When it comes to maintaining high-performance vehicles, understanding the intricacies of the power units is essential for every enthusiast. This section aims to provide invaluable insights into the upkeep and potential challenges associated with these sophisticated machinery components. With a focus on practical knowledge, it serves as a resource for both novice and seasoned individuals looking to enhance their mechanical expertise.

As one delves into the specifics of maintenance techniques, it becomes clear that familiarity with the assembly and functionality of these systems is crucial. By mastering key procedures, individuals can not only extend the lifespan of their vehicles but also improve overall performance. This guide will cover essential practices, common issues, and troubleshooting methods, empowering readers to take charge of their automotive care.

Through careful attention to detail and a systematic approach to problem-solving, enthusiasts can ensure their vehicles remain in peak condition. Whether facing minor adjustments or significant challenges, the knowledge shared in this guide aims to equip readers with the tools necessary for effective management and restoration of their prized possessions.

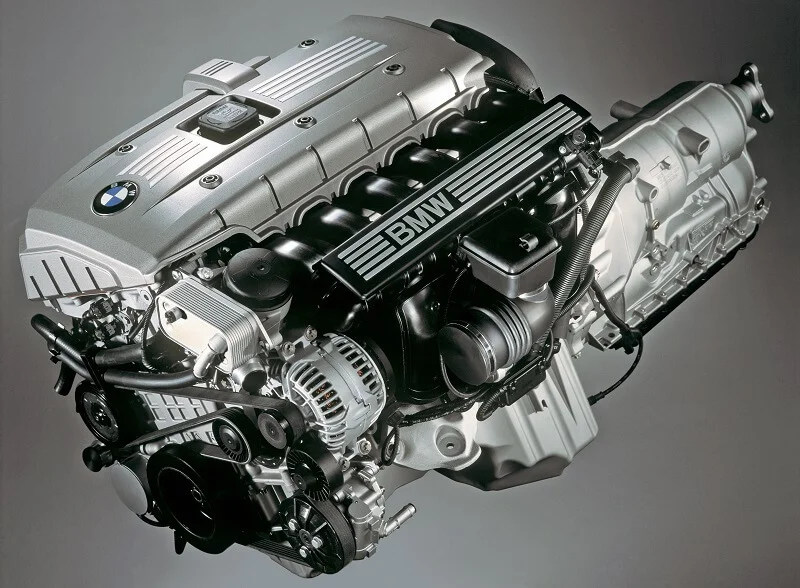

Understanding the BMW N52 Engine

The complexity and engineering excellence behind this power unit have made it a notable choice in the automotive world. It combines performance with efficiency, providing a harmonious driving experience that appeals to enthusiasts and casual drivers alike.

Key Features and Innovations

One of the standout aspects of this power unit is its lightweight construction, which enhances handling and responsiveness. The incorporation of advanced technologies, such as variable valve timing and a sophisticated intake system, contributes to its remarkable balance of power and fuel economy.

Common Challenges

Despite its strengths, this unit is not without its issues. Owners may encounter challenges related to the cooling system and oil leaks. Regular maintenance and attention to these areas can ensure longevity and optimal performance, allowing drivers to fully enjoy the capabilities of this remarkable piece of machinery.

Common Issues with the N52 Engine

Many enthusiasts have encountered various challenges with this particular power unit over the years. Understanding these prevalent problems can aid in maintaining optimal performance and longevity. Below are some of the most frequently reported concerns that users should be aware of.

Cooling System Failures

One significant issue involves the cooling system, where components such as the thermostat and water pump may fail prematurely. This can lead to overheating and subsequent damage if not addressed promptly. Regular checks and maintenance of these parts are essential to prevent severe complications.

Oil Leaks

Another common problem is the occurrence of oil leaks, often originating from the valve cover gasket or the oil filter housing. These leaks can compromise engine lubrication and performance. It is advisable to inspect these areas regularly and replace any worn gaskets to ensure a tight seal and avoid potential damage.

Essential Tools for N52 Repairs

To successfully maintain and service a complex power unit, having the right equipment is crucial. A well-equipped workspace not only facilitates efficient work but also ensures safety and accuracy during the process. Below is a list of indispensable tools that every technician should consider for effective maintenance tasks.

- Socket Set: A comprehensive socket set is essential for accessing various bolts and nuts throughout the assembly.

- Torque Wrench: This tool allows for precise tightening of fasteners to manufacturer specifications, preventing damage from over-torquing.

- Jack and Jack Stands: Proper lifting equipment is necessary to safely elevate the vehicle for underbody access.

- Oil Filter Wrench: This tool simplifies the removal of oil filters, making oil changes more manageable.

- Screwdriver Set: A variety of screwdrivers is required to handle different types of fasteners throughout the system.

- Pliers: Needle-nose and adjustable pliers are useful for gripping, twisting, and cutting tasks.

- Diagnostic Scanner: An electronic diagnostic tool can quickly identify issues by reading fault codes from the control unit.

- Multimeter: This device is essential for testing electrical components and diagnosing electrical issues.

By investing in these fundamental tools, enthusiasts and professionals can ensure they are well-prepared to tackle various challenges that may arise during maintenance and service work.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle’s power unit. Following a systematic approach to maintenance not only enhances reliability but also helps in identifying potential issues before they escalate. This guide outlines crucial procedures to keep your system running smoothly.

1. Fluid Checks

Maintaining proper fluid levels is vital for the functionality of your vehicle. Follow these steps to ensure everything is in order:

- Check the oil level using the dipstick. Make sure the oil is clean and at the recommended level.

- Inspect coolant levels in the reservoir; refill if necessary.

- Examine the brake fluid and power steering fluid, ensuring both are at appropriate levels.

2. Filter Replacements

Filters play a critical role in maintaining the cleanliness of essential fluids. Regularly replacing them can prevent damage and improve efficiency.

- Replace the oil filter during oil changes to ensure contaminants are removed.

- Change the air filter to maintain optimal airflow and engine performance.

- Inspect and replace the fuel filter to ensure clean fuel delivery.

Following these maintenance procedures will contribute to the overall health of your vehicle’s power unit, reducing the likelihood of unexpected repairs and enhancing driving enjoyment.

Diagnosing Engine Problems Effectively

Identifying issues within a power unit is a crucial skill for any automotive enthusiast or professional. A systematic approach helps in pinpointing malfunctions, leading to more efficient troubleshooting and resolution. Understanding symptoms and employing the right techniques can save time and resources.

To effectively diagnose problems, follow these essential steps:

- Gather Information:

- Listen for unusual sounds during operation.

- Observe warning lights on the dashboard.

- Check for any noticeable changes in performance.

- Perform Visual Inspections:

- Examine hoses and belts for wear and tear.

- Look for fluid leaks under the vehicle.

- Inspect connections and wiring for damage.

- Utilize Diagnostic Tools:

- Employ an OBD-II scanner to retrieve error codes.

- Monitor live data to assess performance metrics.

- Use a multimeter to check electrical components.

- Conduct Tests:

- Perform a compression test to assess cylinder integrity.

- Run a leak-down test to check for air leaks.

- Evaluate fuel pressure to ensure adequate delivery.

- Analyze Results:

- Compare findings with standard specifications.

- Determine potential causes based on symptoms and test results.

- Prioritize issues based on severity and impact on performance.

By following these steps, one can efficiently diagnose and address issues, ensuring optimal functionality of the vehicle’s components. Regular maintenance and prompt attention to symptoms can prevent more severe problems in the future.

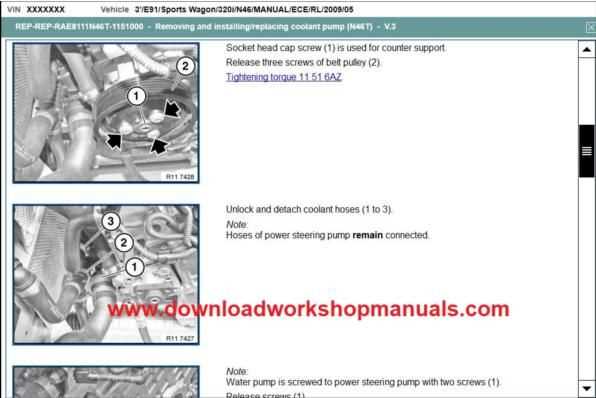

Repairing the Cooling System Components

Maintaining the integrity of the cooling system is crucial for optimal vehicle performance. This section covers essential procedures for addressing issues related to various components that ensure effective temperature regulation. Regular inspections and timely interventions can prevent overheating and other complications that may arise from system failures.

Common Cooling System Components

- Radiator

- Water Pump

- Thermostat

- Hoses

- Cooling Fan

Steps for Addressing Cooling System Issues

- Inspection: Begin by visually examining all components for signs of wear, leaks, or corrosion.

- Fluid Check: Ensure coolant levels are adequate and free from contaminants.

- Replacement: Identify any faulty parts that require replacement, such as hoses or the thermostat.

- Testing: After repairs, run the system to verify that it operates at the correct temperature.

- Regular Maintenance: Schedule periodic checks to maintain system efficiency and prevent future problems.

By following these guidelines, you can ensure that the cooling components remain in optimal condition, providing reliable performance and longevity for your vehicle.

Replacing the Oil Filter and Oil

Regular maintenance of the lubrication system is crucial for the longevity and performance of any automotive unit. This process involves changing both the oil filter and the lubricant itself, ensuring that contaminants are removed and that the system operates smoothly. Properly executing this task will enhance efficiency and prevent potential damage over time.

Tools and Materials Needed

| Item | Purpose |

|---|---|

| Wrench Set | For loosening and tightening the oil filter and drain plug |

| Oil Filter Wrench | To easily remove the old oil filter |

| Oil Catch Pan | To collect the old lubricant during the drain process |

| New Oil Filter | To replace the old, clogged filter |

| Fresh Lubricant | To replenish the system with high-quality oil |

| Funnel | For pouring the new lubricant without spills |

Procedure Steps

Begin by ensuring the vehicle is on a level surface and the engine is cool. First, place the oil catch pan under the drain plug and remove it to allow the old lubricant to drain completely. Next, use the oil filter wrench to unscrew the old filter. Before installing the new filter, apply a small amount of fresh lubricant to its rubber seal to ensure a good fit. Install the new filter by hand, tightening it securely. Once everything is in place, replace the drain plug and fill the system with the new lubricant using the funnel. Start the unit and allow it to run for a few minutes, checking for leaks around the filter and drain plug. Finally, dispose of the used oil and filter responsibly.

Tuning and Performance Upgrades

Tuning and performance enhancements play a crucial role in maximizing the potential of a vehicle’s powertrain. By modifying various components, enthusiasts can significantly improve horsepower, torque, and overall driving dynamics. This section explores key strategies for optimizing performance, ensuring that every modification harmonizes with the vehicle’s characteristics.

Intake and Exhaust Systems

Upgrading the intake and exhaust systems is one of the most effective methods to enhance airflow. A high-performance air intake can increase the volume of air entering the combustion chamber, while an optimized exhaust system reduces back pressure, allowing for smoother expulsion of gases. Together, these upgrades can lead to noticeable gains in power.

Tuning Software

Utilizing advanced tuning software allows for precise adjustments to fuel maps and ignition timing. This customization ensures that the vehicle operates efficiently under various conditions, unlocking hidden power while maintaining reliability. A professional tune can adapt the vehicle’s performance characteristics to suit individual driving preferences.

Suspension and Handling

Enhancing suspension components not only improves ride quality but also elevates handling capabilities. Upgrading to sport shocks, springs, and sway bars can significantly reduce body roll and enhance cornering stability. A well-tuned suspension transforms the driving experience, making it more engaging and responsive.

Performance Chips and Modules

Performance chips and modules offer an accessible way to increase power and efficiency. These devices modify the factory settings, allowing for increased boost pressure in forced induction setups or altered fuel delivery. This simple installation can yield impressive results without extensive modifications.

Forced Induction

Adding a supercharger or turbocharger can dramatically increase power output. These systems force more air into the combustion chamber, leading to a substantial increase in horsepower. However, it’s essential to support these upgrades with corresponding enhancements to fuel delivery and cooling systems to ensure longevity and reliability.

By carefully selecting and implementing these enhancements, enthusiasts can create a more dynamic and powerful vehicle, tailored to their specific driving needs and preferences. Each upgrade should be approached with a focus on balance and integration, ensuring that performance is enhanced without sacrificing reliability.

Electrical System Troubleshooting Tips

Tackling issues within the electrical framework of a vehicle can be a daunting task. However, understanding common problems and employing systematic approaches can significantly simplify the process. This section provides valuable insights and strategies to diagnose and resolve electrical malfunctions effectively.

Common Symptoms of Electrical Issues

- Flickering lights

- Unresponsive dashboard indicators

- Difficulty starting the vehicle

- Unusual noises when activating electrical components

- Inconsistent power delivery

Troubleshooting Steps

- Check the battery condition. Ensure terminals are clean and securely connected.

- Examine fuses for any signs of damage or failure. Replace as necessary.

- Inspect wiring for frays, corrosion, or loose connections.

- Use a multimeter to test voltage and continuity across circuits.

- Consult wiring diagrams to understand the layout and identify potential issues.

By following these steps, one can systematically identify and rectify electrical system challenges, ensuring a smooth and reliable operation of the vehicle.

Preventive Measures for Engine Longevity

Maintaining the durability and performance of a power unit requires a proactive approach. Implementing preventive strategies can significantly extend its lifespan and enhance its reliability. By focusing on regular maintenance, proper usage, and timely interventions, owners can ensure optimal functioning and reduce the likelihood of unexpected failures.

Regular Maintenance Practices

- Conduct routine inspections to identify wear and tear early.

- Change lubricants and filters according to the recommended intervals.

- Check and adjust fluid levels regularly to prevent overheating.

- Examine belts and hoses for signs of cracking or fraying.

Driving Habits and Usage

- Avoid rapid acceleration and hard braking to minimize stress.

- Warm up the unit before heavy use, especially in cold weather.

- Maintain a consistent speed during operation to reduce wear.

- Limit short trips that may not allow for optimal temperature levels.

By adhering to these preventive measures, owners can foster a more resilient performance, ultimately leading to a more satisfying experience over the lifespan of the vehicle.