In the realm of automotive care, having a detailed reference can significantly enhance the maintenance and troubleshooting processes. This section aims to provide essential insights and instructions to ensure that enthusiasts and owners can effectively address various issues that may arise with their vehicle.

Understanding the inner workings of a vehicle is crucial for its longevity and performance. The information presented here covers a range of topics, from basic upkeep to more intricate repairs, equipping readers with the knowledge needed to tackle common challenges. Whether dealing with minor adjustments or more substantial overhauls, a solid foundation in vehicle maintenance will empower individuals to keep their machines running smoothly.

Through this guide, users will discover practical advice and step-by-step procedures tailored to facilitate a better understanding of automotive systems. By following these guidelines, one can ensure their vehicle remains in optimal condition, enhancing both safety and driving experience.

1988 Ford Ranger Overview

This section provides a comprehensive look at a compact pickup vehicle known for its versatility and reliability. Designed to meet various driving needs, this model combines practicality with efficiency, appealing to a wide range of drivers.

Specifications and Features

The vehicle features a robust engine lineup, offering options that balance power and fuel economy. With a well-thought-out design, it boasts a comfortable interior and ample cargo space, making it suitable for both everyday use and more demanding tasks.

Performance and Handling

Equipped with advanced suspension systems, this model ensures a smooth ride while maintaining excellent maneuverability. Its lightweight structure enhances fuel efficiency and overall performance, making it a popular choice among enthusiasts and casual drivers alike.

Engine Specifications and Features

This section delves into the essential characteristics and attributes of the powertrain, emphasizing performance, efficiency, and innovative engineering. Understanding these elements is crucial for optimizing vehicle performance and ensuring longevity.

Key Performance Metrics

Power output is a significant factor, with the engine typically delivering robust horsepower and torque ratings. This ensures smooth acceleration and adequate power for various driving conditions. Additionally, the combination of fuel efficiency and emission control technologies enhances the overall driving experience while adhering to environmental standards.

Engine Design and Construction

The architecture of the powerplant includes features such as a multi-valve configuration and advanced fuel injection systems. These innovations contribute to improved combustion efficiency and overall engine responsiveness. The materials used in construction prioritize durability and lightweight properties, enhancing both performance and reliability over time.

Common Maintenance Procedures

Routine upkeep is essential for ensuring optimal performance and longevity of any vehicle. Regular checks and simple tasks can prevent more significant issues down the line. Understanding the fundamental maintenance tasks will help keep your automobile in peak condition.

One of the most critical procedures involves monitoring fluid levels, including oil, coolant, brake fluid, and transmission fluid. Regularly checking and replacing these fluids as needed can help maintain the functionality of various systems within the vehicle.

Tire maintenance is another vital aspect. Regularly inspecting tire pressure, tread depth, and alignment not only enhances safety but also improves fuel efficiency. Rotating tires periodically can extend their lifespan and ensure even wear.

Additionally, replacing air filters and spark plugs at recommended intervals is crucial for optimal engine performance. Clean air filters improve air intake, while fresh spark plugs ensure efficient combustion.

Lastly, maintaining the battery by checking connections and cleaning terminals can prevent electrical issues. Regular inspections of the vehicle’s belts and hoses are also important to avoid unexpected breakdowns.

Electrical System Troubleshooting

This section focuses on identifying and resolving common issues related to the electrical components of your vehicle. Understanding the electrical system’s functionality is crucial for effective diagnostics and repairs. Various components can lead to malfunctions, affecting performance and reliability.

Common Symptoms of Electrical Problems

- Dim or flickering lights

- Battery drainage

- Inconsistent operation of electronic devices

- Failure to start or intermittent starting issues

- Unresponsive dashboard indicators

Troubleshooting Steps

- Inspect the battery for corrosion and secure connections.

- Check the alternator to ensure it is charging the battery properly.

- Examine fuses and relays for any signs of damage or failure.

- Test wiring harnesses for continuity and secure connections.

- Utilize a multimeter to check voltage levels at various components.

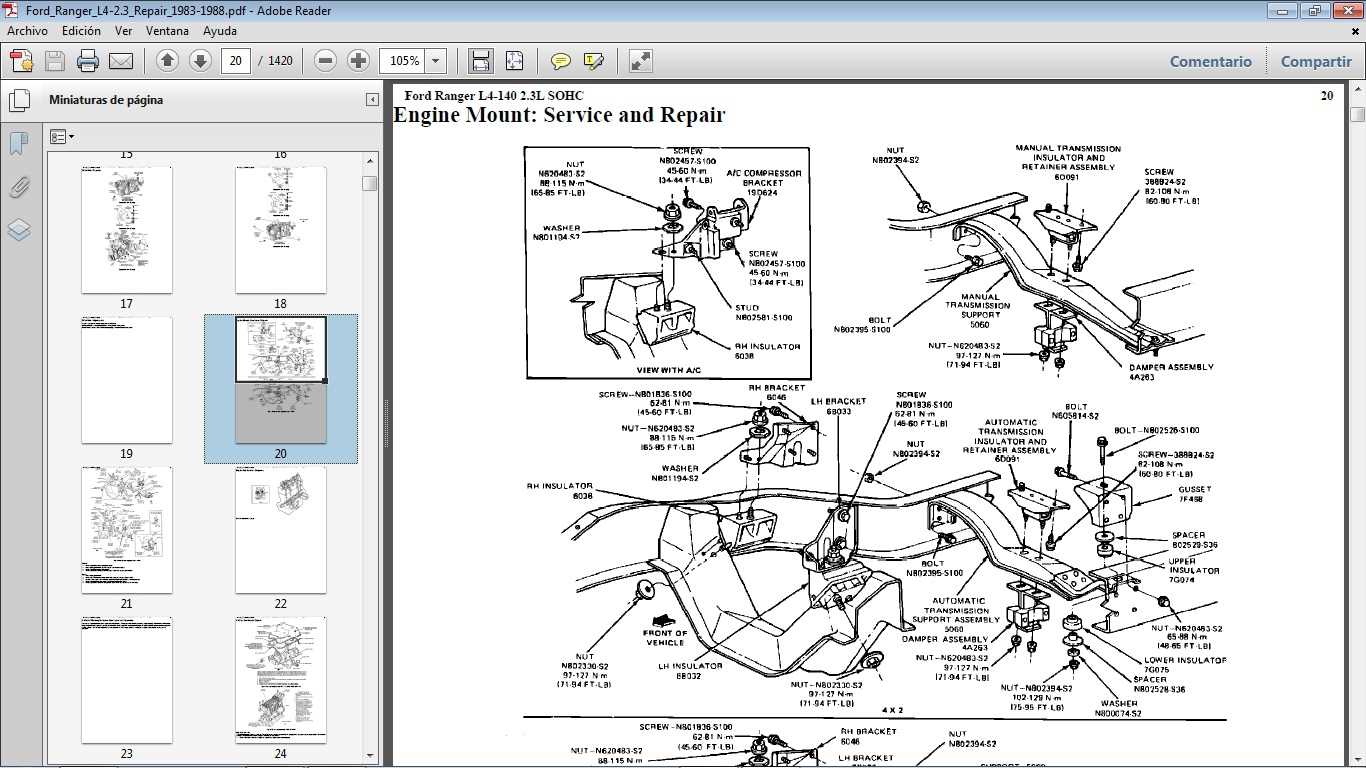

Transmission and Drivetrain Details

This section provides an overview of the components responsible for transferring power from the engine to the wheels. Understanding these elements is essential for ensuring optimal performance and reliability.

The transmission plays a crucial role in managing engine output and adjusting vehicle speed. It enables smooth gear shifts, contributing to fuel efficiency and overall driving experience. Various types of transmissions may be present, each offering distinct features and characteristics.

The drivetrain encompasses all parts involved in delivering power to the wheels. This includes the driveshaft, differentials, and axles, which work together to transmit force effectively. Regular maintenance of these components is vital to prevent wear and tear, ensuring longevity and proper functioning.

Common Issues: Problems in the transmission or drivetrain can manifest as unusual noises, difficulty in shifting gears, or vibrations while driving. Timely diagnosis and resolution of these issues are critical to maintaining vehicle performance.

Maintenance Tips: Regular fluid checks and changes, along with visual inspections of components, can help identify potential problems early. Keeping these systems well-maintained is key to enhancing vehicle reliability and safety.

Suspension and Steering Components

The suspension and steering systems play a vital role in the overall performance and handling of a vehicle. These components work together to provide stability, control, and comfort during driving. A well-functioning suspension ensures that the wheels maintain contact with the road, while the steering system allows for precise maneuvering and direction changes.

Key Components: The suspension system comprises various elements, including springs, shock absorbers, and control arms. Each part contributes to the vehicle’s ability to absorb bumps and irregularities in the road surface. In contrast, the steering system includes parts like the steering wheel, rack and pinion, and tie rods, which facilitate smooth and accurate navigation.

Maintenance and Inspection: Regular checks and maintenance of these systems are crucial for ensuring safety and longevity. Look for signs of wear such as unusual noises, uneven tire wear, or difficulty in steering. Addressing any issues promptly can prevent more significant problems down the road and enhance the driving experience.

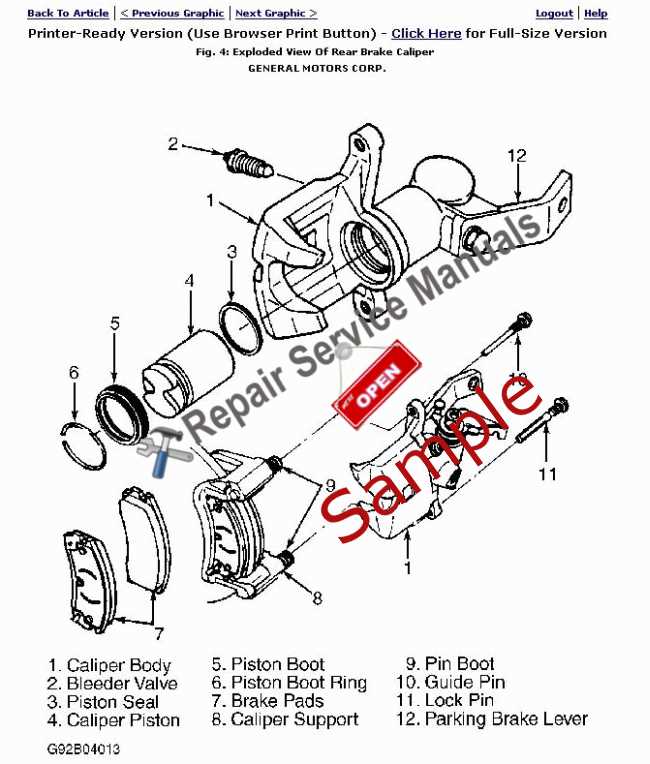

Brake System Maintenance Tips

Ensuring the optimal performance of your vehicle’s stopping mechanism is crucial for safety and reliability. Regular upkeep not only enhances the longevity of components but also contributes to smoother operation. This section outlines essential practices for maintaining the braking apparatus effectively.

Regular Inspections

Frequent examinations of brake parts are vital. Look for signs of wear, such as thin pads or damaged rotors. Inspect the brake fluid level and condition, ensuring it is clean and at the recommended level. Any unusual noises while braking should prompt an immediate check.

Fluid Replacement

Brake fluid should be replaced according to the manufacturer’s guidelines, typically every 1 to 2 years. Contaminated fluid can lead to decreased performance and potential failure of the braking system. Always use the recommended fluid type for optimal results.

Cooling System Insights

The cooling system plays a crucial role in maintaining optimal engine performance. It prevents overheating by regulating the temperature and ensuring that the engine operates within its designed limits. Understanding the components and functionality of this system is essential for effective vehicle maintenance.

Key Components of the Cooling System

The primary elements of this system include the radiator, thermostat, water pump, and coolant. The radiator dissipates heat, while the thermostat controls the flow of coolant based on temperature. The water pump circulates the coolant throughout the engine and radiator, ensuring efficient heat exchange.

Common Issues and Solutions

Frequent problems associated with cooling systems include leaks, clogs, and thermostat failures. Regular inspections can help identify issues early. If leaks are detected, replacing faulty hoses or gaskets is often necessary. In cases of clogging, flushing the cooling system can restore proper flow and functionality.

Exhaust System Repair Techniques

The exhaust system plays a crucial role in a vehicle’s performance and emissions control. Proper maintenance and repair techniques are essential to ensure its efficiency and longevity. This section will outline various methods and considerations for addressing common issues associated with the exhaust system.

Common Issues and Diagnostic Steps

Before embarking on repairs, it is vital to identify the specific problems affecting the exhaust system. Here are some common issues:

- Leaking joints or connections

- Damaged pipes or mufflers

- Corroded components

- Unusual noises during operation

To diagnose these issues effectively, follow these steps:

- Inspect the entire system visually for signs of wear or damage.

- Check for exhaust leaks using a smoke test or soapy water.

- Listen for abnormal sounds while the engine is running.

Repair Techniques

Once issues are identified, various techniques can be employed to restore functionality:

- Welding: For damaged pipes, welding can provide a strong, long-lasting repair.

- Clamping: Use exhaust clamps to secure loose connections and prevent leaks.

- Replacement: If components are severely damaged, replacement may be necessary. Ensure compatibility with the vehicle model.

- Sealing: Apply high-temperature sealant to joints to minimize leakage.

Regular maintenance and timely repairs can enhance the performance of the exhaust system and contribute to a smoother driving experience.

Interior and Exterior Care

Maintaining the aesthetic and functional aspects of your vehicle’s interior and exterior is essential for longevity and performance. Regular attention to these areas not only enhances visual appeal but also contributes to overall driving satisfaction.

For the interior, consider the following care tips:

- Cleaning Surfaces: Regularly wipe down surfaces with appropriate cleaners to remove dust and grime.

- Upholstery Maintenance: Vacuum seats and carpets to prevent dirt buildup; consider using fabric protectants.

- Dashboard Care: Use UV protectants to shield the dashboard from sun damage and fading.

- Odor Control: Keep the interior smelling fresh by using air fresheners and ensuring good ventilation.

For the exterior, follow these guidelines:

- Washing: Regularly wash the vehicle to remove dirt, salt, and other contaminants that can harm the paint.

- Waxing: Apply wax periodically to protect the paint and enhance shine.

- Tire Care: Check tire pressure regularly and clean tires to maintain appearance and performance.

- Glass Maintenance: Keep windows clean and free of streaks for optimal visibility.

Incorporating these practices into your routine will ensure that both the interior and exterior of your vehicle remain in excellent condition.

Body and Frame Repair Guide

This section provides essential insights into the techniques and processes involved in restoring and maintaining the structural elements of a vehicle. A well-maintained body and frame not only enhance the aesthetic appeal but also ensure the safety and performance of the automobile. Understanding the key aspects of structural integrity will aid in addressing common issues effectively.

Assessing Damage and Identifying Issues

Before undertaking any repairs, it is crucial to evaluate the extent of damage. Look for signs such as misalignment, rust, or structural weakness. Documenting these issues will help create a clear plan for restoration. Use appropriate tools to measure and analyze the body and frame for any inconsistencies.

Techniques for Effective Restoration

Utilize various methods for restoring the body and frame, including welding, straightening, and reinforcing. Welding is vital for repairing cracks and strengthening joints, while straightening helps to realign misaligned components. Ensure the use of high-quality materials to achieve durable results and maintain the vehicle’s original integrity.

Tools Required for Repairs

Having the right instruments is crucial for performing maintenance tasks effectively. Proper equipment not only ensures efficiency but also enhances safety during the process. Below is a comprehensive list of essential tools that will facilitate various procedures.

Essential Hand Tools

- Wrenches – various sizes for loosening and tightening bolts

- Screwdrivers – flathead and Phillips for different screw types

- Pliers – for gripping and twisting wires or small parts

- Socket set – for applying torque to fasteners

- Hammer – for driving nails and fitting parts

Power Tools

- Drill – for creating holes or fastening materials

- Impact wrench – for loosening stubborn nuts and bolts

- Angle grinder – for cutting or grinding metal surfaces

- Portable saw – for precise cuts in various materials

Ensuring a well-equipped workspace with these tools will significantly simplify maintenance tasks, allowing for a smoother and more efficient workflow.

Safety Precautions and Best Practices

When working on any vehicle, it is crucial to adhere to specific safety measures to ensure a secure and efficient environment. Understanding the potential hazards and implementing best practices can significantly reduce the risk of accidents and injuries during maintenance tasks.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and steel-toed boots.

- Ensure the workspace is well-ventilated to prevent inhalation of harmful fumes.

- Keep all tools and equipment in good working condition to avoid malfunctions.

- Use jack stands when lifting the vehicle to prevent accidental falls.

- Disconnect the battery before performing any electrical work to minimize the risk of shocks.

Best Practices for Vehicle Maintenance

- Refer to the specific guidelines and specifications for the vehicle model to ensure accuracy in repairs.

- Document all maintenance tasks performed to maintain a record of the vehicle’s history.

- Conduct a thorough inspection before starting any work to identify potential issues.

- Take breaks as needed to maintain focus and prevent fatigue.

- Store hazardous materials and fluids properly to prevent spills and environmental damage.