This section aims to provide an in-depth exploration of essential practices and techniques related to the upkeep of high-performance machinery. By delving into various aspects of maintenance, enthusiasts and professionals alike can enhance their understanding and ensure optimal functionality.

Proper attention to intricate systems can prevent common issues, extending the lifespan and efficiency of the equipment. This guide encompasses a variety of topics, from basic troubleshooting to advanced adjustments, catering to all levels of expertise.

As users navigate through the details, they will discover valuable insights that facilitate effective handling of complex components. With the right knowledge and resources, anyone can master the intricacies of machinery maintenance, empowering them to achieve outstanding performance and reliability.

Understanding Duramax Diesel Engines

This section delves into the intricacies of high-performance power units commonly utilized in heavy-duty vehicles. These robust systems are engineered for optimal efficiency and reliability, catering to various applications where durability is paramount.

Key Features: The design of these power sources emphasizes strength and longevity, allowing them to perform under extreme conditions. Enhanced fuel management and advanced thermal dynamics contribute to their impressive output and fuel economy.

Maintenance Insights: Regular upkeep is crucial for sustaining performance. Familiarity with common components and systems aids in identifying potential issues before they escalate, ensuring that these units operate at their best.

Understanding the technical aspects and maintenance needs of these systems is essential for maximizing their potential and longevity.

Common Issues and Troubleshooting

This section addresses frequent challenges encountered in high-performance power units and provides guidance for effective resolution. Understanding these typical complications is essential for maintaining optimal functionality and longevity.

Frequent Performance Problems

Owners may notice a decline in efficiency or power output, often due to fuel delivery issues or air intake restrictions. Regular inspections of the filtration systems can help identify blockages or contaminants that might be affecting performance. Ensuring that the fuel system is clean and well-maintained is critical to avoiding these issues.

Overheating and Cooling Concerns

Overheating is a common issue that can lead to severe damage if not addressed promptly. It is vital to check the cooling system, including the radiator and hoses, for leaks or blockages. Maintaining proper coolant levels and ensuring that the thermostat functions correctly will help prevent overheating and maintain optimal operating temperatures.

Proactive maintenance and timely troubleshooting are key to extending the lifespan of these complex systems. Regular monitoring and addressing any symptoms early can save significant time and resources in the long run.

Essential Tools for Repairs

To ensure optimal functionality and longevity of your machinery, having the right instruments is crucial. This section outlines the fundamental implements necessary for effective maintenance and troubleshooting.

Below are key categories of tools that every technician should consider:

- Hand Tools:

- Wrenches

- Screwdrivers

- Pliers

- Socket sets

- Diagnostic Equipment:

- Code readers

- Multimeters

- Pressure gauges

- Specialty Tools:

- Torque wrenches

- Pullers

- Timing tools

- Safety Gear:

- Gloves

- Goggles

- Ear protection

Equipping yourself with these essential tools will facilitate efficient tasks, ensuring that all procedures are performed correctly and safely.

Maintenance Practices for Longevity

Ensuring the prolonged life and optimal performance of your vehicle’s power source requires consistent and attentive care. Adopting effective upkeep strategies can prevent common issues and enhance reliability over time.

Regular maintenance tasks include the following:

- Routine oil changes to keep the internal components lubricated and functioning smoothly.

- Regularly checking and replacing air filters to ensure clean airflow, improving efficiency.

- Monitoring fluid levels, including coolant and transmission fluids, to prevent overheating and ensure proper operation.

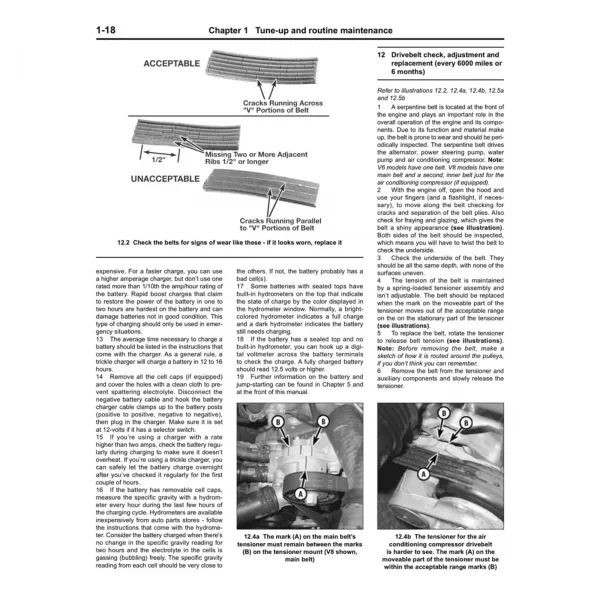

- Inspecting belts and hoses for wear and tear, replacing them as needed to avoid breakdowns.

Additionally, consider implementing these practices:

- Schedule periodic inspections to identify potential issues before they escalate.

- Maintain proper tire pressure for better fuel efficiency and handling.

- Follow manufacturer recommendations for service intervals and required parts.

- Use high-quality fuels and lubricants to maximize performance and minimize deposits.

By committing to these proactive maintenance habits, vehicle owners can significantly enhance the durability and functionality of their power systems.

Replacing Engine Components Effectively

Replacing vital mechanical parts is crucial for maintaining optimal performance and longevity. This section explores best practices and essential tips for executing these tasks efficiently and safely.

Preparation Steps

- Gather necessary tools and replacement parts before starting.

- Review specifications and guidelines related to the components being changed.

- Ensure the workspace is clean and well-organized to facilitate a smooth process.

Replacement Process

- Disconnect power sources and remove any obstructing components.

- Carefully extract the old part, noting any specific connections or fasteners.

- Install the new component, ensuring proper alignment and secure attachment.

- Reassemble any removed parts, double-checking connections for safety.

- Conduct a thorough inspection and testing to confirm successful installation.

Performance Upgrades and Modifications

Enhancing the capabilities of a heavy-duty power unit involves various strategies that can significantly improve its output and efficiency. By focusing on specific components and making thoughtful adjustments, enthusiasts can unlock greater potential and performance in their vehicles.

Common Modifications

- Air Intake Systems: Upgrading the air intake allows for improved airflow, leading to better combustion and increased power.

- Exhaust Systems: A high-performance exhaust system reduces back pressure, enhancing overall performance and sound.

- Turbochargers: Installing a more efficient turbocharger can greatly boost power levels and responsiveness.

- Fuel Delivery Enhancements: Upgrading fuel injectors and pumps ensures optimal fuel flow, supporting increased performance demands.

Benefits of Upgrades

- Improved torque and horsepower, resulting in better towing and hauling capabilities.

- Enhanced fuel efficiency, leading to cost savings over time.

- Increased reliability under heavy loads, ensuring longevity of the unit.

- Greater customization options to tailor performance to specific needs and preferences.

Fuel System Maintenance Guidelines

Proper upkeep of the fuel delivery system is essential for optimal performance and longevity of your vehicle’s power unit. Regular checks and maintenance can prevent common issues that lead to inefficiencies and costly repairs.

Routine Inspection

Regularly examining components such as filters and lines ensures that the fuel pathway remains clear and free of contaminants. Inspecting for leaks and signs of wear can help identify potential problems before they escalate. Maintaining cleanliness in the system is crucial for proper fuel flow and performance.

Filter Replacement

Changing fuel filters at recommended intervals is a vital part of maintenance. Clogged filters can restrict fuel flow, causing performance issues and possible damage. Ensure to follow guidelines for the specific intervals recommended for your vehicle to maintain an efficient fuel system.

Electrical Systems: Diagnostics and Fixes

This section focuses on the intricate components that manage power distribution and control within the vehicle’s framework. Understanding these systems is crucial for identifying issues that may arise during operation, ensuring optimal performance and reliability.

Common Issues and Troubleshooting Steps

Typical problems include faulty connections, shorts, and intermittent failures. To effectively address these, begin with a visual inspection of wiring and connectors. Look for signs of wear, corrosion, or damage. Utilize a multimeter to test for continuity and voltage, ensuring that all circuits are functioning as intended.

Effective Solutions

When a malfunction is detected, pinpoint the source of the issue. Repair or replace damaged components promptly to prevent further complications. In some cases, re-routing wires or using higher quality connectors can enhance system reliability. Always refer to specific guidelines for proper installation and configuration.

Cooling System Repair Techniques

The maintenance of thermal management systems is crucial for optimal performance and longevity of heavy-duty vehicles. Addressing issues within these systems not only enhances efficiency but also prevents potential failures that can lead to extensive downtime. This section delves into effective methods for maintaining and restoring cooling functionalities.

Identifying Common Issues

Recognizing symptoms of overheating or inadequate cooling is the first step in addressing system malfunctions. Common indicators include fluctuating temperature readings, visible leaks, and unusual sounds from the cooling components. Conducting a thorough inspection can help pinpoint the root cause of these problems.

Techniques for Effective Restoration

Once issues are identified, employing proper techniques for remediation is essential. Flushing the system can remove accumulated debris and contaminants, while replacing worn-out components, such as hoses and clamps, ensures the system operates efficiently. Additionally, utilizing sealants can help to prevent future leaks and maintain system integrity.

Transmission Service Procedures

This section outlines essential practices for maintaining and servicing the power transfer system of heavy-duty vehicles. Proper procedures are crucial for ensuring optimal performance and longevity of the components involved in the transfer of power from the driving mechanism to the wheels.

Routine Maintenance Checks

Regular inspections and maintenance tasks are vital for preventing issues. Check fluid levels and quality, looking for any signs of contamination or degradation. Replace fluids as needed, and ensure that seals and gaskets are intact to prevent leaks. Additionally, examine the system for any abnormal noises or vibrations that may indicate underlying problems.

Component Replacement and Adjustment

If components show signs of wear, they should be replaced promptly to avoid further damage. Adjustments to the linkages and calibrations may also be necessary to ensure smooth operation. Pay special attention to alignment and secure mounting of all parts to maintain stability and efficiency during operation. Regularly consult the specifications for precise measurements and adjustments.

Safety Precautions During Repairs

Ensuring a safe environment during maintenance tasks is crucial for preventing accidents and injuries. Proper precautions not only protect the individual performing the work but also safeguard the machinery involved. Understanding potential hazards and implementing suitable safety measures can significantly reduce risks.

Before starting any work, it is essential to wear appropriate personal protective equipment (PPE). This includes gloves, goggles, and safety shoes, which provide protection against various hazards. Additionally, ensuring that the workspace is well-ventilated is vital, especially when dealing with chemicals or fumes.

Always disconnect power sources and secure all moving parts before initiating any procedures. This simple step can prevent unexpected starts or movements that could lead to injury. Furthermore, familiarizing oneself with the specific tools and equipment being used enhances safety and efficiency.

Lastly, keeping a first aid kit nearby and being aware of emergency procedures can provide peace of mind. Being prepared for unforeseen incidents is an integral part of maintaining a safe working environment.

Resources for Further Learning

Expanding your knowledge in vehicle maintenance and troubleshooting is essential for both enthusiasts and professionals. A variety of materials are available to help deepen your understanding of complex systems, enhancing your skills and confidence in handling various tasks.

Books and Publications

Numerous books focus on automotive systems, offering detailed insights and practical advice. Look for titles that cover topics such as mechanical principles, diagnostics, and advanced technologies. These resources provide comprehensive information and can serve as valuable references in your learning journey.

Online Forums and Communities

Participating in online communities can be incredibly beneficial. Forums dedicated to automotive discussions allow you to engage with experienced individuals, ask questions, and share knowledge. Connecting with others can expose you to new ideas and solutions, fostering a collaborative learning environment.