In the world of agricultural operations, the significance of effective machinery maintenance cannot be overstated. Understanding the intricate details of each component is essential for ensuring longevity and optimal performance. This section delves into essential guidelines and procedures that aid in the upkeep of your equipment, promoting efficiency in your daily tasks.

Regular maintenance is crucial for preventing unexpected breakdowns and costly repairs. By adhering to systematic checklists and following best practices, operators can enhance the reliability of their machinery. This guide aims to equip you with the knowledge necessary to address common issues and implement effective solutions.

Furthermore, familiarizing oneself with the various systems and functionalities of the equipment can greatly facilitate troubleshooting. With a structured approach, you can gain insights into the workings of your machinery, leading to informed decisions and timely interventions. In this comprehensive resource, you will discover practical tips and valuable information to support your maintenance efforts.

This section aims to provide a comprehensive overview of a specific agricultural machine, focusing on its key features, functionalities, and operational guidelines. Understanding the essential components and systems of this machinery is crucial for effective maintenance and optimal performance.

Key Features and Specifications

The examined model is renowned for its robust build and efficient power delivery, making it suitable for various farming tasks. Below is a table summarizing its main specifications:

| Specification | Details |

|---|---|

| Engine Type | Four-cylinder diesel |

| Horsepower | Approx. 75 HP |

| Transmission | Multi-speed with multiple ranges |

| Weight | About 5,500 lbs |

Operational Guidelines

Familiarity with the operational aspects of this machinery enhances productivity and ensures safety. It is vital to adhere to recommended procedures for starting, operating, and shutting down the equipment.

Common Issues with the Tractor

Tractors are essential machines for agricultural tasks, yet they may experience various complications that hinder their performance. Understanding these common issues can help operators maintain efficiency and extend the lifespan of the equipment.

One frequent problem is engine overheating, which can stem from inadequate coolant levels or a malfunctioning thermostat. Regular checks of the cooling system can prevent this issue from escalating.

Another concern is transmission difficulties, often caused by fluid leaks or improper gear shifting. Ensuring that the hydraulic system is well-maintained can mitigate these challenges.

Additionally, electrical failures, such as dead batteries or faulty wiring, can disrupt operation. Routine inspections of the electrical components are vital to ensure reliable performance.

Lastly, wear and tear on tires can lead to traction issues, affecting overall maneuverability. Monitoring tire pressure and tread can help address this problem before it affects productivity.

Essential Tools for Repairs

Undertaking maintenance and restoration tasks requires a specific set of instruments to ensure efficiency and effectiveness. The right tools not only streamline the process but also enhance safety and precision, making it crucial to equip oneself with essential gear before beginning any work.

Below is a table highlighting the fundamental instruments that are indispensable for performing various tasks:

| Tool Type | Description | Usage |

|---|---|---|

| Wrenches | Used for gripping and turning fasteners. | Loosening or tightening bolts and nuts. |

| Screwdrivers | Tools with a flat or Phillips head for driving screws. | Securing components in place. |

| Pliers | Hand-held tools for gripping and manipulating objects. | Holding, bending, or cutting wires. |

| Socket Set | A collection of sockets and ratchets. | Efficiently working with various fasteners. |

| Multimeter | Device for measuring electrical properties. | Testing voltage, current, and resistance. |

Having these key tools on hand significantly enhances the ability to tackle various tasks, ensuring a smoother process and better outcomes in maintenance endeavors.

Step-by-Step Maintenance Guide

This guide provides a comprehensive approach to preserving the functionality and longevity of your agricultural machinery. Regular upkeep is essential to ensure optimal performance and prevent potential issues down the line. Following these systematic procedures will help you maintain the efficiency and reliability of your equipment.

Essential Checks Before Operation

Before using the equipment, it is crucial to conduct a series of checks. Begin by inspecting fluid levels, including engine oil, coolant, and hydraulic fluid. Ensure that all connections are secure and that there are no signs of leaks. Cleaning the air filter is also vital to promote proper airflow and prevent engine strain.

Routine Maintenance Tasks

Implementing routine maintenance tasks will significantly enhance the machine’s performance. Regularly sharpen and adjust blades to maintain cutting efficiency. Additionally, inspect belts and hoses for wear, replacing them as necessary. Keeping the machinery clean from dirt and debris not only improves appearance but also aids in identifying potential problems early.

Engine Troubleshooting Techniques

When faced with performance issues in a power unit, identifying the underlying cause is crucial. Systematic diagnostic approaches enable technicians to pinpoint problems effectively, ensuring efficient restoration. This section outlines key methodologies for addressing common engine complications, enhancing understanding and facilitating timely repairs.

Identifying Symptoms

Observing unusual behaviors is the first step in troubleshooting. Common indicators may include irregular sounds, reduced power output, or unexpected fluid leaks. Careful assessment of these symptoms can guide technicians toward specific areas that require attention.

Utilizing Diagnostic Tools

Employing specialized instruments, such as pressure gauges and multimeters, can provide valuable insights into engine performance. These tools help measure critical parameters, allowing for a more accurate diagnosis. Regular checks can prevent minor issues from escalating into major failures.

Hydraulic System Diagnostics

The hydraulic system is a crucial component in various machinery, responsible for the efficient transfer of power and control. Diagnosing issues within this system requires a systematic approach to identify and resolve potential malfunctions. Understanding the key aspects of hydraulic operation can facilitate effective troubleshooting and maintenance.

Common Symptoms of Hydraulic Issues

- Inconsistent operation of hydraulic components

- Unusual noises during operation

- Fluid leaks around fittings and hoses

- Poor responsiveness of hydraulic controls

Diagnostic Steps to Follow

- Inspect hydraulic fluid levels and quality.

- Check for visible leaks in hoses and connections.

- Test the operation of hydraulic pumps and actuators.

- Examine filters for blockages or contamination.

- Monitor system pressure with a gauge for abnormalities.

By following these steps, operators can effectively diagnose and address issues within the hydraulic system, ensuring optimal performance and longevity of the equipment.

Electrical Components Overview

This section provides an insightful look into the various electrical components essential for optimal functionality. Understanding these elements is crucial for diagnosing issues and ensuring efficient operation.

Key Electrical Elements

- Battery: Serves as the primary power source, supplying energy to start the engine and operate electrical systems.

- Alternator: Converts mechanical energy into electrical energy, recharging the battery and powering the vehicle’s electrical systems during operation.

- Starter Motor: Initiates engine operation by turning the crankshaft.

- Fuses: Protect electrical circuits by preventing overloads, ensuring safety and preventing damage to components.

Control Systems

- Wiring Harness: A network of wires that connects various electrical components, facilitating communication and power distribution.

- Relay: Acts as a switch to control high-current circuits using low-current signals, enhancing system efficiency.

- ECU (Electronic Control Unit): Manages various electronic systems, optimizing performance and efficiency through precise control.

Transmission and Drive Train Repairs

The efficiency and performance of agricultural machinery heavily rely on the condition of the power transmission and drive systems. Proper maintenance and timely interventions are crucial to ensure smooth operation and prevent costly breakdowns. This section outlines essential practices and considerations for servicing these vital components.

Regular inspections are key to identifying potential issues before they escalate. Common signs of wear may include unusual noises, difficulty shifting gears, or decreased responsiveness. Addressing these symptoms promptly can enhance longevity and functionality.

When it comes to servicing, it is important to consult the appropriate guidelines for disassembly and reassembly of the components. Utilizing quality parts during replacements is essential, as inferior materials can lead to further complications. Additionally, ensuring proper lubrication will facilitate smoother operation and reduce friction within the system.

In summary, maintaining the power transmission and drive systems involves careful observation, quality replacements, and adherence to service protocols. Implementing these strategies will contribute to the overall efficiency and durability of the machinery.

Replacing Wear and Tear Parts

Maintaining the functionality of heavy machinery requires regular attention to components that naturally degrade over time. Identifying and replacing these parts is essential to ensure optimal performance and prevent further damage.

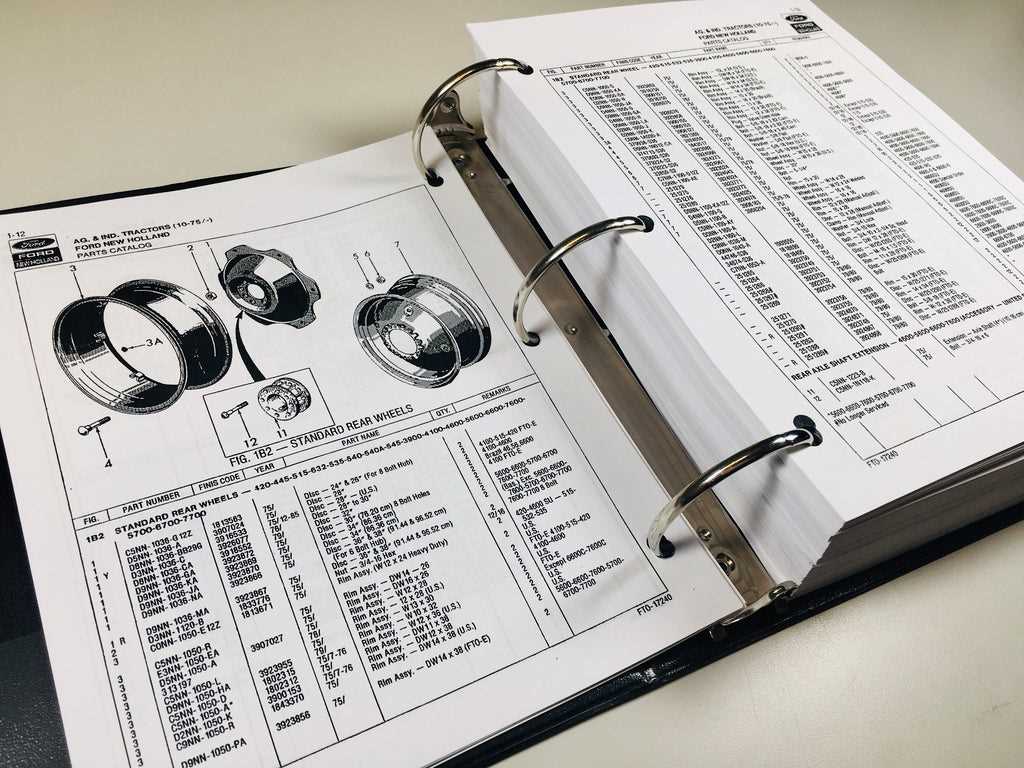

Commonly affected elements include belts, seals, and filters. Understanding how to replace these components not only extends the life of the equipment but also enhances efficiency. Below is a table outlining typical wear items and their recommended replacement intervals.

| Component | Symptoms of Wear | Replacement Interval (Hours) |

|---|---|---|

| Belt | Cracking or fraying | 500 |

| Seal | Leaking fluid | 1000 |

| Filter | Reduced performance | 250 |

By proactively addressing these wear and tear parts, operators can significantly enhance the reliability and longevity of their machinery.

Safety Procedures During Repairs

Ensuring safety during maintenance tasks is paramount to prevent accidents and injuries. Adopting appropriate precautions not only protects the technician but also prolongs the lifespan of the equipment. Proper preparation and awareness can significantly reduce risks associated with handling machinery.

Pre-Repair Preparations

Before initiating any work, it is essential to gather the necessary tools and materials. Conduct a thorough inspection of the workspace to eliminate hazards such as spills, clutter, or inadequate lighting. Additionally, wearing appropriate personal protective equipment (PPE), such as gloves, goggles, and steel-toed boots, is critical for safeguarding against potential injuries.

During the Maintenance Process

While performing tasks, maintain a clear focus on the job at hand. Avoid distractions and keep the work area organized. Always follow manufacturer guidelines and use the correct techniques when handling components. In case of any unusual noises or malfunctions, cease operations immediately and investigate the issue before proceeding.

Upgrading Performance Features

Enhancing the capabilities of agricultural machinery can significantly improve efficiency and productivity. By focusing on key modifications, operators can ensure their equipment meets the demands of modern farming techniques.

One of the most effective ways to boost overall performance is by upgrading the engine components. This may include installing a high-performance air intake system and optimizing fuel delivery. Such enhancements not only increase horsepower but also improve fuel efficiency.

Additionally, adjusting the transmission can lead to better torque management. Consider replacing standard gears with performance-oriented options that provide quicker acceleration and smoother shifting. This modification can be especially beneficial in challenging terrains.

Lastly, addressing the hydraulic system plays a crucial role in overall functionality. Upgrading to a more responsive hydraulic pump can enhance lifting capabilities and implement performance. Regular maintenance of these systems is essential to ensure optimal operation and longevity.

Resources for Further Assistance

When undertaking maintenance or restoration of agricultural machinery, having access to reliable information and support can significantly enhance the process. Various sources are available to provide guidance and expertise, ensuring that tasks are completed efficiently and effectively.

Here are some valuable resources you can explore for additional help:

| Resource Type | Description | Access Link |

|---|---|---|

| Online Forums | Communities of enthusiasts and experts sharing knowledge and experiences. | Tractor Forum |

| Technical Guides | Comprehensive documents covering various aspects of machinery operation and maintenance. | TractorByNet |

| Local Dealerships | Authorized centers offering professional advice, parts, and services tailored to specific models. | Find a Dealer |

| Video Tutorials | Step-by-step visual guides available on platforms like YouTube for practical demonstrations. | YouTube |