Radiator | Ensure that the radiator is free of obstructions and damage. | Every 100 hours of operation |

| Monitor Coolant Level | Keep coolant at the recommended level. Add as needed. | Weekly |

By following these maintenance practices, the cooling system can function effectively, supporting the overall health and efficiency of the engine. Consistent monitoring and timely interventions can help avoid costly repairs and enhance performance.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is essential for both personal well-being and the longevity of the equipment. Adhering to specific guidelines can prevent accidents and enhance the efficiency of the work process.

- Always wear appropriate protective gear, such as gloves, goggles, and sturdy footwear.

- Ensure the working area is clean and free of clutter to minimize hazards.

- Disconnect any power sources before beginning any disassembly or maintenance work.

- Use the right tools for the job to avoid damaging components and ensure safe operation.

- Familiarize yourself with the equipment’s layout and components to understand potential risks.

Following these measures can significantly reduce the risk of injury and ensure a smoother maintenance process.

Additionally, always consult relevant guidelines or documentation to stay informed about specific safety requirements.

Finding Replacement Parts Efficiently

Locating suitable components for machinery can be a challenging task. However, with the right approach, it becomes significantly easier to identify and acquire necessary items. This section explores effective strategies for sourcing high-quality replacements, ensuring that repairs are completed swiftly and effectively.

Utilizing Online Resources

The internet serves as a valuable tool for finding components. Numerous websites specialize in parts distribution, offering extensive catalogs that can be filtered by specifications. When searching online, consider the following:

| Tip | Description |

|---|---|

| Part Number Search | Always start with the part number for accurate results. This ensures you find the exact match needed for your equipment. |

| Read Reviews | Customer feedback can provide insights into the quality and reliability of parts from various suppliers. |

| Compare Prices | Check multiple sites to find the best prices. Variations in cost can often be significant. |

Local Suppliers and Salvage Yards

While online shopping is convenient, local suppliers and salvage yards can also be excellent resources. Visiting these places allows for direct inspection of parts, ensuring their condition and compatibility. When exploring local options, keep these points in mind:

- Build relationships with local suppliers for better service and potential discounts.

- Inquire about warranties or return policies to protect your investment.

- Check for bulk purchase options, which can lead to cost savings over time.