In the realm of automotive craftsmanship, understanding the intricacies of a vehicle’s power unit is essential for both enthusiasts and professionals alike. This section delves into the vital aspects of maintaining and troubleshooting a specific type of propulsion mechanism, ensuring optimal performance and longevity.

The complexity of modern machines necessitates a thorough grasp of their components and systems. By familiarizing oneself with the structure and function of these crucial parts, one can address common issues effectively. Here, we will explore a range of procedures and insights aimed at empowering individuals to undertake necessary tasks with confidence.

Whether you are a seasoned technician or a curious novice, having access to detailed procedures and helpful tips can significantly enhance your understanding. This guide aims to provide clarity on maintenance strategies, enabling you to navigate the challenges that may arise while working on these sophisticated systems.

Understanding the 1ZZ FE Engine

This section aims to provide a comprehensive overview of a specific automotive power unit that has garnered attention for its efficiency and reliability. It serves as a key component in various vehicle models, known for its balanced performance and engineering precision.

The design focuses on achieving optimal fuel consumption while maintaining a smooth operation. Its lightweight construction contributes to enhanced agility and responsiveness, making it a popular choice among manufacturers seeking to deliver an engaging driving experience.

Moreover, this power unit incorporates advanced technologies that promote durability and reduce emissions, aligning with modern environmental standards. As such, it is a testament to the evolution of automotive design, combining performance with sustainability.

Understanding the inner workings and specifications of this particular assembly can aid enthusiasts and technicians in diagnosing issues and optimizing performance. Familiarity with its components and their functions enhances one’s ability to maintain and improve overall vehicle efficiency.

Common Issues with the 1ZZ FE

This section explores frequent problems encountered in this particular power unit, shedding light on typical concerns that owners may face. Understanding these common pitfalls can aid in early diagnosis and maintenance, ensuring smoother performance and longevity.

One of the prevalent issues involves oil consumption, where the system tends to burn oil at a higher rate than expected. This can lead to the necessity for more frequent top-ups and potential damage if not monitored closely.

Another significant concern is overheating, often attributed to coolant leaks or a malfunctioning thermostat. Regular checks of the cooling system are crucial to prevent severe consequences that could arise from elevated temperatures.

Misfiring is also a notable problem, typically linked to faulty ignition components or fuel delivery issues. Identifying and rectifying these components promptly can restore proper operation and efficiency.

Lastly, users may experience vibration or noise emanating from the unit, which can indicate wear in internal parts or mounting issues. Addressing these symptoms early can help avoid more extensive repairs down the line.

Essential Tools for Repairs

Having the right equipment is crucial for effectively addressing mechanical issues. A well-equipped workspace allows for efficient troubleshooting and enhances the overall quality of work. Each task may require a specific set of implements, so understanding which tools to have on hand is essential for anyone involved in maintenance and enhancement projects.

Wrenches are fundamental for loosening and tightening fasteners. A set that includes various sizes will ensure versatility in different situations. Screwdrivers, both flat and Phillips, are equally important for accessing screws in various components.

Additionally, pliers come in handy for gripping and manipulating parts. A quality socket set allows for greater torque application, making it easier to work with stubborn bolts. For precise measurements, a caliper is indispensable, helping to ensure all adjustments are accurate.

Furthermore, investing in a reliable jack and jack stands is vital for safely elevating the vehicle or unit, providing necessary access to the underside. Lastly, a good work light will illuminate darker areas, making intricate tasks easier and more efficient.

By equipping yourself with these essential tools, you will be better prepared to tackle any challenges that arise during maintenance projects.

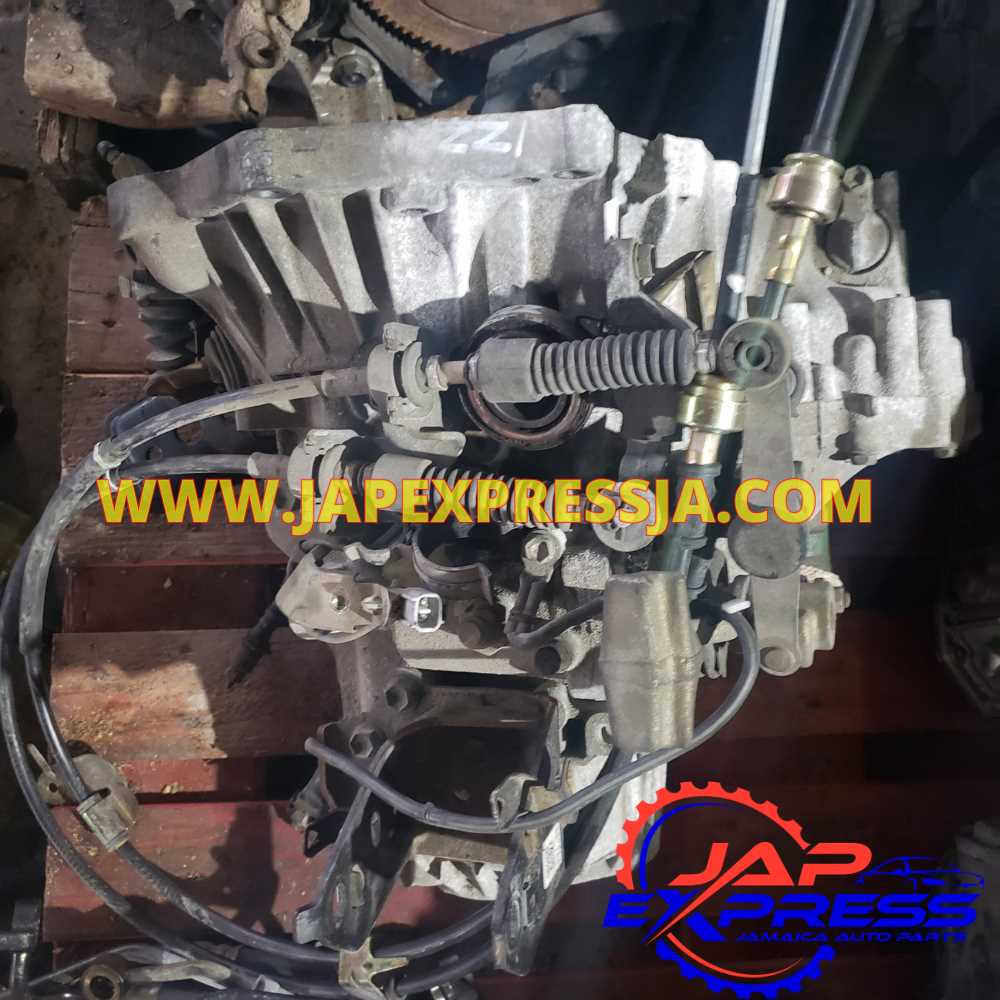

Step-by-Step Engine Disassembly

This section provides a detailed approach to systematically dismantling a power unit. Following a structured process ensures that each component is handled with care and that no vital part is overlooked during the procedure.

Begin by ensuring that the workspace is organized and all necessary tools are readily available. Safety precautions are paramount, so wear protective gear throughout the task.

Start by disconnecting the battery to prevent any electrical hazards. Next, remove external components such as the intake manifold and exhaust system, taking note of their configurations for reassembly. Labeling parts can significantly ease the reconstruction phase.

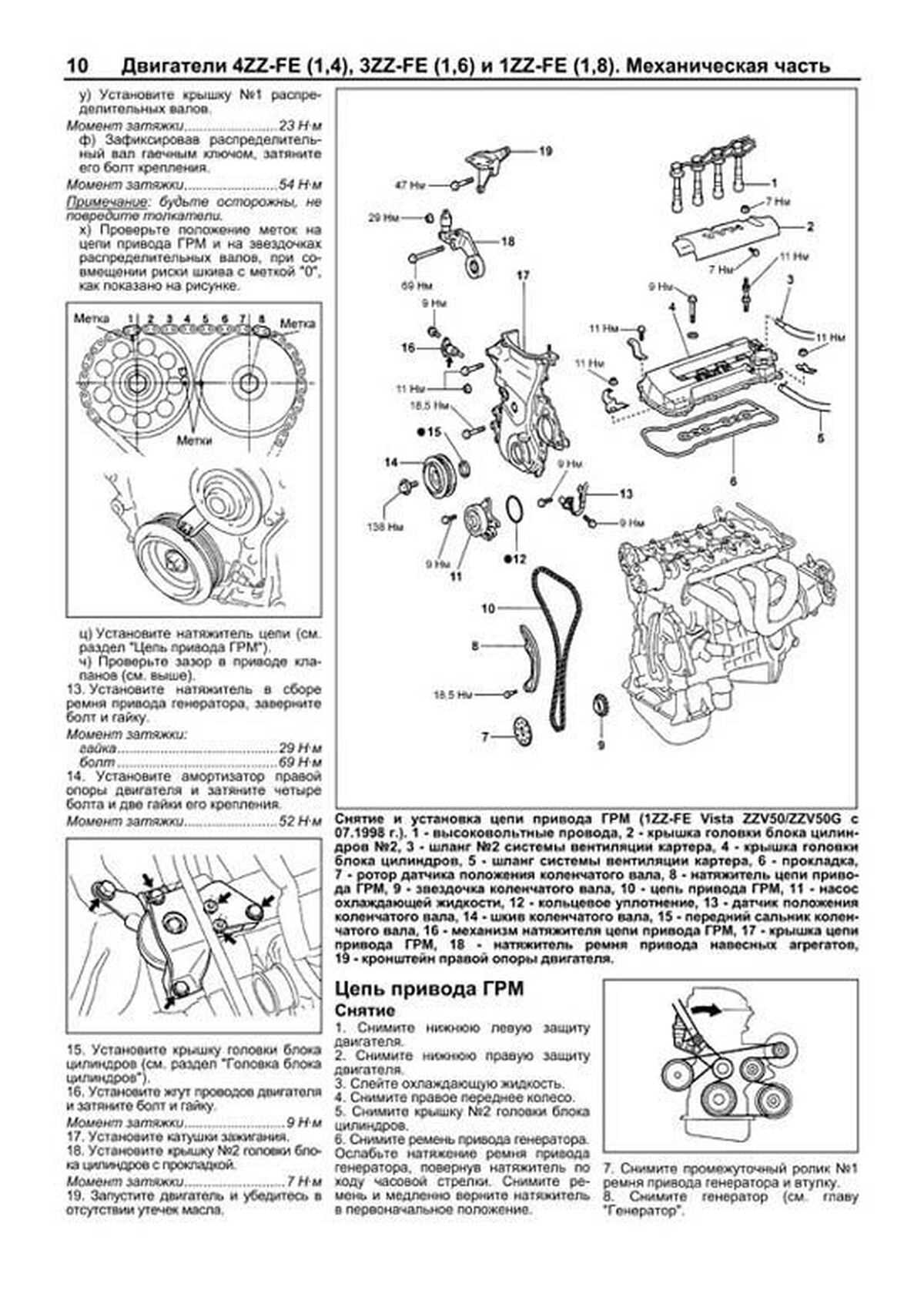

Once external elements are removed, proceed to detach the timing belt or chain, ensuring to align any timing marks to maintain synchronization. Following this, the cylinder head can be unbolted, allowing access to the internals.

Carefully extract the pistons and connecting rods, taking care to document their arrangement and condition. Each piece should be inspected for wear or damage, as this will inform any necessary replacements.

Finally, remove the crankshaft, noting its position and securing any bearings for future use. At this stage, all components should be categorized and cleaned for a thorough examination, laying the groundwork for effective servicing.

Inspecting Engine Components Thoroughly

Conducting a meticulous examination of various parts is crucial for ensuring optimal performance and longevity of the machinery. Identifying potential issues early can prevent significant malfunctions and reduce repair costs. A systematic approach to inspection allows for the detection of wear, damage, or any irregularities that could affect functionality.

Key Areas to Focus On

- Seals and Gaskets

- Cooling System Components

- Fuel Delivery Parts

- Ignition System Elements

- Mechanical Connections

Inspection Techniques

- Visual Inspection: Look for signs of wear, leaks, or corrosion.

- Physical Checks: Wiggle and pull components to check for looseness or damage.

- Measurement: Use calipers or micrometers to measure critical dimensions.

- Fluid Analysis: Examine oils and coolants for contaminants or degradation.

By focusing on these areas and employing these techniques, you can maintain the integrity and reliability of your machinery, ensuring it operates smoothly and efficiently.

Reassembling the 1ZZ FE Engine

Reassembling a power unit is a crucial phase in the overall restoration process. This step requires meticulous attention to detail and a systematic approach to ensure that every component fits together flawlessly, leading to optimal performance. Proper sequencing and alignment of parts are essential to avoid future complications.

Preparation for Reassembly

Before embarking on the reassembly journey, it is important to prepare all necessary components and tools. Cleaning all parts thoroughly will help eliminate any debris that could affect functionality. Organizing components in a logical order can streamline the process, making it easier to follow the assembly sequence. Ensure that all gaskets and seals are fresh and ready to be installed, as these play a vital role in preventing leaks.

Step-by-Step Assembly Process

Begin by carefully placing the lower assembly on a stable surface. Apply the appropriate lubricant to moving parts to facilitate smooth operation. As you install each section, double-check the torque specifications to ensure tightness without over-stressing the materials. Pay special attention to timing mechanisms and ensure that they are correctly aligned to maintain performance standards.

Following this systematic approach will lead to a successful reassembly, allowing for reliable operation and longevity of the unit. Remember that patience and precision are key in this intricate process.

Key Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your vehicle’s components. By following a few straightforward guidelines, you can significantly extend the lifespan of critical systems and enhance overall performance.

Regular Fluid Checks: Make it a habit to routinely inspect and top off all essential liquids, including coolant, oil, and transmission fluid. Maintaining optimal levels helps prevent overheating and wear.

Scheduled Filter Replacements: Change filters according to the recommended intervals. Clean filters promote better circulation and reduce strain on various systems, ultimately improving functionality.

Timely Inspections: Conduct regular visual assessments to catch any signs of wear or damage early on. Look for leaks, cracks, or unusual noises, as these can indicate potential issues that require attention.

Routine Maintenance Services: Adhere to a consistent maintenance schedule. Professional services, including tuning and adjustments, can help identify and rectify problems before they escalate.

Driving Habits: Adopt smooth driving practices. Rapid acceleration and heavy braking put unnecessary stress on components, leading to premature wear. Gentle driving enhances longevity.

Storage Conditions: If the vehicle will be unused for extended periods, ensure it is stored in a suitable environment. A cool, dry place protects against corrosion and other environmental damage.

By implementing these essential practices, you can maximize the lifespan and reliability of your vehicle’s systems, ensuring that it remains in top condition for years to come.

Performance Upgrades for the Engine

Enhancing the capabilities of your vehicle’s power unit can lead to improved responsiveness, efficiency, and overall driving experience. By implementing various modifications, you can unlock the hidden potential of your system and achieve better performance on the road.

Common Upgrades to Consider

- Cold Air Intake: Increases airflow to the combustion chamber, leading to improved throttle response and horsepower.

- High-Performance Exhaust System: Reduces back pressure, allowing for better exhaust flow and enhancing sound.

- Tune-Up Software: Optimizes the vehicle’s electronic control unit, resulting in improved fuel mapping and performance metrics.

- Upgraded Fuel Injectors: Provides a more precise fuel delivery, supporting increased power output.

- Turbocharger or Supercharger Installation: Significantly boosts power by forcing more air into the combustion chamber.

Benefits of Upgrading

- Increased Horsepower: Enhancements can result in noticeable gains in power.

- Improved Fuel Efficiency: Certain modifications can help in optimizing fuel consumption.

- Better Throttle Response: Upgrades often lead to quicker acceleration and a more engaging driving experience.

- Enhanced Reliability: Some performance parts are designed to handle increased stress and can extend the lifespan of components.

Diagnosing Electrical Problems

Identifying issues within the electrical system of a vehicle requires a systematic approach. Understanding the interplay of various components can help pinpoint malfunctions effectively. This section will guide you through essential steps and techniques to uncover electrical faults.

Common Symptoms of Electrical Issues

- Dim or flickering lights

- Unresponsive dashboard indicators

- Difficulty starting the vehicle

- Unusual noises from the battery area

- Frequent blown fuses

Diagnostic Steps

- Check the battery condition and connections.

- Inspect fuses and relays for damage or malfunction.

- Utilize a multimeter to measure voltage at various points.

- Examine wiring for signs of wear, corrosion, or disconnections.

- Test individual components like alternators and starters for functionality.

Following these steps can lead to the identification of underlying electrical issues, ensuring a smoother resolution process.

Replacing Timing Belts Effectively

Timely replacement of belts that synchronize critical components is essential for optimal performance and longevity of a vehicle’s machinery. This process, while straightforward, requires attention to detail and adherence to specific procedures to ensure a successful outcome. Proper techniques not only enhance efficiency but also prevent future complications.

Before embarking on the replacement, it is crucial to gather the necessary tools and materials. Having everything ready will streamline the process and minimize potential delays. Here’s a basic checklist:

| Tools | Materials |

|---|---|

| Socket set | New belt |

| Torque wrench | Timing cover gasket |

| Crankshaft pulley tool | Lubricant (if required) |

| Safety gloves | Replacement tensioner (if needed) |

Begin by disconnecting the battery to ensure safety. Follow this with the removal of the necessary components to access the belt. It is advisable to document the configuration of parts for easier reassembly. After the old belt is taken out, compare it with the new one to confirm compatibility.

Installation of the new belt should be approached with caution. Align the belt according to the manufacturer’s specifications, ensuring that all timing marks are correctly positioned. Once installed, check the tension to confirm it meets the required standards. This crucial step helps prevent premature wear or failure.

After reassembly, perform a thorough inspection of the surroundings to ensure that all tools are accounted for and that no components have been left unfastened. Finally, reconnect the battery and start the machinery, monitoring for any unusual sounds or vibrations that could indicate an issue.

Understanding Engine Specifications

Grasping the intricacies of technical parameters is essential for anyone looking to delve into vehicle performance and maintenance. These specifications provide critical insights into the capabilities and requirements of an automotive power unit, influencing everything from efficiency to compatibility with various systems. A clear comprehension of these details empowers enthusiasts and professionals alike to make informed decisions regarding upgrades, repairs, and overall care.

Key specifications often include measurements such as displacement, compression ratio, power output, and torque ratings. Each of these elements plays a significant role in determining how a vehicle performs under different conditions. Understanding these factors helps in assessing the suitability of components and predicting the behavior of the system as a whole.

| Specification | Description |

|---|---|

| Displacement | The total volume of all the cylinders in the assembly, usually measured in liters or cubic centimeters. |

| Compression Ratio | The ratio of the maximum to minimum cylinder volume, influencing power and efficiency. |

| Power Output | The maximum power produced, typically measured in horsepower or kilowatts. |

| Torque Rating | The rotational force generated, important for acceleration and towing capacity. |

In conclusion, a thorough understanding of these specifications not only enhances the performance of a vehicle but also aids in identifying potential issues before they become significant problems. This knowledge forms the foundation for successful engagement with any automotive system.

Resources for Further Learning

For those eager to deepen their understanding of automotive systems and maintenance, a wealth of resources is available. Engaging with various materials can enhance your knowledge and skills, ensuring you’re well-equipped for any tasks ahead.

- Online Forums: Platforms where enthusiasts share experiences, tips, and solutions can be invaluable for practical insights.

- Technical Books: Comprehensive literature provides detailed explanations and step-by-step guides on various automotive topics.

- Video Tutorials: Visual demonstrations are effective for grasping complex concepts and techniques.

- Workshops and Classes: Hands-on learning opportunities can offer direct experience and expert guidance.

- Manufacturer Websites: Official resources often contain specifications, troubleshooting tips, and product updates.

Exploring these resources will not only boost your confidence but also empower you to tackle challenges effectively.