In the realm of agricultural machinery, understanding the intricacies of maintenance and troubleshooting is crucial for optimal performance. For operators and enthusiasts alike, having access to comprehensive resources is invaluable. These documents serve as a cornerstone for ensuring longevity and efficiency in heavy-duty machinery, enabling users to tackle various challenges with confidence.

With a wealth of information at one’s fingertips, individuals can easily navigate the complexities of their machines. From fundamental upkeep to advanced diagnostics, these resources provide detailed insights that empower users to address issues effectively. By fostering a proactive approach, operators can minimize downtime and enhance productivity.

Moreover, the availability of structured guidance ensures that even those new to machinery can grasp essential concepts. Whether it’s understanding engine components or deciphering electrical systems, clear instructions facilitate a smooth learning curve. Emphasizing safety and proper techniques, these guides play a pivotal role in cultivating a skilled community of operators dedicated to maintaining their equipment.

Understanding John Deere Repair Manuals

This section aims to provide insights into the essential documentation that guides users in maintaining and troubleshooting their equipment. These resources serve as valuable references, offering comprehensive instructions and detailed illustrations to facilitate effective service and upkeep. Familiarity with this information can enhance the longevity and performance of machinery.

The Importance of Detailed Documentation

Having access to thorough guides is crucial for anyone involved in the maintenance of machinery. These resources not only help in identifying potential issues but also outline the correct procedures for performing various tasks. With step-by-step instructions, users can gain confidence in their ability to handle repairs, ultimately reducing downtime and enhancing efficiency.

Key Components of the Guides

These resources typically include various sections that cover topics such as troubleshooting, assembly, and disassembly. Diagrams and schematics are essential features, providing visual aids that complement written instructions. Additionally, parts lists and specifications help ensure that the correct components are used during any servicing process, promoting optimal functionality.

Benefits of Using Official Manuals

Utilizing authorized documentation for machinery maintenance offers numerous advantages that enhance both the efficiency and effectiveness of the repair process. These resources provide detailed insights, ensuring that users have access to the most accurate and relevant information.

- Accuracy: Official guides are developed by experts, ensuring that the information is precise and tailored to specific models.

- Comprehensive Coverage: These resources cover all aspects of the equipment, including assembly, disassembly, and troubleshooting, which aids in thorough understanding.

- Safety Standards: Authorized documentation includes vital safety protocols that protect users while performing maintenance tasks.

- Cost-Effectiveness: Proper use of these guides can prevent costly mistakes and reduce the need for professional services.

- Warranty Protection: Following official guidelines often helps maintain warranty coverage, safeguarding against potential issues.

In summary, relying on trusted documentation not only facilitates smoother repairs but also contributes to the longevity and optimal performance of equipment.

Common Repairs for John Deere Tractors

Maintaining heavy machinery is crucial for optimal performance and longevity. Understanding frequent issues and solutions can greatly enhance efficiency and reduce downtime. This section highlights typical challenges faced by operators and effective methods to address them.

Engine Overheating is a prevalent concern. This problem often arises from insufficient coolant levels, blocked radiators, or malfunctioning thermostats. Regular checks and timely replacements can prevent overheating and ensure smooth operation.

Hydraulic System Failures may occur due to leaks or worn-out components. Routine inspections of hoses and seals are essential. Addressing these issues promptly can maintain lifting capabilities and enhance overall productivity.

Electrical System Issues can lead to starting problems or equipment failure. Common culprits include dead batteries or faulty wiring. Regular maintenance and testing can mitigate risks and ensure reliable performance.

Transmission Problems are also frequent. Symptoms may include unusual noises or difficulty shifting gears. Proper lubrication and timely servicing can help prevent significant damage and extend the lifespan of the transmission.

By being aware of these common concerns and implementing proactive measures, operators can ensure their machinery remains in peak condition, ultimately leading to enhanced productivity and reduced operational costs.

Finding the Right Manual Online

Locating the appropriate guide for your machinery can significantly enhance your maintenance and troubleshooting experience. With a plethora of resources available on the internet, understanding how to navigate these options is crucial for efficient assistance.

Steps to Locate Your Guide

- Identify Your Equipment Model

- Utilize Specific Search Terms

- Explore Reputable Websites

- Check Online Forums and Communities

- Consider Digital Libraries and Archives

Helpful Tips

- Verify the Source: Always choose trusted websites to ensure accurate information.

- Look for PDF Versions: These formats are often easier to download and view.

- Take Advantage of User Reviews: Feedback can guide you to quality resources.

- Save Your Findings: Bookmark useful pages for quick access in the future.

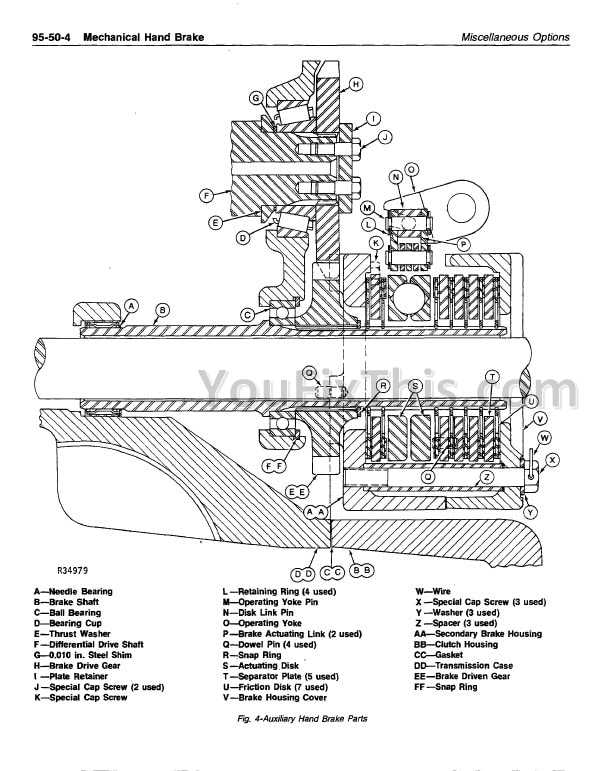

How to Interpret Technical Diagrams

Understanding technical illustrations is essential for effective troubleshooting and maintenance. These visuals provide crucial information on components, connections, and operations, enabling users to grasp complex systems quickly.

Key Elements to Analyze

- Symbols: Familiarize yourself with the common symbols used to represent various parts and functions.

- Legends: Pay attention to legends that explain the meaning of different colors and lines.

- Scale: Understand the scale used to ensure accurate interpretation of sizes and distances.

Steps to Follow

- Start by reviewing the title and general layout of the diagram.

- Identify the main components and their relationships.

- Follow the flow of operations, noting any connections or sequences.

- Refer to the legends for clarification on symbols and markings.

Essential Tools for Tractor Maintenance

Proper upkeep of agricultural machinery is crucial for ensuring optimal performance and longevity. Having the right equipment at hand can make all the difference in executing maintenance tasks efficiently and effectively. This section outlines the indispensable items that every operator should consider for their routine checks and service work.

Wrenches and Socket Sets: A comprehensive set of wrenches and sockets is vital for loosening and tightening bolts and nuts. These tools come in various sizes and types, allowing for versatility when addressing different components.

Multimeter: For those dealing with electrical systems, a multimeter is essential for diagnosing issues. It helps in measuring voltage, current, and resistance, ensuring that all electrical connections are functioning properly.

Grease Gun: Regular lubrication of moving parts prevents wear and tear. A grease gun allows for easy application of lubricant, ensuring that joints and bearings remain in good condition.

Safety Gear: Never overlook the importance of safety equipment. Items such as gloves, goggles, and ear protection are crucial for safeguarding against potential hazards during maintenance tasks.

Jack and Jack Stands: Lifting machinery safely is a must for any significant maintenance work. A reliable jack, paired with sturdy jack stands, ensures that operators can access undercarriages without risking injury.

Equipping oneself with these essential tools will streamline the maintenance process, leading to a more efficient and reliable operation. Regular checks and proper care contribute to the overall health of the equipment, ensuring it remains a valuable asset for years to come.

Safety Tips During Repairs

Engaging in maintenance tasks requires a mindful approach to ensure the well-being of the individual and the longevity of the equipment. Adhering to safety protocols can prevent accidents and facilitate a smoother working experience. Awareness and preparation are key to successful servicing activities.

Preparation Before Starting

Prior to commencing any work, it is crucial to gather the necessary tools and equipment. Ensuring that the workspace is organized and free from hazards can significantly reduce risks. Here are some essential preparatory steps:

| Step | Action |

|---|---|

| 1 | Wear appropriate personal protective equipment (PPE). |

| 2 | Ensure all tools are in good condition and suitable for the task. |

| 3 | Clear the area of unnecessary items and debris. |

| 4 | Check for proper lighting to avoid accidents. |

During the Maintenance Process

While engaged in servicing, maintaining focus is essential. Distractions can lead to mistakes or accidents. Here are important considerations:

- Always follow operational guidelines and instructions.

- Never work alone; having a buddy can provide assistance in case of emergencies.

- Be aware of your surroundings and potential hazards, such as moving parts or chemicals.

Upgrading vs. Repairing Your Tractor

When faced with the choice of enhancing or fixing your equipment, it’s essential to consider various factors that can influence your decision. Both options have their own advantages and challenges, and understanding them can help you make an informed choice that best suits your needs.

Here are some key considerations to keep in mind:

- Cost: Analyze the expenses involved in both approaches. Upgrading may require a larger initial investment, while repairs can often seem more budget-friendly at first glance.

- Longevity: Think about how long each option will extend the lifespan of your machinery. Upgrades may offer more sustainable benefits over time compared to repeated fixes.

- Performance: Assess how each choice affects the functionality of your equipment. An enhancement might provide significant boosts in efficiency, whereas repairs may restore it to its original condition.

- Technology: Consider the advancements available in new models. Upgrading could bring the latest innovations that enhance productivity and safety.

- Usage Requirements: Evaluate how often and in what conditions you use your equipment. If your demands have changed, an upgrade might be more beneficial than a simple fix.

Ultimately, the decision between enhancing and mending hinges on your specific circumstances, preferences, and future goals. Careful evaluation of the above factors will guide you toward the best solution for your equipment needs.

Frequency of Routine Maintenance Tasks

Regular upkeep is essential for ensuring the longevity and efficiency of agricultural machinery. By adhering to a structured schedule of maintenance activities, operators can prevent unexpected breakdowns and enhance overall performance.

Here are key tasks and their recommended frequencies:

- Fluid Checks:

- Engine oil: every 50 hours of operation

- Hydraulic fluid: every 100 hours of operation

- Coolant: every 200 hours of operation

- Filter Replacements:

- Oil filter: every 100 hours or annually

- Air filter: every 50 hours or as needed

- Fuel filter: every 200 hours or annually

- Inspection and Cleaning:

- Belt and hose condition: every 50 hours

- Electrical connections: every 100 hours

- Exterior cleaning: as needed, preferably after each use

Sticking to these intervals not only maximizes efficiency but also extends the lifespan of equipment, ensuring that it remains reliable throughout its operational life.

Common Issues and Their Solutions

Every machine may encounter operational challenges over time, necessitating troubleshooting to ensure efficiency. Understanding frequent problems can help users address these issues promptly and maintain peak performance.

- Starting Difficulties:

Check the battery connections and fuel levels. If issues persist, inspect the ignition system.

- Overheating:

Ensure the cooling system is functioning properly. Clean the radiator and check coolant levels regularly.

- Poor Performance:

Examine air filters and fuel filters. Replace them if they appear clogged or dirty.

- Unusual Noises:

Identify the source of the noise. Inspect belts, gears, and bearings for wear and tear.

- Hydraulic Issues:

Check fluid levels and look for leaks. Ensure hoses are not damaged and connections are secure.

Addressing these common concerns efficiently can extend the lifespan of the equipment and enhance its productivity.

Where to Buy Printed Manuals

Finding high-quality printed guides for your machinery can enhance your maintenance and operational knowledge. Whether you’re looking for comprehensive resources or quick reference books, there are several reliable sources to consider for purchasing these valuable documents.

Online Retailers

One of the most convenient options is to explore various online retailers. Websites specializing in machinery and equipment often stock a range of printed resources. Be sure to check customer reviews and ratings to ensure you are getting a reputable product. Amazon, eBay, and other dedicated online shops frequently offer competitive prices and a wide selection.

Local Dealerships

Visiting local dealerships can be beneficial as well. They typically carry a selection of printed guides that cater to specific models. Engaging directly with staff can provide insights into the most relevant resources for your needs. Additionally, you may find exclusive publications that are not available online. Consider inquiring about any upcoming workshops or training sessions that may complement your purchase.