The intricacies of automotive upkeep require a thorough understanding of the vehicle’s components and systems. This section aims to provide essential insights and instructions for individuals seeking to enhance their knowledge and skills in vehicle maintenance. By focusing on practical advice and techniques, readers will gain the confidence needed to tackle various challenges encountered in everyday usage.

Understanding the fundamental aspects of your vehicle can lead to improved performance and longevity. Whether you are a seasoned enthusiast or a newcomer, having access to reliable information is crucial. This guide will explore various aspects, from troubleshooting common issues to conducting routine inspections, ensuring that your vehicle remains in optimal condition.

Equipping yourself with the right knowledge not only saves time and resources but also empowers you to make informed decisions regarding your automobile. By following the detailed processes outlined here, you can take proactive steps toward maintaining your vehicle effectively. Embrace the opportunity to learn and apply these techniques for a smoother and more enjoyable driving experience.

Essential Tools for Vehicle Maintenance

Maintaining a vehicle requires a set of essential instruments that ensure efficient upkeep and functionality. Having the right tools on hand not only simplifies the process but also enhances the overall experience of caring for your automobile. This section will discuss various items that are indispensable for routine maintenance and troubleshooting.

Basic Hand Tools

- Wrenches: Various sizes to accommodate different fasteners.

- Screwdrivers: Flathead and Phillips types for a range of applications.

- Plier Set: Useful for gripping, twisting, and cutting.

Specialized Equipment

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Oil Filter Wrench: Facilitates easy removal of oil filters during changes.

- Multimeter: Essential for electrical system diagnostics and repairs.

Having these fundamental tools at your disposal will significantly improve your ability to perform maintenance tasks effectively and efficiently.

Common Issues with the 99 Dodge Ram

Owners of this particular vehicle model often encounter a range of frequent challenges that may impact performance and reliability. Understanding these common problems can help in troubleshooting and maintenance, ensuring a smoother driving experience.

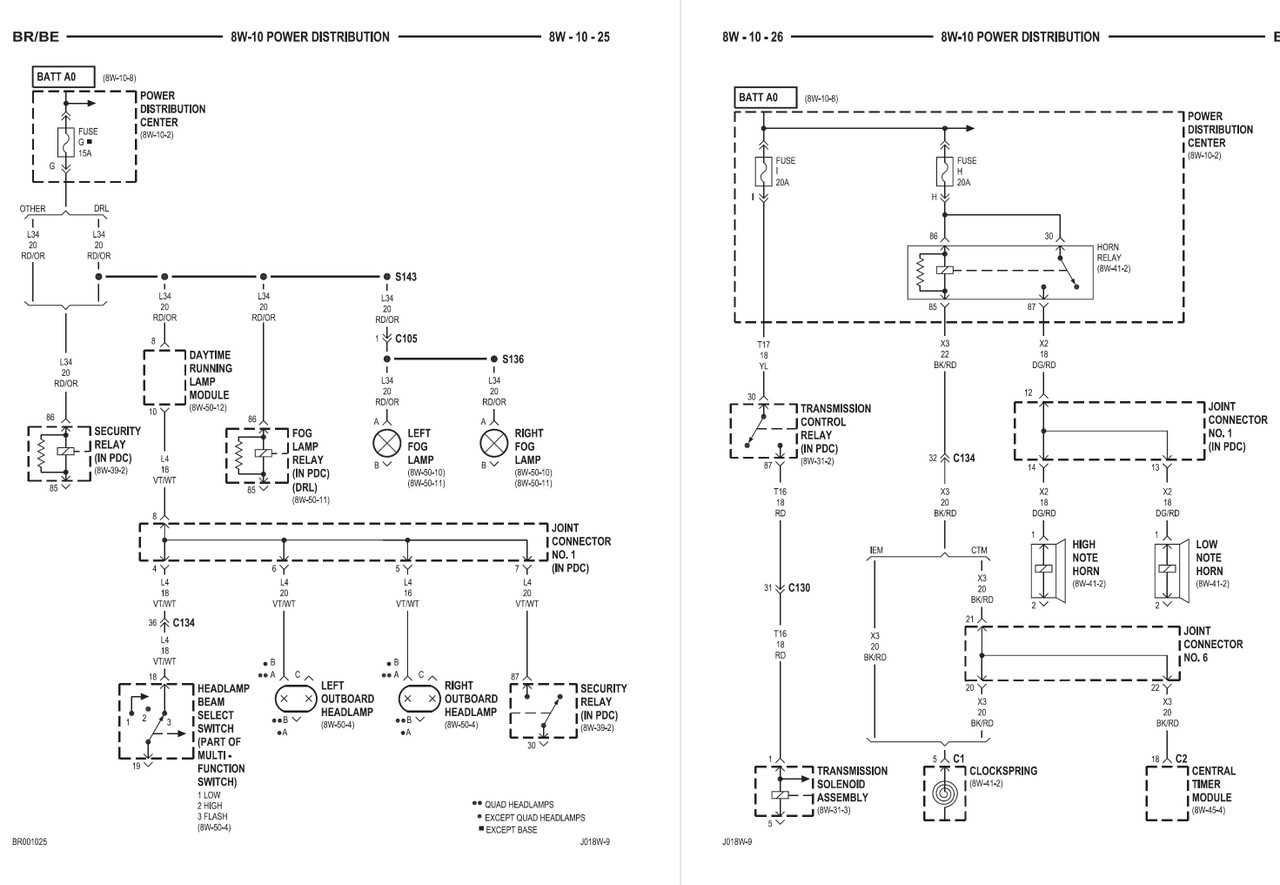

One prevalent issue involves the electrical system, where users report inconsistent functionality of lights and dashboard indicators. This can stem from faulty wiring or worn-out components that require attention.

Another common concern is related to the engine’s cooling system. Overheating can occur due to a malfunctioning thermostat or radiator, leading to potential damage if not addressed promptly. Regular checks can help prevent severe complications.

Lastly, suspension problems are frequently noted, particularly in relation to the vehicle’s handling and comfort. Worn-out shocks or struts may cause a bumpy ride, necessitating timely replacements to restore proper function.

Step-by-Step Repair Procedures

This section outlines a comprehensive approach to addressing various issues that may arise in your vehicle. By following a structured series of actions, you can effectively troubleshoot and resolve common problems, ensuring optimal performance and longevity.

Preparation for the Process

Before beginning any work, it’s crucial to gather the necessary tools and materials. Ensure your workspace is clean and organized, allowing for efficient access to all required items. Familiarize yourself with the vehicle’s layout and components to facilitate a smoother procedure.

Executing the Steps

Follow the outlined steps methodically to achieve the desired outcome. Begin with diagnostics, then proceed to disassemble parts as needed, making sure to document each stage for reference during reassembly. Always prioritize safety and accuracy.

| Step | Description | Tools Needed |

|---|---|---|

| 1 | Identify the issue through visual inspection and testing. | Multimeter, Flashlight |

| 2 | Gather the necessary tools and replacement parts. | Tool Kit, Replacement Components |

| 3 | Carefully disassemble the affected area, noting the order of components. | Screwdrivers, Wrenches |

| 4 | Replace any faulty parts with new ones. | Replacement Parts, Lubricant |

| 5 | Reassemble the components in reverse order, ensuring everything is secure. | Tool Kit |

| 6 | Test the system to confirm that the issue has been resolved. | Diagnostic Tools |

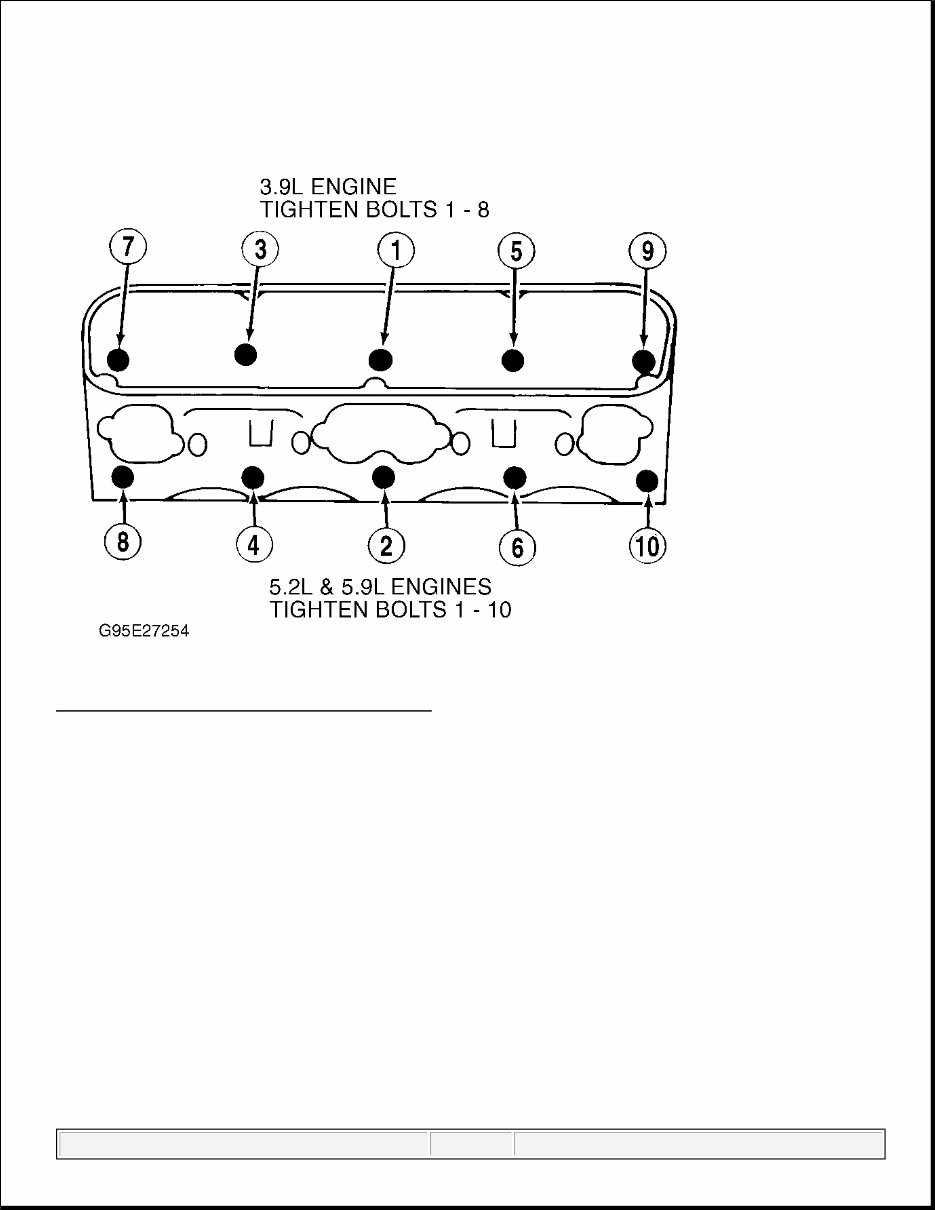

Understanding Engine Components and Functions

Engines are intricate systems designed to convert fuel into motion. Each component plays a crucial role in ensuring optimal performance and efficiency. By familiarizing oneself with these parts, one can better appreciate their functions and the overall operation of the power unit.

Key components of an engine include:

- Cylinder: The space where fuel and air mix and ignite.

- Piston: Moves within the cylinder to create mechanical energy.

- Crankshaft: Converts linear motion of the piston into rotational motion.

- Camshaft: Regulates the timing of the valve openings and closings.

- Valves: Control the intake of air and fuel as well as the exhaust of gases.

- Ignition System: Initiates combustion within the cylinder.

Each of these elements works in harmony to facilitate the engine’s operation. Understanding their specific roles can aid in diagnosing issues and ensuring proper maintenance.

Overall, grasping the functions of engine components allows for a more informed approach to vehicle care and performance enhancement.

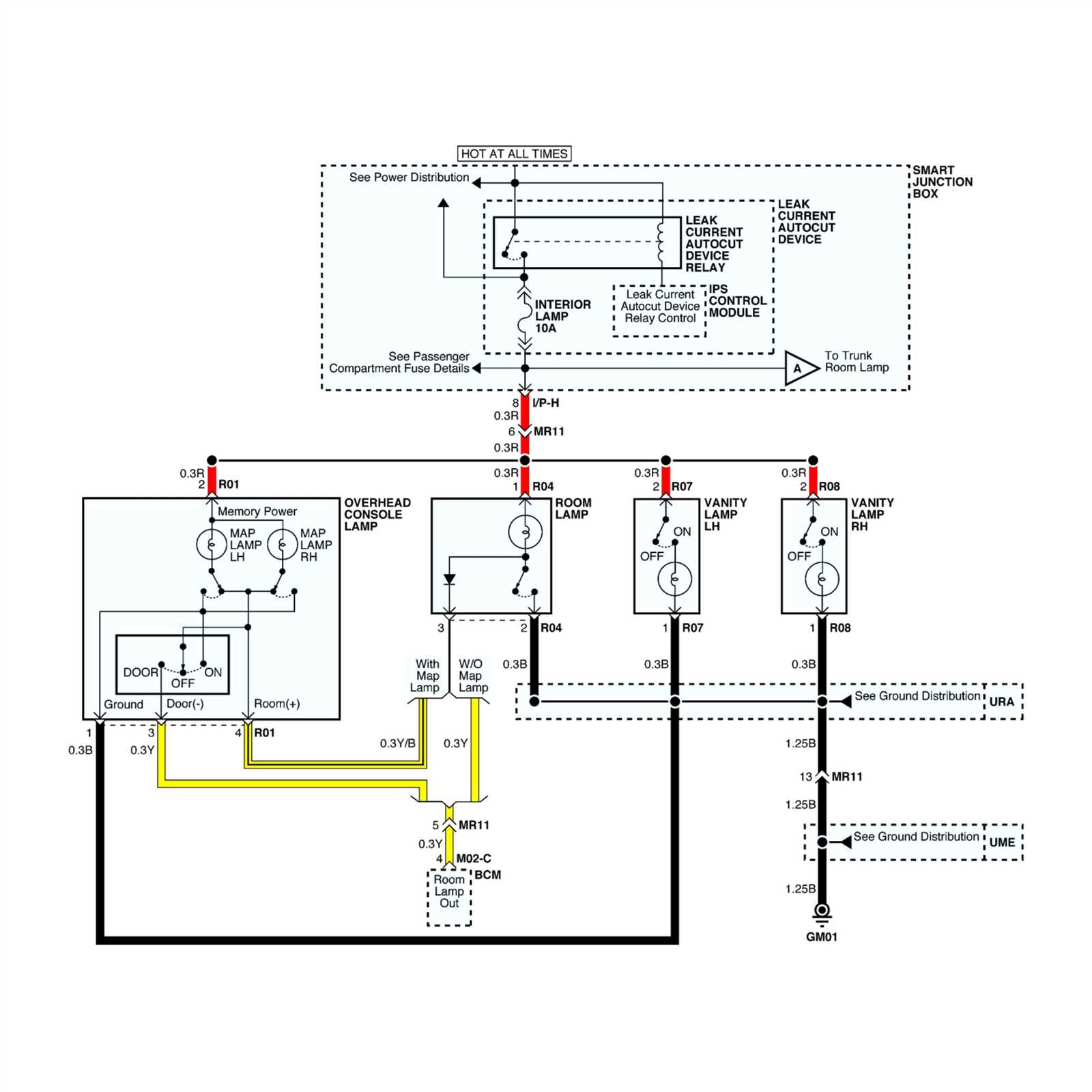

Electrical System Troubleshooting Guide

This section provides a comprehensive approach to diagnosing issues related to the electrical components of your vehicle. Understanding how to systematically evaluate the electrical system can help identify problems efficiently, ensuring reliable operation and preventing further complications.

When experiencing electrical malfunctions, follow these steps:

| Step | Description |

|---|---|

| 1 | Check the battery for proper voltage and connections. |

| 2 | Inspect fuses for any signs of damage or failure. |

| 3 | Examine wiring for corrosion, breaks, or loose connections. |

| 4 | Test switches and relays to ensure they are functioning correctly. |

| 5 | Utilize a multimeter to verify circuit continuity and voltage levels. |

By following these steps, you can effectively troubleshoot and resolve electrical issues, leading to improved performance and safety.

Transmission Care and Maintenance Tips

Proper upkeep of your vehicle’s gear system is crucial for ensuring longevity and optimal performance. Regular attention to this component can prevent costly repairs and enhance the overall driving experience.

To begin with, it is essential to regularly check the fluid levels, as low or dirty fluid can lead to inefficiencies and potential damage. Ensure that the fluid is replaced according to the manufacturer’s recommendations to maintain smooth operation.

Additionally, pay attention to any unusual noises or shifting patterns while driving. These signs can indicate underlying issues that may require immediate attention. Promptly addressing such symptoms can help avoid more severe complications.

Lastly, consider professional inspections at regular intervals. A trained technician can provide valuable insights and perform necessary adjustments, ensuring that the transmission remains in peak condition.

Brake System Inspection Techniques

Regular evaluation of the braking mechanism is essential for ensuring vehicle safety and optimal performance. Effective assessment involves identifying wear patterns, evaluating component functionality, and recognizing potential issues before they escalate. Implementing systematic inspection methods allows for timely interventions, prolonging the lifespan of the braking system.

Visual Examination

Begin with a thorough visual assessment of the brake components. Inspect pads for signs of wear, such as uneven thickness or scoring on the surface. Check rotors for cracks, discoloration, or grooves, which can indicate overheating or excessive use. Look for leaks in hydraulic lines and ensure that all fittings are secure.

Functional Testing

After the visual inspection, conduct functional tests to gauge performance. Press the brake pedal to feel for firmness and responsiveness. Listen for unusual noises during application, which could suggest problems with calipers or pads. Additionally, evaluate the vehicle’s stopping distance to confirm that the system is operating within acceptable limits.

Suspension and Steering Adjustments

Proper alignment and calibration of the suspension and steering components are crucial for maintaining vehicle stability and handling. Regular adjustments ensure that the vehicle responds accurately to driver input and enhances overall safety during operation.

Key Components to Inspect

- Shock absorbers and struts

- Ball joints and tie rods

- Steering rack and pinion

- Control arms and bushings

Adjustment Procedures

- Start by checking the tire pressure and tread wear to eliminate any variables affecting handling.

- Inspect the alignment angles: camber, caster, and toe settings should meet manufacturer specifications.

- Examine and replace any worn-out components, such as bushings and joints, to prevent misalignment.

- Use a professional alignment machine to achieve precise adjustments.

- Conduct a test drive to ensure that the steering feels responsive and the vehicle tracks straight.

Regular Maintenance Schedule Recommendations

Maintaining your vehicle in optimal condition is essential for ensuring longevity and reliable performance. A structured schedule for routine upkeep helps in identifying potential issues early and preserving the functionality of various systems.

Key Maintenance Tasks

Regular checks on vital components such as the engine oil, coolant levels, and brake fluid are crucial. Additionally, tire rotation and pressure monitoring should be part of your routine to enhance safety and performance. Following the manufacturer’s guidelines regarding service intervals can prevent unexpected breakdowns.

Seasonal Considerations

Different seasons may require specific attention. For instance, checking the battery health before winter and ensuring the air conditioning system is functioning well before summer can make a significant difference in your driving experience. Adhering to these seasonal checks is a proactive approach to vehicle maintenance.

Safety Protocols for Repair Work

Ensuring a safe working environment is crucial when performing maintenance tasks on any vehicle. Adhering to established safety measures not only protects the individual but also extends the lifespan of the equipment. This section outlines essential guidelines that should be followed to minimize risks during service procedures.

Prior to commencing any maintenance activity, it is important to gather the necessary tools and materials. Proper organization can significantly reduce the likelihood of accidents. Additionally, understanding the vehicle’s components and systems is vital for effective and safe handling.

| Safety Measure | Description |

|---|---|

| Personal Protective Equipment | Wear appropriate gear such as gloves, goggles, and masks to protect against injuries and exposure to harmful substances. |

| Workspace Organization | Keep the workspace tidy and free from clutter to prevent slips and falls. |

| Tool Inspection | Regularly check tools for damage or wear to ensure they are safe to use. |

| Proper Lifting Techniques | Utilize correct body mechanics to avoid strain or injury when lifting heavy components. |

| Emergency Preparedness | Have a first-aid kit and emergency contact information readily available in case of accidents. |

By following these guidelines, individuals can contribute to a safer working environment, ultimately leading to more efficient and successful maintenance operations.