Understanding the intricacies of modern power units is essential for both enthusiasts and professionals in the automotive realm. This segment delves into the vital aspects of maintaining and rejuvenating these complex systems, ensuring they perform at their best for years to come.

Within this guide, readers will uncover a wealth of information designed to assist in the meticulous examination and enhancement of these mechanical marvels. From common issues to advanced troubleshooting techniques, each section provides insights that empower individuals to take charge of their vehicles’ performance.

Furthermore, practical advice and step-by-step instructions will serve as valuable tools for anyone looking to deepen their knowledge and skills. Whether you are a seasoned technician or a curious novice, this resource aims to equip you with the necessary expertise to navigate the challenges of automotive maintenance with confidence.

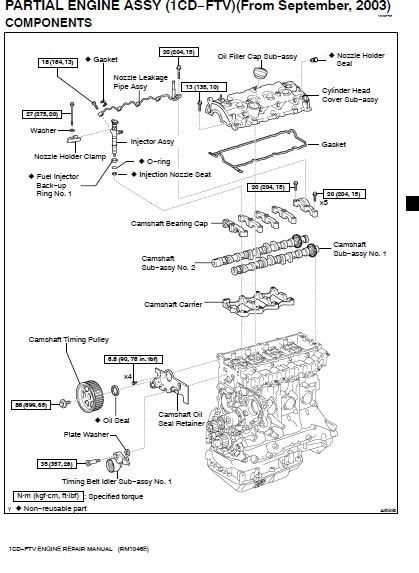

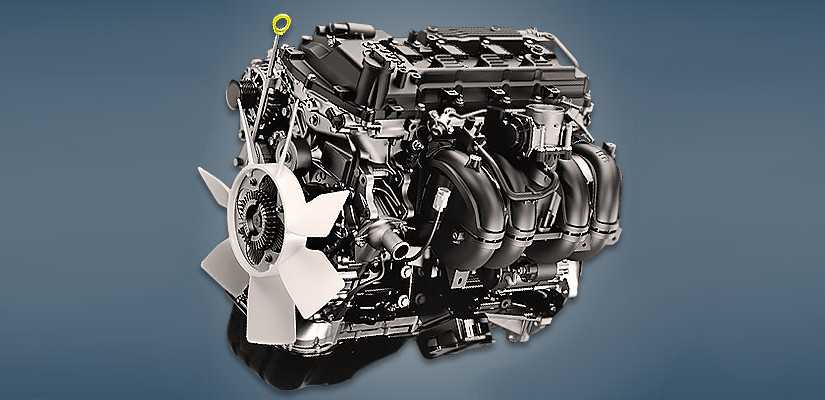

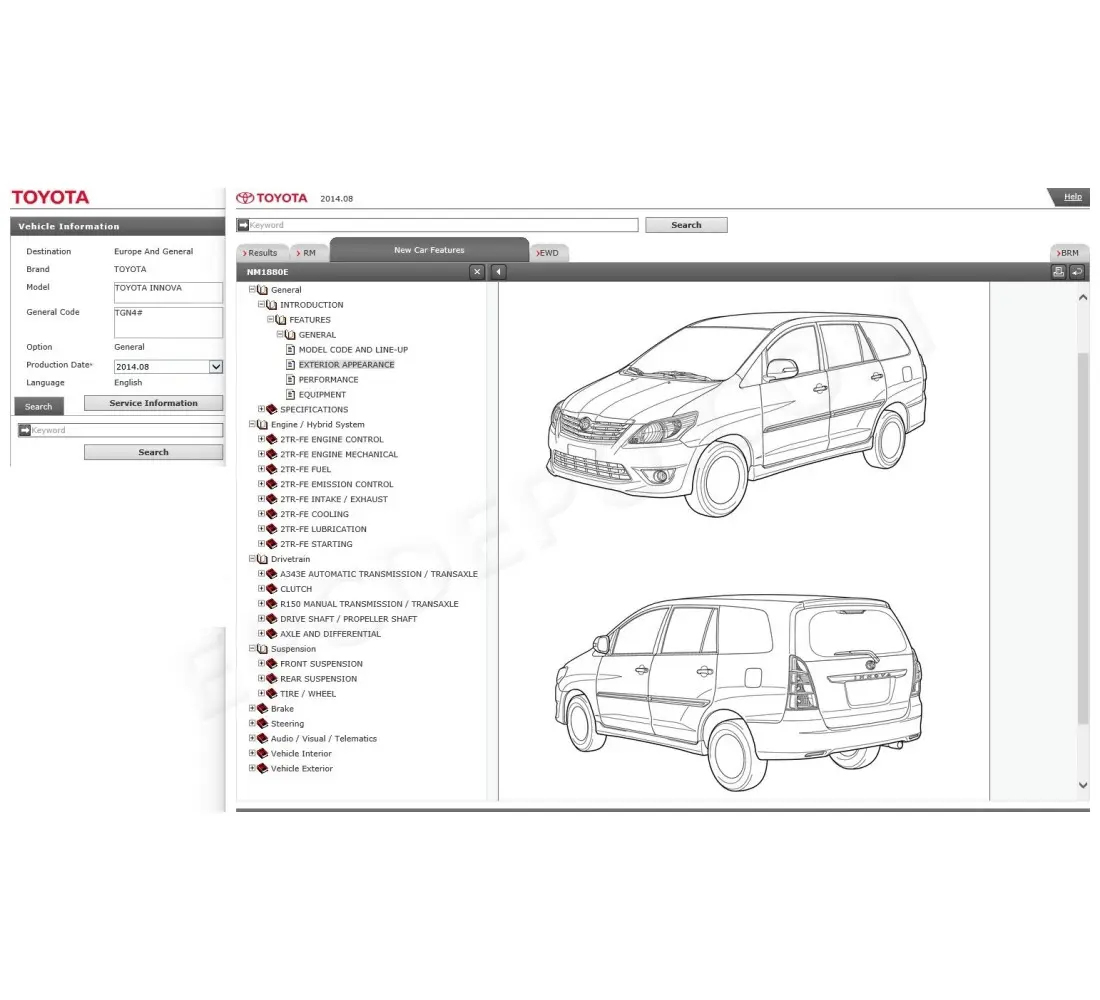

Understanding the 2TR-FE Engine

This section delves into the essential features and characteristics of a specific powertrain configuration known for its reliability and performance. Aimed at providing insights, it highlights the various components and systems that contribute to its functionality, emphasizing its role in modern vehicles.

Key Characteristics

This particular configuration is recognized for its robust construction and efficient fuel management. Designed to deliver a balanced output, it combines power and economy, making it suitable for a variety of applications. The engineering behind it ensures longevity and reduced maintenance needs, appealing to both manufacturers and end-users.

Components and Systems

Understanding the main elements involved is crucial for grasping how this setup operates. Key parts include the intake and exhaust systems, which optimize airflow, as well as the lubrication and cooling mechanisms that maintain optimal operating temperatures. Each component plays a vital role in enhancing overall performance and reliability.

Common Issues with the 2TR-FE

Many users experience a range of challenges with their power units, leading to performance concerns and potential reliability issues. Identifying these common problems can help in maintaining optimal function and longevity.

Oil Consumption: One prevalent issue is excessive oil usage. This may manifest as frequent refills, which could indicate wear in critical components. Regular monitoring can prevent severe damage.

Overheating: Another frequent challenge is overheating. Factors such as a malfunctioning cooling system or blocked passages can contribute to this condition, requiring immediate attention to avoid catastrophic failures.

Noise Levels: Unusual sounds during operation can signal mechanical problems. These noises might stem from worn bearings or timing components, highlighting the need for prompt inspection.

Starting Difficulties: Users often report issues with ignition. Problems may arise from the fuel delivery system or electrical components, leading to frustrating experiences when attempting to start.

Vibration: Excessive vibrations can indicate misalignment or imbalance within the system. Addressing these concerns early can enhance comfort and prevent further complications.

By staying vigilant and addressing these typical issues, owners can ensure a smoother and more reliable experience with their vehicle.

Essential Tools for Engine Repair

Undertaking maintenance on mechanical systems requires a specific set of instruments to ensure precision and efficiency. The right tools not only facilitate the process but also enhance safety and effectiveness. A well-equipped workspace allows for smooth operation and can significantly impact the outcome of your work.

Basic Hand Tools

At the core of any maintenance task are basic hand tools. A wrench set is essential for loosening and tightening fasteners, while screwdrivers in various sizes help tackle different types of screws. Additionally, having pliers on hand allows for better grip and manipulation of small components, making them invaluable for intricate tasks.

Specialized Instruments

Beyond the basics, some specialized instruments can greatly aid in complex jobs. A torque wrench ensures that bolts are tightened to the manufacturer’s specifications, preventing damage due to over-tightening. A multimeter is also crucial for diagnosing electrical issues, allowing for accurate measurement of voltage, current, and resistance. Investing in these tools enhances your ability to perform tasks effectively and reliably.

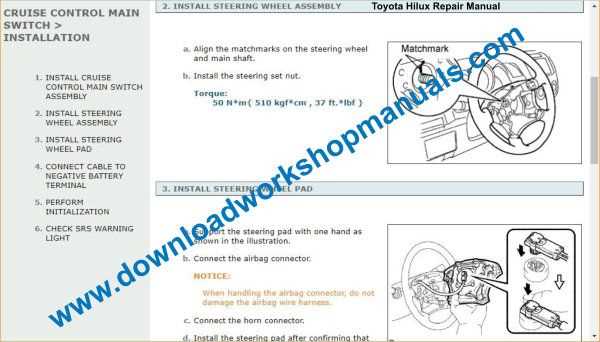

Step-by-Step Disassembly Process

This section outlines a detailed procedure for carefully taking apart a mechanical assembly, ensuring that each component is handled with precision and care. Following these steps will facilitate a smooth reassembly process and help maintain the integrity of all parts involved.

| Step | Description |

|---|---|

| 1 | Begin by ensuring that all necessary tools are at hand. A clean workspace is essential for organizing components as they are removed. |

| 2 | Disconnect any electrical connections and remove fluids as required. This prevents spills and damage to sensitive parts. |

| 3 | Carefully remove any external covers or panels. Take note of fastener types and their locations for easy reference during reassembly. |

| 4 | Proceed to detach the primary components. Use the appropriate techniques to avoid damaging any interlocking parts. |

| 5 | As each piece is removed, label and store them in an organized manner. This will significantly aid in tracking parts and reinstallation. |

| 6 | Inspect each component for wear or damage as it is disassembled. Document any issues for future reference. |

| 7 | Finally, take special care when removing intricate parts. Use tools designed for precision to prevent accidental breakage. |

Following this systematic approach will ensure that the disassembly process is efficient and minimizes the risk of errors, ultimately leading to a successful restoration.

Diagnosing Engine Problems

Identifying issues in mechanical systems is crucial for maintaining optimal performance. A systematic approach allows for effective troubleshooting and resolution of faults that may arise during operation. Recognizing the signs and understanding the underlying causes can lead to timely interventions and prevent further complications.

When diagnosing performance-related issues, consider the following steps:

- Visual Inspection: Examine the unit for obvious signs of wear, leaks, or damage.

- Listen for Unusual Noises: Pay attention to any irregular sounds that may indicate malfunction.

- Check Fluid Levels: Ensure that all necessary fluids are at appropriate levels and free from contamination.

- Monitor Performance: Evaluate the behavior during operation, including acceleration, idle stability, and responsiveness.

Utilizing diagnostic tools can enhance the evaluation process:

- OBD-II Scanner: A device that reads trouble codes and provides insights into potential issues.

- Pressure Gauge: Helps assess pressure levels in various systems to identify abnormalities.

- Multimeter: Measures electrical parameters, crucial for diagnosing electrical-related problems.

Lastly, documentation of symptoms and findings plays a vital role in establishing a clear picture of the situation. By systematically addressing each aspect, one can efficiently pinpoint the root cause and formulate a plan for resolution.

Parts Replacement Guidelines

This section provides essential recommendations for the process of substituting components in mechanical assemblies. Understanding the proper procedures is crucial for maintaining performance and ensuring longevity.

Assessment: Before beginning any replacement, thoroughly assess the condition of the parts. Look for signs of wear, damage, or any irregularities that may affect functionality. A comprehensive evaluation helps determine whether a component needs immediate attention or can be serviced later.

Selection: Choose high-quality replacements that meet the specifications required for compatibility. Using parts from reputable manufacturers ensures reliability and performance. Always refer to the specifications to verify the correct dimensions and materials.

Installation: When installing new components, follow a systematic approach. Ensure all necessary tools are at hand and work in a clean environment to prevent contamination. Follow the manufacturer’s guidelines for torque settings and alignment to avoid future issues.

Testing: After the replacement process, conduct thorough testing to confirm that the new parts function correctly. Monitor for unusual noises or performance issues, as these may indicate improper installation or defective components.

Documentation: Keep detailed records of all replacements performed. Documenting each change aids in tracking the maintenance history and can be invaluable for future diagnostics or servicing.

By adhering to these guidelines, one can ensure effective and efficient component substitution, leading to optimal performance and enhanced durability.

Reassembly Techniques for Longevity

Effective reassembly is crucial for ensuring the durability and optimal performance of mechanical systems. This process not only involves the careful placement of components but also emphasizes the importance of attention to detail and adherence to best practices. By implementing specific techniques, one can significantly enhance the lifespan of the entire assembly.

Prioritize Cleanliness: Before beginning the reassembly, ensure that all parts are thoroughly cleaned. Residual dirt and contaminants can lead to premature wear or malfunction. Use appropriate solvents and tools to remove any debris, grease, or old lubricants.

Use Quality Fasteners: Always opt for high-grade fasteners that meet the necessary specifications. Utilizing subpar or worn-out bolts and nuts can compromise structural integrity. Additionally, consider using locking mechanisms to prevent loosening over time.

Apply Correct Torque Settings: During the fastening process, adhere to the specified torque settings. Over-tightening can lead to material deformation, while under-tightening may result in insufficient clamping force. Utilize a calibrated torque wrench to ensure precision.

Incorporate Lubrication Wisely: Proper lubrication is vital for reducing friction and wear. Select suitable lubricants for each application and apply them evenly. Avoid excessive amounts, as this can attract dirt and create sludge.

Inspect Components: Before reassembly, conduct a thorough inspection of all components for signs of wear or damage. Replace any parts that do not meet quality standards, as even minor imperfections can lead to larger issues in the future.

Follow Manufacturer Guidelines: Always refer to the manufacturer’s specifications and recommendations throughout the reassembly process. These guidelines provide critical insights into the proper methods and tolerances required for successful assembly.

By applying these techniques, one can ensure that the system not only functions optimally but also enjoys a prolonged lifespan, ultimately resulting in improved performance and reduced maintenance costs.

Maintaining Engine Performance Post-Repair

Ensuring optimal functionality after maintenance involves a series of strategic practices that enhance longevity and efficiency. Following an overhaul or significant adjustments, it’s crucial to implement a routine that supports peak operation. This encompasses not only regular inspections but also a comprehensive understanding of how various components interact with one another.

Regular Inspections

Conducting periodic evaluations can identify potential issues before they escalate. Check fluid levels consistently and monitor for any unusual sounds or vibrations that could indicate underlying problems. Staying proactive allows for timely interventions, which can prevent costly breakdowns.

Optimal Operating Conditions

Maintaining ideal conditions is vital for sustained performance. This includes adhering to recommended service intervals and using high-quality fluids. Additionally, ensure that all components are functioning within their designated parameters. A well-maintained system will operate more efficiently, providing better fuel economy and overall reliability.

Safety Precautions During Repairs

When undertaking any mechanical tasks, ensuring safety should be a top priority. Proper precautions not only protect the individual performing the work but also prevent potential damage to the equipment and surroundings. Adhering to recommended guidelines can significantly reduce the risk of accidents and injuries.

Personal Protective Equipment (PPE) is essential. Always wear appropriate gear, such as gloves, safety glasses, and sturdy footwear. These items serve as a barrier against various hazards, including sharp objects, chemicals, and heavy components.

Additionally, maintaining a clean and organized workspace is crucial. Clutter can lead to mishaps, so ensure that tools and materials are stored properly. This practice enhances efficiency and minimizes the likelihood of tripping or misplacing important items.

Ventilation is another critical factor. When working with substances that emit fumes, ensuring adequate airflow can prevent inhalation of harmful chemicals. Always work in a well-ventilated area, or utilize fans and exhaust systems to maintain air quality.

Lastly, being aware of electrical hazards is vital. Before beginning any work, disconnect power sources to avoid electric shocks. Familiarize yourself with the locations of fuses and circuit breakers, and always double-check that the equipment is safe to handle.

By implementing these safety measures, individuals can create a secure environment conducive to effective and worry-free work. Prioritizing safety not only protects you but also enhances the overall success of the task at hand.

Cost Estimation for Repairs

When addressing mechanical issues, understanding the potential expenses involved is crucial for effective budgeting and planning. Accurate cost estimation allows vehicle owners to make informed decisions about the necessary actions to take, whether it involves minor adjustments or extensive overhauls.

Factors influencing costs can vary widely. These may include the specific components that require attention, the availability of parts, and labor rates in different regions. Additionally, the complexity of the task plays a significant role; simpler fixes often require less time and resources compared to more intricate undertakings.

It’s also important to consider additional expenses that may arise during the process. Unexpected complications can lead to increased labor time and the need for extra parts. Therefore, having a buffer in the budget can be beneficial to accommodate any unforeseen circumstances.

Consulting with professionals and obtaining multiple quotes can help in achieving a more accurate financial overview. Many workshops provide estimates that detail the expected costs, which can serve as a useful reference for planning.

Ultimately, a well-prepared budget not only eases the financial burden but also ensures that the vehicle remains in optimal condition for years to come. Being proactive in understanding potential costs can save time, money, and stress in the long run.

Expert Tips for DIY Mechanics

For those who enjoy hands-on projects and tackling mechanical challenges, having a few expert tips can make a significant difference. Whether you are maintaining your vehicle or enhancing its performance, a thoughtful approach can lead to successful outcomes. Here are some valuable insights to elevate your skills and streamline your process.

Preparation and Organization

- Gather all necessary tools and parts before starting to minimize interruptions.

- Create a clean and well-lit workspace to enhance focus and safety.

- Read through relevant guides or documentation to understand the task at hand.

Common Practices for Success

- Always disconnect the battery when working on electrical systems to avoid shocks.

- Label and organize screws and components as you disassemble parts to simplify reassembly.

- Use quality replacement parts and tools to ensure reliability and longevity.

- Take your time and don’t rush; precision often trumps speed.

By incorporating these strategies into your workflow, you can enhance your mechanical abilities and achieve more satisfying results in your projects.