When the chilly season arrives, having reliable machinery becomes essential for tackling the elements. Ensuring that your equipment runs smoothly is crucial for effective snow removal, allowing you to maintain clear pathways and driveways during harsh weather. This guide aims to provide insights into keeping your winter apparatus in optimal condition.

Understanding the inner workings and functionality of your device can make a significant difference in its performance. Regular upkeep not only extends the lifespan of the machine but also enhances efficiency, making your winter tasks less laborious. By familiarizing yourself with maintenance practices, you can confidently face the challenges posed by snow and ice.

In this section, we will explore various techniques and tips that will help you troubleshoot common issues, ensuring that your equipment remains a reliable ally throughout the season. With the right knowledge, you’ll be prepared to handle any situation that arises, keeping your outdoor spaces safe and accessible.

Overview of John Deere 47 Snowblower

The 47-inch clearing device is designed to tackle winter conditions efficiently, making it an essential tool for maintaining clear pathways. With its robust construction and advanced features, it is engineered to deliver optimal performance in snow removal tasks.

This model showcases a powerful engine that ensures reliable operation, even in heavy snowfall. The versatile design allows it to adapt to various terrains, providing users with the flexibility needed for effective outdoor maintenance. Additionally, the intuitive controls enhance user experience, enabling precise handling and maneuverability.

Overall, this equipment stands out for its durability and functionality, making it a valuable asset for homeowners and professionals alike who require dependable snow-clearing solutions.

Common Issues and Symptoms

When dealing with outdoor power equipment, it’s essential to recognize frequent challenges that may arise during operation. Understanding these problems can help in timely troubleshooting and maintenance, ensuring optimal performance throughout the winter season.

| Issue | Symptoms |

|---|---|

| Loss of Power | Difficulty starting, sluggish operation, and reduced throwing distance. |

| Uneven Performance | Inconsistent clearing, strange noises, and vibrations during use. |

| Blockages | Material not being discharged, frequent jams, and increased strain on the engine. |

| Excessive Wear | Visible damage to components, unusual grinding sounds, and decreased efficiency. |

Essential Tools for Repair

When tackling maintenance tasks on your machinery, having the right equipment is crucial for efficiency and effectiveness. Proper tools not only facilitate the process but also enhance safety, ensuring that every component functions optimally.

Basic Hand Tools

Starting with the fundamentals, a set of reliable hand tools is indispensable. This includes wrenches, screwdrivers, and pliers, which are essential for loosening or tightening various parts. Investing in quality items will ensure longevity and performance during demanding tasks.

Specialized Equipment

In addition to standard hand tools, certain specialized instruments may be required for more intricate work. Diagnostic tools help in identifying issues, while replacement components ensure that repairs can be completed efficiently. Having these items on hand can significantly reduce downtime.

Step-by-Step Maintenance Guide

Proper upkeep of your equipment is essential for ensuring optimal performance and longevity. This section provides a detailed process to follow for regular servicing, aimed at keeping your machinery in excellent working condition. Adhering to these guidelines will help you identify potential issues before they become major problems.

Regular Inspection and Cleaning

Begin by examining all accessible components for signs of wear or damage. Ensure to clear away any debris that may have accumulated. Routine cleaning not only improves efficiency but also helps prevent premature wear. Focus on areas where snow and ice might build up, as these can hinder functionality.

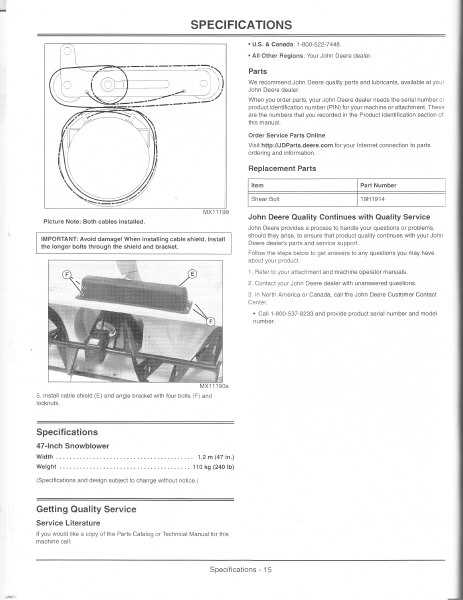

Lubrication and Adjustment

After inspection, it’s crucial to apply the appropriate lubricants to moving parts. This reduces friction and extends the life of your machine. Additionally, make necessary adjustments to belts and cables, ensuring they are tight and in proper alignment. Regular maintenance of these elements is key to achieving smooth operation.

Replacing Worn Parts Effectively

Ensuring optimal performance of equipment often requires timely replacement of worn components. Identifying signs of wear and understanding the best practices for replacement can significantly extend the life of your machinery.

Identifying Worn Components

Before proceeding with any replacements, it’s crucial to recognize which parts need attention. Common indicators include:

- Unusual noises during operation

- Decreased efficiency or performance

- Visible signs of damage, such as cracks or fraying

- Difficulty in operation or handling

Replacement Process

Once the worn components have been identified, follow these steps for effective replacement:

- Gather necessary tools and new parts.

- Ensure the equipment is powered off and secure.

- Carefully remove the damaged component.

- Install the new part, ensuring proper alignment and fit.

- Test the equipment to confirm successful replacement.

By following these guidelines, you can maintain the functionality of your equipment and prevent future issues.

Adjusting the Auger and Impeller

Proper calibration of the rotating components is essential for optimal performance in clearing snow. Ensuring that both the cutting tool and the fan are correctly aligned and adjusted will enhance efficiency and prevent potential damage during operation.

Steps for Adjustment: Start by inspecting the clearance between the blades and the housing. The distance should be uniform to guarantee effective snow intake. If there are inconsistencies, adjustments can be made by loosening the mounting bolts and repositioning the components as necessary.

Checking for Wear: Regularly examine the edges of the auger and the impeller for signs of wear or damage. If any blades appear chipped or worn down, it is crucial to replace them to maintain performance. New components will ensure that the snow is efficiently drawn in and expelled without obstruction.

Testing Functionality: After making adjustments, conduct a test run in a controlled environment. Monitor the operation to confirm that the adjustments have led to improved performance. Listen for any unusual noises that may indicate misalignment or other issues that need to be addressed.

Safety Precautions During Repairs

Ensuring safety while working on machinery is crucial for both the technician and the equipment. Proper measures can prevent accidents and injuries, creating a secure environment for maintenance tasks. Familiarity with safety protocols is essential to effectively manage potential hazards during service activities.

Personal Protective Equipment

Utilizing appropriate personal protective gear is vital. Always wear gloves, goggles, and sturdy footwear to shield yourself from debris and sharp objects. Hearing protection may also be necessary if operating equipment produces significant noise. By prioritizing personal safety, you can minimize risks associated with maintenance tasks.

Environment Considerations

Maintaining a clean and organized workspace is equally important. Clear away any obstacles that might cause tripping or falling. Ensure that your area is well-ventilated, especially when working with chemicals or lubricants. Proper disposal of waste materials further contributes to a safe working environment and promotes effective maintenance practices.

Diagnosing Electrical Problems

Identifying issues related to electrical systems can be a challenging task, requiring a systematic approach to ensure accurate results. Understanding the various components and their functions is essential for effective troubleshooting.

First, begin by checking all connections and ensuring they are secure. Loose or corroded connections can lead to intermittent issues. Inspect wiring for any signs of damage, such as fraying or exposure, which could impact performance.

Next, utilize a multimeter to test voltage levels at different points in the circuit. This tool can help pinpoint where the electrical flow is being interrupted. Compare your readings to the specifications outlined in the documentation for the system to identify any discrepancies.

Finally, consider the condition of the battery. A weak or failing battery can lead to a range of electrical problems, from starting issues to component malfunctions. Regular maintenance and testing of the battery will help ensure reliability in performance.

Winter Preparation Tips for Longevity

Ensuring your equipment remains in peak condition during the colder months is essential for maximizing its lifespan and performance. By following a few straightforward practices, you can help your machinery withstand harsh winter conditions and operate effectively when needed most.

Routine Maintenance Checks

Conducting regular inspections is vital. Before the season begins, check all components for wear and tear. Ensure that all moving parts are lubricated and free from debris. A clean, well-maintained machine not only runs better but also reduces the risk of unexpected breakdowns.

Fuel Considerations

Using high-quality fuel is crucial for optimal performance. Consider adding a fuel stabilizer to prevent degradation during storage. This will ensure that your equipment starts easily and runs smoothly throughout the winter months. Additionally, always check the fuel levels before storage to avoid condensation build-up.

Storing Your Snowblower Properly

Effective storage of your winter equipment is essential for maintaining its performance and longevity. Proper care ensures that it remains in excellent condition, ready for use when the cold season returns. Here are key considerations for optimal storage practices.

- Clean the equipment thoroughly to remove any debris or dirt that may cause corrosion.

- Drain the fuel tank to prevent stale fuel issues that could hinder starting.

- Lubricate moving parts to protect against rust and ensure smooth operation.

Choosing the right location is crucial. Store in a dry, sheltered space away from extreme temperatures. This will help to maintain the integrity of the machine and prolong its life.

- Consider using a cover to protect it from dust and moisture.

- Avoid placing heavy objects on top to prevent any physical damage.

Regular checks during the off-season can also prevent unforeseen issues. By following these guidelines, you can ensure your equipment is ready to tackle winter challenges effectively.

Resources for Further Assistance

When tackling maintenance or troubleshooting challenges with your equipment, various resources can provide valuable support. These options range from official guides to online communities where enthusiasts share their expertise and experiences. Accessing the right information can enhance your understanding and skills, making the process smoother and more efficient.

Official Support Channels

For comprehensive guidance, consider visiting the official website dedicated to your equipment. Here, you can find detailed documentation, FAQs, and customer service contacts. Utilizing these resources ensures you receive accurate information tailored to your specific model.

Online Communities and Forums

Engaging with fellow users in forums or social media groups can be incredibly beneficial. These platforms allow you to ask questions, share insights, and learn from others who have faced similar challenges. Participating in discussions not only expands your knowledge but also helps build a supportive network.