Maintaining a vintage pickup truck requires a blend of knowledge, skill, and the right resources. This guide aims to provide enthusiasts with the necessary tools and information to ensure their vehicle runs smoothly and remains in prime condition. Understanding the intricacies of classic automotive systems is crucial for both novice and experienced owners alike.

In this comprehensive resource, readers will find detailed insights into the various components of their beloved truck. From engine performance to electrical systems, the information is tailored to address common issues and facilitate effective troubleshooting. Proper upkeep not only enhances performance but also preserves the vehicle’s value over time.

Whether you are embarking on a restoration project or simply looking to maintain your ride, this guide will serve as a valuable companion. With practical tips and step-by-step instructions, you can confidently tackle any challenge that arises, ensuring that your classic truck continues to deliver reliability and enjoyment on the road.

Understanding the 1993 Ford F250

This section delves into the key features and characteristics of a specific heavy-duty truck model that has gained a loyal following among enthusiasts and professionals alike. Known for its robust design and reliable performance, this vehicle has been a staple in both personal and commercial applications. Understanding its mechanics and functionalities can significantly enhance the ownership experience and maintenance practices.

Key Features

This truck is equipped with a powerful engine, offering impressive towing capacity and durability. Its spacious interior provides comfort for long journeys, while the rugged exterior is built to withstand tough conditions. Additionally, various trims and options allow for customization to meet specific needs, making it versatile for diverse tasks.

Common Maintenance Tips

Common Issues and Solutions

When dealing with older vehicles, it’s important to be aware of frequent problems that can arise due to wear and tear over time. Understanding these common issues and their remedies can help owners maintain performance and longevity, ensuring a smoother driving experience.

Frequent Problems

- Engine Performance Issues

- Transmission Slipping

- Electrical System Failures

- Suspension Noises

- Brake System Malfunctions

Possible Solutions

- Engine Performance Issues: Regularly check and replace air filters, spark plugs, and fuel filters to enhance efficiency.

- Transmission Slipping: Inspect fluid levels and quality; changing the transmission fluid may resolve slipping.

- Electrical System Failures: Examine battery connections and wiring for corrosion; replacing fuses may also be necessary.

- Suspension Noises: Check shock absorbers and bushings for wear; replacing them can eliminate unwanted sounds.

- Brake System Malfunctions: Regularly inspect brake pads and rotors; replacing worn components ensures safety and performance.

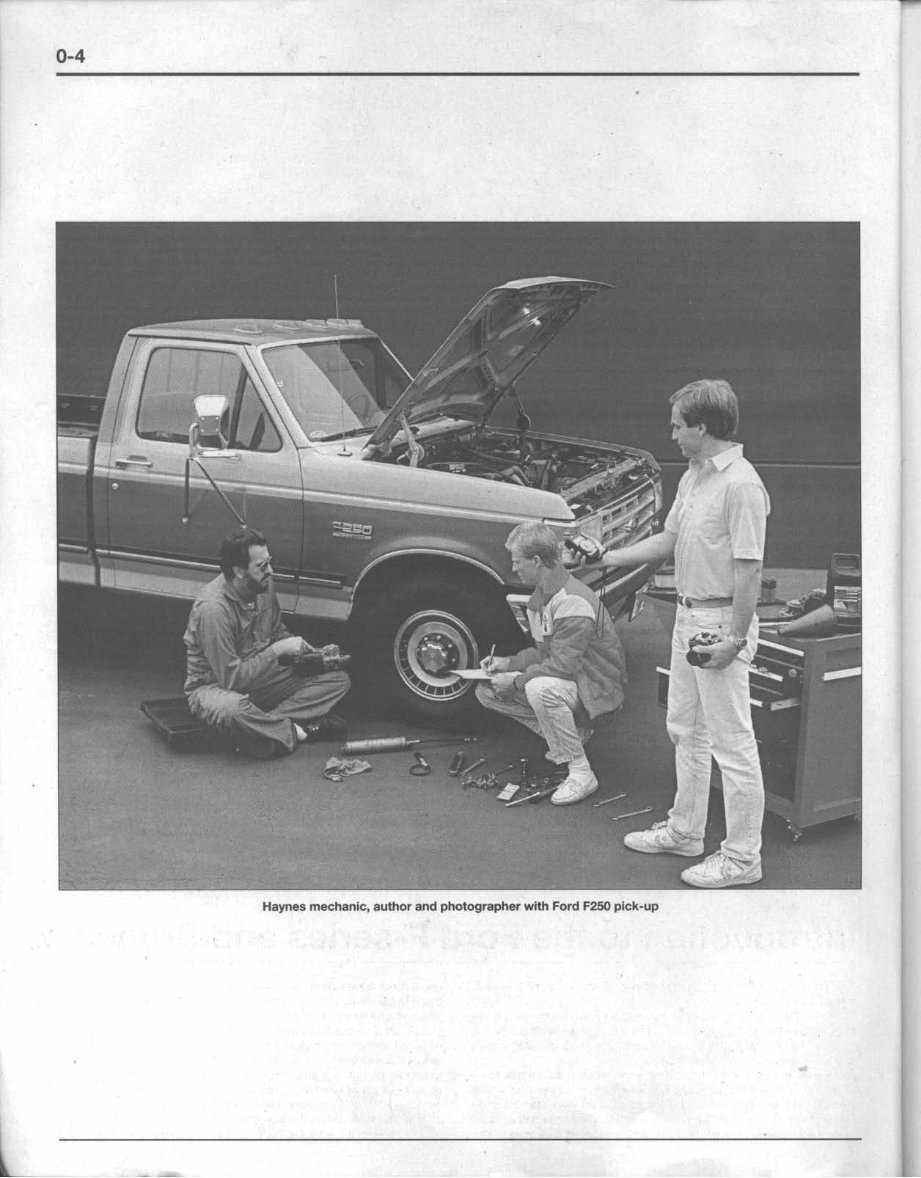

Essential Tools for Repairs

When tackling vehicle maintenance or restoration, having the right equipment is crucial for efficiency and effectiveness. The right instruments not only streamline the process but also enhance the quality of the work performed. From basic hand tools to specialized devices, each plays a significant role in achieving optimal results.

Hand Tools: Basic hand tools are fundamental for any automotive task. Wrenches, sockets, and screwdrivers are essential for loosening and tightening various components. Investing in a quality set ensures durability and ease of use.

Power Tools: Power tools can significantly speed up tasks that would otherwise be time-consuming. Impact wrenches and drills can make quick work of stubborn bolts and fasteners, allowing for more efficient progress.

Diagnostic Equipment: In the modern automotive landscape, diagnostic tools are invaluable. Scanners and multimeters help identify issues quickly, enabling accurate troubleshooting and repairs.

Safety Gear: Ensuring personal safety is paramount. Proper gloves, goggles, and masks protect against potential hazards while working. Investing in safety equipment is a vital step in any project.

Storage Solutions: Keeping tools organized is essential for maintaining efficiency. Toolboxes and storage racks help manage equipment, ensuring that everything is easily accessible when needed.

In summary, a well-equipped workspace with the right tools not only simplifies tasks but also enhances the overall repair experience, leading to successful outcomes.

Engine Maintenance Tips

Maintaining the engine of your vehicle is essential for ensuring its longevity and optimal performance. Regular attention to key components can prevent costly repairs and keep your ride running smoothly. Here are some vital practices to keep in mind.

- Regular Oil Changes: Change the oil and filter at intervals recommended by the manufacturer to keep the engine lubricated and reduce wear.

- Check Fluid Levels: Regularly inspect coolant, transmission fluid, brake fluid, and power steering fluid to ensure they are at appropriate levels.

- Inspect Belts and Hoses: Look for signs of wear, cracking, or fraying in belts and hoses. Replace them as necessary to prevent breakdowns.

- Replace Air Filter: A clean air filter ensures optimal air flow to the engine, improving efficiency and performance.

- Monitor Battery Health: Keep terminals clean and check the battery’s charge regularly to avoid unexpected failures.

- Examine Spark Plugs: Check spark plugs for wear and replace them to ensure proper ignition and fuel efficiency.

Implementing these maintenance tasks can significantly enhance your vehicle’s engine performance and reliability, ensuring a smoother driving experience for years to come.

Transmission Troubleshooting Guide

This section provides essential insights for diagnosing common issues associated with automatic and manual gear systems. Understanding the typical symptoms and their underlying causes can significantly aid in restoring functionality and enhancing performance.

Common Symptoms and Their Causes

Several signs may indicate problems with the shifting mechanism. If the vehicle experiences delayed or harsh shifting, it could be due to low fluid levels or contamination. A slipping transmission might suggest worn components or inadequate hydraulic pressure. In contrast, unusual noises during operation may point to internal damage or misalignment.

Diagnostic Steps

To effectively identify the source of transmission issues, start by checking the fluid level and quality. Inspect for leaks around seals and gaskets. Additionally, utilizing a diagnostic tool can reveal error codes related to the transmission control system. Always ensure that the system is properly maintained to prevent future complications.

Electrical System Diagnostics

The electrical system of a vehicle plays a crucial role in its overall performance and functionality. Understanding how to effectively diagnose issues within this system is essential for maintaining reliable operation and ensuring safety on the road.

Common symptoms of electrical problems may include:

- Dim or flickering lights

- Unresponsive electrical components

- Difficulty starting the engine

- Battery drain

To accurately identify and troubleshoot these issues, follow these essential steps:

- Visual Inspection: Start by examining the battery, wiring, and connectors for signs of wear, corrosion, or damage.

- Check Battery Voltage: Use a multimeter to measure the voltage of the battery. A fully charged battery should read around 12.6 volts.

- Test Alternator Functionality: Ensure the alternator is charging the battery correctly by measuring voltage while the engine is running. It should read between 13.7 and 14.7 volts.

- Inspect Fuses and Relays: Check for blown fuses or faulty relays that may interrupt electrical flow.

- Utilize Diagnostic Tools: Employ OBD-II scanners to retrieve trouble codes and gain insights into potential issues.

By systematically following these steps, you can effectively pinpoint electrical system malfunctions and implement the necessary repairs to restore optimal vehicle performance.

Bodywork and Paint Restoration

Restoring the exterior of a vehicle involves meticulous attention to detail and a deep understanding of materials and techniques. This process not only enhances the aesthetic appeal but also protects the underlying structure from corrosion and damage. A comprehensive approach ensures longevity and maintains the vehicle’s value.

Assessing Damage

The first step in bodywork restoration is a thorough evaluation of the exterior. Look for dents, scratches, rust spots, and any signs of wear. Documenting these issues provides a clear roadmap for the restoration process. Identifying the extent of damage will help in determining whether repairs are needed or if replacement parts are required.

Preparation for Repair

Before any work begins, it’s essential to prepare the surface properly. This includes cleaning the area, sanding down imperfections, and applying any necessary filler to smooth out dents and scratches. Ensuring a clean and even surface is crucial for a successful paint application.

Painting Techniques

When it comes to applying paint, choosing the right type and color is vital. Using high-quality automotive paint ensures durability and a flawless finish. Techniques such as spraying and buffing can significantly affect the outcome. Layering paint correctly and allowing adequate drying time are key factors in achieving a professional result.

Finishing Touches

Once the paint has dried, it’s important to finish with a clear coat to provide protection against UV rays and environmental elements. Polishing the surface adds a glossy shine and can help to mask any minor imperfections. Regular maintenance of the painted surface will prolong its life and keep the vehicle looking pristine.

Braking System Overhaul Procedures

The braking system is crucial for vehicle safety and performance. Overhauling this system involves a series of methodical steps to ensure its optimal functioning. A thorough understanding of the components and their interactions is essential for effective maintenance and repair.

Step 1: Inspection – Begin by conducting a comprehensive examination of the braking components. Check for signs of wear, damage, or leakage in the brake lines, calipers, and pads. Ensure that the rotors are not warped and have sufficient thickness.

Step 2: Removal – Safely lift the vehicle and remove the wheels to access the braking assemblies. Detach the calipers from the rotors, taking care to support them to avoid strain on the brake lines. Remove the old brake pads and inspect the calipers for any necessary replacement.

Step 3: Replacement – Install new brake pads, ensuring they are properly aligned with the rotors. If any components, such as the calipers or rotors, are worn beyond acceptable limits, replace them. Use high-quality parts to guarantee reliability and performance.

Step 4: Bleeding the System – After reassembly, it is crucial to bleed the brake lines to remove any trapped air. This step is vital for maintaining the integrity of the braking system. Follow the appropriate procedure to ensure all air is expelled, restoring proper brake fluid pressure.

Step 5: Testing – Once the system is reassembled and bled, conduct a thorough test. Check the responsiveness of the brakes at low speeds before taking the vehicle on the road. Monitor for any unusual sounds or sensations during operation.

By adhering to these systematic procedures, the integrity of the braking system can be restored, enhancing both safety and driving experience.

Suspension and Steering Adjustments

The precision of a vehicle’s handling and comfort is significantly influenced by the suspension and steering systems. Proper adjustments in these areas ensure optimal performance, stability, and safety while driving. Addressing these components not only enhances the overall driving experience but also prolongs the lifespan of related parts.

To achieve ideal alignment and handling characteristics, it is crucial to regularly check and modify the suspension settings. This includes assessing the ride height, adjusting the dampers, and ensuring that the springs are in good condition. Improper alignment can lead to uneven tire wear, reduced fuel efficiency, and a compromised ride quality.

Steering adjustments are equally important for maintaining control. Ensuring the steering gear is properly calibrated and that the linkage is free from wear can significantly improve responsiveness. Regular inspections of the steering components help in identifying issues before they escalate, allowing for timely corrections that enhance safety and driving pleasure.

In summary, meticulous attention to suspension and steering adjustments plays a vital role in a vehicle’s overall performance. By adhering to recommended practices, drivers can ensure their vehicles remain reliable and enjoyable to operate.

Safety Checks and Precautions

Ensuring safety during maintenance and repairs is crucial for both the technician and the vehicle’s longevity. This section outlines essential checks and practices that should be followed to minimize risks and enhance the overall safety of the process.

Pre-Maintenance Safety Measures

Before starting any work, it is important to gather the necessary tools and equipment. Always inspect the work area for potential hazards, such as spills or obstructions. Wearing appropriate personal protective equipment, such as gloves and safety glasses, can significantly reduce the risk of injury. Additionally, ensure that the vehicle is parked on a flat, stable surface and that the parking brake is engaged to prevent any unintended movement.

Post-Maintenance Procedures

After completing any maintenance tasks, it is vital to conduct a thorough inspection of the vehicle. Check that all tools and materials have been removed from the work area to avoid potential accidents. Ensure that all components are securely fastened and that no fluid leaks are present. Conduct a final safety check, including lights and signals, before taking the vehicle back on the road to ensure it is in optimal working condition.