The process of maintaining a vehicle is essential for ensuring its longevity and optimal performance. Understanding the intricacies of your automobile’s components can empower owners to make informed decisions regarding upkeep and troubleshooting. This section aims to provide detailed insights into various aspects of the vehicle’s inner workings, offering practical advice and guidance.

Proper maintenance not only enhances the efficiency of your automobile but also helps in avoiding costly repairs down the line. By familiarizing yourself with essential practices, you can develop a routine that safeguards your investment and maximizes driving satisfaction. This guide serves as a valuable resource, equipping you with the knowledge necessary to navigate common issues effectively.

As you delve into the specifics, you will discover a wealth of information tailored to assist you in understanding crucial operations. Whether you’re facing minor adjustments or more significant challenges, the expertise provided here will support you in achieving successful outcomes, ultimately leading to a smoother driving experience.

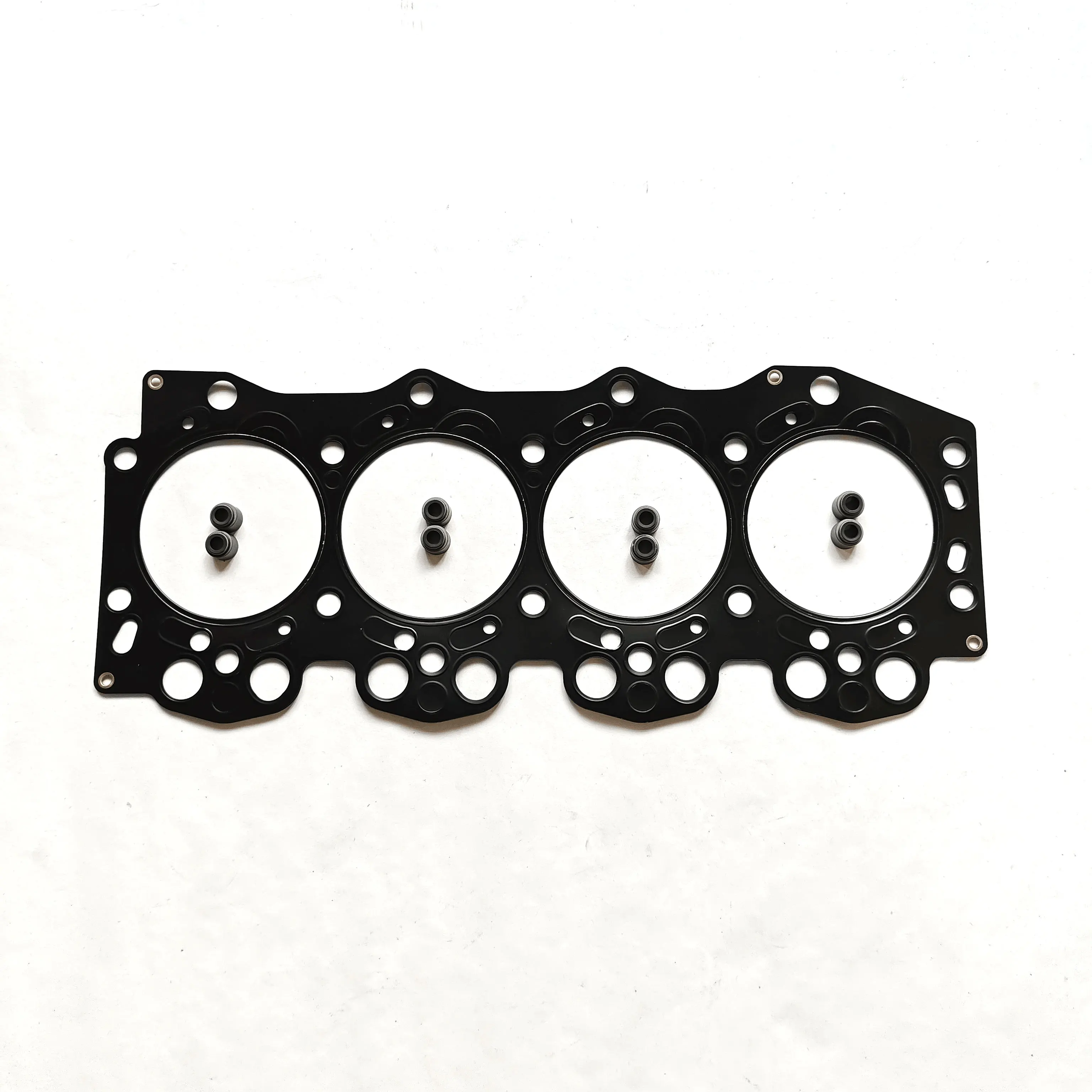

Kia J2 Engine Repair Overview

The following section delves into the intricate processes involved in maintaining and restoring the power unit of a particular vehicle model. Understanding the fundamental aspects of this task is essential for ensuring optimal performance and longevity.

Key Considerations: When addressing the intricacies of this component, one must pay attention to various factors including the condition of individual parts, proper tools, and techniques required for efficient handling. The goal is to enhance functionality while minimizing the risk of future complications.

Step-by-step Guidance: It is crucial to follow a systematic approach throughout the maintenance activities. Begin with an assessment to identify potential issues, followed by the necessary disassembly, inspection, and reassembly. Adhering to these guidelines will significantly contribute to achieving desired outcomes.

Essential Tools for Engine Repair

When undertaking maintenance or restoration of a power unit, having the right instruments is crucial for achieving optimal results. The right set of tools not only enhances efficiency but also ensures precision in each task.

Wrenches are among the most fundamental instruments needed. A variety of sizes, including both standard and metric options, will accommodate different fasteners effectively. Additionally, a socket set allows for more versatility and easier access to hard-to-reach bolts.

Screwdrivers come in various types, such as flathead and Phillips, to tackle a range of screws. Investing in a set with magnetic tips can facilitate better handling of small components. Moreover, pliers serve multiple functions, from gripping to bending wires, making them indispensable.

Another important category includes measuring tools. Calipers and micrometers provide accurate measurements essential for ensuring that components fit together perfectly. Torque wrenches are also vital for applying the correct amount of force to bolts, preventing damage from over-tightening.

Lastly, do not overlook the importance of cleaning supplies. A clean workspace and tools are fundamental to maintaining efficiency and ensuring that all parts function smoothly. Keeping everything organized not only saves time but also enhances safety.

Common Issues with Kia J2 Engine

This section addresses frequent problems encountered with the vehicle’s power unit. Understanding these challenges can aid in early detection and proper maintenance, ultimately enhancing the longevity and performance of the automobile.

Frequent Mechanical Failures

Several mechanical components may exhibit wear over time, leading to performance issues. Common signs include unusual noises, decreased power output, and abnormal vibrations.

Electrical System Malfunctions

Issues within the electrical system can significantly impact the overall functionality. Symptoms may involve erratic starting behavior, warning lights on the dashboard, and irregular power supply to critical components.

| Issue Type | Symptoms | Possible Causes |

|---|---|---|

| Mechanical Failure | Unusual noises, decreased power | Worn components, lack of lubrication |

| Electrical Malfunction | Erratic starting, warning lights | Faulty wiring, dead battery |

| Cooling System Problem | Overheating, coolant leaks | Clogged radiator, damaged hoses |

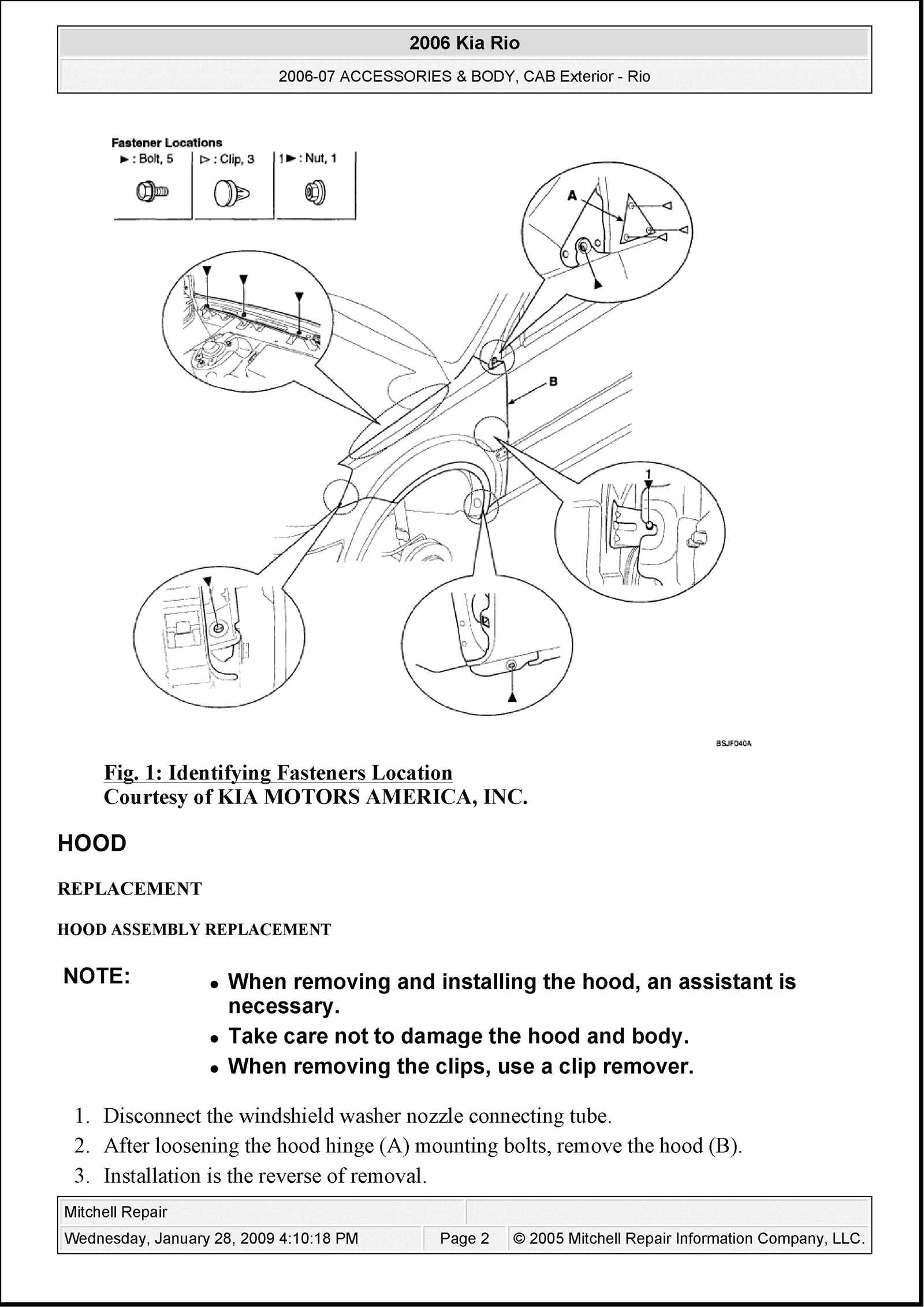

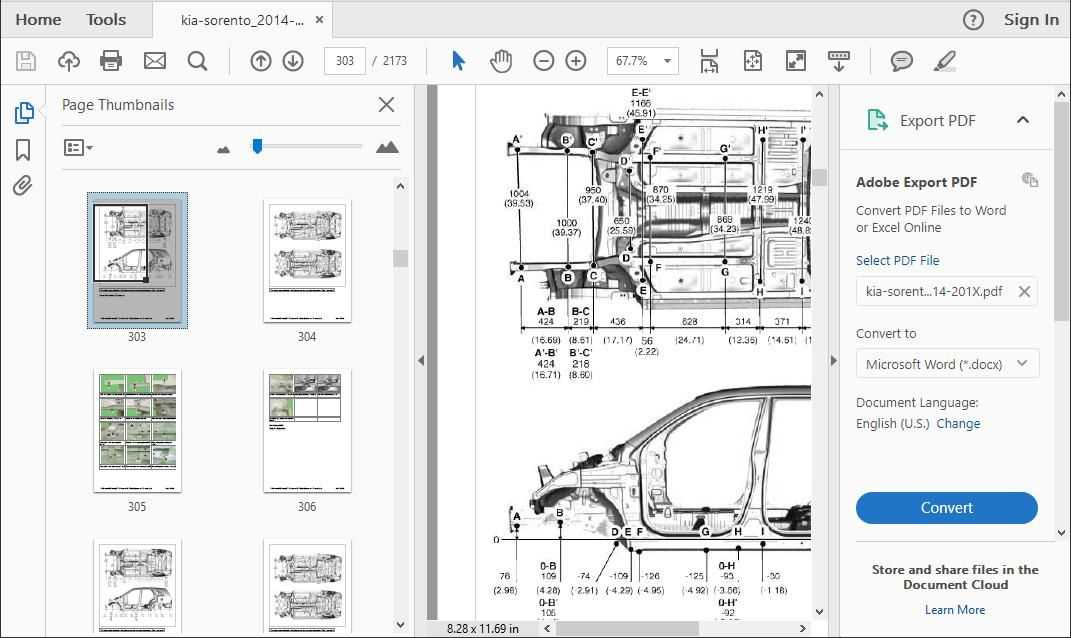

Step-by-Step Disassembly Process

This section outlines a detailed approach to carefully taking apart a specific mechanical unit. Following these steps will ensure that each component is removed systematically, allowing for proper examination and maintenance. It is crucial to adhere to this process to avoid damaging parts and to facilitate reassembly later.

Preparation for Disassembly

Before starting the disassembly, it is essential to gather the necessary tools and materials. Having the right equipment at hand will make the process smoother and more efficient. Additionally, ensure that the workspace is clean and organized to prevent losing any small components.

Disassembly Steps

Follow these steps meticulously to ensure successful disassembly:

| Step | Description |

|---|---|

| 1 | Disconnect all electrical connections and remove any external attachments. |

| 2 | Drain any fluids that may be present to avoid spills and contamination. |

| 3 | Carefully remove covers or casings to expose the internal components. |

| 4 | Label each part as it is removed to facilitate easier reassembly. |

| 5 | Continue to detach components systematically, ensuring not to force any parts. |

| 6 | Inspect each removed piece for wear and damage, documenting findings for reference. |

Inspecting Engine Components Effectively

Thorough evaluation of critical parts is essential for maintaining optimal performance and longevity. A methodical approach ensures that potential issues are identified early, preventing further complications and enhancing the overall functionality.

1. Preparation and Safety

Before initiating any assessment, it is crucial to gather the necessary tools and safety equipment. Ensure the working environment is clean and well-lit. Always prioritize safety by wearing appropriate protective gear and following standard protocols to avoid accidents.

2. Visual Examination

Start with a comprehensive visual inspection of all accessible components. Look for signs of wear, corrosion, or leaks. Pay close attention to seals, hoses, and connections, as these areas are often prone to degradation. Anomalies should be documented for further analysis.

3. Functional Testing

Conduct operational tests to evaluate the performance of various parts. Listening for unusual sounds during operation can provide immediate clues about underlying issues. Use diagnostic equipment to monitor performance metrics, which can highlight discrepancies in functionality.

4. Detailed Analysis

If abnormalities are detected, a more in-depth examination is warranted. Disassemble relevant sections with care, taking note of the arrangement of parts. Inspect internal surfaces for signs of wear and tear, and utilize appropriate measuring tools to assess tolerances and clearances.

5. Documentation and Follow-Up

Keep meticulous records of all findings and actions taken during the inspection process. This documentation serves as a valuable reference for future evaluations and can aid in identifying patterns that may indicate recurring issues. Following up on any repairs or adjustments is essential for ensuring lasting improvements.

Replacing Damaged Parts: A Guide

When components of a vehicle become worn or broken, timely replacement is crucial to maintain optimal performance and safety. This section provides insights into the process of identifying and substituting these faulty elements effectively.

Assessment of the Situation: Begin by thoroughly examining the affected area. Look for signs of wear, cracks, or other indicators that suggest a component is no longer functioning properly. Proper diagnosis is key to ensuring the correct parts are replaced.

Selection of Replacement Components: Once the damaged parts are identified, it is essential to choose high-quality substitutes that match the specifications of the original components. Using genuine or reputable aftermarket parts can prevent future issues and ensure longevity.

Installation Process: Follow a systematic approach when installing new parts. This may involve removing surrounding components, carefully detaching the faulty part, and securing the new one in place. Adhering to manufacturer guidelines will facilitate a smoother process and reduce the likelihood of errors.

Testing and Verification: After replacement, it’s important to test the vehicle to confirm that the new parts are functioning correctly. A thorough check can reveal any potential issues that might need addressing before the vehicle is deemed roadworthy.

By following these guidelines, one can effectively manage the process of replacing damaged components, ensuring the vehicle remains in peak condition.

Reassembling the Engine: Best Practices

Restoring complex machinery requires careful attention to detail and adherence to proven techniques. Each step plays a crucial role in ensuring the components fit seamlessly and operate effectively. Following established procedures not only enhances performance but also prolongs the lifespan of the assembly.

Preparation and Organization

Before commencing the assembly process, it’s vital to prepare the workspace. A clean, organized area minimizes the risk of losing parts and simplifies the task. Group similar components together and utilize labeled containers to keep track of fasteners and small items. This approach aids in efficient reassembly and reduces frustration.

Following Manufacturer Specifications

Utilizing manufacturer specifications as a reference is paramount. These guidelines provide essential torque settings and sequence orders, ensuring each component is tightened appropriately. Neglecting these details can lead to improper functioning and may result in significant damage over time. Always double-check measurements and clearances to confirm proper fitment.

By adhering to these best practices, the reassembly process becomes more manageable, resulting in a well-functioning assembly ready for operation.

Engine Maintenance Tips for Longevity

Proper care and regular attention are essential for ensuring the prolonged performance and reliability of your vehicle’s power unit. By implementing a few simple practices, you can significantly enhance its lifespan and efficiency, leading to a smoother driving experience.

Regular Fluid Checks

Maintaining the appropriate levels of essential liquids is critical. Periodically inspect and replenish oil, coolant, and transmission fluid to keep everything functioning smoothly. Using the recommended types of fluids helps prevent wear and tear.

Scheduled Inspections

Adhering to a timetable for evaluations can identify potential issues before they escalate. Scheduled check-ups allow for the examination of critical components, ensuring that everything operates within optimal parameters. Regular maintenance can save both time and costs in the long run.

Diagnosing Engine Performance Problems

Identifying issues related to powertrain functionality is crucial for optimal vehicle performance. Understanding the symptoms and underlying causes can lead to effective solutions, ensuring a smooth driving experience. This section outlines essential steps for pinpointing these challenges.

Common Symptoms of Performance Issues

Various indicators can signal a malfunctioning system. Drivers may notice a decrease in acceleration, unusual noises, or fluctuating idle speeds. Additionally, increased fuel consumption and warning lights on the dashboard can also provide essential clues. Recognizing these signs early on is vital for preventing further complications.

Steps for Effective Diagnosis

To accurately assess performance dilemmas, follow a systematic approach. Begin with a visual inspection of all related components, checking for leaks or wear. Utilizing diagnostic tools can provide valuable insights by retrieving fault codes. Lastly, conducting road tests while observing the behavior of the vehicle under different conditions helps isolate the problem.

In conclusion, thorough assessment and attention to detail are key to resolving performance challenges effectively. By employing methodical techniques, vehicle owners can maintain reliability and enhance overall functionality.

Understanding Engine Cooling System

The cooling system plays a crucial role in maintaining optimal temperatures within the machinery, ensuring efficient operation and longevity. Its primary function is to dissipate excess heat generated during various processes, preventing overheating and potential damage.

There are several key components that contribute to the functionality of this system:

- Radiator: This component dissipates heat from the coolant into the atmosphere.

- Coolant: A fluid that circulates through the system, absorbing heat and transferring it away from critical areas.

- Water Pump: Responsible for circulating the coolant throughout the system, maintaining a consistent flow.

- Thermostat: Regulates the temperature by controlling the flow of coolant based on heat levels.

Proper maintenance of these elements is essential for optimal performance. Regular checks can prevent failures, ensuring a smooth operation. Understanding the interactions within the cooling mechanism can greatly enhance troubleshooting skills and preventive measures.

In summary, a well-functioning cooling system is vital for preventing overheating and ensuring that the machinery operates effectively over time. By recognizing its components and maintaining them, one can significantly prolong the life of the system.

Fuel System Troubleshooting Techniques

This section provides essential approaches to diagnose and resolve issues related to fuel delivery systems. By understanding common symptoms and applying systematic methods, individuals can effectively identify malfunctions and restore optimal performance.

Common Symptoms and Their Implications

Recognizing the signs of fuel system problems is crucial. The following table outlines typical indicators and their potential causes:

| Symptom | Possible Cause |

|---|---|

| Engine hesitation or stalling | Clogged fuel filter or faulty pump |

| Poor acceleration | Dirty injectors or low fuel pressure |

| Check engine light illuminated | Malfunctioning sensor or emission issues |

| Unusual noises from the fuel tank | Damaged fuel pump or vapor lock |

Diagnostic Procedures

Implementing a structured diagnostic approach is vital for accurate problem identification. Begin with visual inspections to assess components for signs of wear or damage. Following this, utilize appropriate testing equipment to measure fuel pressure and flow rates, ensuring they meet manufacturer specifications. Additionally, scanning for error codes can provide insights into electronic control system issues.

Wiring and Electrical System Insights

This section delves into the intricate network of connections and electrical components that power various functionalities. Understanding the layout and operation of these systems is essential for troubleshooting and enhancing performance.

Key elements to consider include:

- Power distribution and its impact on system efficiency.

- Signal pathways that facilitate communication between components.

- Common issues that may arise in electrical setups.

To maintain optimal functionality, regular inspections and testing are crucial. The following points provide a structured approach to managing electrical components:

- Assessing wiring integrity and identifying signs of wear.

- Verifying voltage levels across key connections.

- Utilizing appropriate tools for diagnostics.

By familiarizing oneself with these aspects, one can ensure reliable operation and address any potential concerns effectively.