Effective upkeep of lawn machinery is essential for ensuring optimal performance and longevity. Whether you are a seasoned professional or a weekend enthusiast, understanding the nuances of your equipment can make all the difference in maintaining a pristine outdoor space. This section delves into essential practices and troubleshooting techniques that can help you keep your machinery running smoothly.

By familiarizing yourself with the specific components and systems of your equipment, you can address common issues proactively. Knowing when to perform routine checks or make adjustments not only enhances efficiency but also prevents costly repairs in the future. This guide aims to equip you with the knowledge needed to tackle maintenance tasks with confidence.

Furthermore, regular attention to your machinery ensures that it operates at peak efficiency, providing reliable results season after season. The insights provided here will empower you to maximize the capabilities of your equipment, allowing you to focus on what matters most–enjoying your beautifully maintained landscape.

Understanding the John Deere X300 Series

The X300 Series represents a robust line of lawn care equipment designed for versatility and efficiency. These machines are engineered to meet the diverse needs of homeowners, providing reliable performance across various terrains. With their user-friendly features and durable construction, they cater to both novice and experienced users, ensuring a seamless mowing experience.

One of the standout characteristics of this series is its innovative design, which integrates advanced technology for enhanced functionality. This includes efficient cutting systems that deliver a clean finish, along with ergonomic controls that make operation intuitive. Furthermore, the models in this lineup are equipped with powerful engines, ensuring that they can tackle even the most challenging landscaping tasks.

Maintenance is a crucial aspect of ownership, and understanding the care requirements of these machines can significantly extend their lifespan. Regular checks on essential components, coupled with timely servicing, are vital for optimal performance. Owners are encouraged to familiarize themselves with the various systems in place to ensure smooth operation and longevity.

In summary, the X300 Series is a reliable choice for those seeking high-quality lawn maintenance solutions. Its combination of performance, durability, and ease of use makes it a valuable asset for maintaining a pristine outdoor space.

Key Features of the X300 Lawn Tractor

This section highlights the essential attributes that make this lawn care machine a reliable choice for homeowners. Its design focuses on efficiency, comfort, and performance, catering to various gardening needs while ensuring user-friendly operation.

Power and Performance

The powertrain of this lawn tractor combines a robust engine with advanced transmission, providing excellent torque and speed for tackling different terrains. Users can expect smooth operation even in challenging conditions.

Comfort and Ergonomics

Designed with user comfort in mind, the machine features an adjustable seat and intuitive controls, making it easy for operators to navigate and maintain their lawns without fatigue. The layout promotes a seamless mowing experience.

| Feature | Description |

|---|---|

| Engine | Powerful engine for optimal cutting performance. |

| Transmission | Automatic transmission for ease of use. |

| Cutting Deck | Durable cutting deck with adjustable height settings. |

| Ergonomic Design | Comfortable seating and user-friendly controls. |

Common Issues and Troubleshooting Tips

In the realm of lawn maintenance equipment, various challenges can arise that hinder optimal performance. Recognizing and addressing these frequent problems can significantly enhance the longevity and efficiency of your machinery. This section will highlight typical issues encountered and provide practical solutions for effective troubleshooting.

Engine Starting Problems: If the engine refuses to start, first check the fuel level and ensure that fresh gasoline is being used. Additionally, inspect the battery for proper charge and connections. If the battery is functioning well, examine the ignition system, including spark plugs, for wear or damage.

Uneven Cutting: An uneven cutting pattern can be frustrating. Begin by checking the mower blades for sharpness and balance. Dull blades can tear grass rather than cut cleanly. Ensure the cutting height is consistent and that the deck is level, as this can also affect performance.

Overheating: If the engine runs hot, verify that the air filter is clean and unobstructed. A clogged air intake can lead to poor airflow, causing overheating. Additionally, check coolant levels and inspect for any leaks in the cooling system.

Fuel Leaks: Detecting fuel leaks requires a thorough inspection of fuel lines and connections. Any signs of wear or damage should prompt immediate replacement of affected components. Maintaining proper seals and gaskets is essential to prevent further issues.

Electrical Issues: Malfunctions in the electrical system can manifest in various ways, such as lights not functioning or the starter not engaging. Begin troubleshooting by checking all fuses and connections for corrosion or damage. Cleaning terminals and ensuring tight connections can often resolve these issues.

By staying vigilant and conducting regular maintenance, operators can mitigate these common issues effectively, ensuring their equipment remains in peak condition.

Essential Maintenance for Longevity

Proper upkeep is vital for ensuring the extended lifespan of any machinery. Regular attention to key components can significantly enhance performance, reduce downtime, and minimize repair costs. By adopting a proactive approach to maintenance, operators can safeguard their investment and enjoy reliable operation for years to come.

Key Maintenance Practices

- Regular Cleaning: Dirt and debris can accumulate, leading to overheating and reduced efficiency. Schedule routine cleanings to maintain optimal performance.

- Oil Changes: Fresh oil is crucial for smooth operation. Replace oil and oil filters as recommended to ensure proper lubrication.

- Blade Sharpening: Keeping blades sharp improves cutting efficiency. Regularly inspect and sharpen blades to achieve clean results.

- Tire Maintenance: Proper tire pressure affects handling and fuel efficiency. Check and adjust pressure frequently to maintain optimal performance.

Seasonal Checks

- Inspect the battery and electrical systems before the onset of extreme weather.

- Examine belts and hoses for signs of wear and replace as needed.

- Test the cooling system to prevent overheating during peak usage.

- Review the fuel system for leaks or blockages to ensure smooth operation.

Adhering to these essential maintenance practices will promote longevity and enhance the reliability of your equipment. A little effort in upkeep can lead to significant rewards in performance and durability.

Tools Needed for Effective Repairs

Having the right equipment is crucial for performing maintenance and troubleshooting tasks effectively. Whether you are addressing minor adjustments or major overhauls, a well-equipped workspace enhances efficiency and safety. Selecting appropriate tools not only simplifies the process but also helps in achieving high-quality results.

Essential items include various wrenches, screwdrivers, and pliers, which are fundamental for loosening or tightening components. A comprehensive socket set allows for easier access to hard-to-reach fasteners. Additionally, a multimeter is invaluable for diagnosing electrical issues, while a set of replacement parts ensures that you can quickly fix any damaged elements.

Safety gear such as gloves and goggles should never be overlooked. Protecting yourself from potential hazards during the maintenance process is vital. Lastly, organizing tools in a designated area can significantly reduce time spent searching for the necessary equipment, allowing you to focus more on the task at hand.

Step-by-Step Repair Procedures Explained

This section provides a detailed guide for performing maintenance and troubleshooting tasks on your equipment. Following a systematic approach can ensure that each process is carried out efficiently, minimizing downtime and maximizing performance.

1. Preparation: Before beginning any task, gather all necessary tools and parts. This will help streamline the process and reduce interruptions. Ensure the workspace is clean and organized to promote safety.

2. Safety First: Always prioritize safety by wearing appropriate protective gear. Disconnect the power source to prevent accidental activation during servicing.

3. Diagnosis: Identify the issue by observing symptoms and conducting preliminary tests. Take notes on any irregularities that may assist in the troubleshooting process.

4. Disassembly: Carefully remove components as needed. Keep track of screws and parts to ensure a smooth reassembly. Use labels if necessary to avoid confusion later.

5. Inspection: Examine parts for wear, damage, or any abnormalities. Replace any faulty components with new or refurbished ones to restore functionality.

6. Reassembly: Reattach components in the reverse order of disassembly. Ensure that all fasteners are tightened to the manufacturer’s specifications to prevent issues down the line.

7. Testing: Once reassembled, conduct a series of tests to verify that the equipment operates correctly. Monitor for any unusual sounds or movements during operation.

8. Maintenance Tips: Implement routine maintenance checks to extend the lifespan of your machinery. Regularly inspect fluid levels, filters, and belts to prevent future complications.

By adhering to these steps, you can effectively address issues and maintain the optimal performance of your machinery, ensuring it remains in top condition for years to come.

Replacing Blades: A Simple Guide

Maintaining sharp cutting edges is crucial for optimal performance in lawn care equipment. Regularly changing these components not only enhances the efficiency of your machine but also contributes to a healthier lawn. This guide will walk you through the straightforward process of swapping out the cutting elements with ease.

Step 1: Gather Your Tools

Before you start, make sure you have all necessary tools on hand. You will typically need a socket wrench, a pair of gloves for safety, and possibly a block of wood to stabilize the equipment while you work.

Step 2: Safety First

Always prioritize safety. Begin by disconnecting the power source to prevent any accidental starts. If your equipment is battery-operated, remove the battery to ensure complete disconnection.

Step 3: Access the Blades

Lift the deck carefully using the appropriate method for your model. Refer to the manufacturer’s guidelines if you’re unsure how to proceed. Once the deck is elevated, you will have clear access to the blades.

Step 4: Remove the Old Blades

Using your socket wrench, carefully unscrew the bolts that secure the blades. It may help to apply some pressure to prevent the blades from rotating while you work. Once loosened, remove the blades and set them aside.

Step 5: Install New Blades

Position the new cutting edges in place, ensuring they align correctly with the mounting holes. Secure them by tightening the bolts firmly, but be cautious not to overtighten as this may damage the components.

Step 6: Lower the Deck and Test

After replacing the blades, lower the deck back to its original position. Reconnect the power source or reinsert the battery. Finally, test the equipment briefly to ensure everything is functioning smoothly and the blades are cutting effectively.

By following these simple steps, you can keep your cutting equipment in top shape, ensuring a pristine lawn all season long.

Electrical System Diagnostics and Fixes

Diagnosing and resolving issues within the electrical framework of a lawn tractor is essential for maintaining optimal performance. A thorough understanding of the components involved can help identify problems, ensuring the machine operates efficiently. This section provides insights into common electrical malfunctions and practical solutions to restore functionality.

Common Electrical Issues

- Battery Problems: Weak or dead batteries can prevent the engine from starting.

- Faulty Connections: Loose or corroded terminals can disrupt the flow of electricity.

- Blown Fuses: A blown fuse can interrupt power to critical systems.

- Defective Switches: Malfunctioning ignition or safety switches may impede operation.

Diagnostic Steps

- Check the battery voltage using a multimeter to ensure it is within the recommended range.

- Inspect all connections for corrosion or looseness and clean or tighten as necessary.

- Examine fuses for any signs of damage and replace blown fuses with the appropriate ratings.

- Test the functionality of switches to confirm they are operating correctly.

Addressing these common issues can significantly enhance the reliability of the electrical system. Regular maintenance and timely diagnostics are key to preventing future problems and ensuring a smooth operation.

Adjusting the Mower Deck Height

Properly setting the height of the cutting deck is essential for achieving an even and healthy lawn. Adjusting this component allows you to customize the grass length to suit various conditions and personal preferences. Whether you’re looking to maintain a pristine appearance or promote growth, understanding how to modify the deck height is key.

To begin the adjustment process, ensure that the mower is parked on a flat surface. This stability is crucial for accurate measurement and alignment. Next, locate the adjustment mechanism, which is typically found near the wheels or at the base of the deck. Most models offer a simple lever or dial for this purpose.

Once you have accessed the adjustment feature, set the desired height according to your specific needs. It is advisable to consult the manufacturer’s guidelines for optimal cutting heights based on the type of grass being maintained. After making the adjustments, double-check that the deck is level from side to side to ensure a uniform cut.

After completing the setup, perform a test run on a small area of your lawn. This will help you verify that the cutting height is appropriate and adjust if necessary. Regular maintenance of the deck height will not only enhance the appearance of your lawn but also contribute to its overall health.

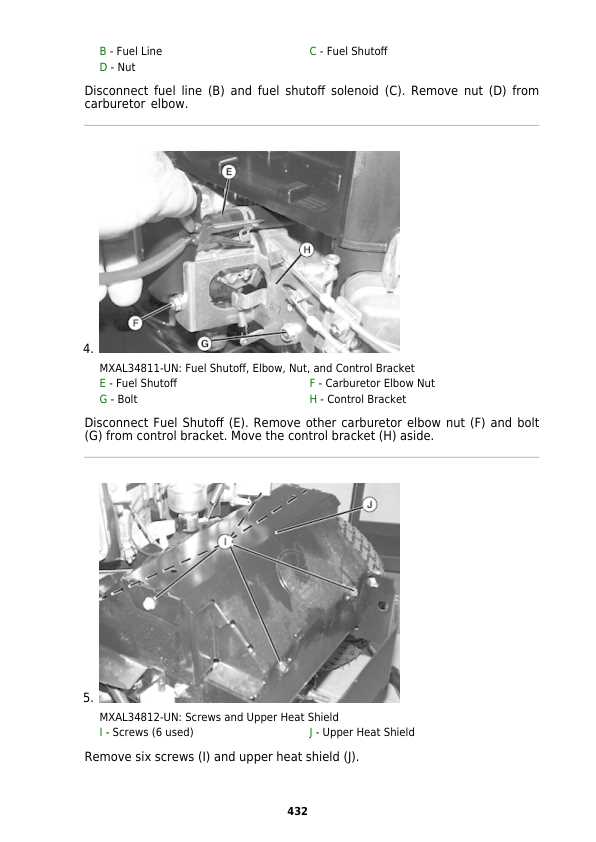

Fuel System Care and Management

Maintaining the efficiency and reliability of the fuel system is crucial for optimal performance. A well-managed fuel system not only ensures smooth operation but also extends the life of the engine. Proper care involves regular checks, cleaning, and the use of high-quality fuels to prevent issues that can arise from neglect.

Regular Inspection

Frequent examination of the fuel system components is essential. Inspect filters for clogs, check fuel lines for leaks, and ensure the tank is clean. Dirty filters can restrict flow, leading to performance issues, while leaks can pose safety hazards. Addressing these concerns promptly can prevent more significant problems down the road.

Quality Fuel and Additives

Using quality fuel is paramount. Premium fuels often contain additives that help prevent deposits and improve combustion efficiency. Additionally, consider periodic use of fuel system cleaners to remove any built-up grime or residues. These measures can enhance performance and fuel efficiency, ensuring that the engine runs smoothly over time.

When to Seek Professional Help

Maintaining your equipment can sometimes become a challenging task, especially when issues arise that are beyond your expertise. Understanding when to call in a professional can save you time, effort, and potentially prevent further damage. Recognizing the limits of your own skills is crucial in ensuring that your machinery remains in optimal condition.

One key indicator that it’s time to seek assistance is when you encounter a problem that persists despite your best efforts. If you’ve attempted basic troubleshooting and the issue continues, a professional can provide a more thorough diagnosis and effective solutions. Additionally, if the repairs require specialized tools or knowledge that you do not possess, enlisting an expert is advisable.

Furthermore, certain situations, such as electrical failures or engine troubles, may pose safety risks. If you feel uncertain about handling these problems, it’s wise to defer to a qualified technician. They not only have the necessary experience but also adhere to safety protocols that can protect you and your equipment.

In conclusion, while self-repair can be rewarding, knowing when to ask for help is essential for maintaining functionality and safety. Trusting professionals with complex issues can ultimately prolong the life of your machinery and ensure optimal performance.

Resources for X300 Owners

For enthusiasts and caretakers of their outdoor machinery, having access to comprehensive support and guidance is essential. A variety of tools and platforms can aid in ensuring optimal performance and longevity of your equipment. This section outlines valuable resources that can assist in maintenance, troubleshooting, and enhancements.

Online Communities and Forums

Engaging with fellow owners through online platforms can provide invaluable insights. Communities dedicated to sharing experiences, tips, and advice can enhance your knowledge and troubleshoot common issues. Websites and social media groups often feature discussions on specific topics, fostering a sense of camaraderie among users.

Manufacturer Resources

Official resources from the manufacturer can offer detailed information on specifications and accessories. Accessing their website can provide downloadable content, including instructional guides and parts catalogs. Additionally, many manufacturers host webinars and workshops aimed at improving the skills of their customers.

Utilizing these resources will empower owners to effectively manage and enhance their equipment, ensuring a seamless experience in their outdoor tasks.