Understanding the intricacies of vehicle maintenance is crucial for every car owner. This section provides an in-depth look into the essential information and guidelines that facilitate the upkeep and functionality of your vehicle. By following these instructions, you can ensure that your automobile remains in optimal condition, enhancing both safety and performance.

With a wealth of knowledge at your fingertips, you’ll be equipped to tackle various tasks with confidence. Whether you’re seeking to perform routine checks or address specific issues, this resource serves as a valuable companion. Comprehending the details outlined here will empower you to make informed decisions, ultimately prolonging the life of your vehicle.

In addition to maintenance tips, this guide emphasizes the importance of understanding your vehicle’s components and their roles. Familiarizing yourself with these aspects can significantly impact your ability to identify problems early, saving you time and money in the long run. Embrace the opportunity to deepen your automotive knowledge and enhance your driving experience.

Dodge Factory Repair Manual Overview

The comprehensive guide provides essential insights for maintaining and understanding vehicle functionality. This resource includes detailed descriptions and step-by-step guidance to address various technical aspects, empowering users to approach tasks with precision and confidence.

Purpose and Benefits

This handbook is crafted to assist users in preserving their vehicle’s performance by offering organized, precise instructions for each section of the car’s systems. Through this reference, one gains knowledge of specific processes, enabling effective troubleshooting and preventive care.

Contents and Organization

Structured to ensure clarity, the guide presents content through detailed sections that cover topics from basic upkeep to advanced technical procedures. Each chapter builds on practical techniques, ensuring a thorough understanding of how components function and interact, ultimately extending vehicle longevity.

Key Features of the Manual

This guide provides comprehensive insights into the essential tools and instructions for maintaining and understanding your vehicle’s key systems. With detailed illustrations and step-by-step directions, it serves as a valuable reference for ensuring smooth operation and troubleshooting common issues.

Step-by-Step Procedures

The guide offers clear, concise procedures for performing a wide range of tasks. Whether handling basic maintenance or tackling more complex system adjustments, each process is presented with structured instructions that help users achieve effective results independently.

Detailed System Descriptions

Each section of the guide includes in-depth explanations of individual systems, outlining their components and operational principles. These sections offer valuable context, making it easier to identify parts, understand functionality, and resolve potential issues confidently.

Importance of Regular Maintenance

Consistent upkeep is crucial to ensuring that a vehicle remains reliable, safe, and efficient over time. Periodic inspections and adjustments help identify potential issues before they escalate into costly repairs, extending the lifespan of the vehicle and enhancing its overall performance.

Key Benefits of Routine Upkeep

Regular maintenance offers numerous advantages. First, it promotes fuel efficiency, which reduces overall costs and supports a smoother ride. Additionally, it minimizes the risk of unexpected breakdowns, keeping travel plans uninterrupted and stress-free. Staying proactive with upkeep also contributes to safer driving conditions by maintaining essential functions and systems.

Recommended Service Intervals

Scheduling routine service can vary depending on the vehicle’s age, driving conditions, and mileage. Below is a table highlighting typical maintenance checkpoints and their suggested frequencies to assist in planning:

| Maintenance Task | Suggested Frequency | |

|---|---|---|

| Oil and Filter Change | Every 5,000 to 7,500 miles | |

| Tire Rotation and Alignment | Every 6,000 to 8,000 miles | |

| Brake Inspection | Every 10,000 to 15,000 miles | |

| Fluid Level Check | Monthly | |

| Battery Inspection | Annually |

| Tool | Purpose |

|---|---|

| Wrenches | Tightening and loosening nuts and bolts |

| Screwdrivers | Driving screws in and out |

| Pliers | Gripping and twisting wires |

| Socket Set | Working with various sizes of fasteners |

Power Tools and Equipment

In addition to hand tools, certain power tools can significantly enhance efficiency during repair work. These tools are designed to tackle more demanding tasks that require additional force or precision.

| Power Tool | Application |

|---|---|

| Drill | Creating holes and fastening |

| Impact Wrench | Loosening stubborn fasteners |

| Angle Grinder | Cutting and polishing surfaces |

| Air Compressor | Powering pneumatic tools |

Safety Precautions During Repairs

Ensuring safety is paramount when working on vehicles. Proper precautions not only protect the individual performing the task but also safeguard the vehicle itself from unintended damage. Adhering to established guidelines helps minimize risks associated with maintenance and servicing.

Before starting any work, it is essential to gather the necessary tools and equipment, and to have a clear understanding of the procedures involved. This preparation lays the groundwork for a safe and efficient working environment.

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate gear such as gloves, goggles, and steel-toed boots to protect against injuries. |

| Work Area Organization | Keep the workspace tidy and free from hazards to prevent accidents. |

| Ventilation | Ensure adequate airflow in the area to avoid inhaling harmful fumes from chemicals or fluids. |

| Secure the Vehicle | Always use jack stands or wheel chocks to stabilize the vehicle when elevated to prevent it from rolling or collapsing. |

| Disconnect Battery | Disconnecting the battery before starting work prevents electrical shocks and accidental deployments of components. |

By following these essential safety measures, individuals can work more confidently and effectively while maintaining a focus on their well-being and the integrity of the vehicle.

Parts Replacement and Upgrades

Maintaining and enhancing vehicle performance often involves swapping out components or introducing new features. This process not only boosts efficiency but can also improve the overall driving experience. Whether addressing wear and tear or seeking to elevate capabilities, understanding which parts to replace and how to upgrade is crucial for any vehicle owner.

When considering replacements, it’s essential to evaluate both the compatibility and quality of the components. High-quality parts can provide better longevity and performance, ensuring that the vehicle runs smoothly. Additionally, upgrades may offer enhanced functionality or aesthetic appeal, making the vehicle more enjoyable to operate.

| Component | Replacement Options | Upgrade Possibilities |

|---|---|---|

| Brakes | OEM brake pads and rotors | Performance brake kits |

| Suspension | Stock struts and shocks | Upgraded coilovers or air suspension |

| Exhaust System | Standard exhaust components | Aftermarket performance exhaust |

| Engine | OEM parts for repairs | Performance chips or turbo kits |

Ultimately, successful parts replacement and upgrades depend on thorough research and careful selection. Consulting professionals or using reliable resources can provide valuable insights, ensuring that modifications align with personal preferences and performance goals.

Diagnosing Electrical Problems

Identifying issues within the electrical system of a vehicle can be a complex task that requires a systematic approach. Common symptoms may include malfunctioning lights, failure of components to operate, or unexpected power loss. Proper diagnosis is essential to pinpoint the root cause of these problems effectively.

To begin, conduct a thorough visual inspection of the wiring and connectors. Look for signs of wear, corrosion, or loose connections, as these can lead to intermittent faults. Additionally, checking for blown fuses is a crucial step, as they serve as protective measures against overloads.

Next, utilize a multimeter to measure voltage, current, and resistance at various points in the circuit. This tool is invaluable for determining whether electrical components are receiving the proper amount of power. Pay attention to any discrepancies, as they may indicate faulty wiring or damaged parts.

Furthermore, consider using a scan tool to retrieve diagnostic trouble codes (DTCs) from the vehicle’s onboard computer. These codes can provide valuable insights into specific malfunctions within the electrical system. Follow up by researching the codes to understand their implications and recommended solutions.

Finally, if problems persist, consult technical resources or seek assistance from professionals who have experience in automotive electrical systems. Accurate diagnosis often requires specialized knowledge, and collaborating with experts can expedite the troubleshooting process.

Scheduled Maintenance Intervals

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle. Establishing a systematic approach to maintenance helps in identifying potential issues before they escalate, thereby enhancing safety and efficiency. Adhering to recommended service intervals is crucial for keeping your automobile in prime condition.

Importance of Adhering to Intervals

Following the suggested service timelines not only prolongs the lifespan of your vehicle but also maintains its resale value. Each interval typically includes a variety of checks and services, such as fluid replacements, filter changes, and inspections of vital components. These actions contribute to the overall health of the engine and other critical systems.

Typical Service Schedule

While specific recommendations may vary, many schedules suggest performing basic maintenance every 5,000 to 7,500 miles. Major inspections and replacements, including brake systems and transmission checks, might be recommended every 30,000 to 60,000 miles. It’s advisable to consult the guidelines for tailored recommendations based on your vehicle’s model and usage patterns.

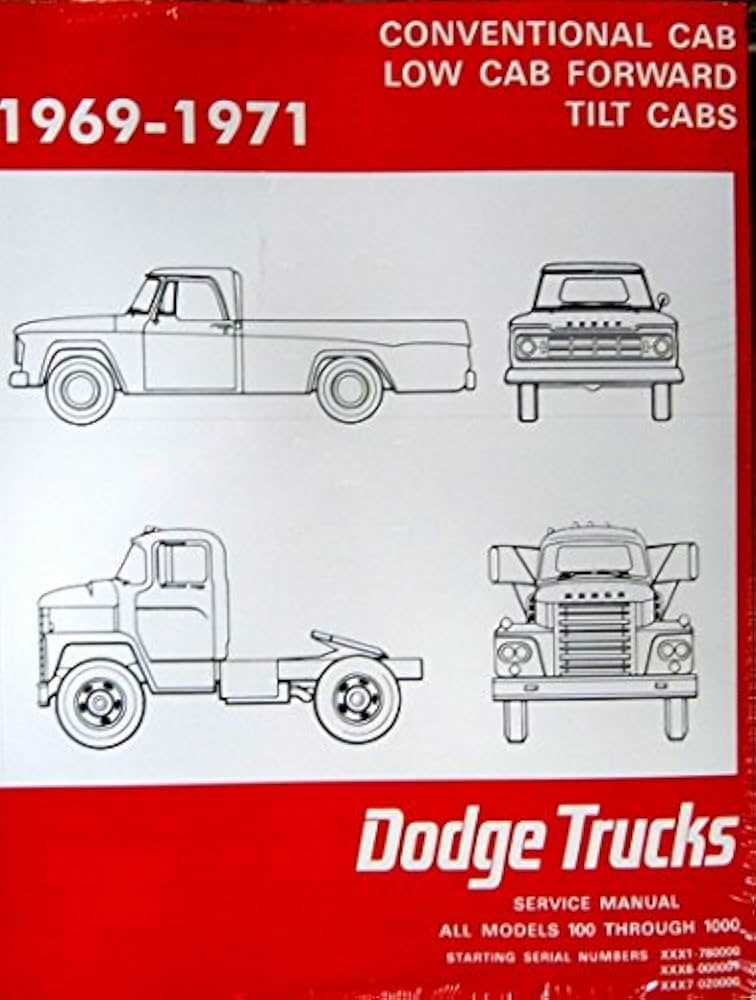

Finding the Right Manual Version

Locating the appropriate guide for your vehicle can significantly enhance your maintenance and repair experience. It’s essential to ensure that the documentation you choose aligns with your specific model and year to avoid confusion and ensure accuracy in the procedures.

Here are some key factors to consider when searching for the correct version:

- Model Specificity: Different models may have unique features or components. Ensure you know the exact model designation.

- Year of Manufacture: Even minor changes can occur between production years, affecting the documentation needed.

- Engine Type: Variations in engine configurations can lead to differences in service requirements.

To assist in your search, follow these steps:

- Check the vehicle identification number (VIN) to gather precise information about your car.

- Visit authorized resources or reputable online platforms that specialize in automotive documentation.

- Consult community forums or groups dedicated to your vehicle type for recommendations and advice.

By focusing on these aspects, you can ensure that you obtain the most relevant and effective guide for your needs, leading to successful and efficient vehicle upkeep.

Resources for Additional Support

When seeking guidance and assistance for vehicle maintenance and troubleshooting, there are various resources available to enhance your knowledge and skills. These tools can help you address common issues effectively and ensure optimal performance.

Consider exploring the following options:

- Online Forums: Communities where enthusiasts share experiences, tips, and solutions.

- Manufacturer Websites: Official sites often provide valuable information, including FAQs and technical bulletins.

- Video Tutorials: Platforms like YouTube host numerous instructional videos demonstrating various procedures.

- Local Workshops: Hands-on training sessions and workshops offered by experienced professionals can provide practical insights.

- Technical Publications: Books and guides available at bookstores or libraries that cover specific topics in detail.

Utilizing these resources can significantly improve your troubleshooting capabilities and enhance your understanding of vehicle systems.