Understanding the intricacies of heavy machinery is crucial for ensuring optimal performance and longevity. This guide aims to provide essential insights into the upkeep and troubleshooting of powerful mechanical systems used in various industrial applications. By familiarizing oneself with these components, operators can enhance efficiency and reduce the likelihood of costly downtime.

Thorough knowledge of maintenance practices is invaluable for anyone working with robust equipment. It encompasses not only routine inspections but also the identification of potential issues before they escalate into significant problems. This proactive approach ultimately contributes to smoother operations and extends the lifespan of the machinery.

Additionally, being aware of the common challenges faced by these systems allows operators to address concerns promptly. By implementing the recommended practices, users can achieve improved functionality and reliability, fostering a safe working environment. Understanding these principles is essential for anyone involved in the operation and maintenance of large-scale mechanical systems.

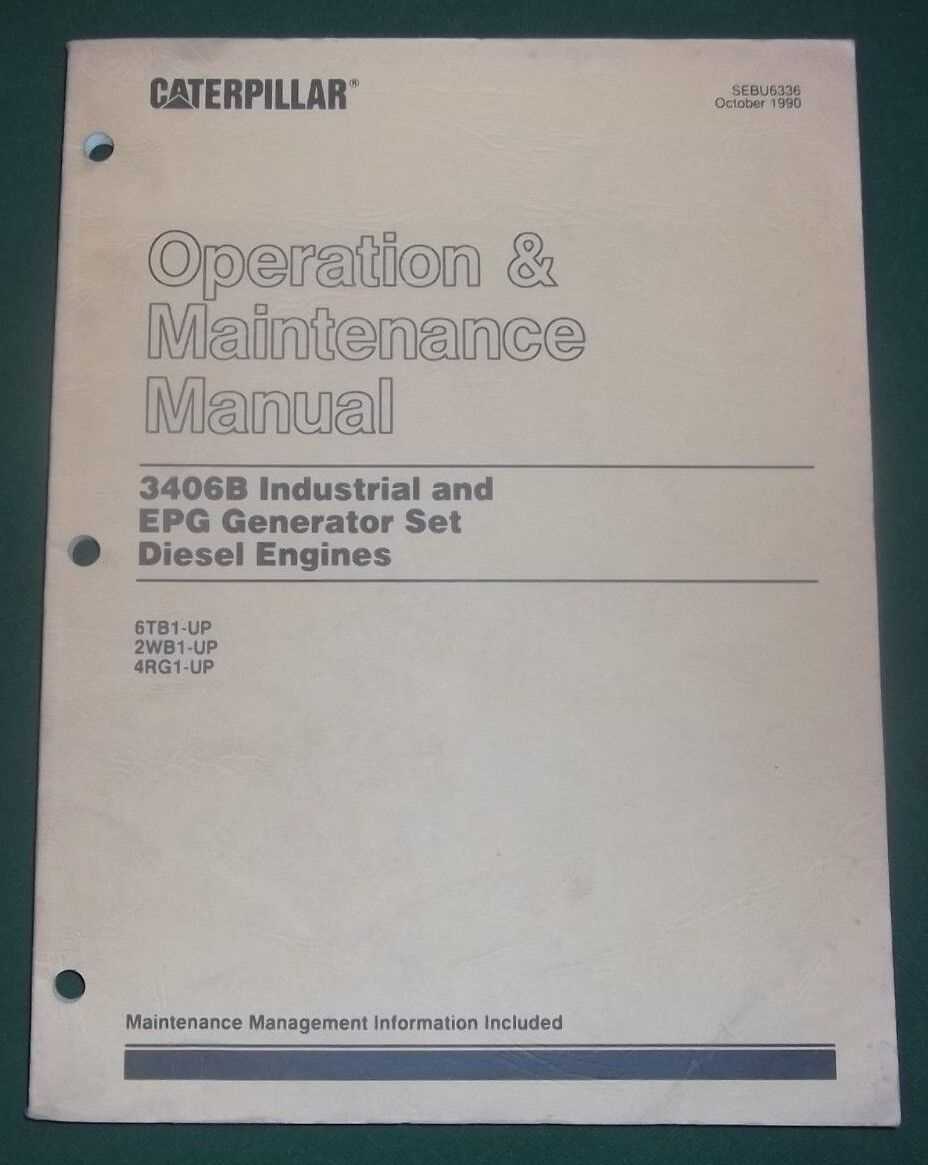

This section provides an overview of the significant aspects related to a specific heavy machinery power unit, including its functionality, maintenance requirements, and troubleshooting techniques. Understanding these elements is essential for those seeking to maximize performance and longevity.

Key Features of the Power Unit

- Durable construction for extended lifespan

- Efficient fuel consumption for cost-effectiveness

- Advanced technology for optimal performance

Common Issues and Solutions

- Difficulty in starting – Check the fuel supply and battery condition.

- Overheating – Ensure proper coolant levels and inspect the cooling system.

- Unusual noises – Investigate potential wear in moving parts or loose components.

Key Features of the 3406B

The 3406B model stands out in its category, showcasing a blend of power and efficiency that appeals to various applications. Its robust design is tailored for heavy-duty tasks, ensuring reliability under demanding conditions.

Performance and Efficiency

One of the most notable aspects of this unit is its impressive performance metrics. The optimal power output ensures that it can handle strenuous workloads while maintaining fuel efficiency. This balance not only enhances productivity but also reduces operational costs.

Durability and Reliability

Built with high-quality materials, this model is designed to withstand the rigors of continuous use. The reliable components ensure minimal downtime, making it an excellent choice for industries that require consistent performance. Maintenance is straightforward, allowing users to keep the system running smoothly with ease.

Common Issues with 3406B Engines

Many individuals experience various challenges with their heavy-duty machines, particularly when it comes to specific high-performance models. Understanding these common problems can help in maintaining optimal functionality and prolonging the lifespan of the machinery. This section will delve into some prevalent issues that users might encounter.

Overheating Problems

One of the most frequent complications involves excessive heat buildup, which can lead to significant operational failures. This often occurs due to coolant leaks, clogged radiators, or malfunctioning thermostats. Regular monitoring and timely interventions can mitigate these risks.

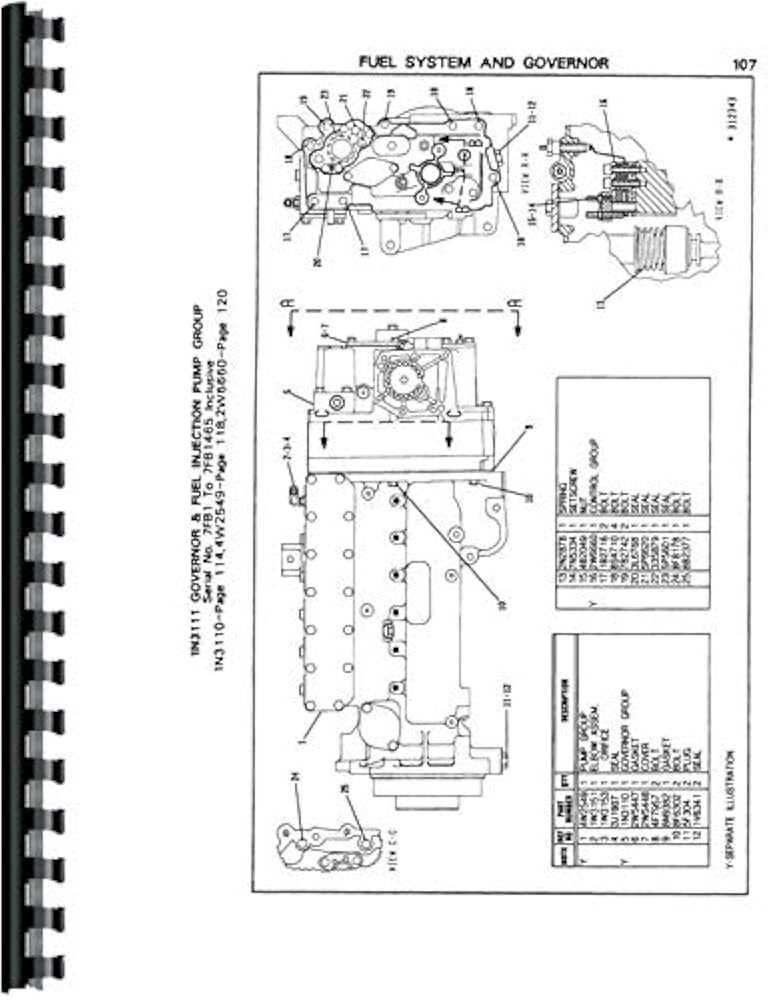

Fuel System Difficulties

Issues with the fuel system can significantly affect performance. Common symptoms include poor acceleration and engine stalling. These problems can arise from clogged filters, failing injectors, or fuel contamination. Proper maintenance and frequent inspections are essential to ensure the fuel system operates smoothly.

Essential Tools for Engine Repair

When undertaking the task of servicing and maintaining complex machinery, having the right instruments at your disposal is crucial for achieving optimal results. This section outlines fundamental implements that are necessary for efficient performance, ensuring that the process runs smoothly and effectively.

Basic Hand Tools

Every technician should have a selection of basic hand tools. These are indispensable for various tasks and can significantly affect the outcome of the project.

| Tool | Purpose |

|---|---|

| Wrenches | Used for loosening and tightening bolts and nuts. |

| Screwdrivers | Essential for driving screws and fastening components. |

| Pliers | Helpful for gripping and manipulating small parts. |

| Torque Wrench | Ensures that fasteners are tightened to the manufacturer’s specifications. |

Diagnostic Equipment

In addition to hand tools, diagnostic instruments are vital for troubleshooting issues effectively. These tools aid in identifying problems and ensuring that repairs are performed accurately.

| Tool | Function |

|---|---|

| Multimeter | Measures electrical parameters and diagnoses electrical issues. |

| Compression Tester | Evaluates the compression levels in the components. |

| Oil Pressure Gauge | Checks the oil pressure to ensure proper lubrication. |

| OBD Scanner | Interprets error codes and assists in troubleshooting electronic systems. |

Step-by-Step Repair Procedures

This section outlines detailed instructions for addressing common issues in heavy machinery. By following these systematic methods, operators can effectively restore functionality and ensure optimal performance. Each procedure is designed to be straightforward, providing clear guidance throughout the process.

Begin by gathering the necessary tools and parts before starting the task. Proper preparation minimizes downtime and enhances efficiency. Carefully review the components involved, and ensure a clean workspace to facilitate smooth operations.

Next, follow the outlined steps methodically. Start with the disassembly of the affected areas, taking care to label and store parts appropriately. After accessing the internal mechanisms, inspect each component for wear or damage.

Once identified, replace any faulty parts with high-quality alternatives. Reassemble the unit in reverse order, ensuring that all connections are secure and that no tools are left behind. After reassembly, perform thorough testing to confirm that everything is functioning as intended.

Finally, maintain a record of the work completed, including any parts replaced and observations made during the process. This documentation aids future maintenance and troubleshooting efforts.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of heavy machinery requires regular upkeep and attention to detail. Following essential practices can significantly extend the lifespan of your equipment while enhancing its efficiency.

Regular Inspections

Conducting frequent assessments is crucial to identifying potential issues before they escalate. Here are key areas to focus on:

- Check fluid levels regularly and top off as necessary.

- Inspect filters for cleanliness and replace them when needed.

- Examine belts and hoses for signs of wear or damage.

- Monitor gauges for any unusual readings during operation.

Scheduled Servicing

Establishing a routine maintenance schedule helps keep your machinery running smoothly. Consider the following tasks:

- Change lubricants according to the manufacturer’s recommendations.

- Perform thorough cleaning of components to prevent debris accumulation.

- Align and adjust parts to maintain optimal functioning.

- Document all service activities to track maintenance history.

Diagnosis Techniques for Engine Problems

Identifying issues within a power unit requires a systematic approach that integrates various methods and tools. These techniques aim to pinpoint the root causes of malfunctions, enabling effective solutions. Understanding symptoms, utilizing diagnostic equipment, and analyzing operational data are essential steps in this process.

One of the primary methods involves listening for unusual sounds, which can indicate specific troubles. Additionally, monitoring performance metrics such as temperature and pressure can reveal discrepancies that necessitate further investigation. Visual inspections are equally important, as they can uncover leaks, wear, or damage that may not be immediately evident.

Another effective technique is the use of specialized diagnostic devices that can provide insights into the internal workings of the system. These tools can read error codes and perform tests that help clarify the nature of the problem. By combining these strategies, technicians can achieve a comprehensive understanding of the underlying issues, leading to more accurate and timely repairs.

Upgrading Components for Performance

Enhancing the efficiency of a power unit can significantly boost overall output and reliability. Focusing on various parts allows for tailored improvements, which can lead to superior performance and longevity. This section explores key areas where upgrades can make a substantial difference.

Air Intake Systems play a crucial role in how well a unit performs. Upgrading to a high-flow air filter can increase airflow, resulting in better combustion and power output. Additionally, enhancing the intake manifold can improve air distribution, allowing for more efficient fuel usage.

Fuel Delivery Components are vital for optimal performance. Replacing standard injectors with high-performance variants can enhance fuel atomization, promoting better combustion efficiency. Furthermore, a performance fuel pump ensures a consistent and adequate fuel supply, preventing any power loss during operation.

Exhaust Systems also contribute to performance enhancements. Upgrading to a less restrictive exhaust can facilitate better gas flow, reducing back pressure and improving overall efficiency. This change not only boosts power but also often leads to a more aggressive sound, appealing to enthusiasts.

Finally, electronic tuning offers a customizable approach to maximizing performance. By recalibrating the control unit, you can optimize fuel mapping and ignition timing, resulting in increased horsepower and torque. Such adjustments, when combined with mechanical upgrades, can yield remarkable improvements.

Safety Precautions During Repairs

When engaging in maintenance tasks, it is essential to prioritize safety to protect both the individual performing the work and the equipment involved. Adhering to proper safety measures helps prevent accidents and ensures a smooth workflow.

Personal Protective Equipment

Utilizing appropriate personal protective gear is crucial. Always wear safety glasses to shield your eyes from debris, gloves to protect your hands from sharp edges, and steel-toed boots to safeguard your feet. Additionally, consider wearing hearing protection if you are working in a loud environment.

Workspace Organization

Maintaining a clean and organized workspace significantly reduces the risk of accidents. Ensure that tools and materials are stored in designated areas, and keep the floor free of hazards such as oil spills or loose items. Proper lighting is also important, as it helps in identifying potential dangers quickly.

Resources for Additional Support

When dealing with complex machinery, having access to supplementary information and assistance can greatly enhance your understanding and troubleshooting capabilities. Various platforms provide valuable resources, from online forums to specialized websites, all aimed at helping users navigate common challenges and gain insights into optimal practices.

Online Communities and Forums

Participating in online forums and communities can be an excellent way to connect with other enthusiasts and professionals. These platforms often feature discussions on specific issues, sharing of experiences, and tips that can help you tackle challenges more effectively. Engaging with these communities allows for real-time feedback and can lead to quicker resolutions.

Technical Support Services

Many organizations offer dedicated technical support for users seeking expert advice. These services can provide guidance on complex problems, ensuring that you have access to knowledgeable individuals who can help troubleshoot issues and recommend effective solutions. Utilizing these resources can save time and enhance the overall efficiency of your operations.

Understanding Engine Specifications

Specifications are crucial elements that define the performance and characteristics of a power unit. They encompass various metrics and features that provide insights into how the unit operates under different conditions. A thorough comprehension of these specifications is essential for anyone involved in maintenance or enhancement activities.

Key parameters typically include aspects such as displacement, horsepower, torque, and fuel efficiency. Each of these metrics plays a vital role in determining the overall capability and efficiency of the unit. For instance, higher displacement often translates to increased power output, while torque values are indicative of the unit’s ability to perform heavy-duty tasks.

Moreover, understanding the various components involved, such as the combustion system and lubrication mechanisms, can greatly influence decision-making processes regarding upgrades or replacements. A well-rounded knowledge of these specifications not only aids in troubleshooting but also in optimizing the performance of the unit for specific applications.

Warranty and Service Information

This section provides essential details regarding the warranty and service options available for your machinery. Understanding these aspects ensures that you can maintain optimal performance and address any potential issues efficiently.

All products typically come with a comprehensive warranty covering parts and labor for a specified duration. It is crucial to follow the manufacturer’s guidelines for usage and maintenance to avoid any complications with the warranty. Regular servicing by certified professionals is recommended to uphold the validity of the warranty.

| Service Type | Description | Frequency |

|---|---|---|

| Routine Maintenance | Scheduled check-ups to ensure all components are functioning correctly. | Every 500 hours of operation |

| Warranty Claims | Procedure for addressing defects or performance issues under warranty. | As needed |

| Parts Replacement | Replacement of worn or damaged components to maintain performance. | As necessary |