Understanding the intricacies of a specific automotive system can significantly enhance your ability to maintain and restore its functionality. This section delves into the essential aspects of revitalizing a complex mechanical unit, focusing on practical techniques and valuable insights that every enthusiast should know. By familiarizing yourself with the fundamental principles, you can ensure a smoother operation and longevity of the system.

In the upcoming segments, we will explore a variety of procedures aimed at troubleshooting and enhancing performance. With an emphasis on practical tips and detailed steps, you will gain the confidence needed to tackle any challenges that arise during the process. Whether you are a seasoned technician or a passionate hobbyist, this guide aims to equip you with the knowledge necessary for effective maintenance.

By breaking down the tasks into manageable sections, we will facilitate a deeper understanding of how each component interacts within the whole assembly. This approach not only clarifies complex relationships but also highlights critical areas that may require special attention. Prepare to embark on an informative journey that transforms your perspective on automotive care.

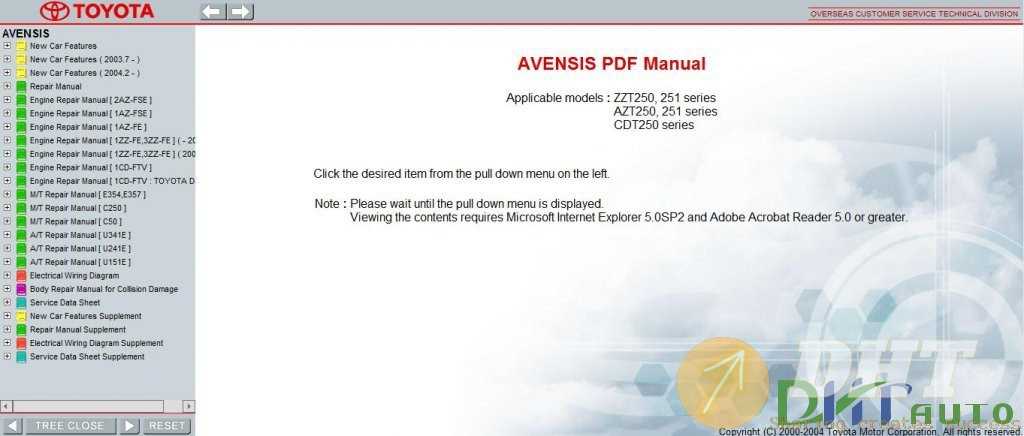

Overview of the 1AZ-FE Engine

This section delves into the characteristics and specifications of a notable power unit that has gained recognition for its efficiency and performance in various vehicles. Understanding its design and functionality can provide valuable insights for enthusiasts and mechanics alike.

Key features include:

- Four-cylinder layout, contributing to a compact size and lightweight structure.

- DOHC (Double Overhead Camshaft) configuration, enhancing airflow and efficiency.

- Displacement of approximately 2.0 liters, striking a balance between power and fuel economy.

In addition to these specifications, this unit is renowned for:

- Robust performance in urban and highway driving scenarios.

- Durability, often leading to a long service life with proper maintenance.

- Compatibility with various models, making it a versatile choice for manufacturers.

Exploring these aspects reveals the significance of this power unit in modern automotive applications.

Common Issues with the 1AZ-FE

This section highlights frequent problems encountered with the 1AZ-FE configuration, focusing on aspects that may lead to performance degradation and operational challenges. Understanding these common faults can aid in proactive maintenance and enhance longevity.

Overheating Concerns

One of the prevalent issues with this setup is overheating, which can stem from various factors. Common causes include:

- Insufficient coolant levels

- Malfunctioning thermostat

- Blocked radiator

- Poor water pump performance

Fuel Delivery Problems

Another area that can cause difficulties involves fuel delivery. Inconsistent fuel supply can result in poor performance, leading to a range of symptoms such as:

- Reduced power output

- Difficulty starting

- Increased fuel consumption

Addressing these issues promptly can significantly improve functionality and ensure a smoother operation.

Essential Tools for Engine Repair

When embarking on a journey of mechanical restoration, having the right instruments at your disposal is crucial for success. A well-equipped workspace not only enhances efficiency but also ensures safety and precision during the process. Understanding which tools are fundamental can make a significant difference in achieving optimal results.

Wrenches are indispensable for loosening and tightening various components. A set that includes both standard and metric sizes is essential, as different fittings require different dimensions. For hard-to-reach areas, consider using ratcheting wrenches for added convenience.

Sockets and ratchets also play a vital role in accessing stubborn fasteners. A comprehensive socket set allows for quick transitions between different sizes, making the task much smoother. Pair these with an extension bar to reach deeper spots with ease.

Furthermore, torque wrenches are critical for ensuring that fasteners are secured to the manufacturer’s specifications. This prevents over-tightening, which can lead to damage, as well as under-tightening, which may result in leaks or failures.

Finally, don’t overlook the importance of screwdrivers in various configurations. A complete set, including both flathead and Phillips types, will allow you to handle diverse tasks effectively.

Step-by-Step Disassembly Guide

This section provides a detailed approach to carefully dismantling a power unit for thorough examination and maintenance. Following this guide will help ensure that all components are handled properly, preventing damage and facilitating reassembly.

Preparation: Before starting the disassembly process, gather all necessary tools and equipment. A clean workspace is essential for organizing parts and avoiding loss.

Step 1: Remove the Covers: Begin by detaching any protective coverings. This may involve unscrewing bolts or unclipping fasteners. Make sure to keep track of all small parts during this phase.

Step 2: Disconnect Accessories: Carefully unplug any attached components such as sensors and wires. Labeling each connection can aid in reassembly, ensuring correct placement of each element.

Step 3: Take Off the Main Assembly: With the accessories removed, proceed to unfasten the primary structure. Use the appropriate tools to avoid stripping screws or damaging threads.

Step 4: Inspect and Clean: As each section is taken apart, inspect it for wear or damage. Cleaning surfaces can prevent contamination during reassembly and enhance performance.

Final Note: Document each step with notes or photographs. This record will serve as a valuable reference during reassembly, ensuring accuracy and efficiency.

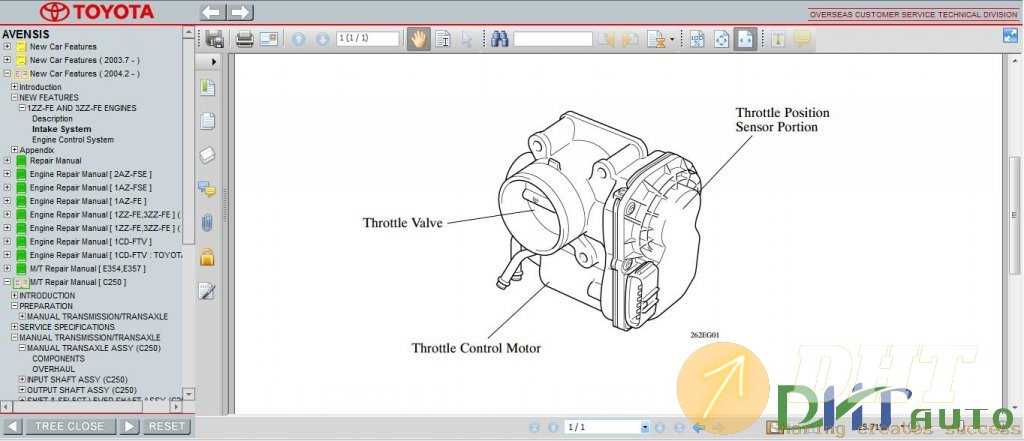

Understanding Engine Components and Parts

The intricate design of a vehicle’s power unit is vital for its performance and reliability. Each element plays a specific role, contributing to the overall functionality and efficiency. Familiarity with these components allows for better insights into maintenance and enhancement of the system.

Key Elements of the Power Unit

Central to the operation are the various parts that work in harmony. These include the block, where the main structure resides, along with pistons that move within cylinders to generate force. The connecting rods serve as crucial links, transferring motion to the crankshaft, which ultimately powers the vehicle.

Supporting Systems

In addition to the primary components, auxiliary systems play significant roles. The intake and exhaust assemblies regulate airflow, ensuring optimal combustion. The cooling system, essential for maintaining operational temperatures, prevents overheating and enhances durability. Understanding these supporting elements is crucial for anyone looking to delve deeper into automotive mechanics.

Tips for Replacing Engine Gaskets

When undertaking the task of swapping out sealing elements, it’s essential to approach the process with care and precision. Proper installation is crucial to ensure optimal performance and prevent leaks that can lead to significant issues down the line.

1. Prepare the Workspace

Before starting, clear the area and gather all necessary tools and materials. A clean and organized workspace reduces the risk of losing parts and helps maintain focus on the task at hand.

2. Clean Surfaces Thoroughly

Ensure that all surfaces are free of debris, old sealant, and any residual material. Using a scraper or a suitable solvent can help achieve a smooth, clean finish, which is vital for a proper seal.

3. Use Quality Replacement Parts

Select high-quality gaskets that meet or exceed original specifications. Using subpar materials can lead to premature failure and necessitate repeated work.

4. Follow Proper Torque Specifications

When reassembling, adhere strictly to the recommended torque settings. Over-tightening or under-tightening can compromise the integrity of the seals, leading to leaks or damage.

5. Allow for Proper Curing Time

If a sealant is used, give it sufficient time to cure as per the manufacturer’s instructions. Rushing this step can lead to inadequate bonding and potential leaks.

6. Inspect for Other Issues

While performing the swap, take the opportunity to inspect other components for wear or damage. Addressing these problems during the process can save time and effort in the future.

Inspecting and Rebuilding Cylinder Heads

The process of examining and restoring the upper sections of combustion units is crucial for maintaining optimal performance. A thorough assessment helps identify any damage or wear, ensuring that all components function harmoniously. This segment will guide you through essential steps for inspection and the rebuilding process.

Start by removing the cylinder head from the block carefully. Clean the surface thoroughly to eliminate any debris or old sealing material. This ensures a precise fit when reassembling. Next, check for cracks, warping, or other imperfections using a straightedge and feeler gauge. Pay attention to the valve seats and guides, as these areas are prone to wear.

Once inspection is complete, it’s time to rebuild. Ensure all components, such as valves and springs, are within specifications. Replace any damaged parts to maintain integrity. Reassembly should be done methodically, following the recommended torque specifications to secure the head properly to the block.

| Step | Description |

|---|---|

| 1 | Remove the cylinder head with care. |

| 2 | Clean surfaces thoroughly. |

| 3 | Inspect for cracks and warping. |

| 4 | Check valve seats and guides. |

| 5 | Replace damaged components. |

| 6 | Reassemble with proper torque specifications. |

By adhering to these procedures, you can ensure that the upper sections of your combustion units are in excellent condition, ready for optimal functionality once reinstalled.

Importance of Timing Belt Replacement

Replacing the timing belt is a crucial aspect of maintaining a vehicle’s functionality. This component plays a vital role in synchronizing key parts, ensuring optimal performance and longevity. Neglecting its upkeep can lead to significant issues, including costly repairs and decreased efficiency.

Consequences of Delayed Replacement

- Potential Engine Damage: A worn or broken belt can result in severe internal damage.

- Performance Decline: Inconsistent timing can lead to reduced power and responsiveness.

- Increased Repair Costs: Addressing problems caused by a failed belt can be much more expensive than regular maintenance.

Signs of Wear

- Visible Cracks: Inspect the belt for any visible signs of deterioration.

- Noisy Operation: Listen for unusual sounds, which can indicate belt issues.

- Check Engine Light: An illuminated warning light may suggest timing-related problems.

Diagnosing Electrical System Problems

Identifying issues within a vehicle’s power distribution can often be a complex task. It requires a systematic approach to uncover underlying faults that may affect functionality. Proper diagnosis not only saves time but also ensures the longevity of various components.

Begin by inspecting connections and wiring for any visible damage or corrosion. A thorough examination of fuses and relays is essential, as they serve as the first line of defense against electrical failures. Utilizing a multimeter can aid in measuring voltage and continuity, helping to pinpoint areas needing attention.

Next, consider checking the battery health. A weak or faulty battery can lead to intermittent problems, causing components to malfunction sporadically. If necessary, test the alternator to ensure it is providing adequate charge to the system.

Additionally, be aware of any warning lights on the dashboard. These indicators can provide valuable information about the state of the electrical network. Documenting any unusual behavior can greatly assist in the diagnostic process.

By approaching the investigation methodically, you can effectively address and resolve electrical anomalies, restoring optimal performance and reliability.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your vehicle requires consistent care and attention. Regular upkeep not only enhances performance but also prevents potential issues from developing into significant problems. Adopting a proactive approach to maintenance can lead to a more reliable and efficient experience.

Regular Inspections: Schedule routine checks to monitor key components. This practice helps identify wear and tear early, allowing for timely interventions.

Fluid Levels: Keep an eye on all vital fluids, including oils and coolants. Maintaining optimal levels is essential for smooth operation and heat management.

Filter Changes: Replace air and fuel filters according to the manufacturer’s guidelines. Clean filters promote efficient airflow and fuel delivery, enhancing overall functionality.

Tire Care: Inspect tires regularly for proper inflation and tread depth. Properly maintained tires contribute to safety and fuel efficiency.

Driving Habits: Adopt gentle driving practices. Avoiding harsh acceleration and abrupt stops can significantly reduce stress on various components, leading to improved durability.

Scheduled Servicing: Follow the recommended service intervals for comprehensive check-ups. Professional maintenance ensures that all systems operate optimally and helps prevent unexpected failures.

By implementing these strategies, you can foster a dependable performance and prolong the life of your vehicle.