Owning an all-terrain vehicle brings immense joy and adventure, allowing enthusiasts to explore various terrains with ease. Proper upkeep is essential to ensure optimal performance and longevity of your machine. This section provides insights into essential maintenance practices that every owner should consider to keep their vehicle in top shape.

Understanding the mechanics of your vehicle is crucial for troubleshooting issues and performing routine tasks. Familiarizing yourself with the components and systems will empower you to address minor problems before they escalate. Regular inspections and timely interventions can significantly enhance your riding experience.

In addition to basic care, following a structured approach for maintenance can prevent unexpected breakdowns. This guide will delve into key procedures, offering practical tips and advice tailored for enthusiasts looking to maximize their vehicle’s capabilities. Embrace the journey of ownership by committing to thorough and effective maintenance strategies.

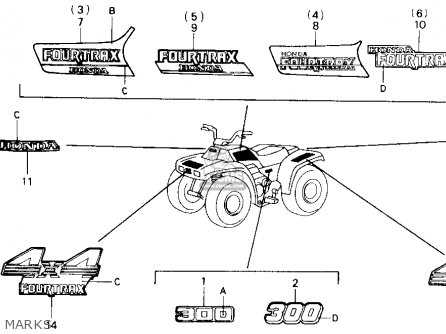

Honda 300 Fourtrax Overview

This section provides a comprehensive look at a popular all-terrain vehicle known for its versatility and reliability. Designed for both recreational use and practical applications, this model offers a balance of performance and ease of handling, making it a favorite among enthusiasts and professionals alike.

Engine Performance: The vehicle is equipped with a powerful engine that delivers excellent torque and acceleration, enabling it to tackle various terrains with confidence. Its robust design ensures durability, which is crucial for off-road adventures.

Features: Users can expect a range of features designed to enhance comfort and control. The suspension system is engineered to absorb shocks effectively, providing a smooth ride even on uneven surfaces. Additionally, the ergonomic layout of controls promotes intuitive handling.

Maintenance: Regular upkeep is essential for optimal performance. Owners should familiarize themselves with the essential maintenance tasks, including routine inspections and fluid changes, to ensure longevity and reliability.

Overall, this all-terrain vehicle stands out as a dependable choice for those seeking adventure and utility in their outdoor activities.

Common Issues and Solutions

When it comes to off-road vehicles, certain challenges frequently arise that can hinder performance and reliability. Understanding these common problems and their resolutions is essential for maintaining optimal functionality.

1. Starting Difficulties: Many users encounter issues with ignition. This may stem from a weak battery or faulty connections. Ensuring the battery is fully charged and inspecting the wiring can often resolve this issue.

2. Overheating: An overheating engine can lead to severe damage. Regularly checking coolant levels and ensuring the radiator is clear of debris are effective preventative measures.

3. Unusual Noises: Strange sounds from the engine or drivetrain can indicate wear or damage. Conducting a thorough inspection of moving parts and replacing worn components can mitigate this problem.

4. Brake Failure: Ineffective braking can pose serious safety risks. Regularly inspecting brake pads and fluid levels, and addressing any leaks promptly, will help maintain braking efficiency.

5. Tire Wear: Uneven or excessive tire wear can affect handling. Ensuring proper alignment and regularly checking tire pressure can enhance tire lifespan and performance.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and optimal performance of your all-terrain vehicle. By following a consistent maintenance routine, you can significantly extend its lifespan and enhance your riding experience.

Routine Inspections

Conducting frequent checks on various components, such as the tires, brakes, and engine, helps identify potential issues before they escalate. Look for signs of wear and tear, and address them promptly. This proactive approach not only safeguards your investment but also enhances safety while riding.

Fluid Changes and Cleanliness

Maintaining proper fluid levels is crucial for efficient operation. Regularly change the oil and coolant, as recommended in the guidelines. Additionally, keeping the exterior clean prevents dirt buildup, which can lead to corrosion and mechanical problems over time. A clean machine not only performs better but also looks good on the trails.

Tools Required for Repairs

Effective maintenance and troubleshooting of your vehicle necessitate the right set of instruments. Having the appropriate tools on hand not only streamlines the process but also enhances safety and efficiency during tasks. Understanding the basic requirements can greatly assist in addressing various issues that may arise.

Essential hand tools include wrenches, sockets, and screwdrivers, which are fundamental for loosening or tightening components. A comprehensive toolkit will allow you to tackle a variety of tasks, from routine checks to more extensive fixes.

Power tools can also be beneficial, particularly for more labor-intensive jobs. Electric or battery-operated options help reduce effort and time, making them invaluable for challenging tasks.

Additionally, specialized equipment such as diagnostic scanners and compression testers can provide crucial insights into the functionality of various systems. These tools are particularly useful for identifying underlying issues that may not be immediately visible.

Lastly, don’t forget the importance of safety gear. Items like gloves, goggles, and appropriate clothing can protect you from potential hazards while working on your vehicle.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to addressing mechanical issues through methodical procedures. Each task is broken down into clear steps to ensure effective troubleshooting and restoration of functionality.

1. Gather Necessary Tools and Materials: Before beginning, collect all essential tools, including wrenches, screwdrivers, and lubricants. Having everything on hand will streamline the process.

2. Prepare the Vehicle: Ensure the machine is on a stable surface. Disconnect the battery to prevent accidental starts during maintenance.

3. Identify the Issue: Conduct a thorough inspection to pinpoint the specific malfunction. Look for signs of wear, leaks, or damage that may need attention.

4. Disassemble Affected Components: Carefully remove the parts associated with the identified problem. Keep track of screws and small components to avoid losing them during reassembly.

5. Perform Repairs: Address the issues found during inspection. This may involve replacing worn-out parts, tightening loose fittings, or applying necessary lubricants.

6. Reassemble: Once repairs are complete, reattach the components in the reverse order of disassembly. Ensure everything is secured properly to prevent future issues.

7. Test the Functionality: Reconnect the battery and conduct a test run to confirm that the repairs have resolved the problem. Monitor for any unusual sounds or behaviors.

8. Document the Process: Keep a record of the repairs made and any parts replaced. This documentation can be valuable for future reference and maintenance.

Electrical System Troubleshooting

This section focuses on diagnosing and resolving issues related to the electrical components of the vehicle. Proper functioning of the electrical system is crucial for optimal performance, as it powers various systems, including ignition and lighting. Understanding common problems and their solutions can aid in maintaining reliability and efficiency.

Begin by examining the battery connections. Ensure that terminals are clean and secure. A loose or corroded connection can lead to power loss. Next, check the fuses for any signs of damage or burnout. Replacing a faulty fuse can restore functionality to affected circuits.

If electrical components are still malfunctioning, inspect the wiring harness for any frayed or broken wires. Look for signs of wear, such as insulation damage. Repairing or replacing damaged wiring can prevent further issues. Additionally, utilizing a multimeter can help measure voltage and continuity, aiding in identifying problematic areas.

Lastly, consult the specifications for components like relays and switches. Verifying their operation ensures that the system functions correctly. Addressing these areas systematically can significantly enhance the reliability of the electrical system.

Suspension Adjustments and Repairs

Properly managing the suspension system is crucial for optimal performance and comfort during rides. Adjustments can significantly enhance handling and stability, allowing for a smoother experience on various terrains. Regular maintenance and timely repairs can prevent issues that may affect the overall functionality of the vehicle.

When addressing the suspension, it’s important to check components such as shocks, springs, and linkages. Ensuring that these parts are in good condition can help maintain the correct ride height and prevent bottoming out. Adjusting the preload settings on springs can also tailor the ride to individual preferences and load requirements.

If any part exhibits signs of wear or damage, prompt attention is necessary. Leaks in shock absorbers or broken springs can lead to decreased performance and potentially hazardous situations. Replacing worn components and ensuring proper lubrication can restore functionality and extend the lifespan of the suspension system.

Regularly inspect for any unusual noises or handling characteristics, as these can indicate underlying issues. Keeping a maintenance schedule that includes suspension checks can contribute to the longevity and reliability of the vehicle, ensuring enjoyable rides for years to come.

Engine Rebuild Instructions

This section provides essential guidelines for overhauling the internal combustion unit of your vehicle. A thorough understanding of the components and procedures involved will ensure a successful restoration, enhancing performance and longevity.

Preparation and Tools

Before commencing the rebuild, gather necessary tools and materials. A complete toolkit should include wrenches, sockets, and torque specifications. Additionally, ensure you have gaskets, seals, and any replacement parts readily available. Proper workspace organization will facilitate a smoother workflow and minimize the risk of losing components.

Disassembly Steps

Begin by draining fluids to prevent spills. Carefully remove the outer casing, taking note of the order and orientation of each part. Utilize labels or photographs to document the assembly for reference during reinstallation. Pay special attention to wear on components; this will guide decisions on what needs replacing or refurbishing.

Transmission Service Guidelines

Maintaining the transmission is crucial for ensuring the longevity and performance of your all-terrain vehicle. Proper service not only enhances functionality but also prevents potential issues that could arise from neglect. Regular checks and appropriate actions can significantly extend the lifespan of the transmission system.

Routine Inspections

Conduct regular inspections of the transmission to identify any signs of wear or damage. Look for fluid leaks, unusual noises, or difficulties in shifting gears. Checking the fluid level and condition is essential; it should be clean and at the recommended level. If you notice any discrepancies, address them promptly to avoid further complications.

Fluid Replacement

Changing the transmission fluid at specified intervals is vital. Over time, the fluid can become contaminated and lose its effectiveness, leading to poor performance. Refer to the manufacturer’s guidelines for the appropriate type of fluid and replacement schedule. After draining the old fluid, ensure to replace the filter if applicable, and fill with fresh fluid to the correct level.

Brake System Inspection and Repair

The braking mechanism is essential for the safety and performance of any vehicle. Regular evaluation and maintenance of this system ensure that it operates efficiently, preventing potential accidents and enhancing overall reliability. This section will cover crucial steps for assessing and addressing issues related to the braking components.

Inspection Process

Begin by visually examining the brake components for any signs of wear or damage. Check the brake pads for thickness; if they are too thin, replacement is necessary. Inspect the rotors for grooves or scoring, which may indicate a need for resurfacing or replacement. Additionally, ensure that the brake lines are free from leaks or cracks, as these can significantly compromise performance.

Maintenance and Troubleshooting

After identifying any issues, proceed with appropriate maintenance actions. Replacing worn pads and rotors is crucial, as is flushing the brake fluid periodically to remove contaminants. If the braking force feels inconsistent, it may be necessary to bleed the brake system to eliminate air trapped in the lines. Regular upkeep will not only extend the lifespan of the braking system but also enhance overall driving safety.

Fuel System Maintenance Tips

Maintaining the fuel system is crucial for optimal performance and longevity of your vehicle. Regular attention to this area can prevent common issues and ensure a smooth operation. This section provides essential guidance for keeping the fuel delivery mechanism in top shape.

1. Regularly Check Fuel Filters: Inspect and replace fuel filters as recommended by the manufacturer. Clogged filters can hinder fuel flow and affect engine efficiency.

2. Use Quality Fuel: Always opt for high-quality fuel from reputable sources. This helps prevent the buildup of harmful deposits that can impair performance.

3. Inspect Fuel Lines: Routinely examine fuel lines for any signs of wear or leaks. Damaged lines can lead to fuel loss and pose a safety risk.

4. Clean Injectors: Periodically clean the fuel injectors to ensure they are delivering fuel properly. Dirty injectors can cause poor engine performance and increased emissions.

5. Monitor Fuel System Pressure: Keeping an eye on fuel system pressure is essential. Abnormal pressure readings can indicate underlying issues that need attention.

By following these maintenance tips, you can help ensure that the fuel system operates efficiently, enhancing the overall performance and reliability of your vehicle.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when performing maintenance or modifications on your vehicle. Proper precautions not only protect the individual performing the task but also enhance the overall efficiency of the work. Following specific guidelines can help prevent accidents and injuries while working on machinery.

Personal Protective Equipment

Wearing appropriate gear is essential. Always utilize gloves, goggles, and sturdy footwear to shield against potential hazards. This protective equipment minimizes the risk of injuries from sharp objects, chemical spills, or falling debris.

Workspace Organization

A tidy workspace is vital for safety. Keep tools and materials organized to avoid tripping hazards and ensure quick access to necessary items. Additionally, ensure proper ventilation in enclosed areas to prevent inhalation of harmful fumes. Staying organized enhances focus and reduces the likelihood of accidents during maintenance tasks.